3D Printing and Scaning

For this assignment I decided to make a keychain cylinder for my car key.

In order to test our Ultimaker 2 3D Printer we printed This File and this setings:

In order to troubleshoot our printer we used this Website

I learned that 3d printing is just like making a cake, it takes time and pacience to get it right. If you try to print something like a bridge you will need support to the gap bellow the bridge.

If you print something and do not level the bed you wiil not have a print

I needed to stay aware that as close as we get to 90 degree angle gap it will probably have strings and deformation on the bottom side of the print that is not touching the build plate

Printing in PLA is a lot easier than printing on ABS or a flexible filament, PLA dosen't need a heated bed while the ABS and the flexible filament does

PLA dosent need a closed cabinet aroud the 3D printer but ABS does, the change in temperature causes "warping" on the ABS material

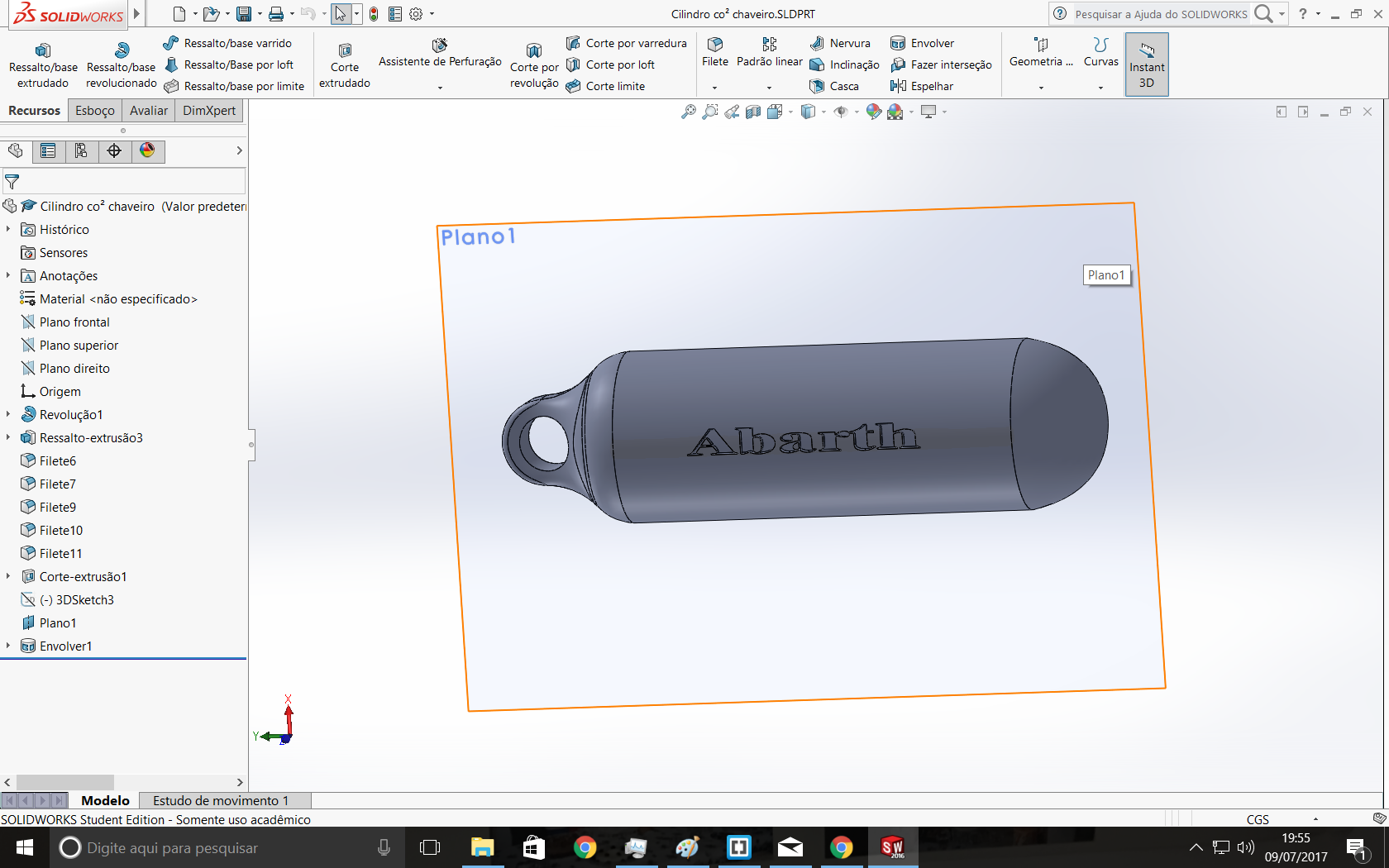

I started my desing on SolidWorks, I drew a overall shape that wanted and used the revolve tool to generate the cylinder.

After that I drew an arch so I can put a chain on it, I used a circle as a starting point, than I extruded that circle.

To make the hole I drew a smaller circle and used the cut tool.

After that I used the chamfer tool to make the sharp edges round and it was pretty much it, when i took my stl file to Cura I was able to add a feature that only 3d printers can, wich is making the object with internal structures, so I can save material and not loosing too much strength and resistence.

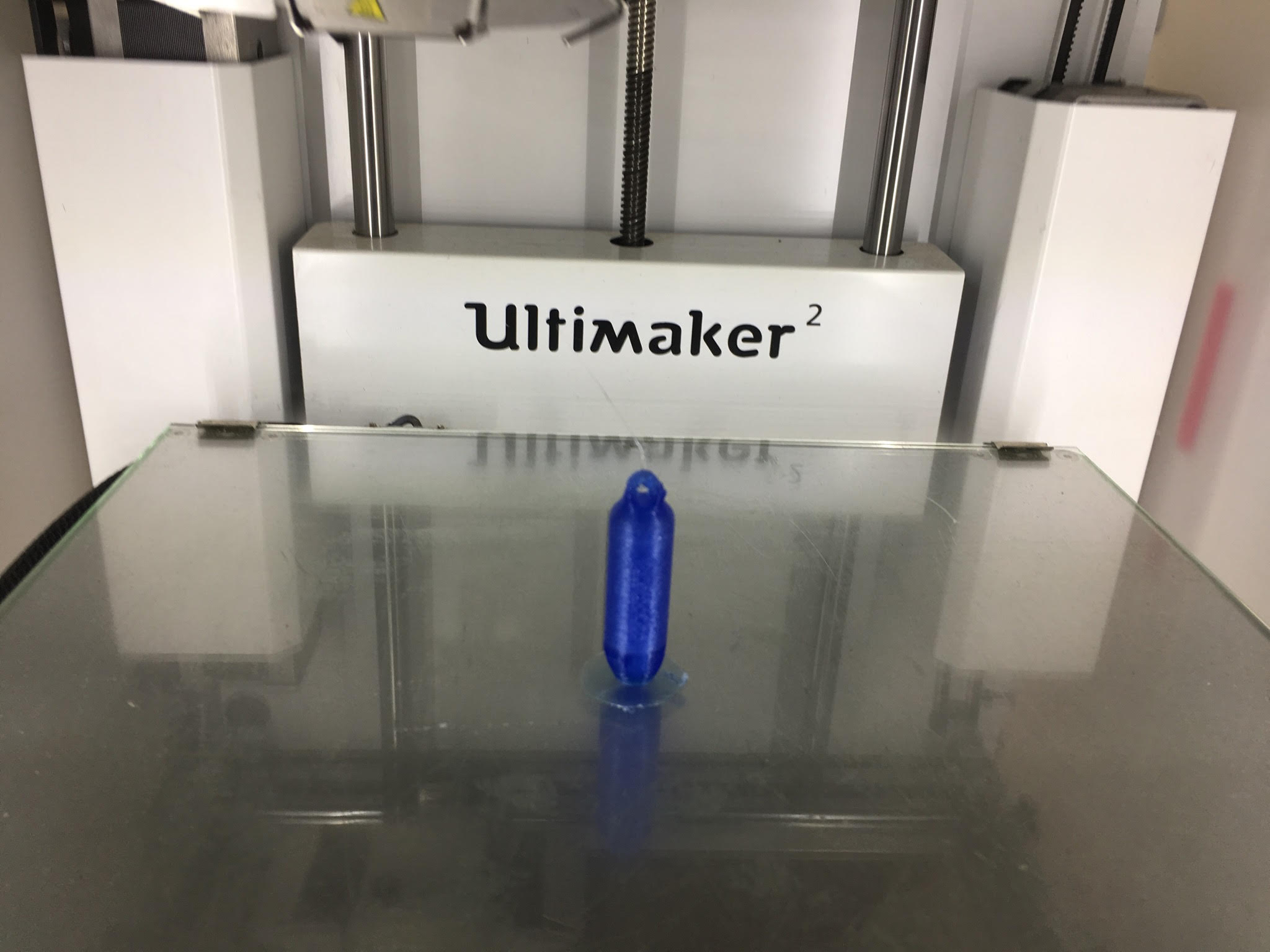

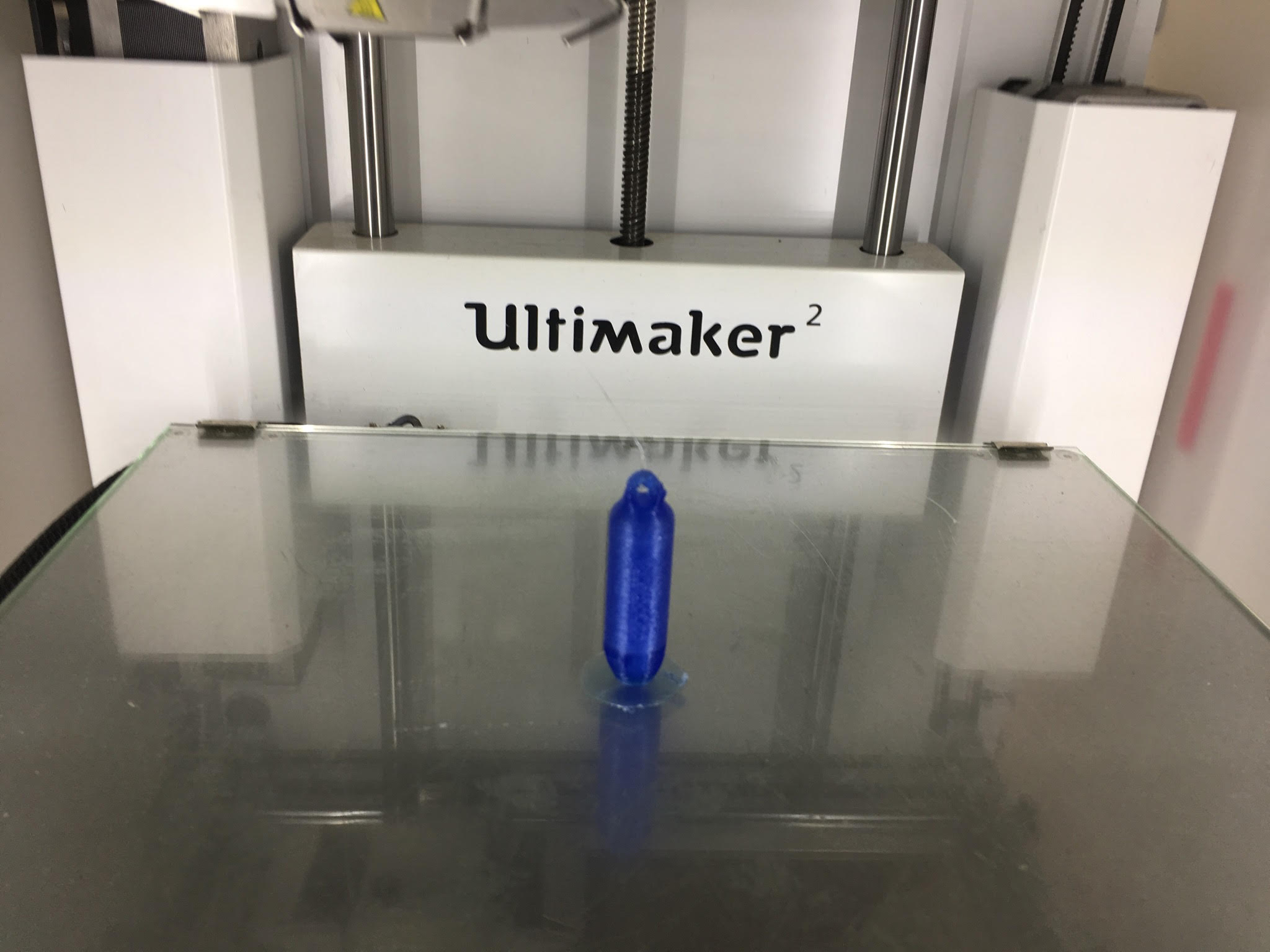

When I tried to print I used ABS at 0.1 mm layer height and brim to have more grip on the build plate, I even used card board in front of the printer to avoid warping but unfortunately my print failed at the very end.

So i was forced to printed again but this time i used PLA and the final result was a lot better, with no erros

File Avaliable Here

SLDPRT File Avaliable Here

File Avaliable Here

SLDPRT File Avaliable Here

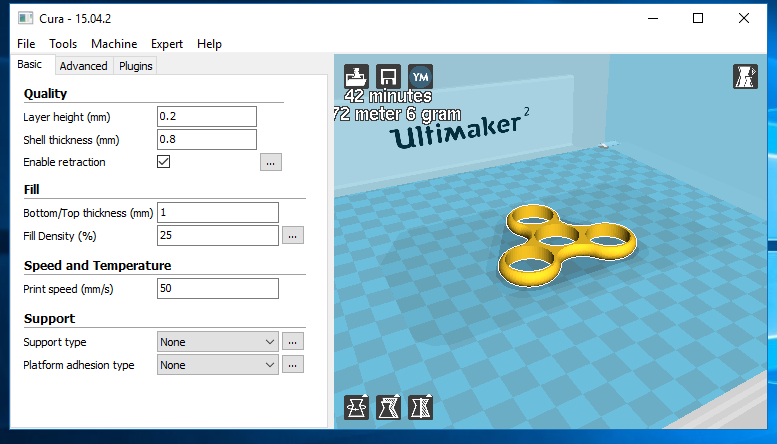

I also made a Fidget Spinner, because why not, and i follow this tutorial on how to make one but insted of using SolidWorks i have used Fusion360.

To print the fidget spinner using PLA I used 25% infil, 0,2mm of layer height with no rafts or support material

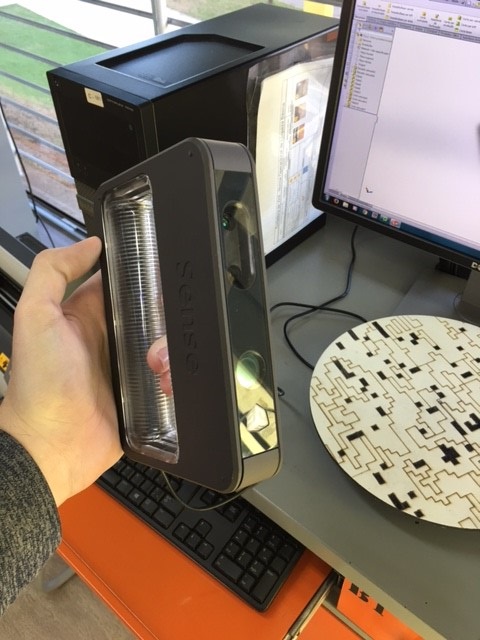

I tried to scan my shoe, but due to an software error I was unable to export or save the file. The scanner I was using was the 3d Sense. We tried everithing, we even installed all the software again but the problem persisted. Bellow are the pictures i took during the process.

After a complete PC Format, I tried again, and the previous problem was solved, but I could't understand why.

Anyhow, this is the finished files on my first attempt after the PC format.

I choose the option "person" > "face" > then I asked for a friend of mine help to scan my face, thank you Vitor.

After a 3 tries we finally got a good scan, as you can see on the pictures above.

After a good scan I choose the "Solidify" option and I made a few adjustments using "smoothing" tool, its just click and drag in order to make the STL file smoother

File Avaliable Here