Week 7:

Computer-controlled Machining

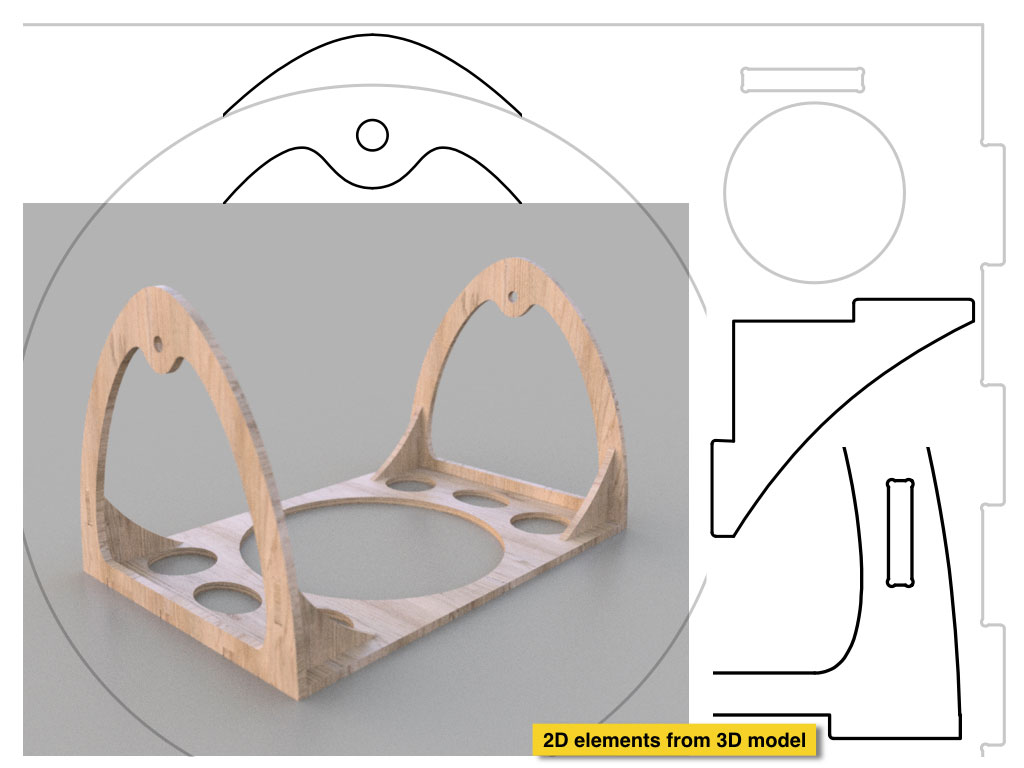

Modeling

The focus in this fabrication process with CNC is at the biggest part of my final project. The plywood structure will be placed on motorized rotation base and will turn during the sun tracking. The second turnable axis for parabolic mirror will be placed between two holes on the structure walls.

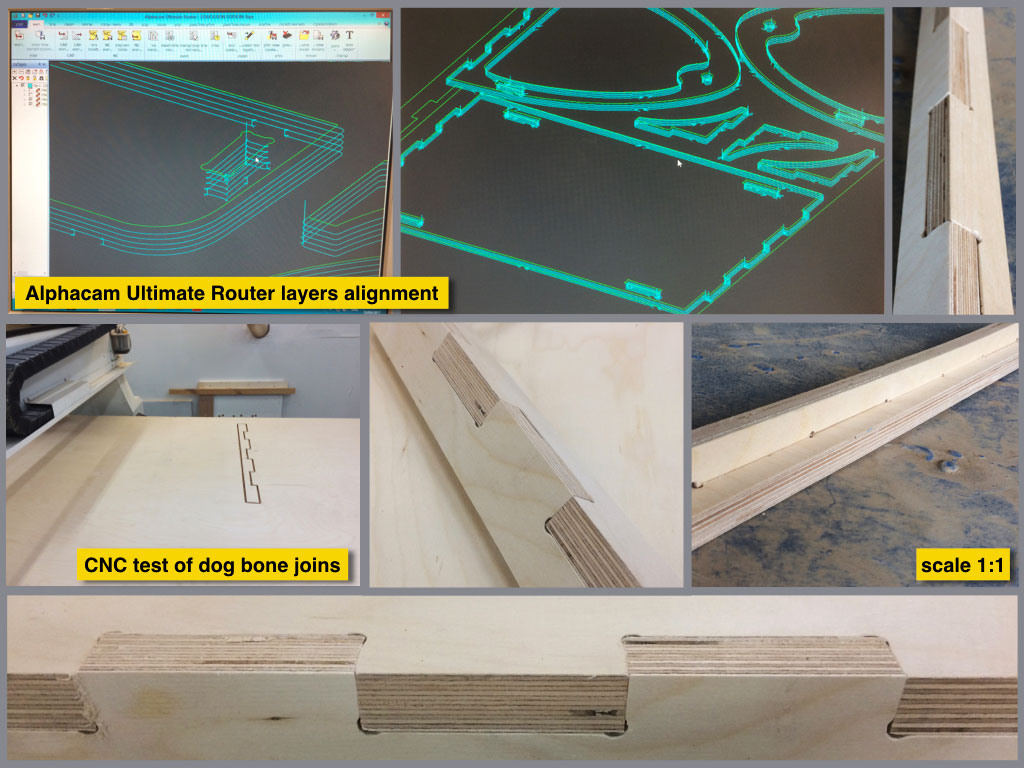

Files preparation

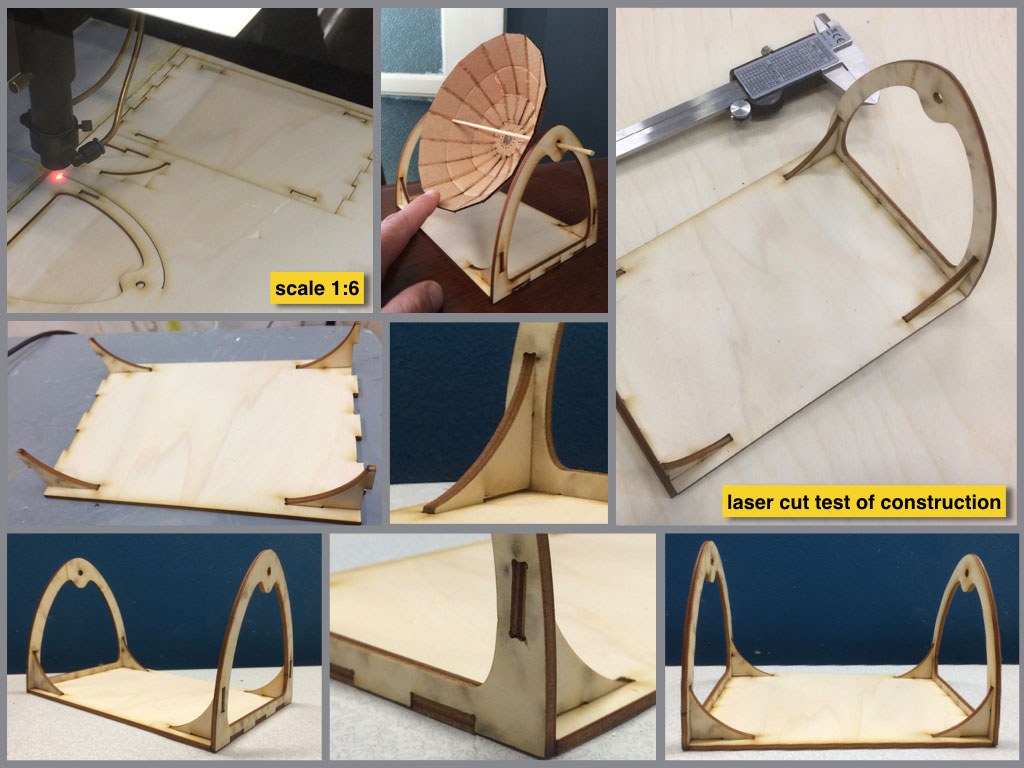

Press-fit constructure

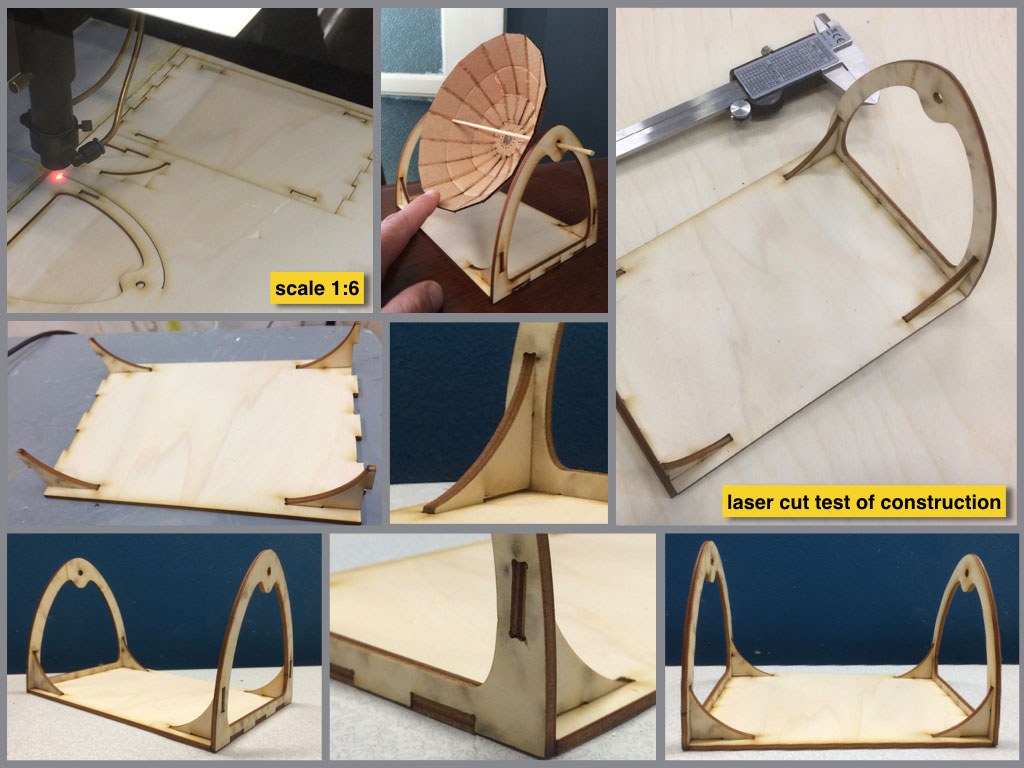

Scaled test

Laser cut test 1:6 scale

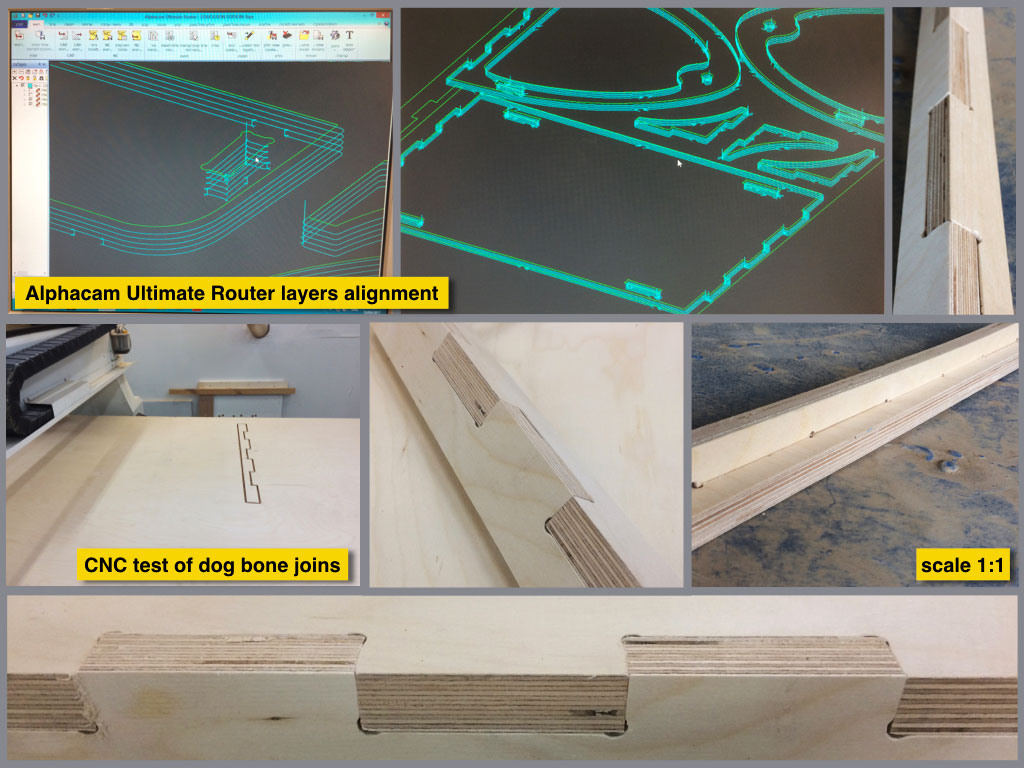

1:1 CNC test

CNC 1:1 joint test

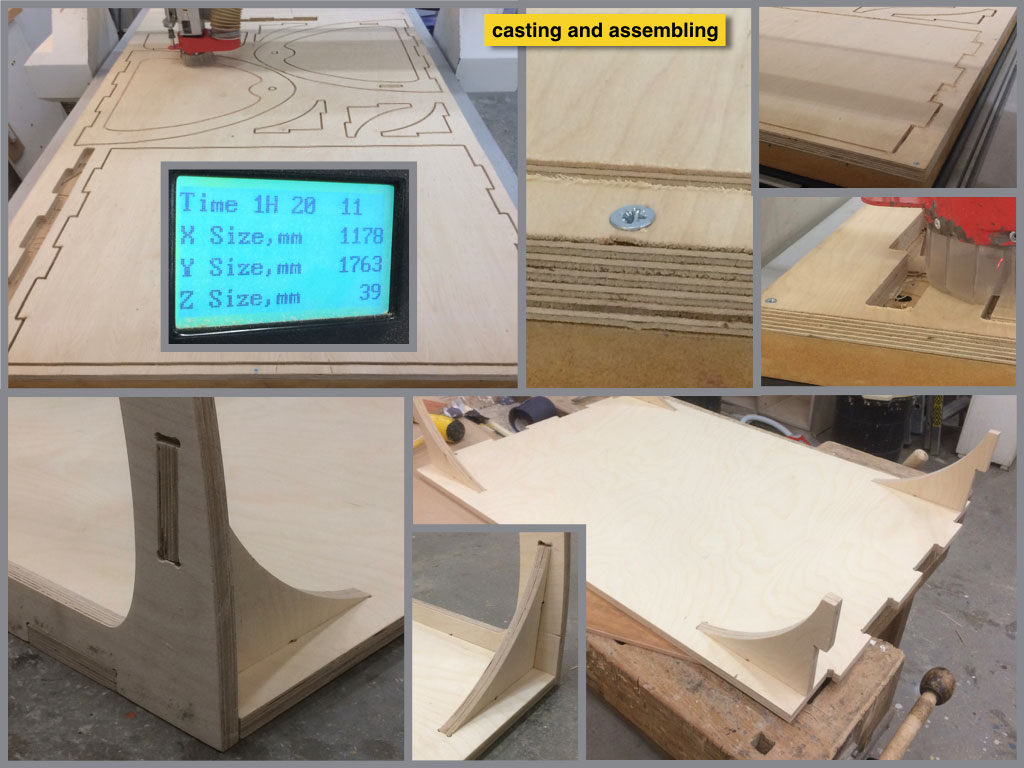

Fabrication

Final result