This week, the assignment is make something big(with CNC machine). In Litchee Lab, we happened to need a shelf for the computer of the laser cutter. So I made this shelf this week.

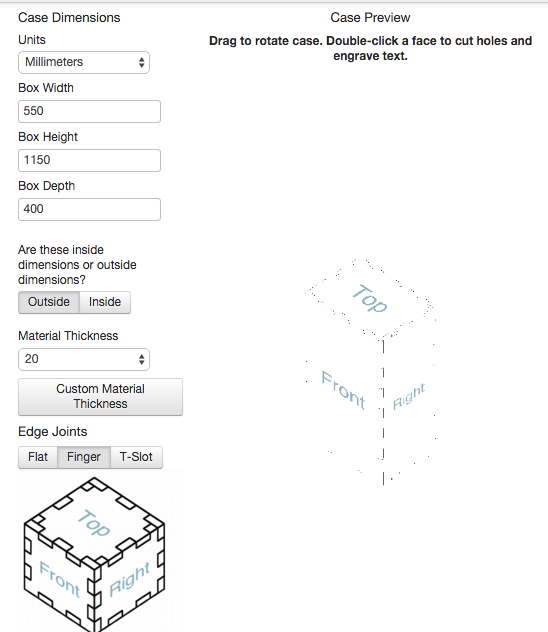

It is a simple design. I did the measurement of the space for this shelf. And enter all data into an online tool which helps me generate the plan.

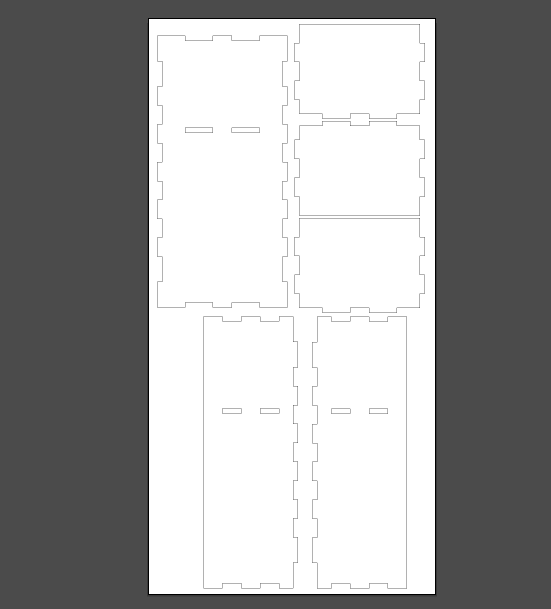

This tool gives you a box. But what I want is not 100% a box. So I changed the design a bit in AI and made it into two layers without front side.

Cause the local lab in SZ does not have the shop bot setup yet. So I went to a local wood market for material and machine.

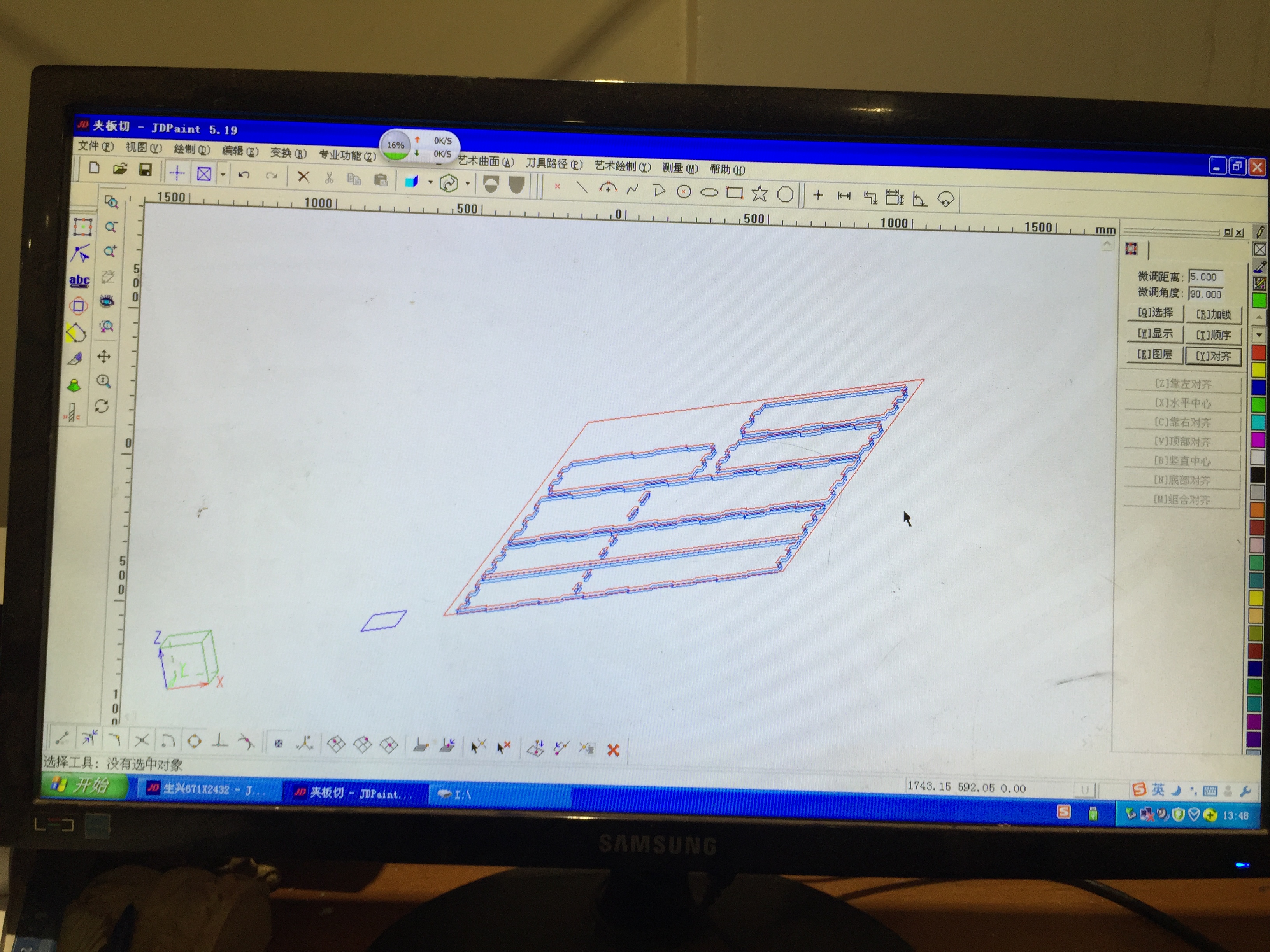

It is kind for the engineer in the CNC shop to teach me a lot about he software and the machine.

So basically control a CNC machine is not very different from control a laser cutter. But because CNC machine cuts things with knife not laser, so the settings is a little bit different.

Some interesting things to note:

1) for CNC machine, instead of setting the power, we set the depth of each cut.

2) instead of adjusting the focus, we set the direction of knife: inside and outside.

Example: cut a 10 x 10 cm piece with a 4mm knife. If you set INSIDE, then you get a 10 x 10 cm hole; if you set OUTSIDE, then you get a 10 x 10 cm piece.

So I moved all pieces back to Litchee Lab, and here is the picture in action.