For the course we have made a group medal which involved all three steps of the assignment: machined wax positive mold, casting soft negative mold from it and then hard material positive replica casted in the silicine mold.

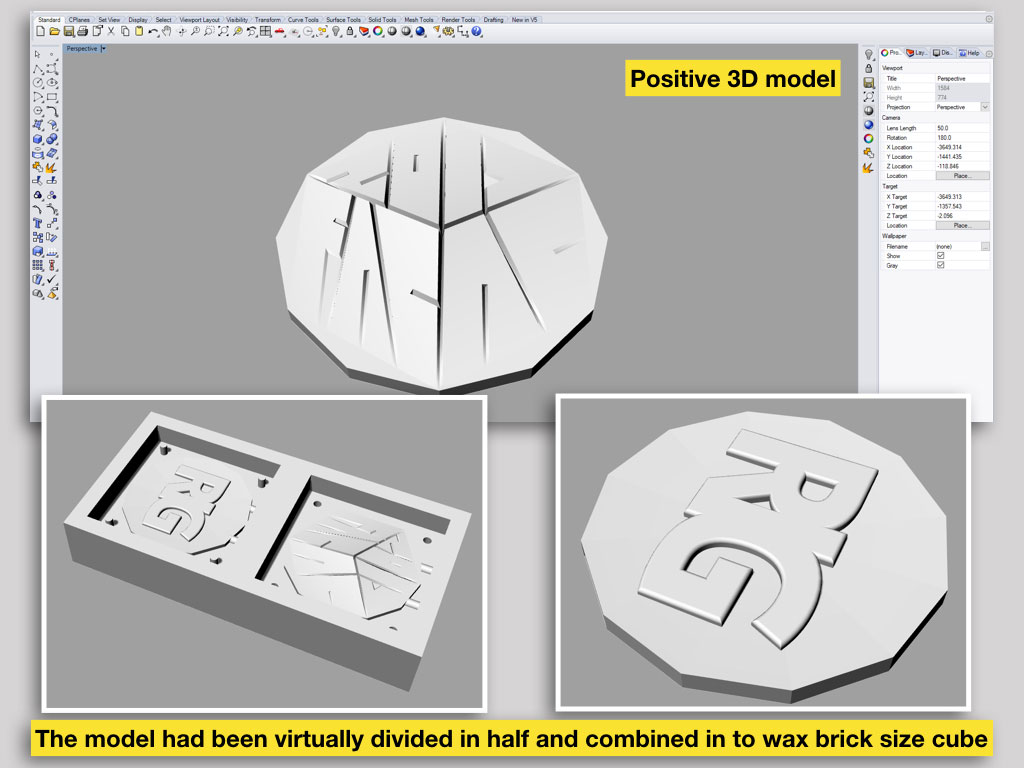

Splitting the 3D medal model in the middle in two opposite surfaces let us combine each half of the medal in to separate "bath" wax mould. We also added the material enter and release/exit canals to the "baths" to avoid air pockets.

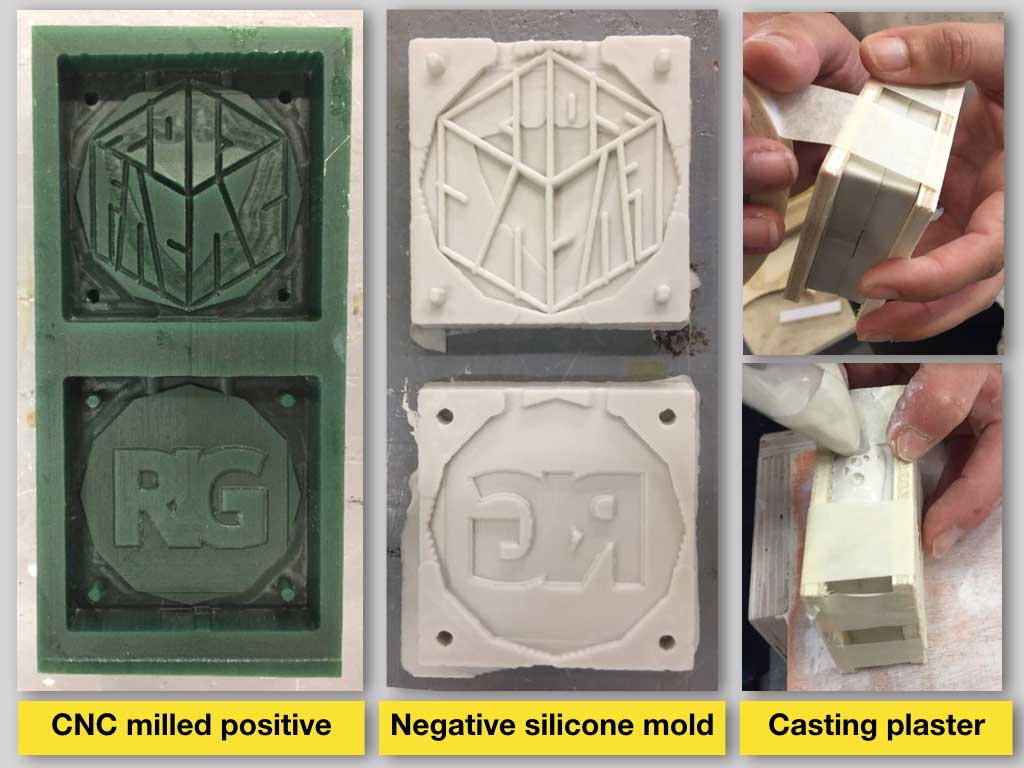

Each positive half medal got its own silicone “bath” with hole and pin mold connectors. After silicone mould was dry it was wasy to connect it in right position thanks to those pins and holes. If the mould parts do not fit perfect you will get leaks and ugly parting lone on the casted replica.

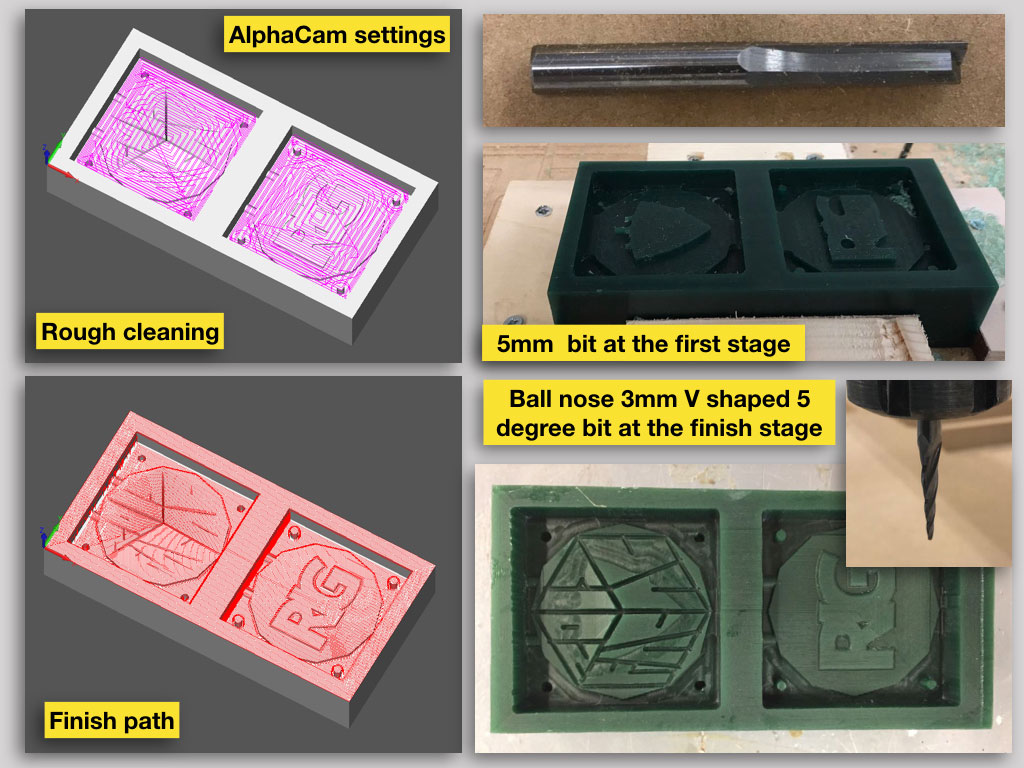

In first two stages we used same machine settings and materials that I describe above on this page, with the same safety measures.

Hard dental plaster was used at the last casting step to make the medals stronger.

We do have our own FabAcademy graduation medals now.