This week, the assignment is cut something on the vinyl cutter and design, make, and document a parametric press-fit contraction kit. The vinyl cutter part, I made some stickers for our makerspace:

And the parametric press-fit part, I want to make something that can be used to build curves. I tried my first thought out by drawing a sketch on cardboard and cut it out by hand.

I like the curve. But to build a beautiful construction, many curves with different radius are needed. Whatever, I tried this with 1/4 circle first.

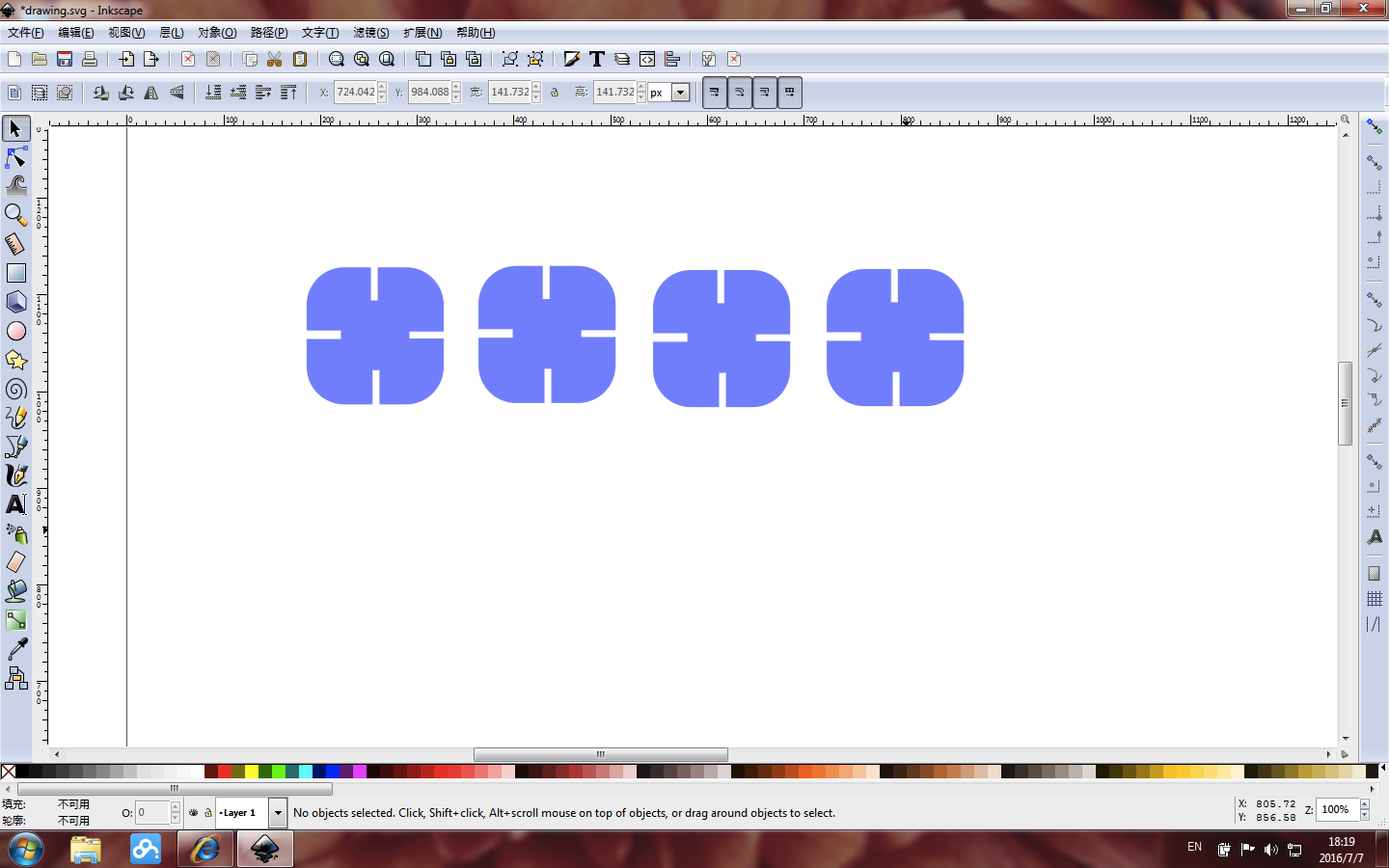

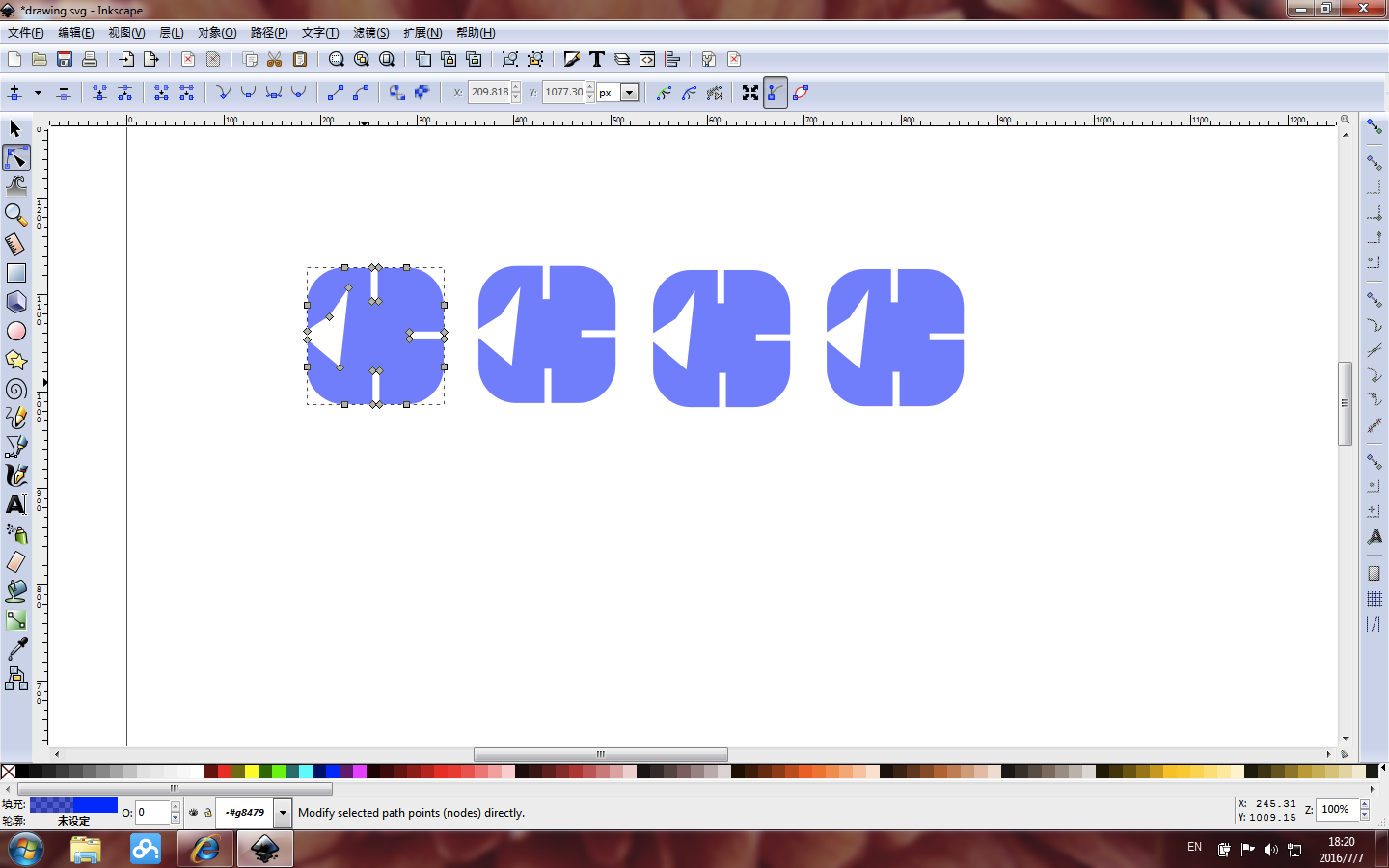

This is my drawing in Inkscape. Inkscape provides a function named Clone which can link objects up and copy changes made to the original object to the other objects. It is convenient for design that requires lots of tiny changes.

You can find information about Clone and Inkscape in the Reference part of this blog.

One more thing to share:

I am using a Mac. To install Inkscape on mac, you need to create a window environment for it. Inkscape recommends Xquartz. I installed it also and Inkscape runs ok. But the experience is not satisfying. So reminder here, if you want inkscape, try a window or linux, not OS X.

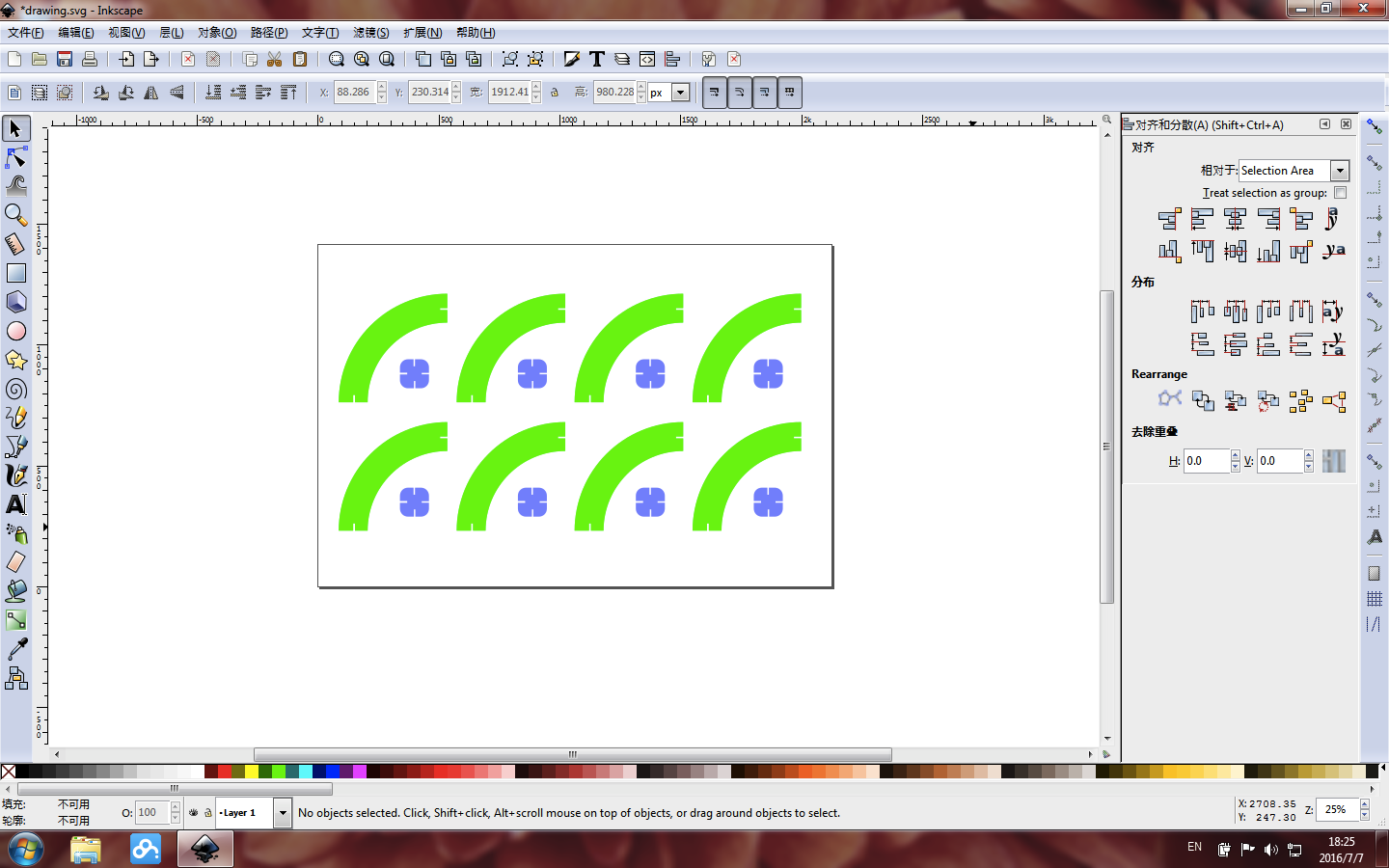

And here are what I got from the design:

I am using 2.5mm acrylic and laser cut things out. What I have learned about this:

1) Laser cutting can not provide you something exactly the same as your design. You want 2.5mm gap, but what it gives you is 2.98mm. And worse, this unwelcome deviation changes depending on materials and settings of the machine.

2) Acrylic is quite fragile. When the gap is 2.5mm, the kit requires me to press a bit to fit. However, when I pressed, it breaks(a lot), annoying...

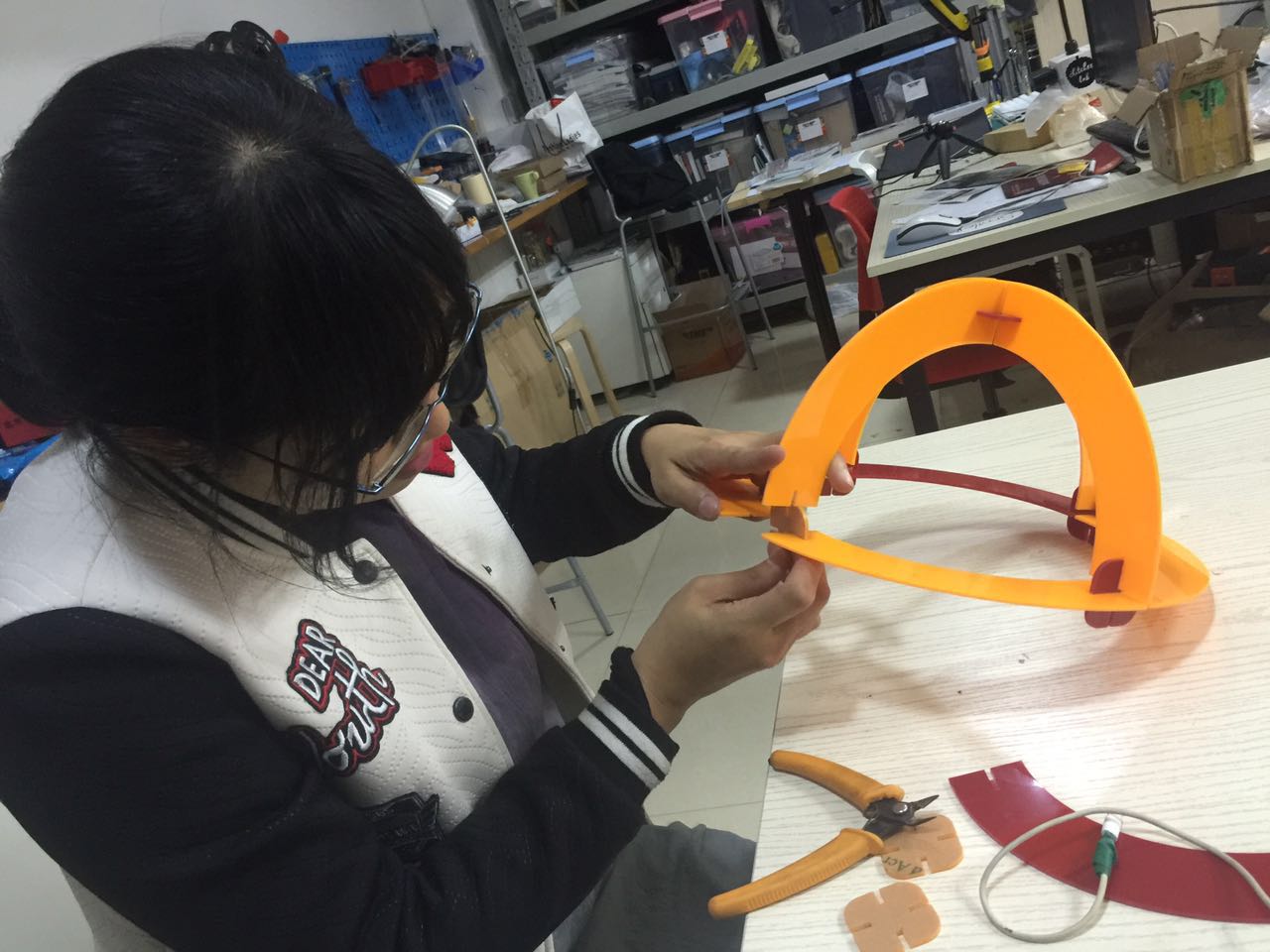

And this is what I got after breaking some connectors:

This kit is not finished. What I want to do next including:

1) add more arcs with different radiuses;

2) try other tougher materials.