Final Project Process

During the weekly assignments I tried to stick as possible with my final project as the main mission motive.

At weeks 2nd, 3rd, 5th, 7th, 10th, 12th, 13th and 14th I achieved progress in it.

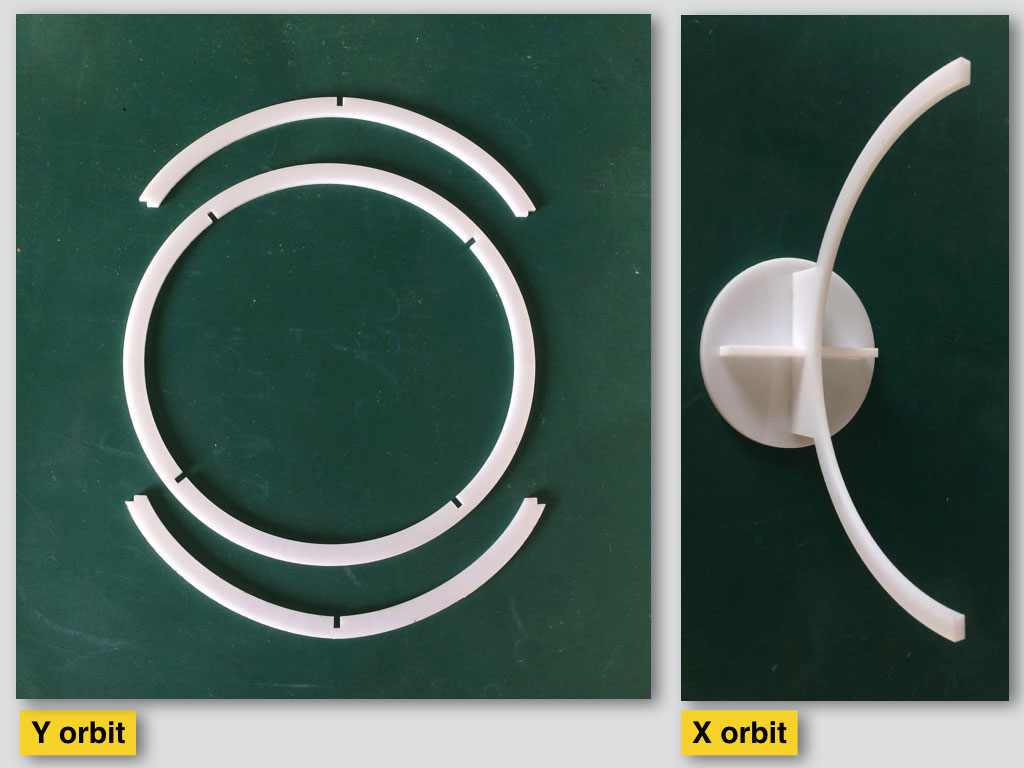

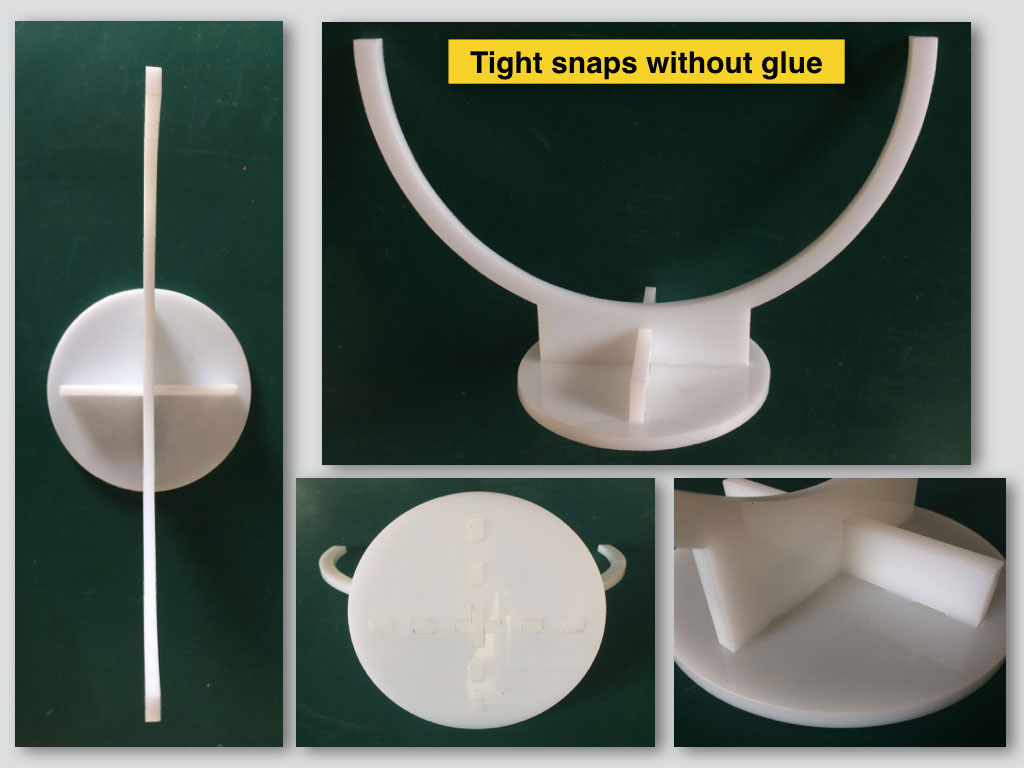

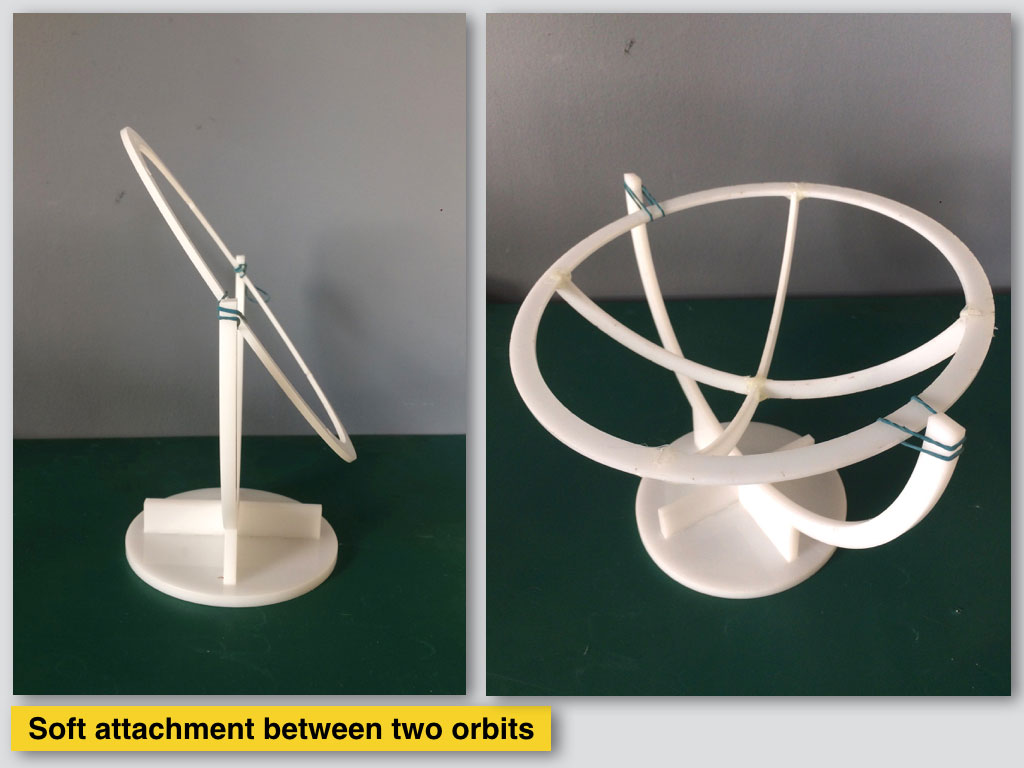

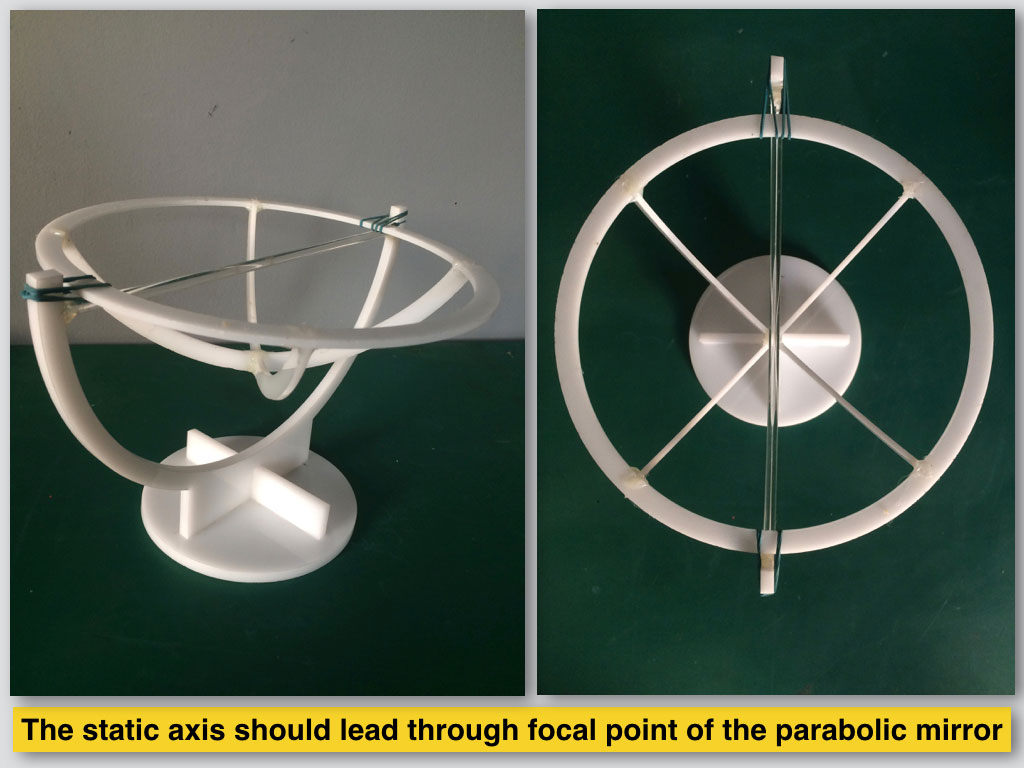

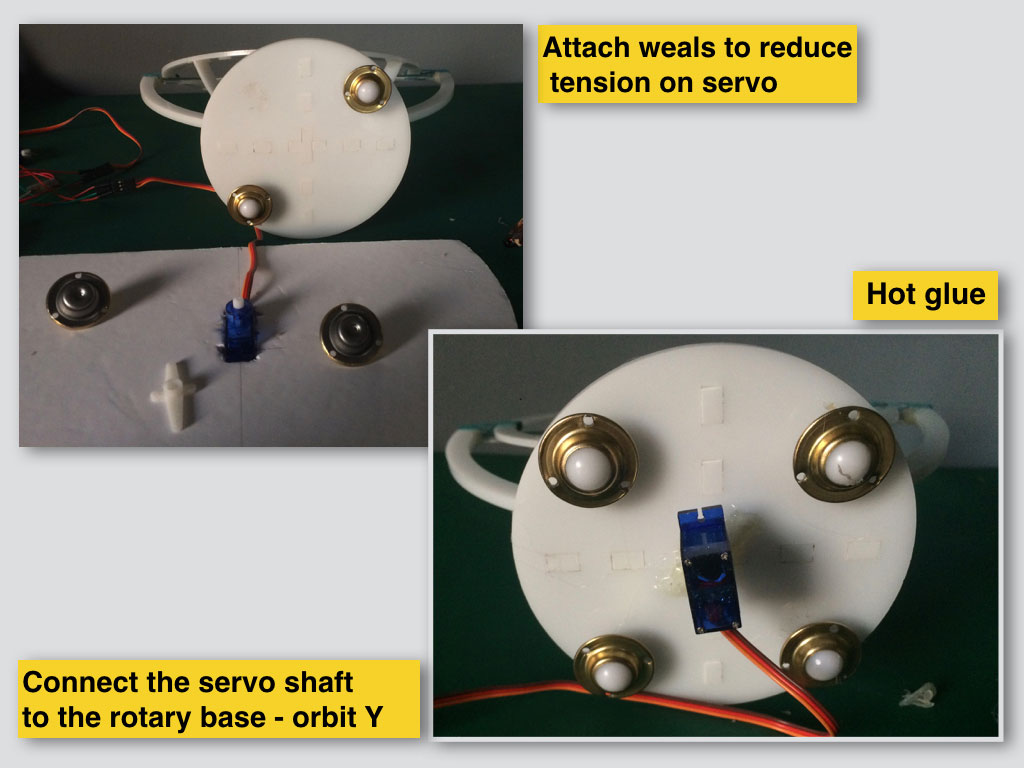

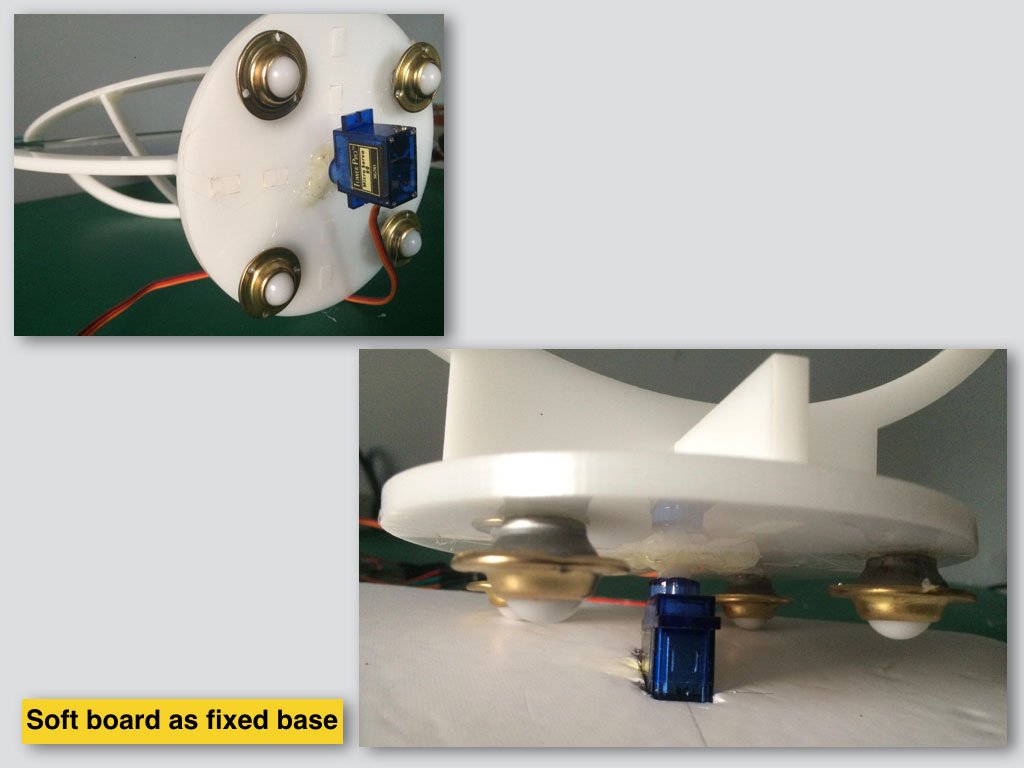

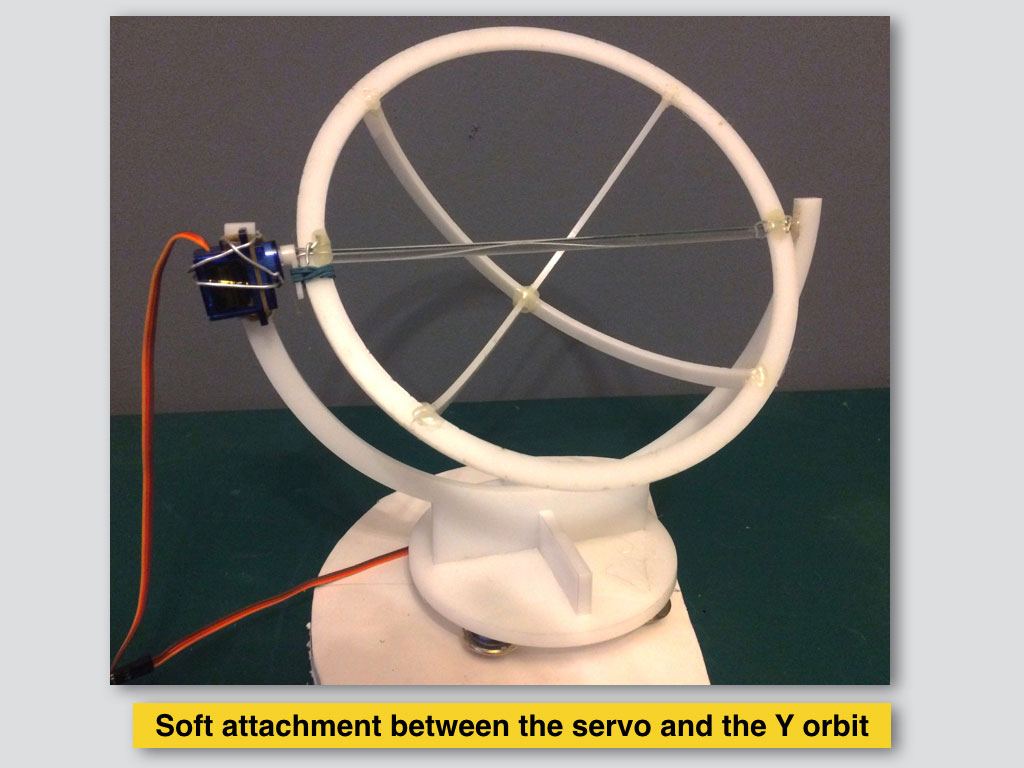

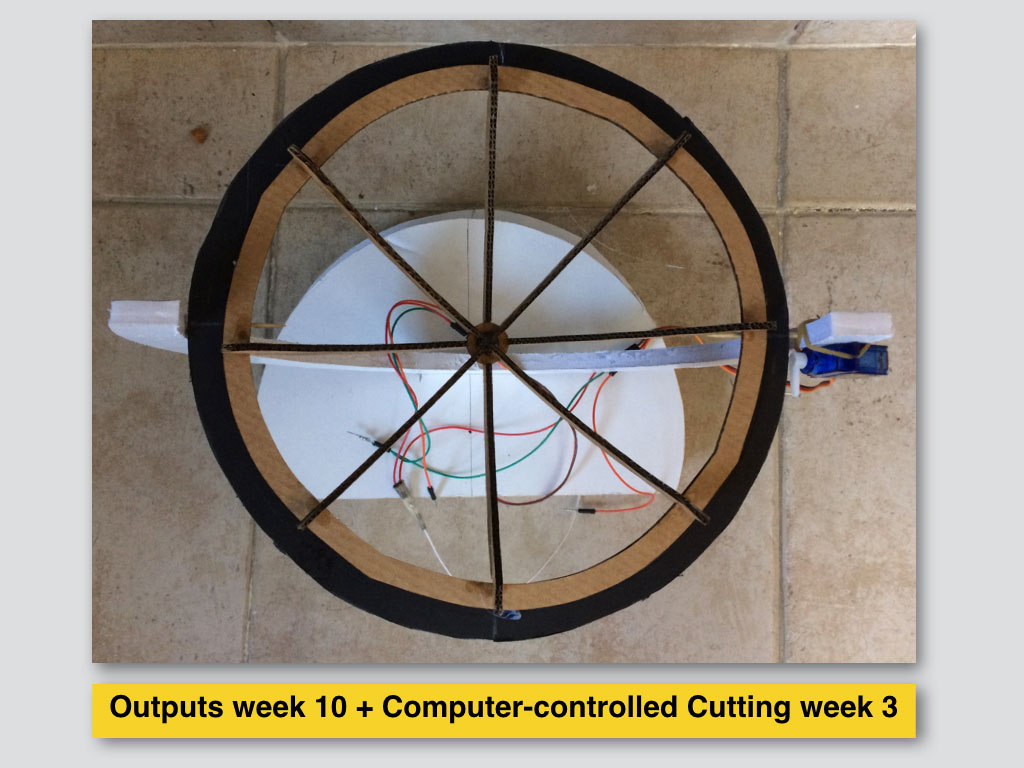

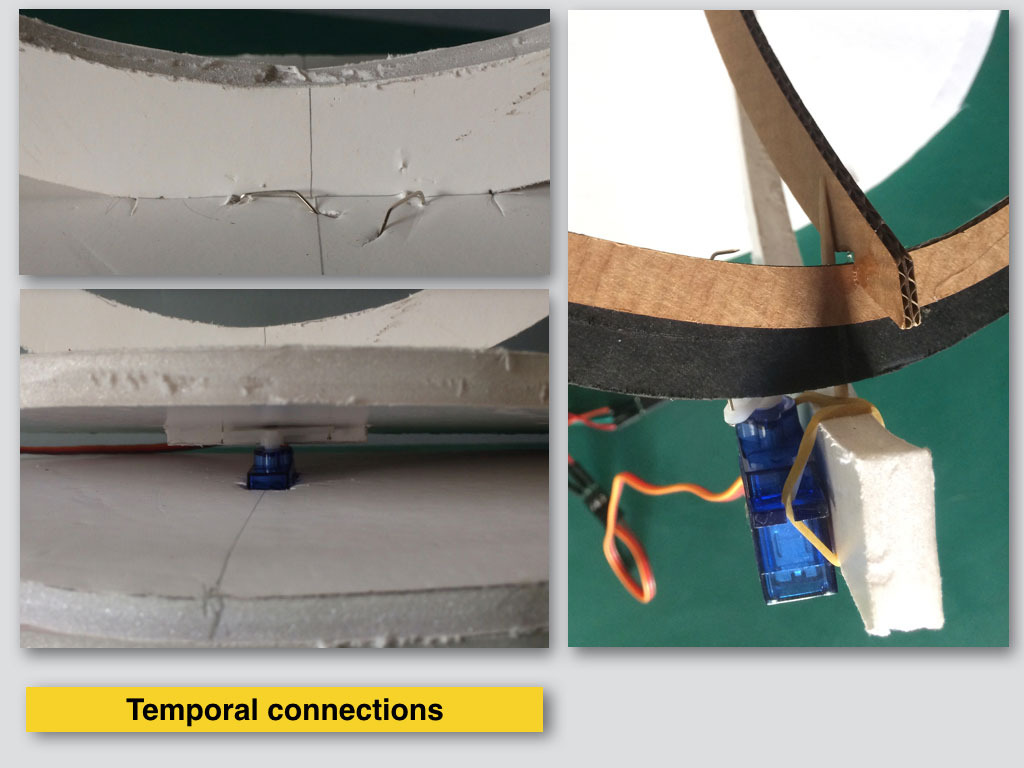

First mockup

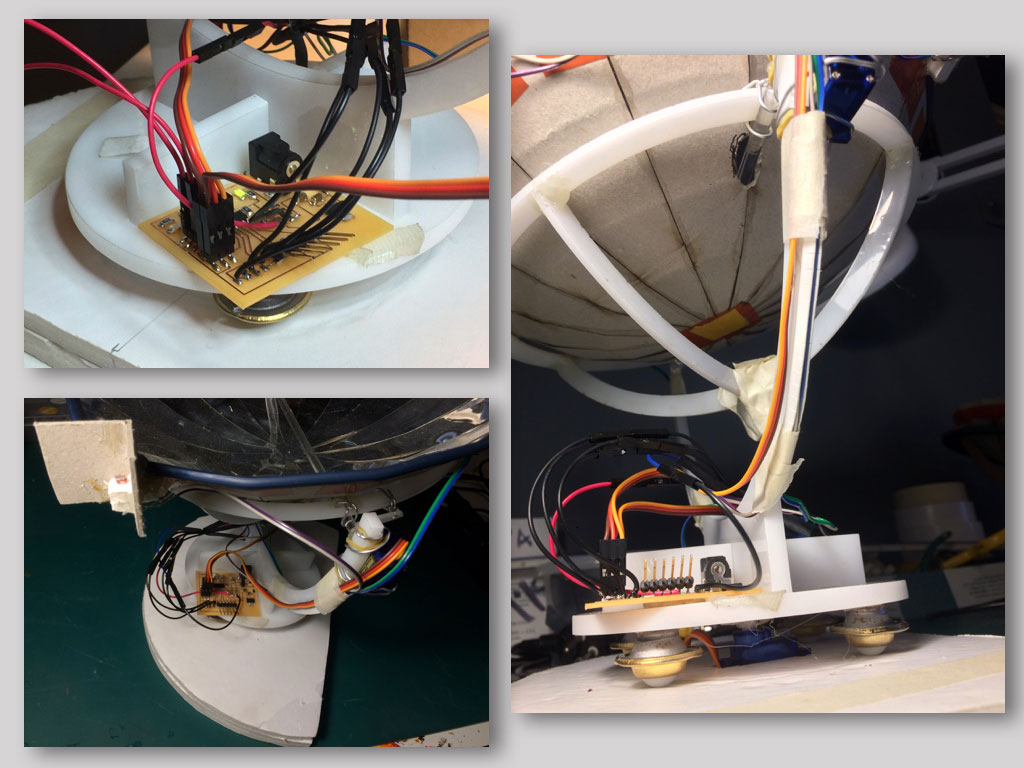

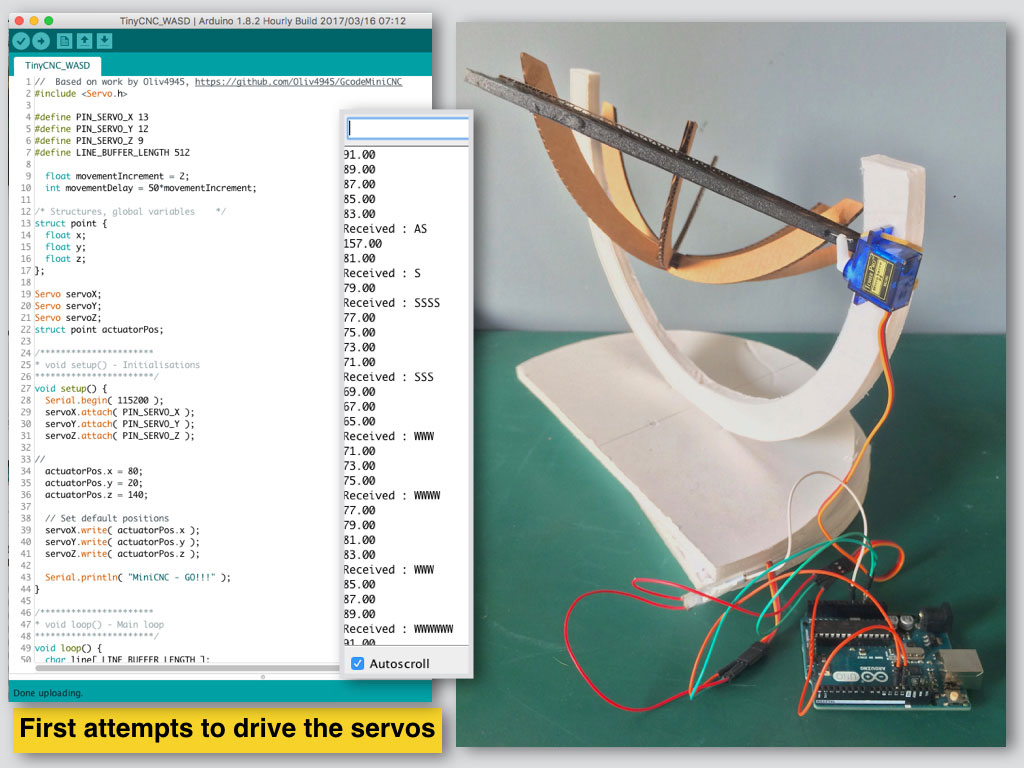

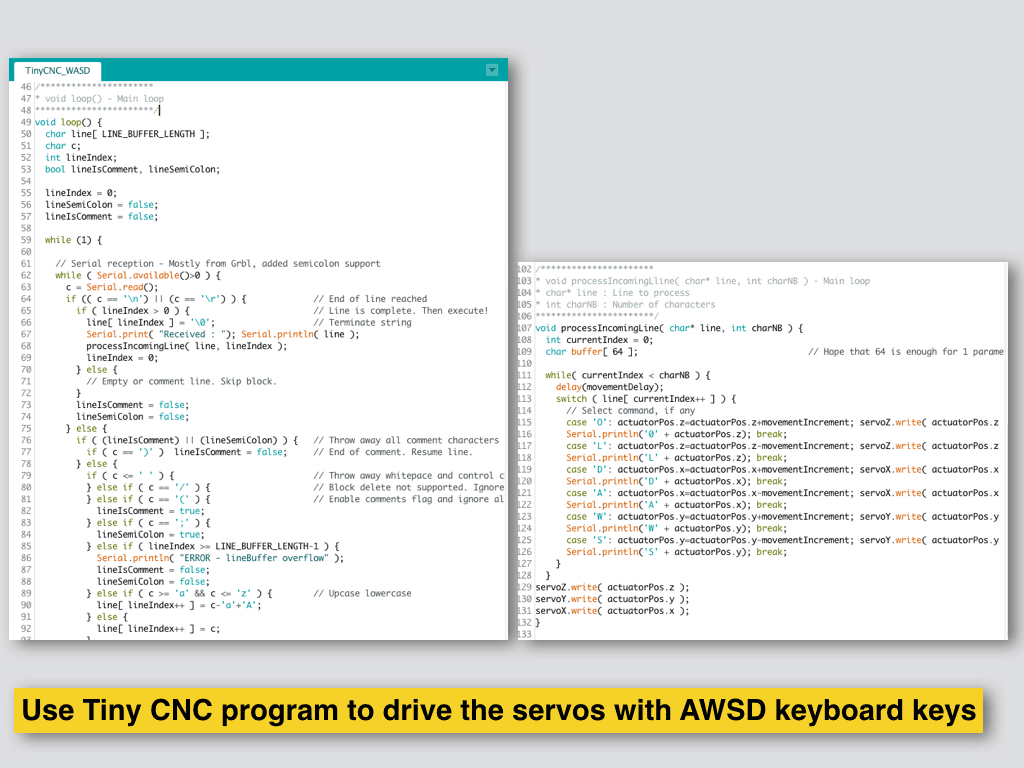

Programing - motion check

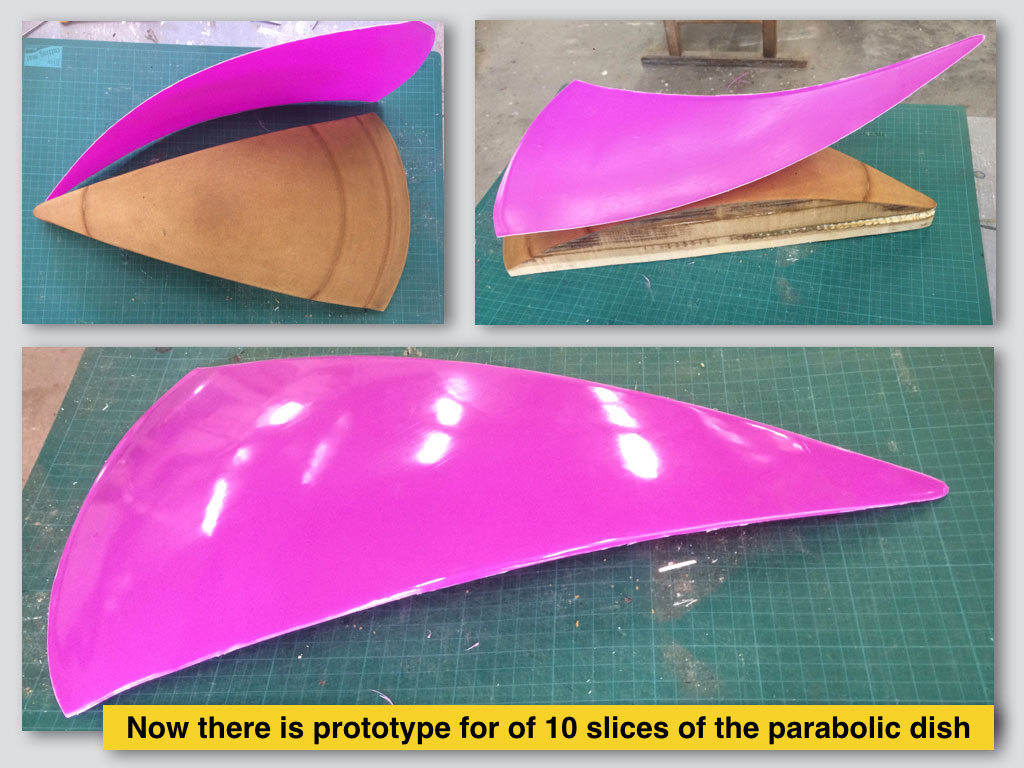

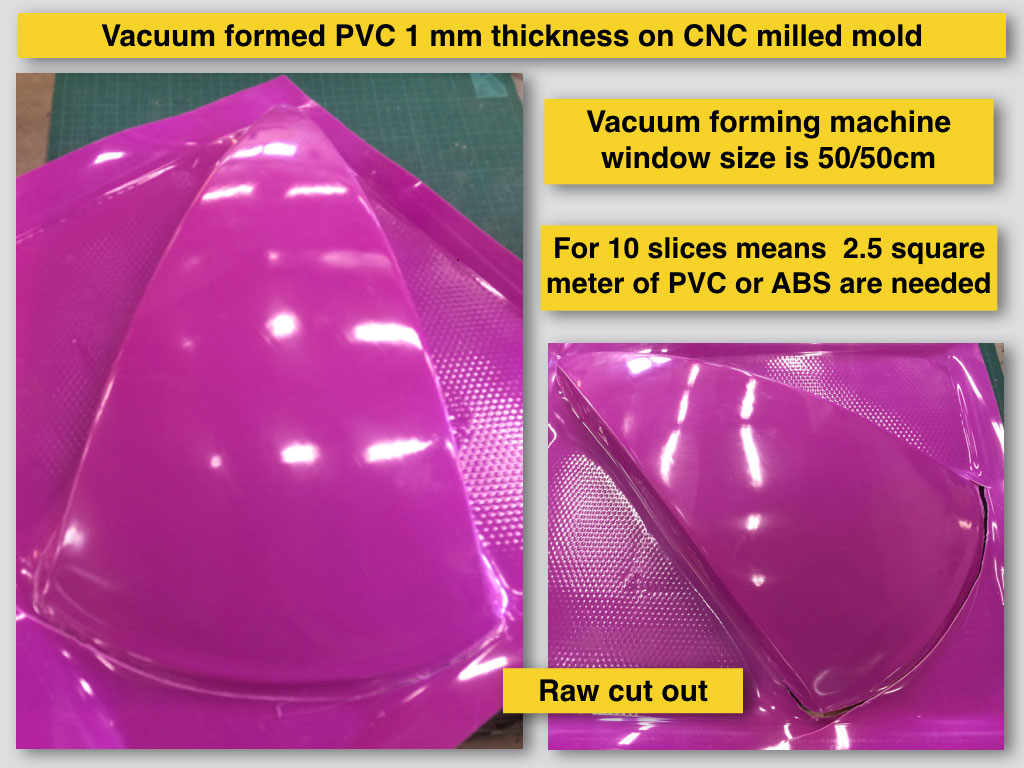

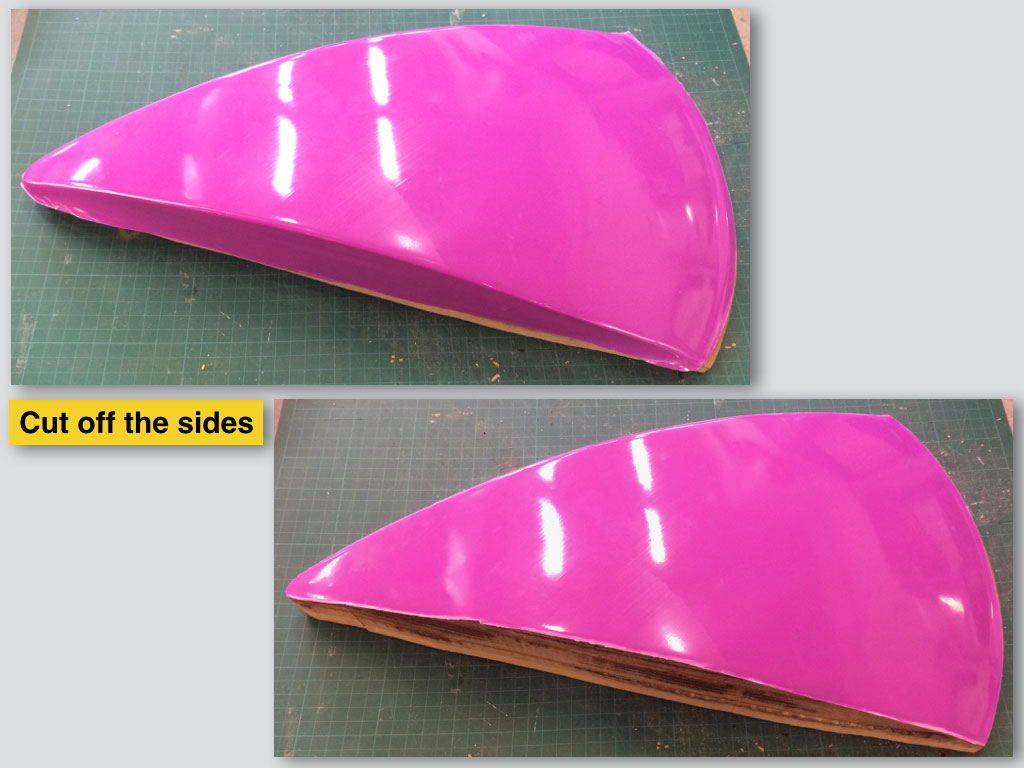

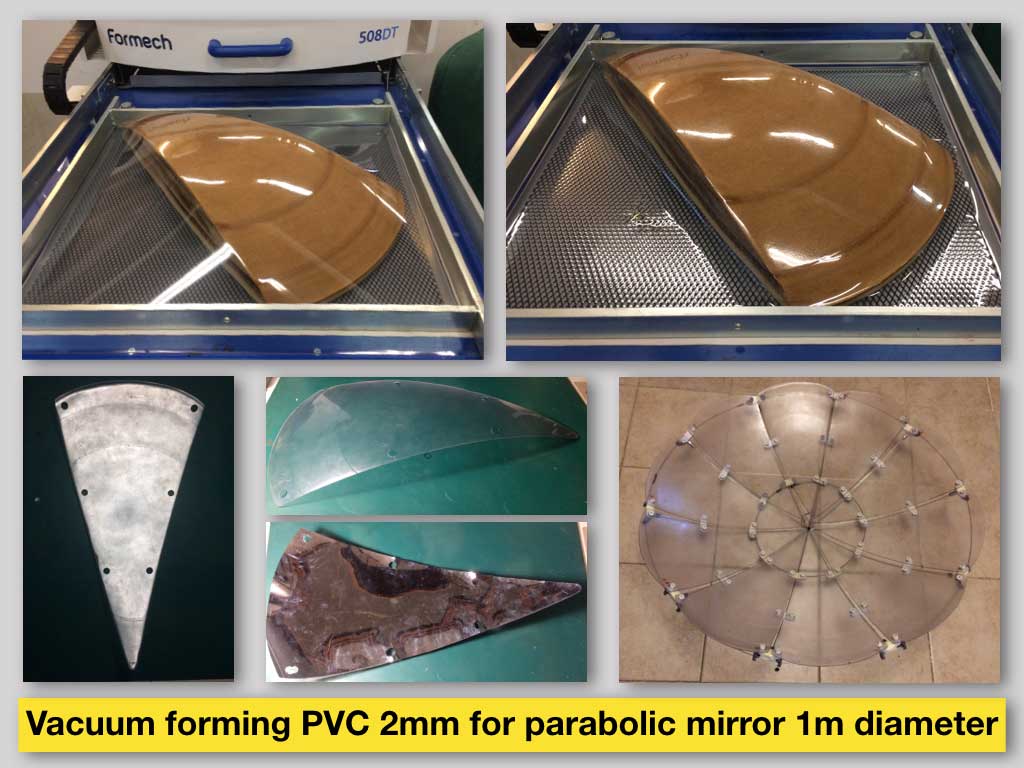

Vacuum forming prototype - parabolic mirror slice 1:1 scale

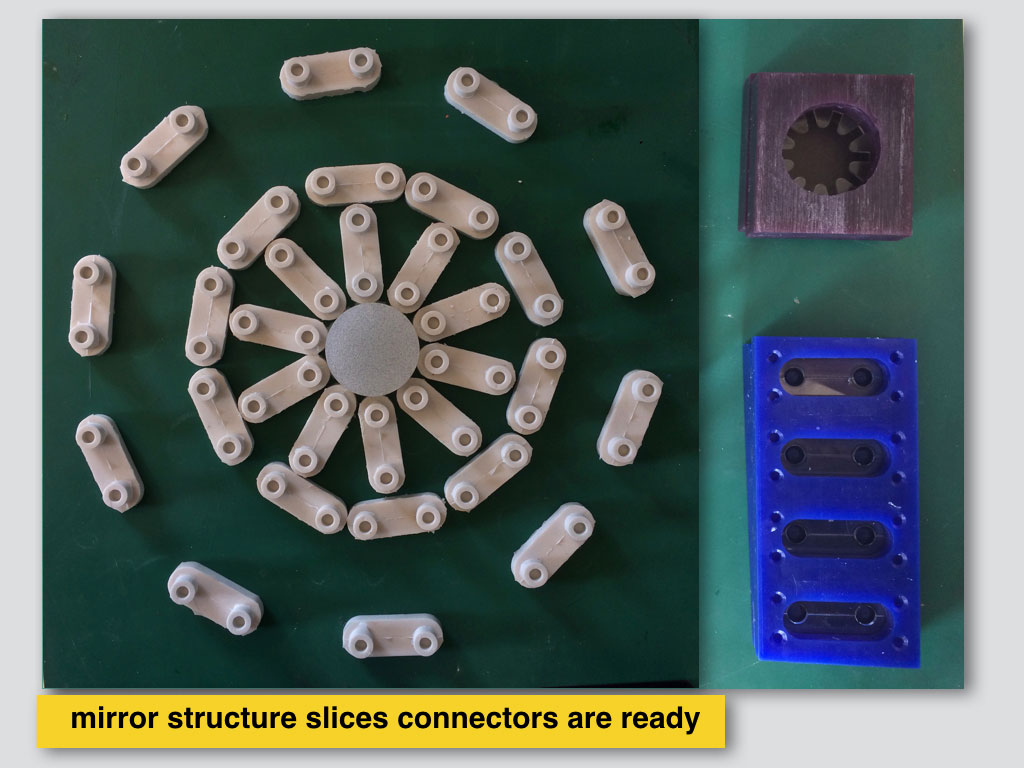

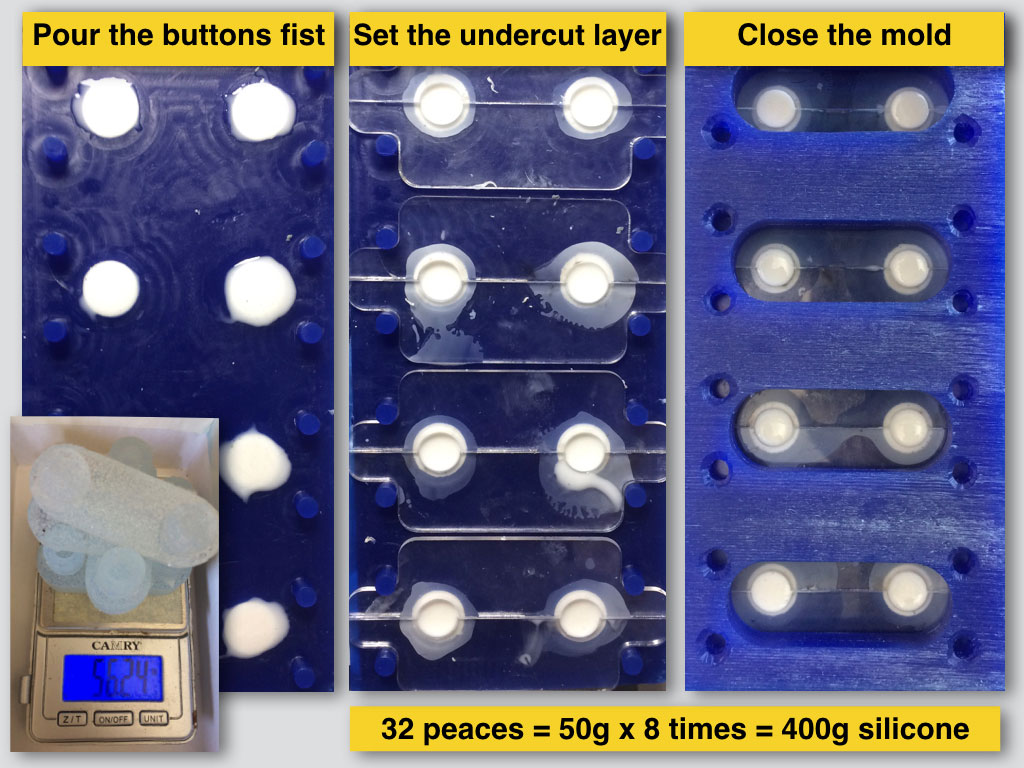

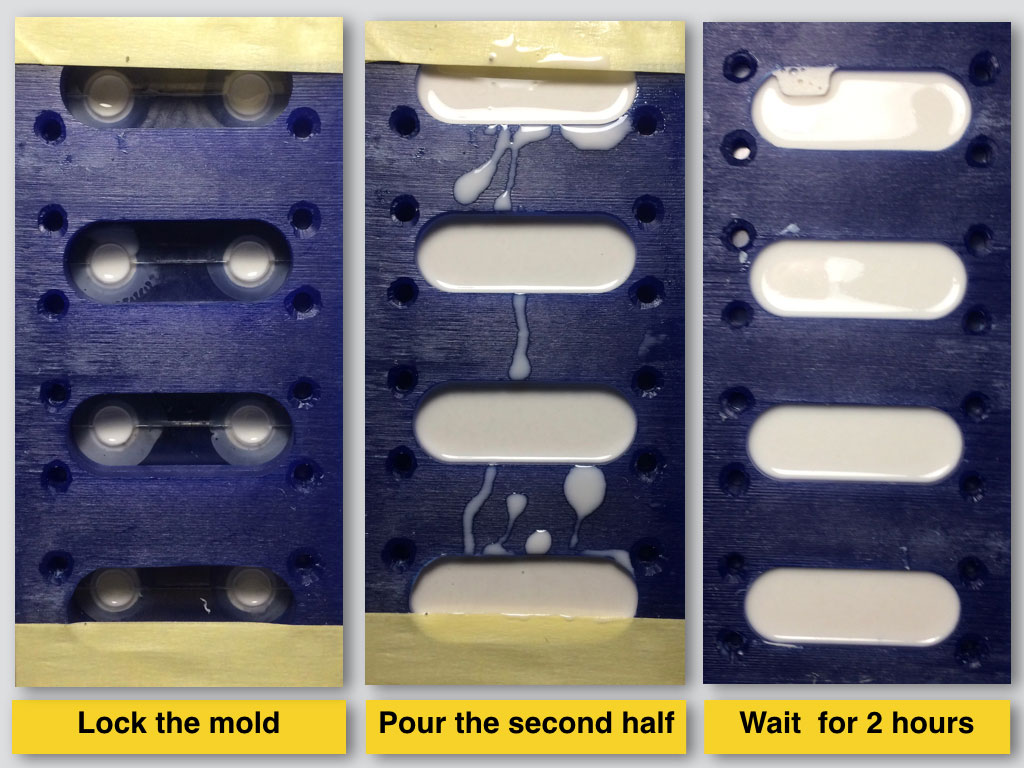

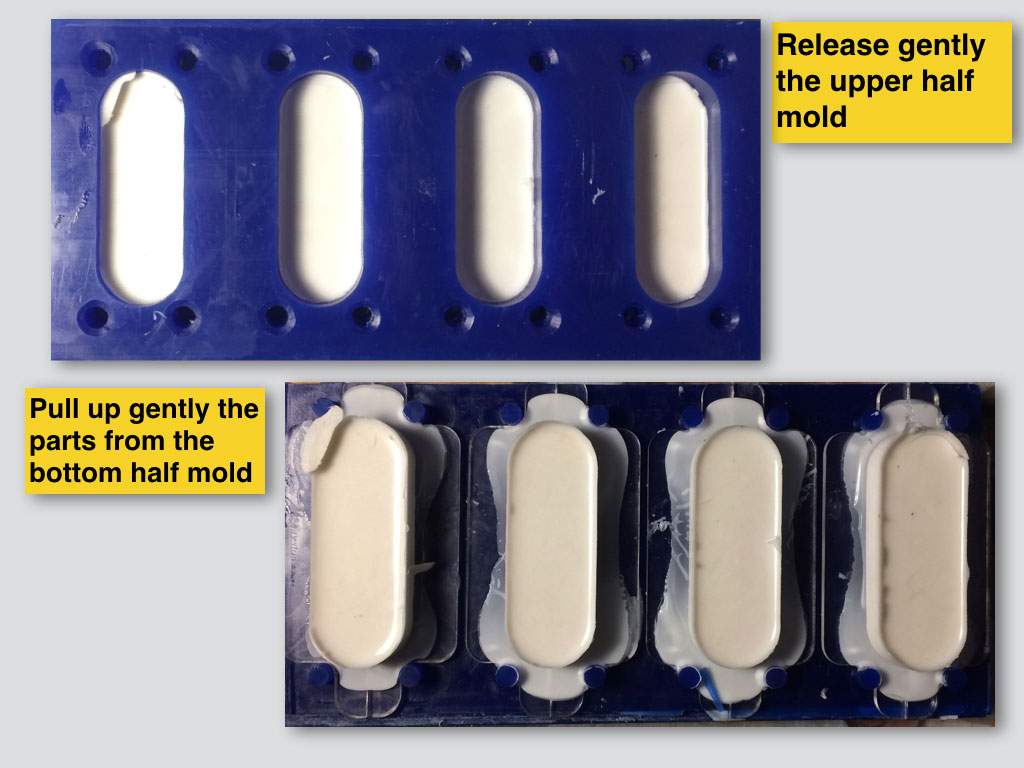

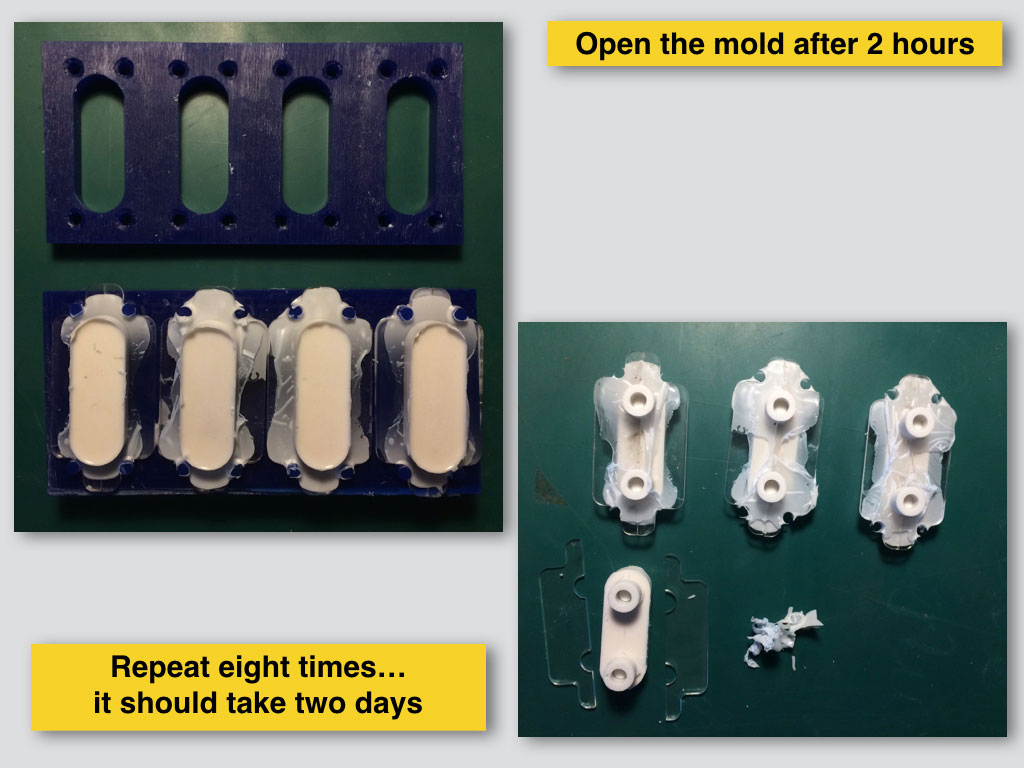

Casting 30 silicone parts

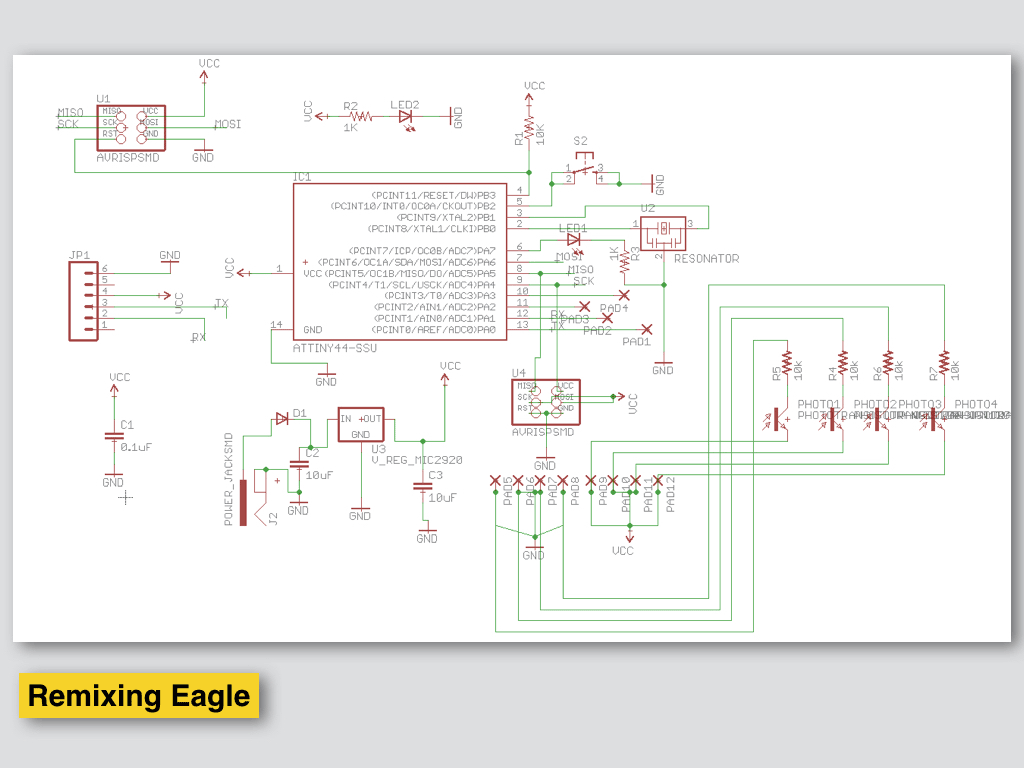

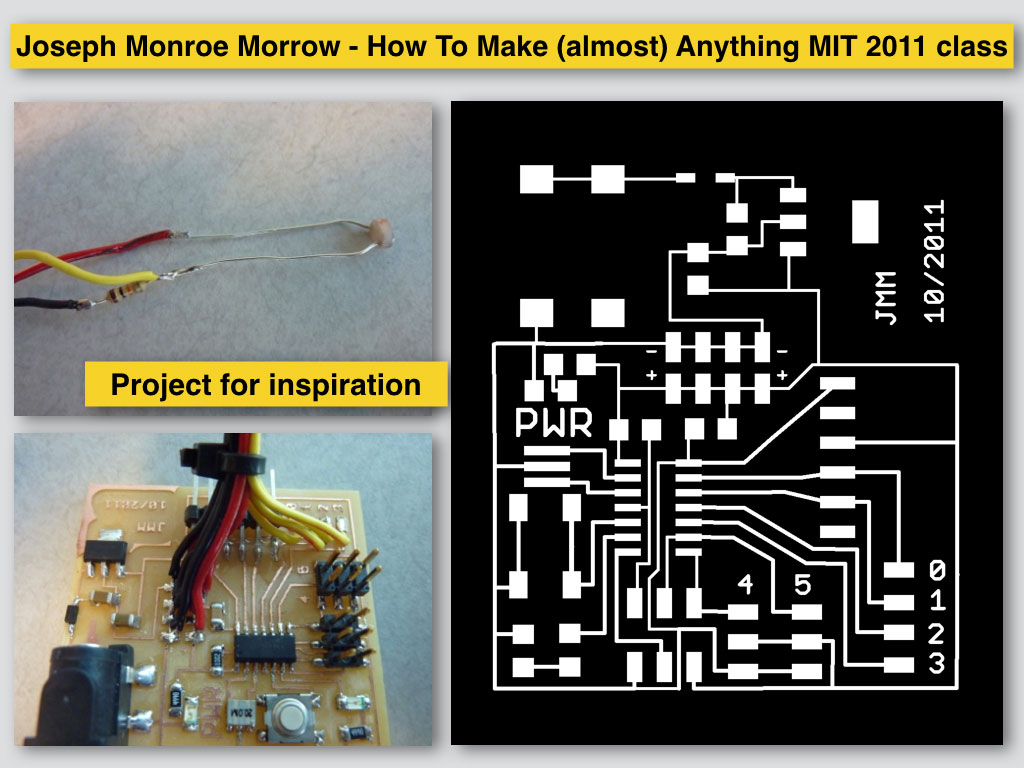

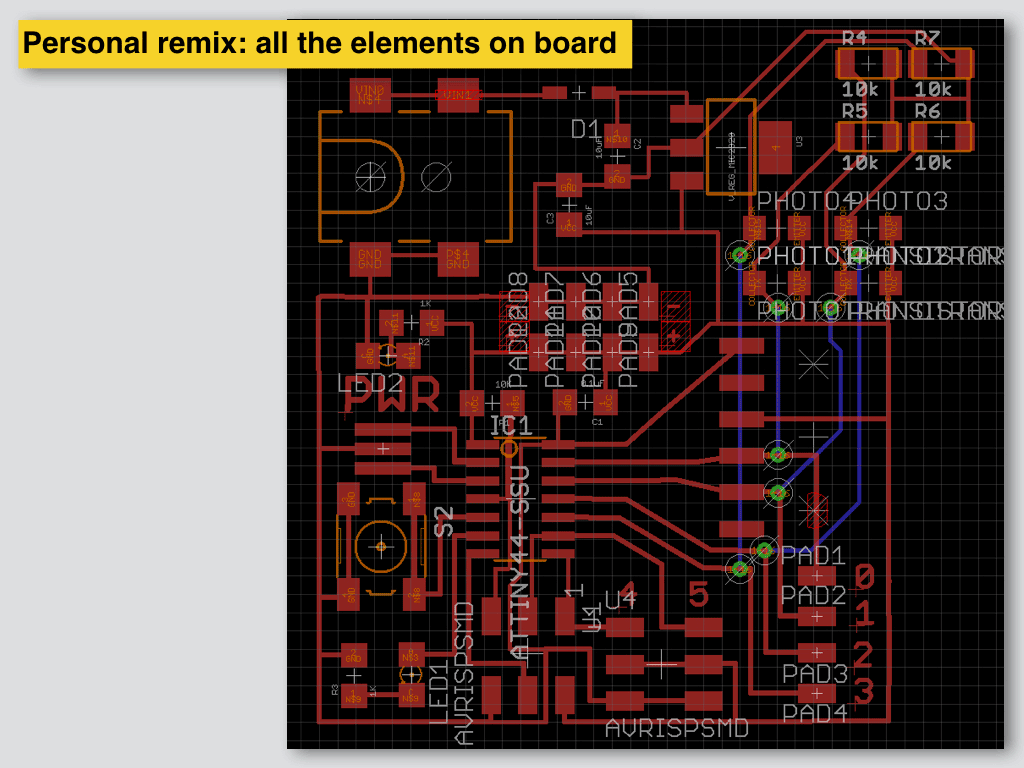

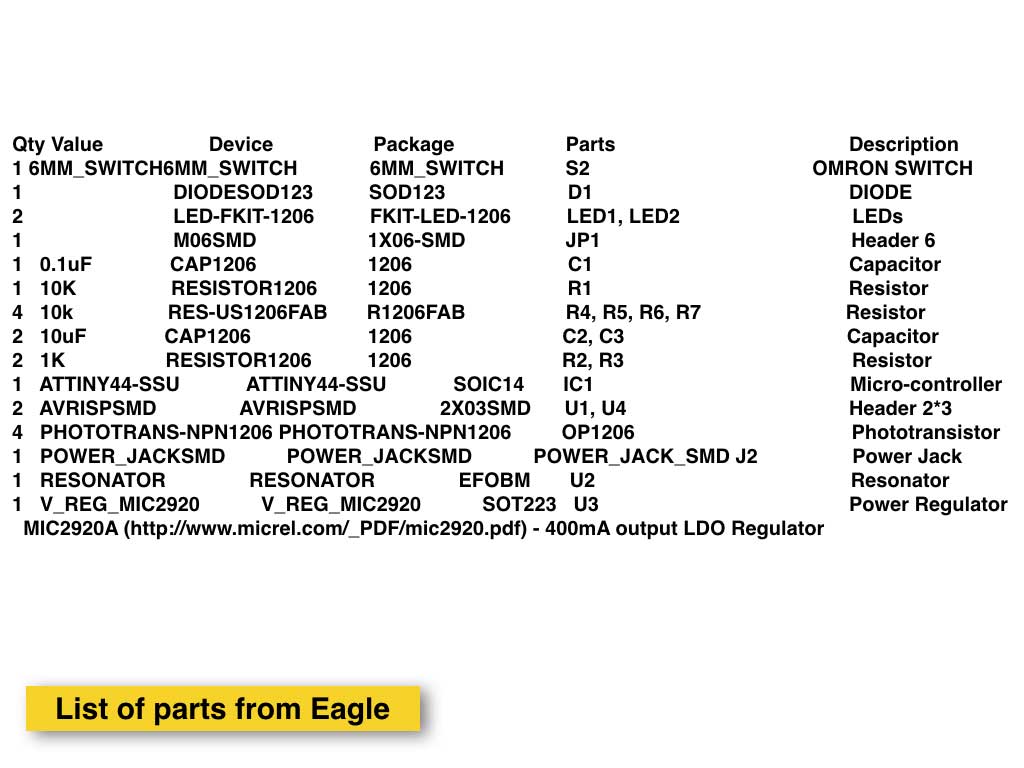

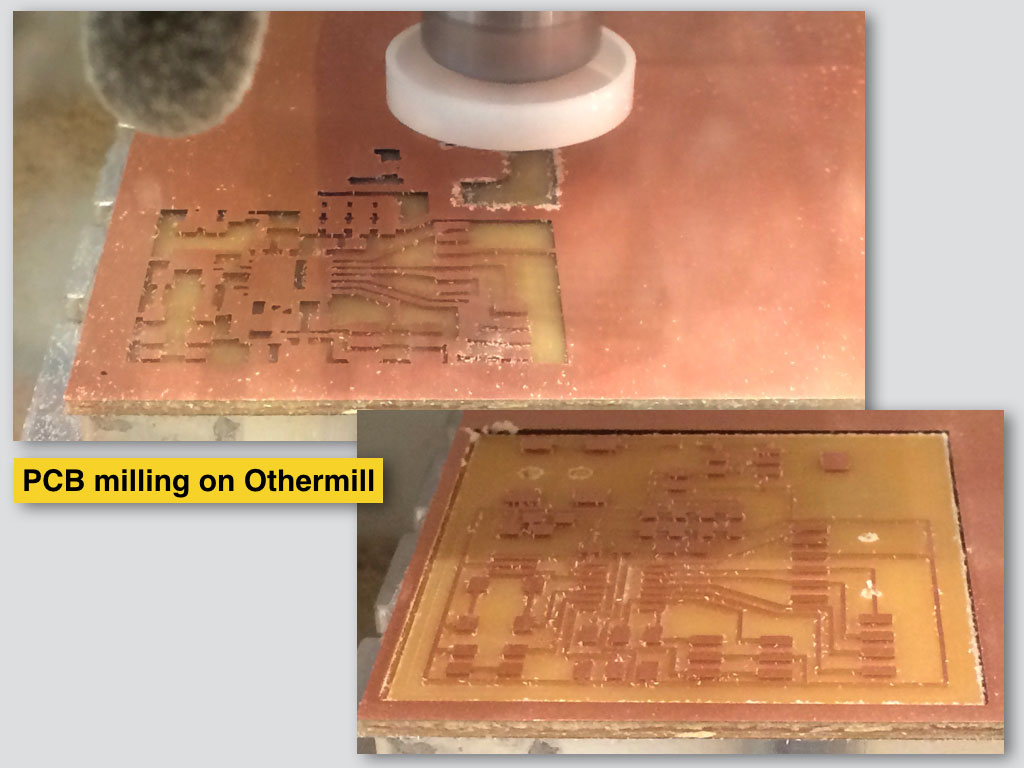

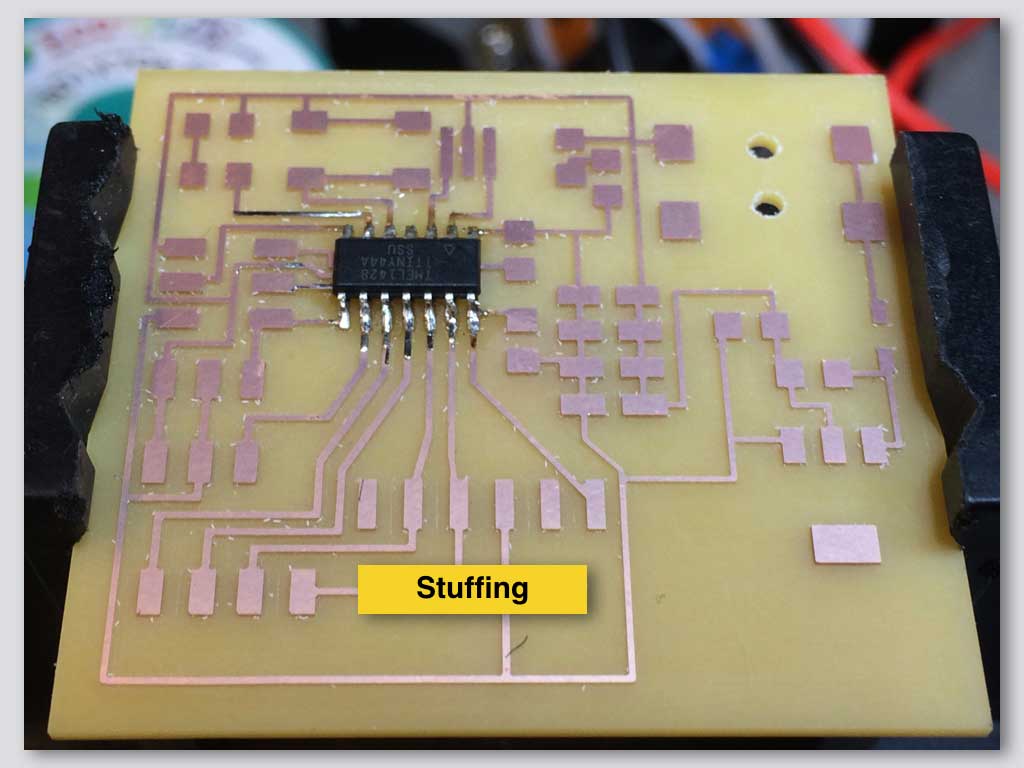

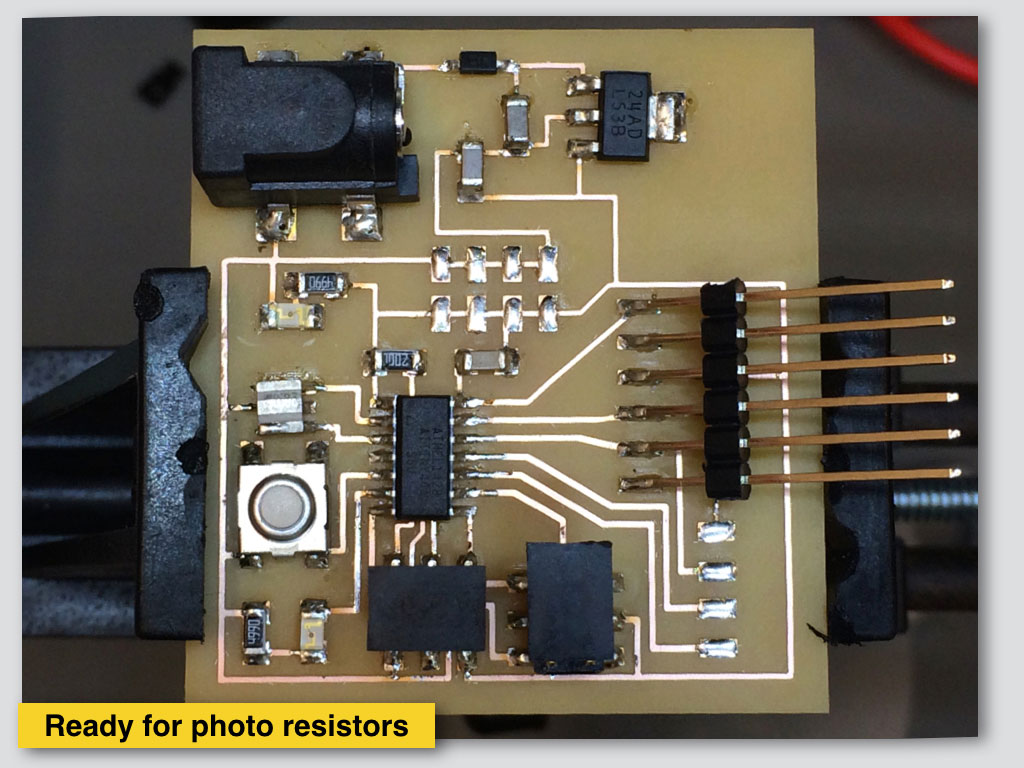

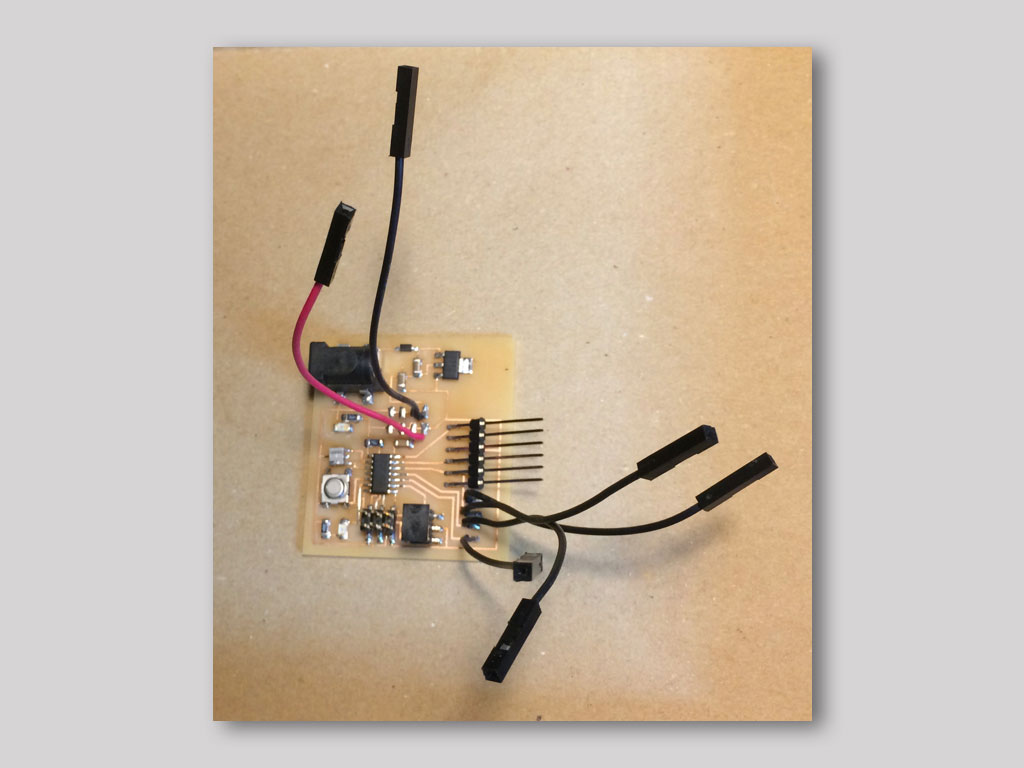

Electronics production - solar traking circuit

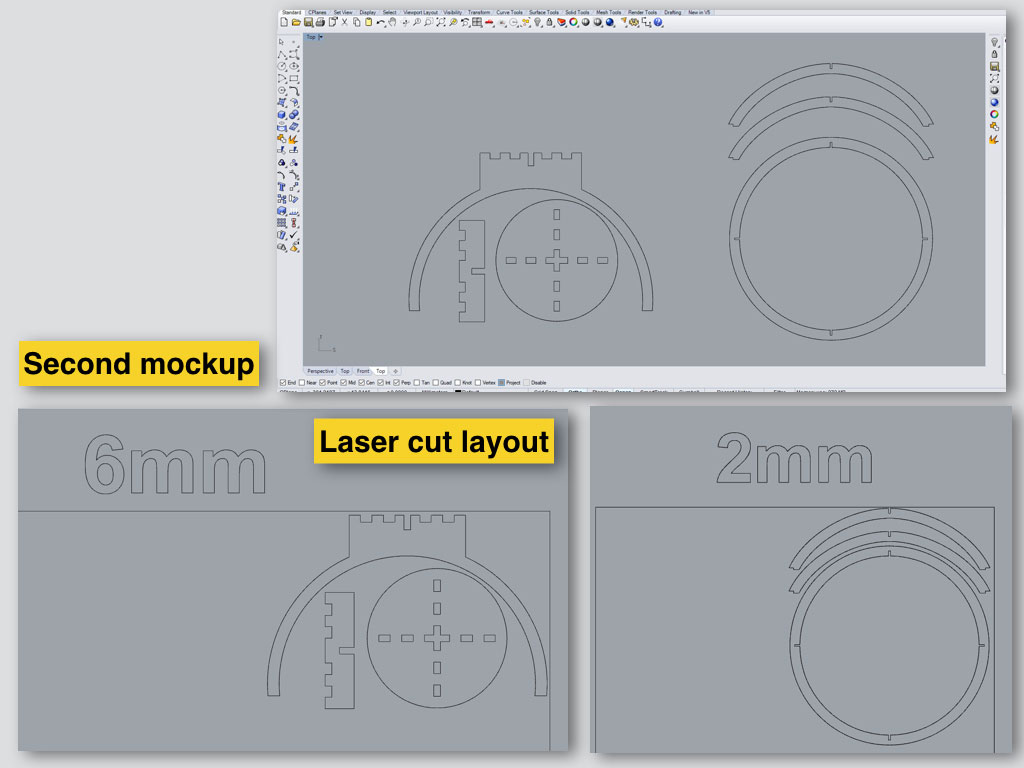

Second mockup - acryl laser cut