Composites

Making a Fruit Bowl

On this assingment I used Jute fibers and Epoxi resing to create a fruit bowl

To use this product i needed follow the safety instructions that can be found here:Link to safety guide

I used the same epoxi resing at my "molding and Casting" Link to the Epoxi resing website, This resin have a 2/1 resing hardener mix ratio and the curing time is 24 hours

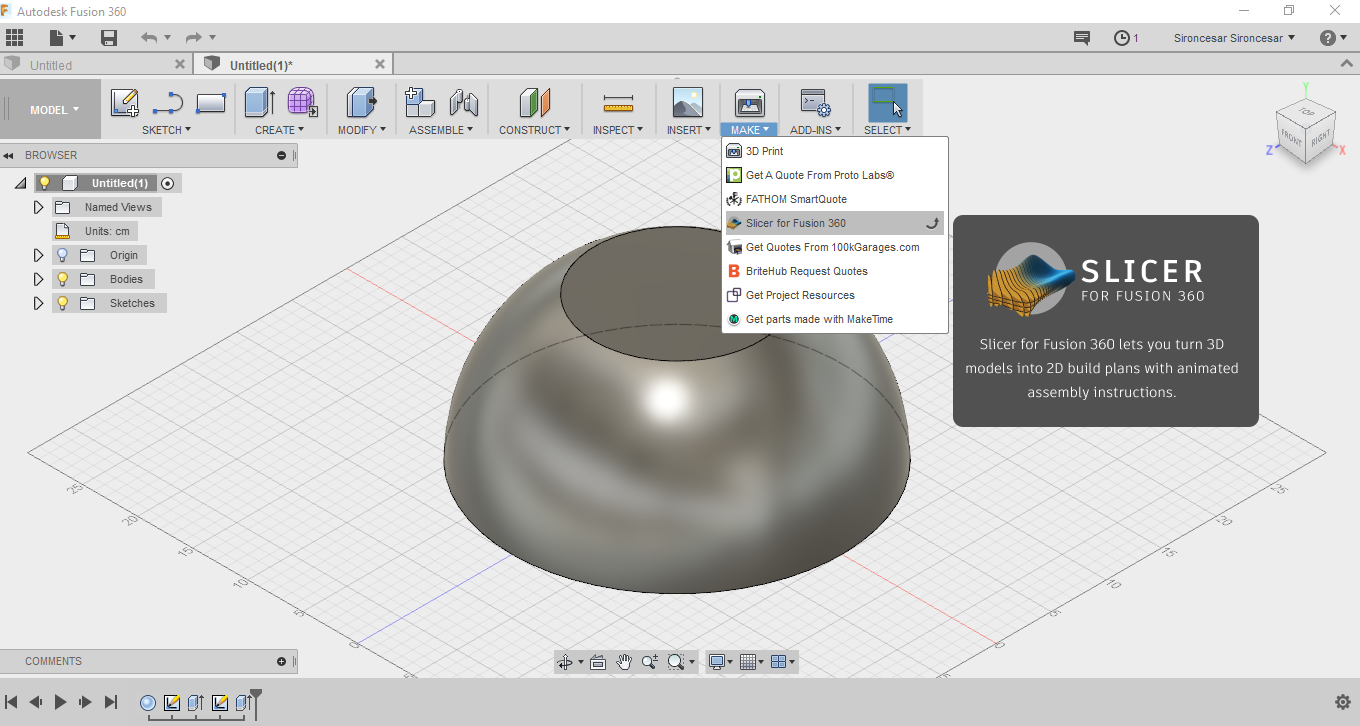

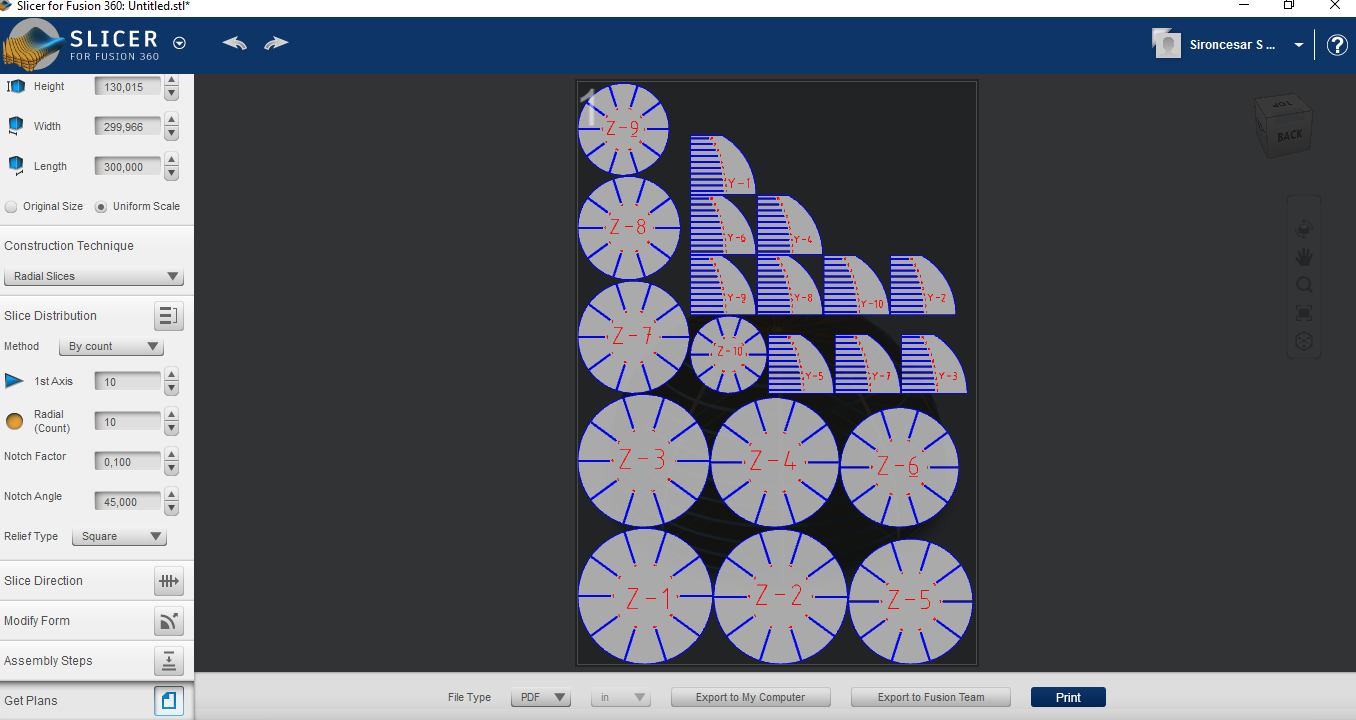

Before i needed to make a "negative" using Fusion360, make a sphere and then cut it and half and using the 123d make software to make the joints, and then cutting it on the lazer cnc

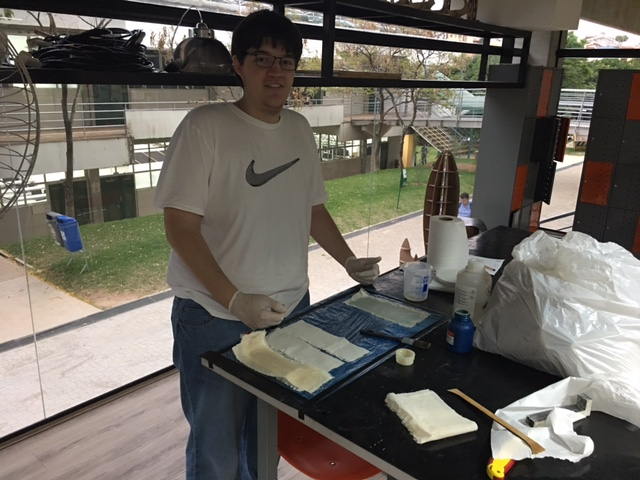

After cutting and assemblig the "negative" it was time to prepare the local i was goint to use, epoxi resing can and will make a mess if you are not carefull

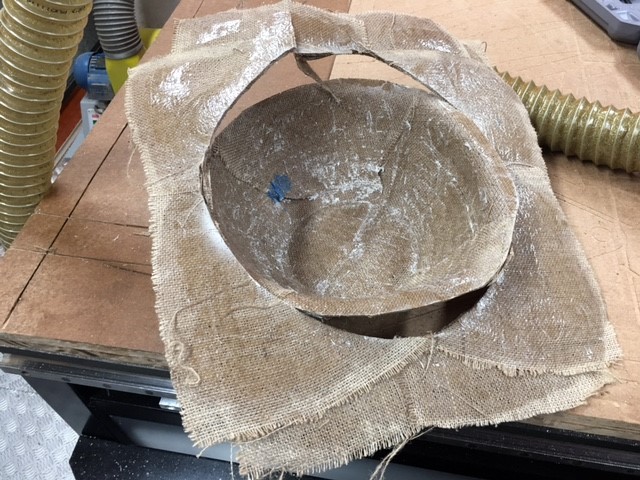

With that ready it was time to prepare the negative, I used a plastic bag and some demolding wax to make the resing dons't stick too much

With the negative ready it was time to spread the resing on the jute fiber and carefully put the wet fibers over the negative

My final product had to much bubbles both on the inside and on the outside, this was probably due to my fisrt time duing it and we don't have a vacuum pump, that could be helpful to make the results even better