Study archive - Week 17

Applications and implications

The task of the week is to propose a final project that integrates the range of units covered, answering:

- what will it do?

- who's done what beforehand?

- what materials and components will be required?

- where will they come from?

- how much will it cost?

- what parts and systems will be made?

- what processes will be used?

- what tasks need to be completed?

- what questions need to be answered?

- what is the schedule?

- how will it be evaluated?

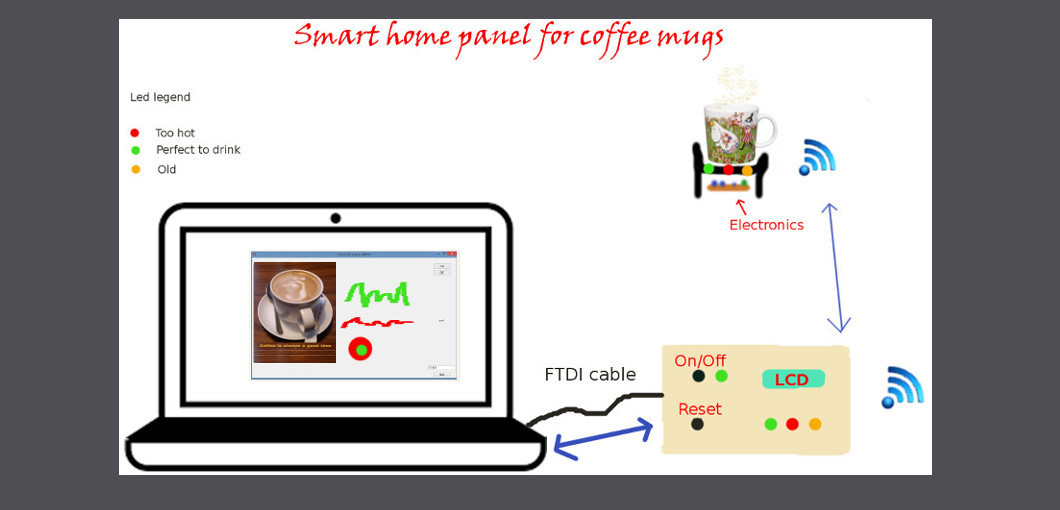

The final project refers to building a smart home device that measures the temperature in a mug and time. The information is wirelessly sent to and then displayed on a computer device and control panel. With the control panel the user is able to control the device and the data.

Basic features:- activate/deactivate system (reset)

- measure temperature in coffee mug

- send data (temperature, time, and reset signal) to computer device and control panel

- display temperature, time, reset on LCD

- display temperature, time, reset on GUI on a computer device screen

- mug holder (3d printing)

- temperature sensor for coffee mug

- control panel (plywood laser cutter and milling)

- on/off buttons for activate/deactivate/reset

- LCD

- (LEDs, optional)

- networking components (wired and wireless)

- power sources

- computer and GUI

A sketch of the system and interactions is shown below. The LEDs will be implemented if time allows.

2. Who's done what beforehand?

2. Who's done what beforehand?

Doing some research, I found that a similar device (in fact, a mechanical tea alarm) was presented at a TV show Manlab by James May in episode 5 season 3 (see here the episode; the relevant part starts at min 35 and ends at 41:40). My proposal is different because it is digital. Some advantages are: the sensor is not in the mug, but in the mug holder; the information is visually presented on a control panel and computer screen. For this project I choose to tailor the mug holder for the most popular mug in Finland, Arabia Moomi Series. All source files are open and one can develop futher the device, e.g., to incorporate an audio alarm, customized mug holder for other types of mugs, different computer devices such as mobile phone.

3. What materials and components will be required? 4. Where will they come from? 5. How much will it cost?| Material/component | Source | Cost |

|---|---|---|

| ABS-M30 for the 3D printing | Fablab Oulu | n.a. |

| Support material for the 3D printing | Fablab Oulu | n.a. |

| NTC thermistor | Fablab Oulu | 2.98 USD |

| Microcontroller ATTiny 44A | Fablab Oulu | 1.51 USD |

| LEDs x 6 (max 10) | Fablab Oulu/SparkFun | 3.5 USD |

| Other electronic components | Fablab Oulu | about 10 USD |

| FTDI cable | Fablab Oulu | 16 £ |

| XBee x 2 | Fablab Oulu/SparkFun | 50 USD |

| LCD | Fablab Oulu | 8.38 USD |

| On/off switch | Fablab Oulu | 1.95 USD |

| Plywood | Fablab Oulu | about 10 USD |

| Total | -rounded- | about 100 USD |

| Part made in Fablab | process used |

|---|---|

| 1. Mug holder with slot for electronics | 3D design and 3D printing |

| 2. Electronic board for LCD and control panel | Electronics design, production, and embedded programming |

| 3. Electronic board for temperature sensor | Electronics design, production, and embedded programming |

| 4. Wired and wireless networking | Electronics design, production, and embedded programming |

| 5. Plywood case for control panel | 2D design and laser cutting |

| 6. GUI | Interface and application programming |

Tasks 1-6 in table above need to be completed.

9. What questions need to be answered?Calibration of the temperature sensor has to be done. The use of leds on mug holder as well as on the control panel has to be designed if time allows.

10. What is the schedule?The deadline for presentation and finishing the project documentation is 17.06.

- Week 20 (16. - 22.5) Define final project concept DONE

- Week 21 (23. - 29.5) Make bill of materials and adjust final project concept based on availability of components DONE

- Week 22 (30.5 - 5.6)

- Week 23 (6. - 12.6) Work on electronics production including networking and HCI programming

- Week 24 (13. - 17.6) Finalize the final project, documentation, and presentation. Aim is to present on 17.6.

- Week 25 (20. - 29.6) Revise weekly assignments (CNC, output devices, networking)

(1) Design and fabricate the physical interface: the control panel case and the mug holder

(2) Start the electronics design and production

The project is evaluated a success if the mug holder sends correct data to the panel and computer, displays it and the user is able to interact with the control panel and GUI. Random users can also be asked to provide feedback.

The product is a proof-of-concept and the aim is to extend it further by adding more functionality and/or design features. The project aims also to rise students/children interest in electronics, programming, and especially data analytics. By using a simple, everyday situation to generate data, people of all ages and backgrounds can be involved in the process of creating visual analytics.

Summary of Tools to be used

Software

Python

Atmel Studio C

SolidWorks

Autodesk Inventor Professional

Inkscape

Eagle

Hardware

Laser cutter

Roland milling SRM-20

Stratasys Fortus 3d printer

Pick and place electronics