Conceptualization of the Container Box

- The constraints were :

- 5' X 5' - 18mm Thick, Medium Density FireBoard (MDF)

- Use Snap Fit Joints wherever possible

- Modular Design

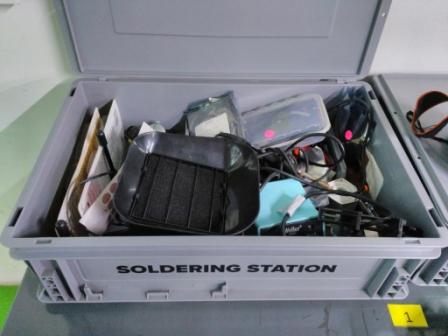

The idea struck me when I saw a "Container Box" in our Lab stuffed with many things used for the soldering exercise. I thought that it would be good if we had partitions in the box so that we sort all the things in a proper manner.

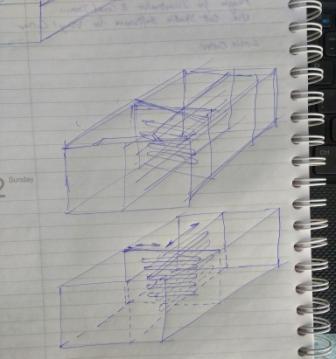

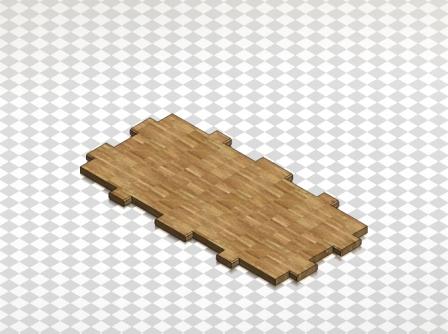

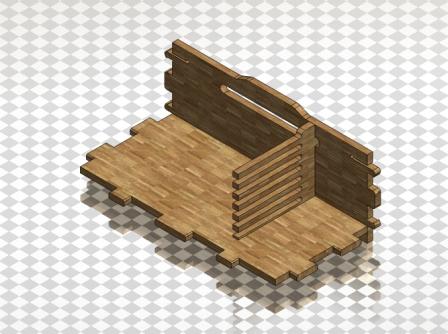

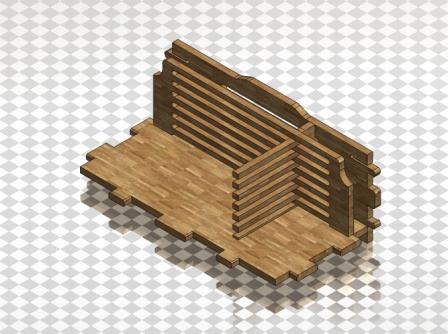

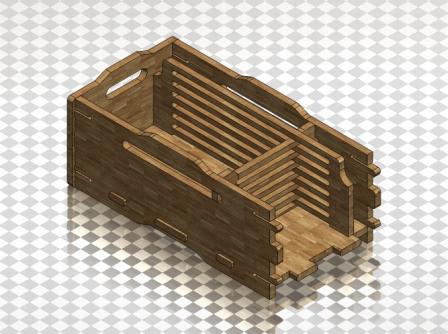

I started sketching a box. The below picture shows what was I thinking of making - "Modular Container Box".

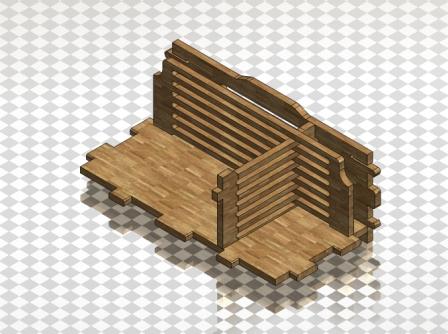

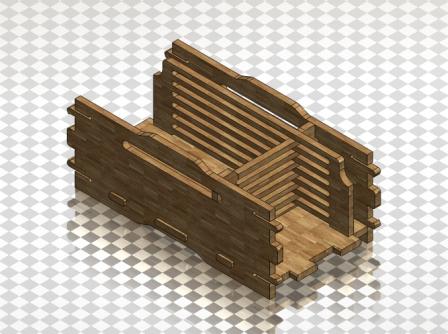

I designed this box using Solidworks 2016 & the below pictures is the final out put of the "Modular Container Box" of size 600mmx300mmx200mm

I had to constantly keep in mind two things of modularity in design & snap fit joints. the below picture shows how I designed a snap fit joint.

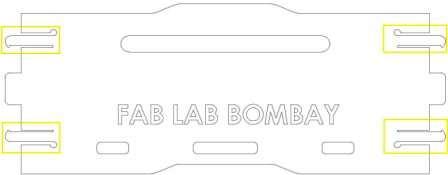

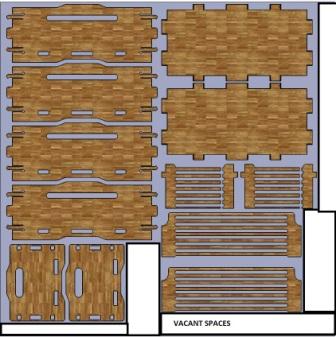

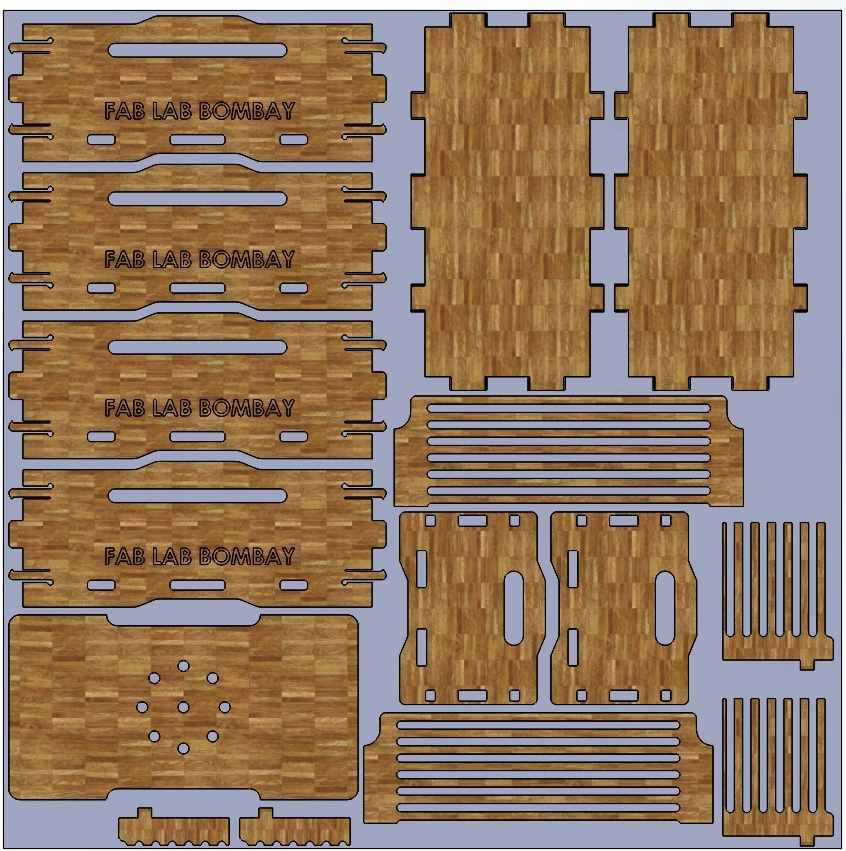

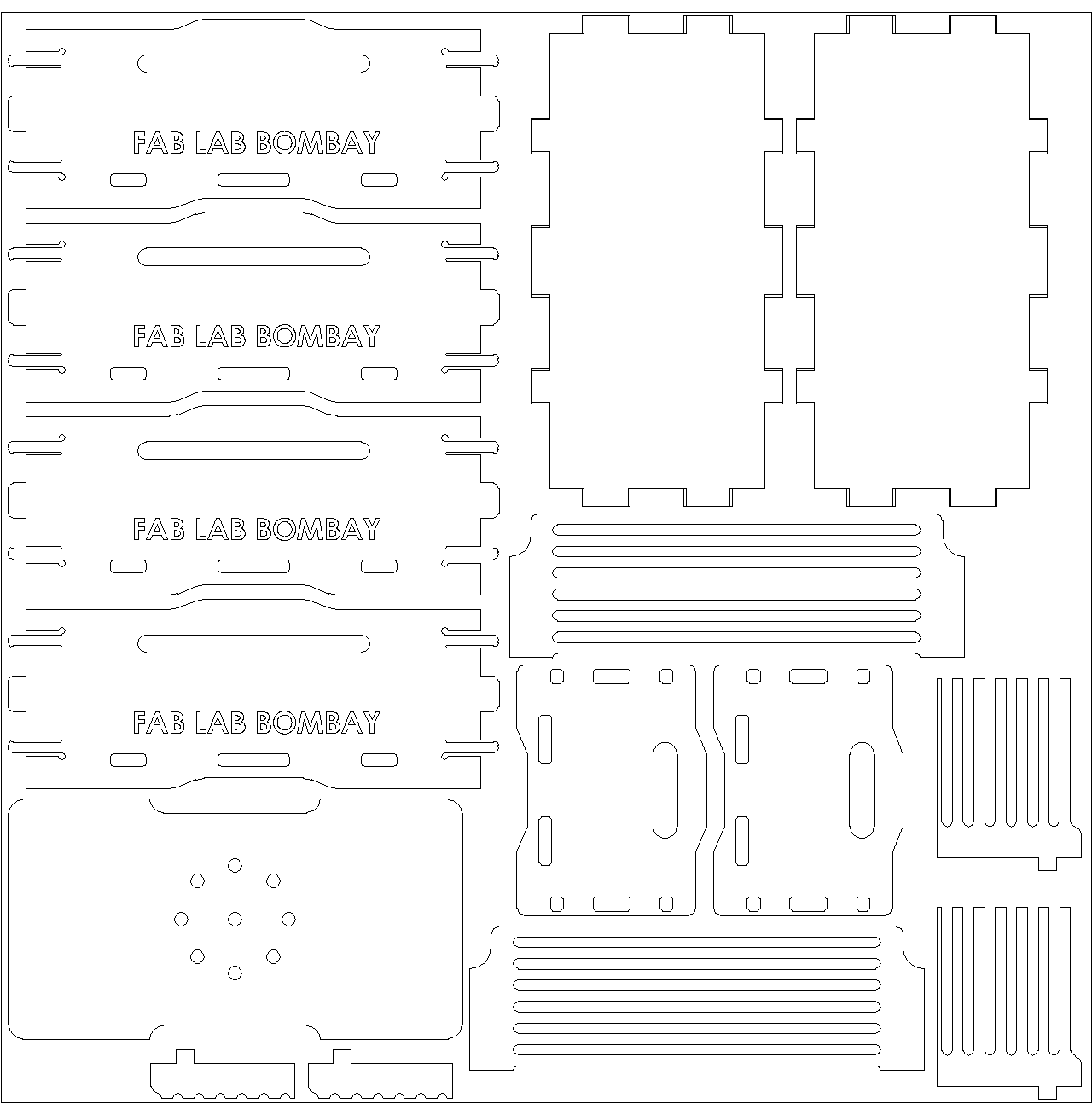

The next thing I had to do is fit the box in the 5' x 5' MDF. Since the size of the bos was small I was able to layout & make 2 boards out the given 5' x 5' board. The below picture shows the initial Layout of the Board

Here it can be seen that there are still some vacant spaces available. This space can also be utilized to fit in another part. Below is the picture showing the layout of the board with optimum usage of space.

I imported the main Layout file to .dxf format to be used in the "Art-CAM" Software.

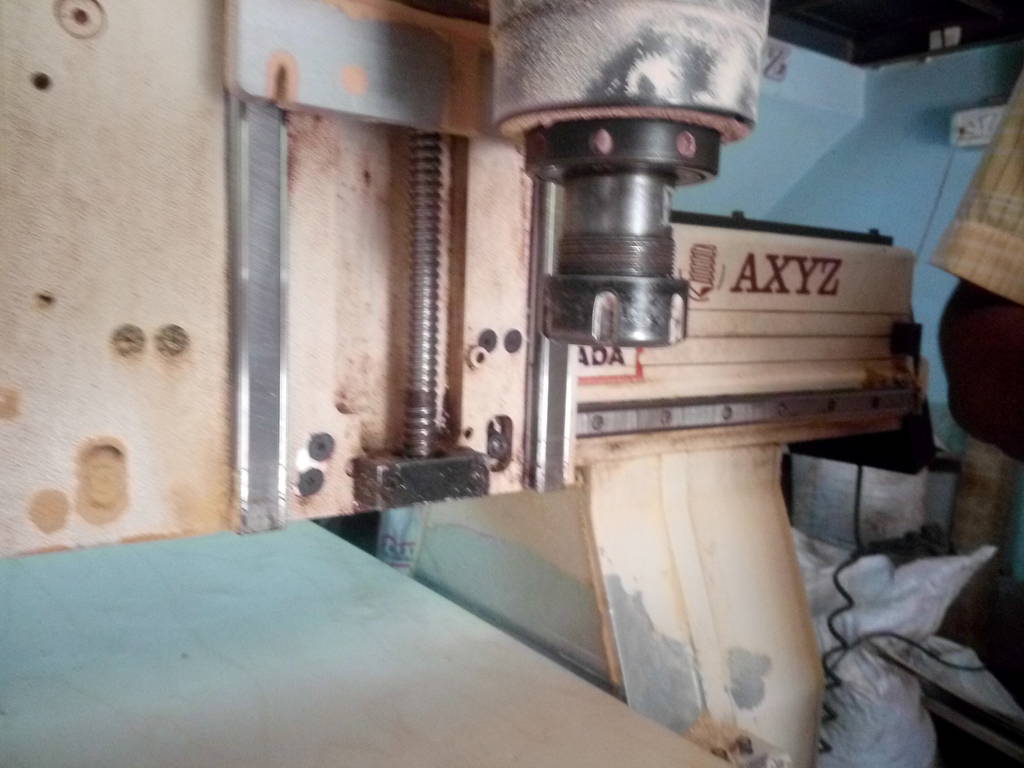

The Machine - AXYZ CNC Router

We used a Canadian make "AXYZ - 4008 CNC machine for cutting this board. This machine is capable of milling, drilling holes, carving, & 3D routing of LDF, MDF, HDF, Aluminum & Vineer Ply too. It can machine a maximum board size of 5' wide & 8' Long.

The primary applications of the machine are as below:

- Sign-making

- General Woodworking

- Solid Surface

- Exhibition Stands

- Scenery & Sets

- Interiors

- Plastic Fabrication

- Metal Fabrication

- Foam Packaging

The complete details of the machine can be seen at the link. AXYZ CNC Router

The cutting parameters that we set in the CNC Art CAM software for routing the board were:

- Spindle Speed: 18,000 rpm

- Feedrate: 2500m/min

- Depth of Cut: 4mm

- No. of passes: 5

- CAM Software: ArtCAM

- Cutter Diameter: 6mm

- Drill Diameter: 4mm

The below images show the machine before the board is loaded & after the board is loaded:

The below images show the collet holding the drill bit

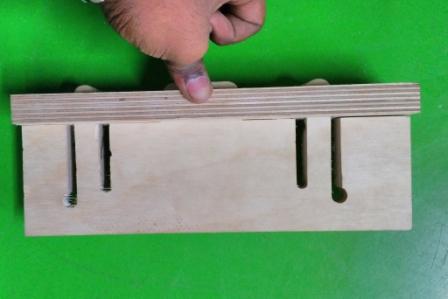

To begin with I wanted to test how the snap fit joint works. Hence I cut a small portion of the snap fit joint & tested how its fitting. Below picture shows the small portion of snap fit joint.

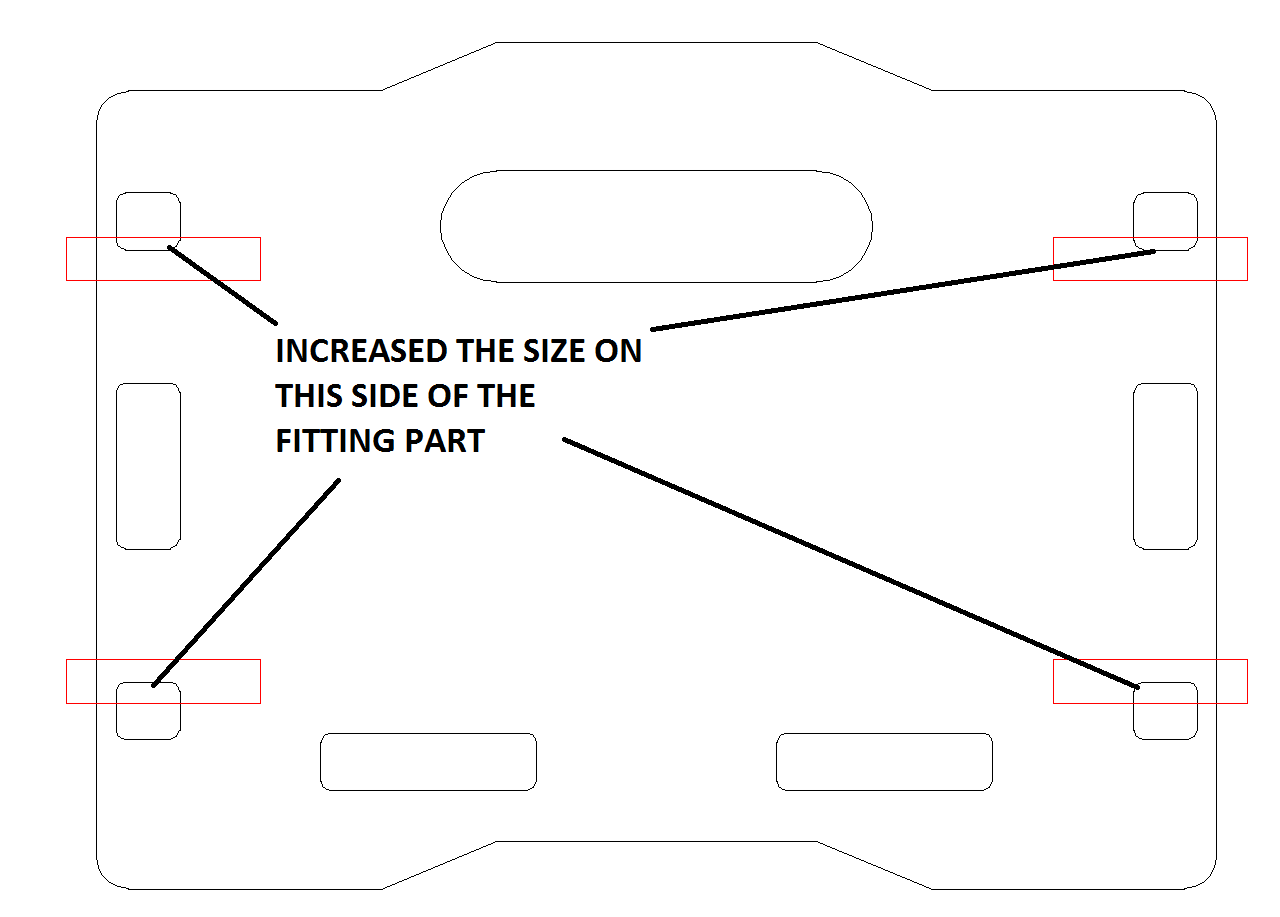

As seen in the above picture I found that with the initial design there is some chipping off of the protrusion that I had given for snap-fit. Hence I increased the size of the fitting part as shown in the below picture.

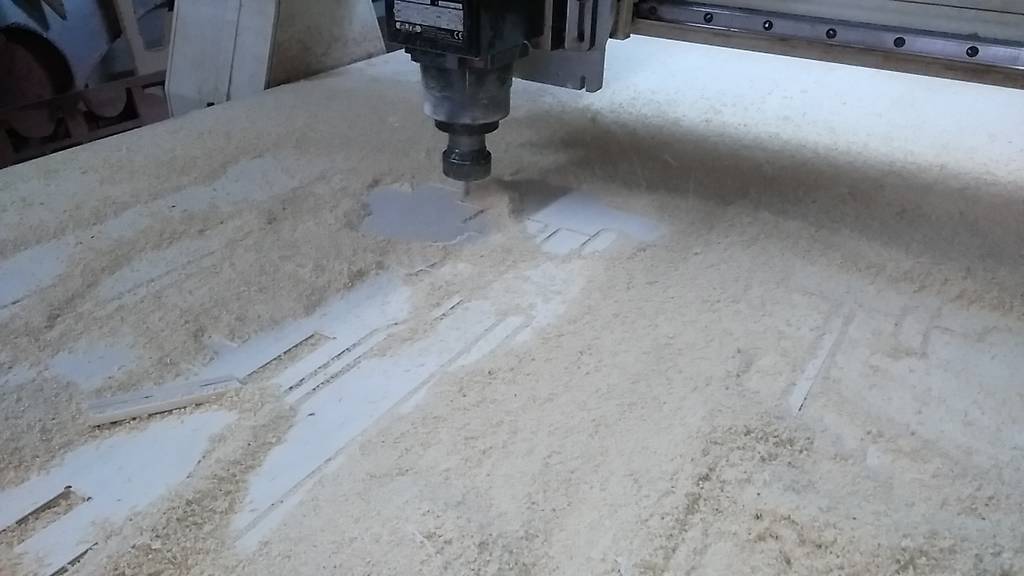

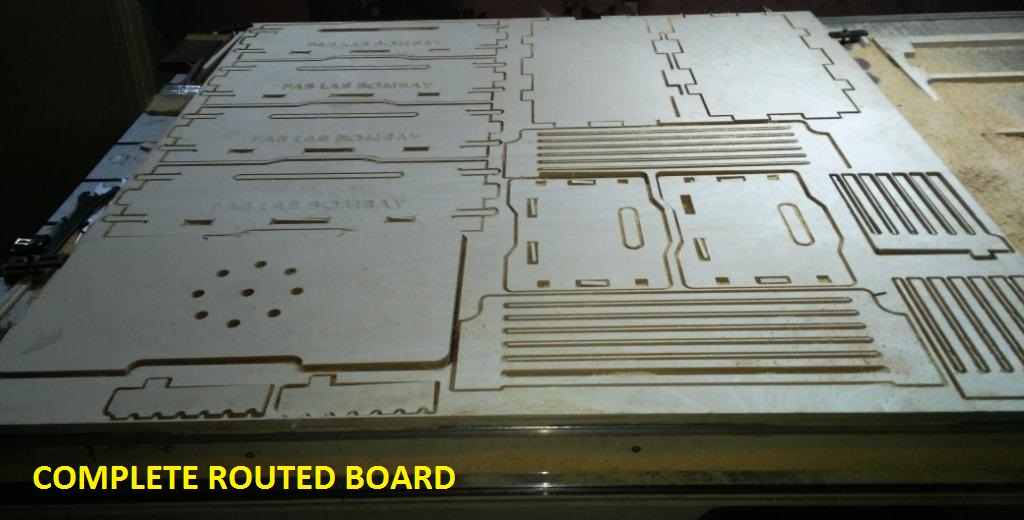

After doing some minor changes in the fitting dimensions I went ahead with the complete cutting of the board. Below pictures shows the cutting in process & the final board after routing is completed.

Assembling the Container Box

I got all the parts in to assemble them and started fitting them piece by piece. The concept of assembly is shown in below .gif file.

Problems Faced

As seen in the picture, when I inserted the smaller partition to slide into the longer partition it was not sliding as intended. The cutting clearance was not enough to slide which I had given earlier. Hence I had to increase the size of the slot of smaller partition for it to slide in the longer partition. I recut the 2 smaller partitions.

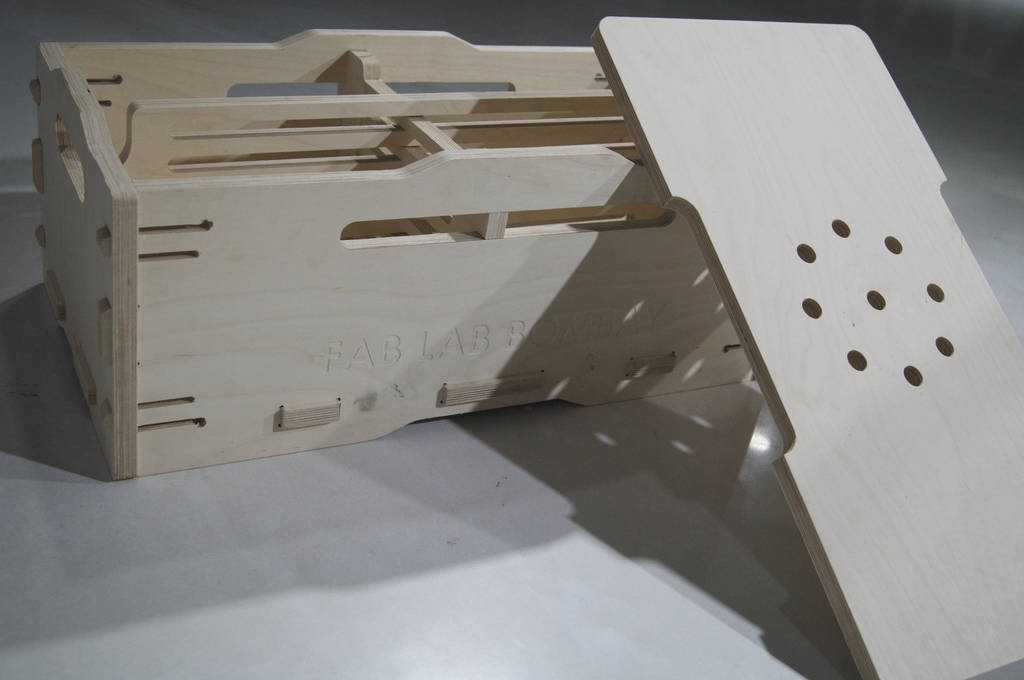

To check the fitting of other parts I did the assembly of the box. Below are the pictures

After all the parts were assembled in the correct sequence my "Modular Container Box" is ready for use.

learnings of this week

- Learnt to use Wood Milling Machine & the parameters to set milling 18mm wood sheet. Neil said rightly that after this assignment we will learn to make our own furniture.

- The tolerances required for good snap fit joints of individual parts.

- The most fascinating part was to develop something big & the realization that we can design our own furnitures & that there are many interesting things we can make for ourselves.