Final Project

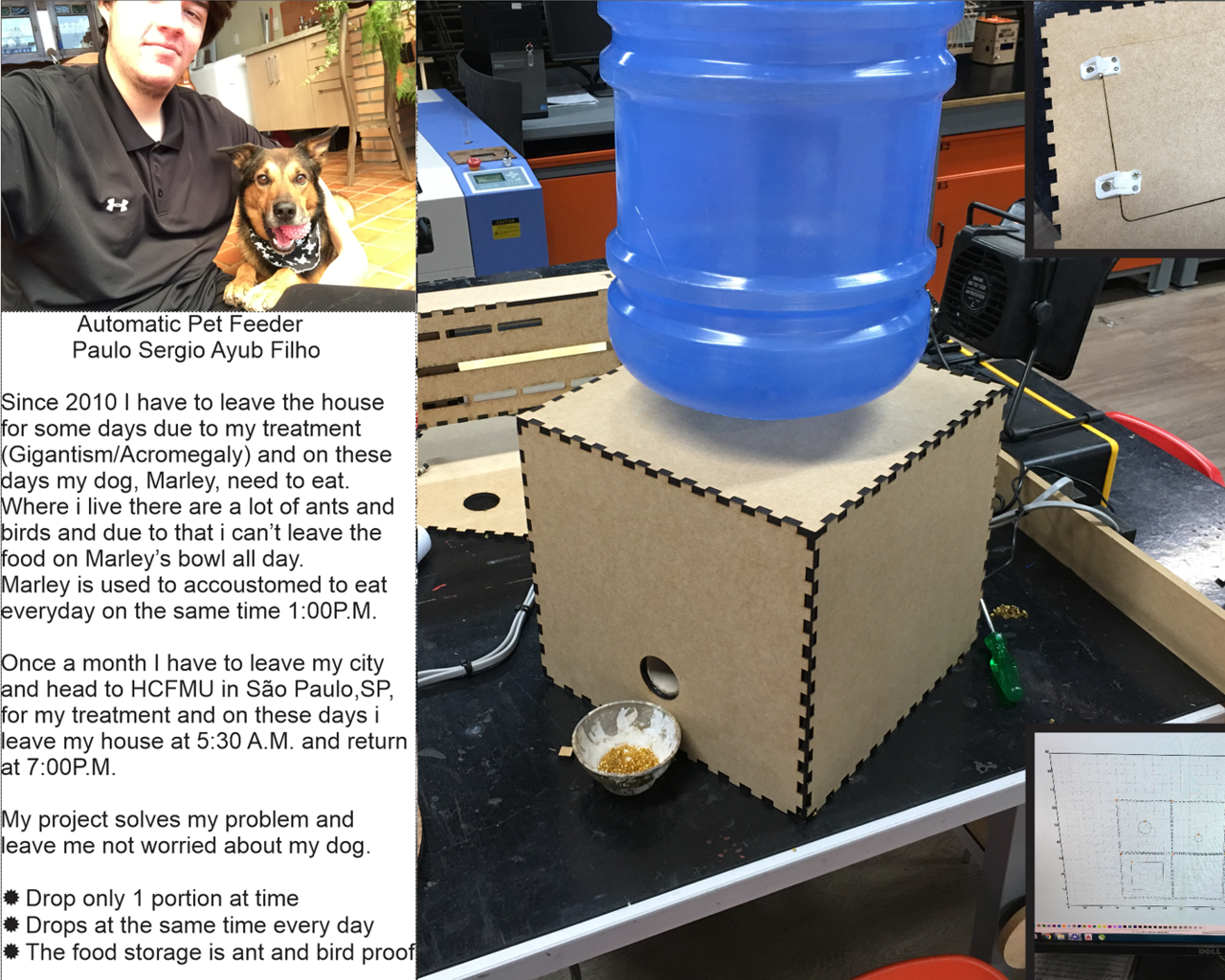

Automatic Pet Feeder

So Here we are, the Final Project, were all the points connects and everithing meets.

As I described on my "About Me" page, I suffer from a condition called Gigantism that right now has became a Acromagaly. All the persons that suffer from this have a overwhelming produting of HGH (Growing Hormone) on their bodys thus making them a LOT taller than their family members and if not treated a "Frankeinstain" like face and body, a LOT of hormonal inbalances and some other health problens such as cardiac condidtions, propensity to new tumros (IGF1 is high as well), and a miserable treatment that can last a life time.

My Final Project is to solve one of many problems i have due to my treatment, in this case, to give my beloved dog Marley his daily portion of food. At every chemo session i leave my house before the sun appears, around 5:30 A.M. and left my house and dog behind. After my chemo session i need to stay in a line to pick up all my meds and take then home with me.

The whole process usually takes 6 hours add to this 2 hours of driving, 1 hour for lunch, and 2-4 hours to make my way home due to traffic at rush hour in Sâo Paulo.

My Project consist of conteiner for food, an attiny for control the time and the amount of food, and a motor to dispense the food.

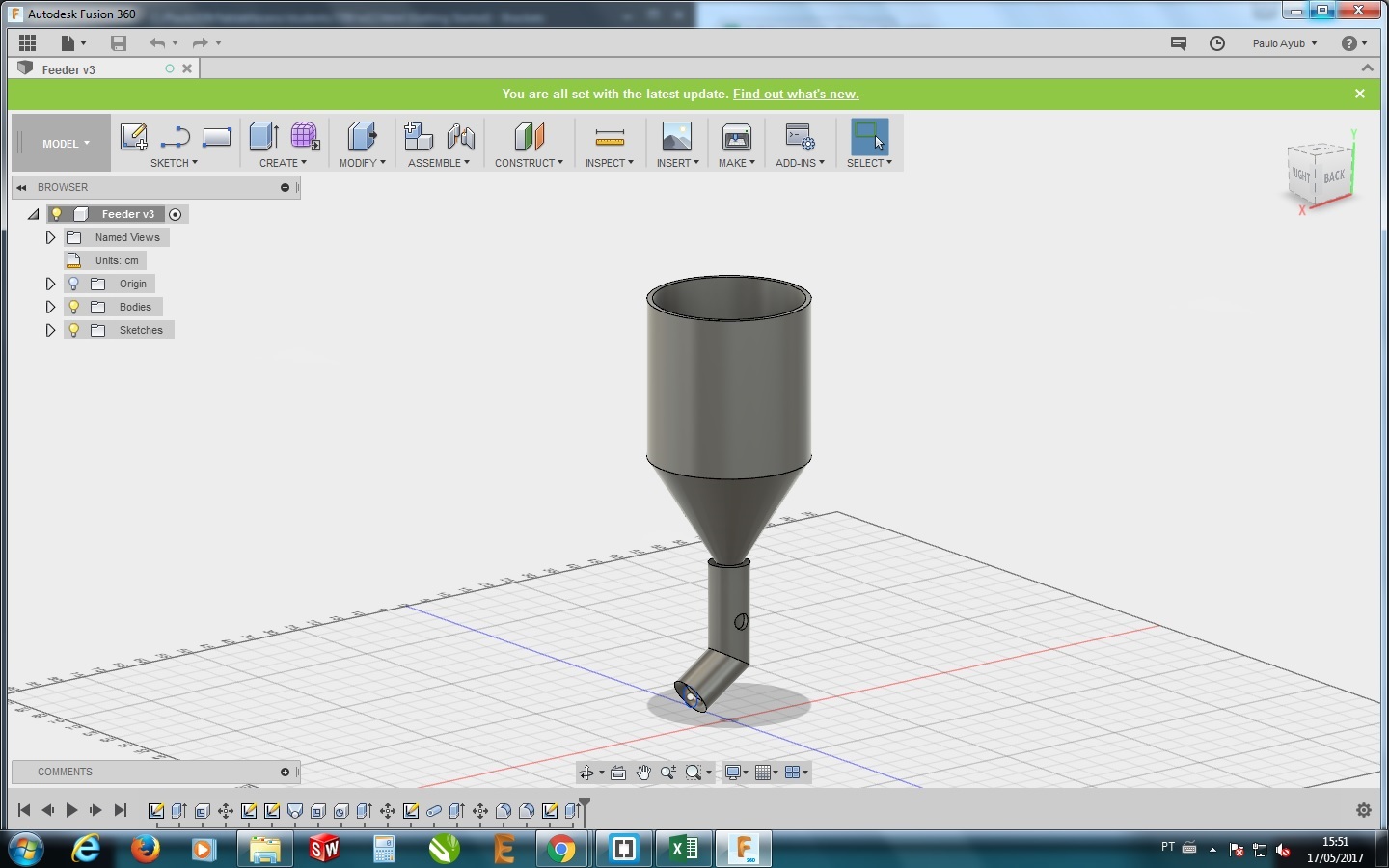

First I desing all in fusion360 that had became my favorite modeling sofware.

Bill Of Materials:

Pvc tube R$10

6mm mdf board R$60

Dc motor R$ 30 (bougth second handed)

Food container R$20

Attiny 84, mosfet and voltage regulator R$10

STL File Avaliable Here

STL File Avaliable Here

For the eletronics part I desing a board using Eagle and the main component is a Attiny84

I Used the Rolland MDX-40 to make the PCB, I ran in to an problem while milling the pcb, even using double-sided tape the pcb was getting loose, to fix that i used doble-sided tape on the bottom of the pcb and another tape on the edges to solve my problem.

In my original desing i was using an power window motor, those are generaly easy to find, they are small, powerfull and realiable. but my FabLab didn't had one so I had to use this model isted

This motor had the same caracteristics as the power window but it was a lot bigger and a lot heavier.

With all this in my hand the only thing missing was the enclosure box, witch suffer some changes due to the bulkier motor.

In order to install the eletronics and for a future maintance/upgrade i used a door hinge and printed using the Ultimaker 2 on PLA filament, using a 0.2 mm layer height and 215c as nozzle temperature, the total pocess took 30 minutes o print

Hinge File Avaliable HereAfter the assembly the final result is this!

This is how my project looks without the front piece

This is the finished electric board

In this image you can see how te wires were connected to the board

In this close up you can see a mistake I've made while desingnig the board, I forgot to add a resistor, I Already fixed the desing on my final desing file

This is the mechanism that realeses and also block the flow os dog food

My code works by pressing the button, followed by a five hour delay and then the motor activates to drop aroud 250-290 grams of dog food

Code File Avaliable HereThe lisence i want on my project is the Fab License.