PrintFilter

Have a look at the the study and the classification of filters to find wich filter(s) i must use.

"Measurements of UFP and individual VOC emission rates presented here have important implications for human exposure and health effects

...styrene, which is classified as a possible human carcinogen by the International Agency for Research on Cancer (IARC classification group 2B),(23) was emitted in large amounts by all ABS filaments and the one HIPS filament".

Caprolactam was also emitted in large amounts by four of the filaments: nylon, PCTPE, laybrick, and laywood. Although caprolactam is classified as probably not carcinogenic to humans,...(24) the California Office of Environmental Health Hazard Assessment (OEHHA) maintains acute, 8-h, and chronic reference exposure levels (RELs) of only 50, 7, and 2.2 μg/m3, respectively.(25)

We are not aware of any relevant information regarding the inhalation toxicity of lactide, the primary individual VOC emitted from PLA filaments.

We should also note that this analysis does not take into account proximity effects that could serve to substantially elevate exposures to both UFPs and VOCs in certain microenvironments compared to well-mixed conditions.

Let us assume that one desktop 3D printer operates continuously in a well-mixed 45 m3 furnished and conditioned office space ... a typical office ventilation rate of 1 h–1,(26) no sorption losses for the three VOCs (likely a conservative estimate),(27, 28) and a typical UFP deposition loss rate constant of 1.3 h–1.(29) Under these conditions, steady-state indoor concentrations of each of these constituents would be elevated to ∼58 000 cm–3 for UFPs, ∼244 μg/m3 for caprolactam, ∼150 μg/m3 for styrene, and ∼6 μg/m3 for lactide.

The predicted caprolactam concentration (244 μg/m3) would exceed all three RELs identified by the California OEHHA,(25) which suggests that although there is considerable uncertainty in this estimate, exposure to caprolactam from desktop 3D printing in a typical office environment with nylon and nylon-based filaments could lead to adverse health outcomes, particularly for susceptible individuals. Acute exposure to high concentrations of caprolactam is known to be “irritating to the eyes and the respiratory tract” and “may cause effects on the central nervous system”, according to the Centers for Disease Control and Prevention (CDC).(30)

The predicted styrene concentration in this configuration (150 μg/m3) would be approximately 20 times higher than the highest styrene concentration measured in commercial buildings in the U.S. EPA BASE study(31) and more than 20 times higher than the average concentration in U.S. residences.(32) There are also reports that suggest exposure to styrene at these concentrations could be problematic for human health. For example, high indoor styrene concentrations have been estimated to yield relatively high lifetime cancer risks in previous studies that assumed typical potency factors,(33) and even moderate styrene concentrations (i.e., greater than only 2 μg/m3) have been associated with elevated risk of pulmonary infections in infants.(34)

Although we are not aware of any regulatory limits for indoor UFP concentrations, an increase in UFP concentrations to ∼58 000 cm–3 would be approximately 10 times higher than what we typically observe in indoor air in our office and laboratory environments and what has been reported as a typical 8-h average indoor concentration in schools.(35) However, it would only be moderately higher than typical time-averaged concentrations in homes(36) but lower than what is often observed in other microenvironments.(37)

Given these findings, we are prompted to make the following recommendations. First, additional measurements should be conducted to more accurately quantify personal exposures to both UFPs and speciated VOCs that account for proximity effects presented by typical 3D printer use patterns. Second, manufacturers should work toward designing low-emitting filament materials and/or printing technologies. Third, in the absence of new low-emitting filaments, manufacturers should work to evaluate the effectiveness of sealed enclosures on both UFP and VOC emissions or to introduce combined gas and particle filtration systems. Until then, we continue to suggest that caution should be used when operating many printer and filament combinations in enclosed or poorly ventilated spaces or without the aid of gas and particle filtration systems. This is particularly true for both styrene- and nylon-based filaments, based on data from the relatively large sample of printers and filament combinations evaluated here."

Study by Parham Azimi, Dan Zhao, Claire Pouzet, Neil E. Crain, and Brent Stephens

Read more : nice article here

So it seems that i'll mainly have to filter Styrene, Caprolactam and UFPs (PM10 to PM2.5)

The appropriate filter for protection against inhalation exposure to styrene is Type A

The appropriate filter for protection against inhalation exposure to Caprolactam is Type A P3

The appropriate filter for protection against inhalation exposure to UFPS is Type F7

I took advices from Joseph Youssef founder of Air Serenity at that step.

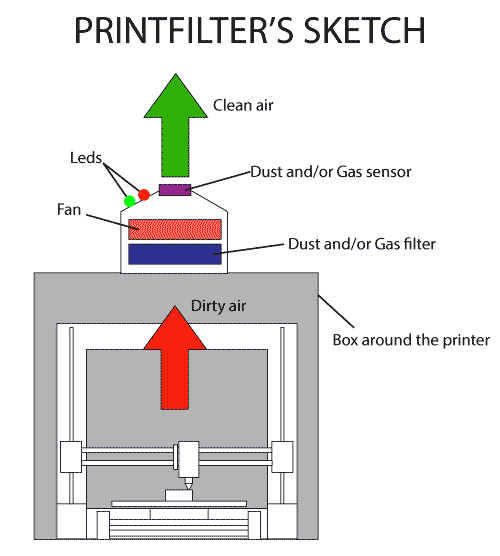

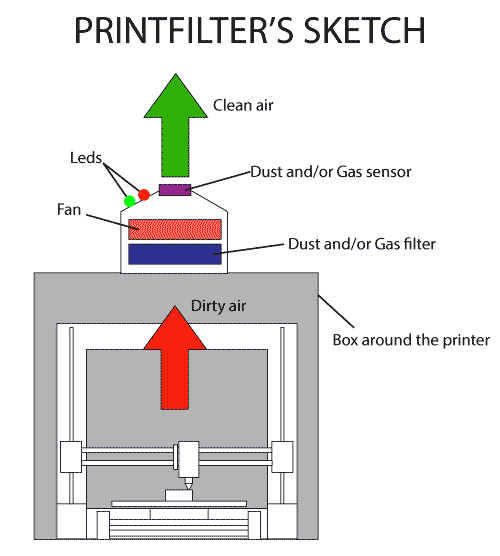

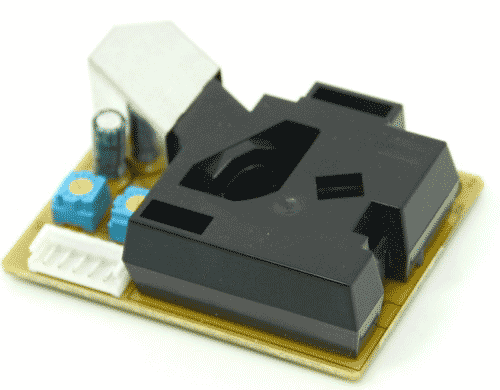

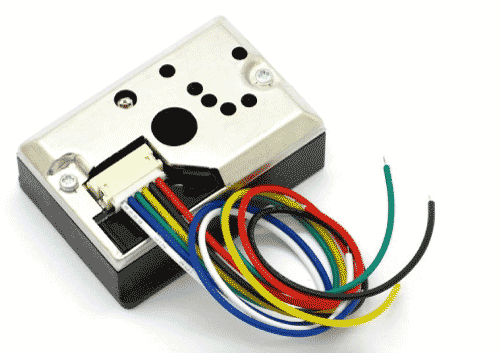

Found the good dust sensor and/or gas sensor to control the air quality coming out the filter and indicate to the user when he must change the filter(s).

My goal is not to give a precise value but to detect a level of dusts coming out the filter to indicate when to change it. So a simple dust sensor should be good.

I've found two of them :

For the gas sensor it looks a little bit harder, for now i haven't found certitudes about wich type of senor to use and why

I've found this documentation, and i still hesitate in between two types of sensors

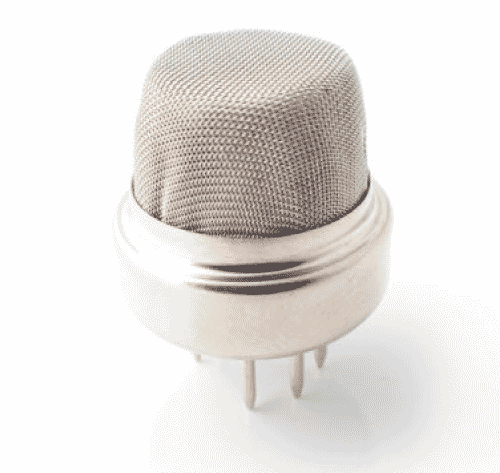

Electro-catalytic gaz sensors

Semiconductor sensor

I hadn't started working on the model for the filter and i had a problem i had to solve quite fast at the lab : 3D printing big ABS parts without wrapping

So i started testing a stove model to heat the air around the print and avoid plastic's retraction

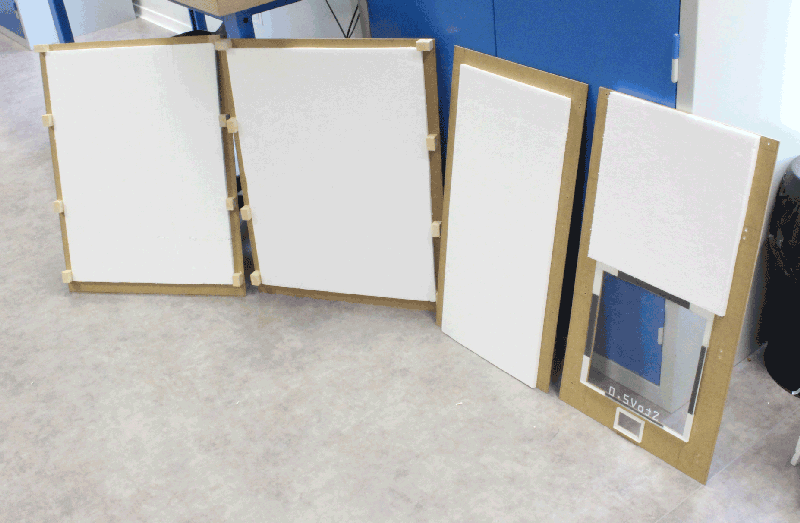

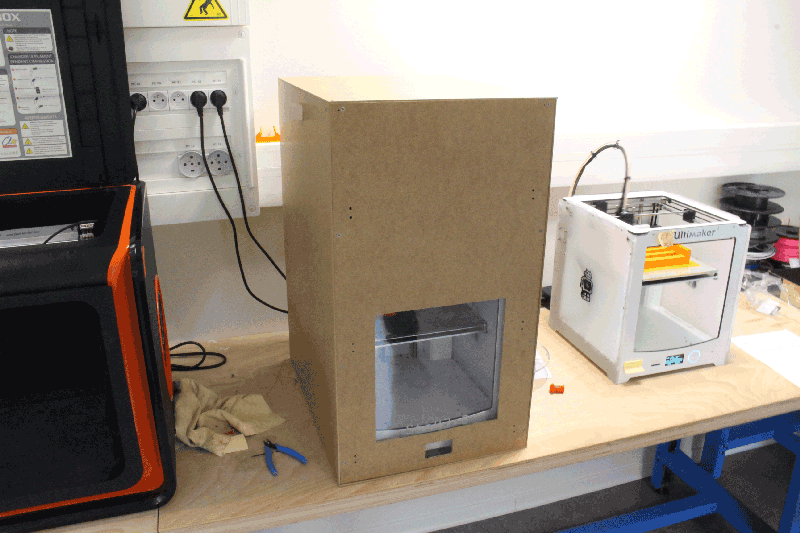

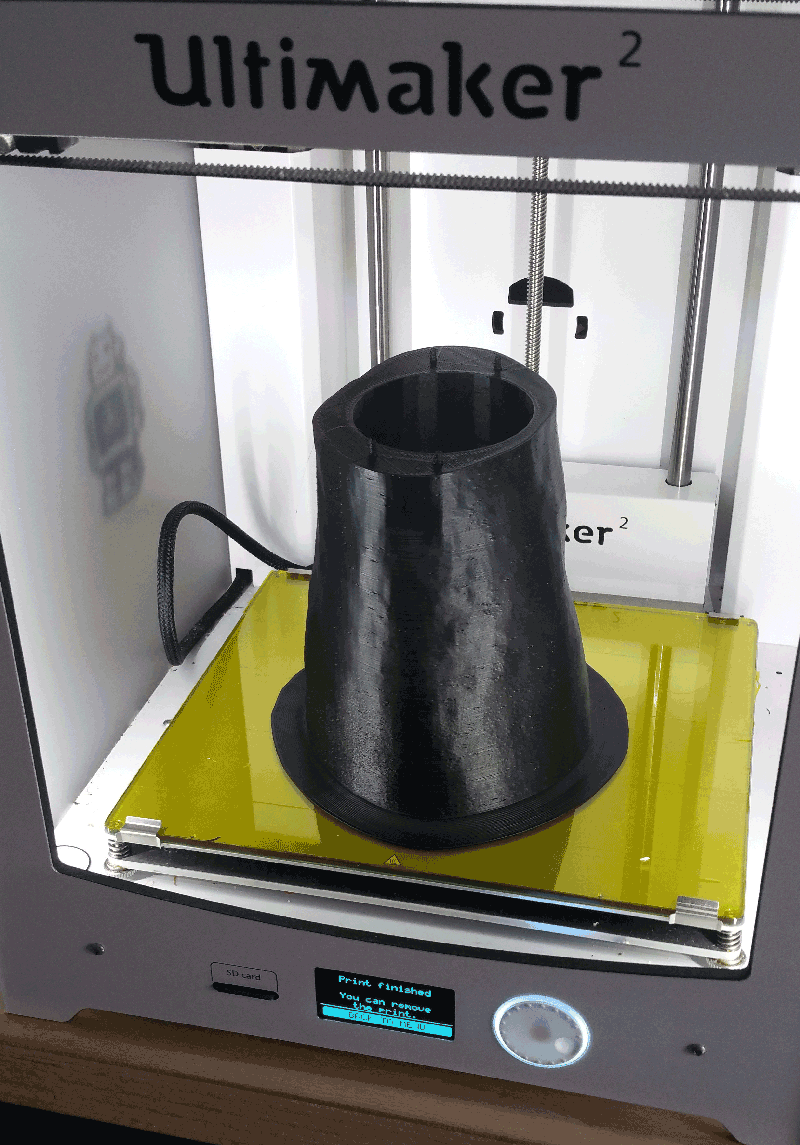

I build a box made for a Ultimaker2

3 mm MDF, Sides 2x(70x55cm) Front and Back 2x(70x40cm) Top and Bottom 2x(55x40cm)PMMA, Big window 1x(28x29cm), Small 1x(7x5cm)Styrofoam, Sides 2x(64x51cm) Front and Back 2x(64x34cm) Top 1x(49x34cm)

I used Glue gun to glue Styrofoam and double sided tape for windows

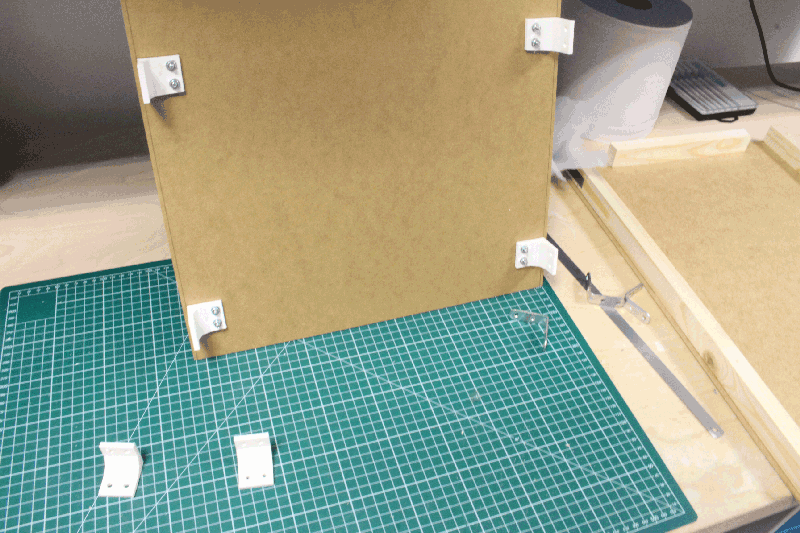

I 3D printed assembly parts, but i mounted the box with wood parts because printing was to long

The complete box

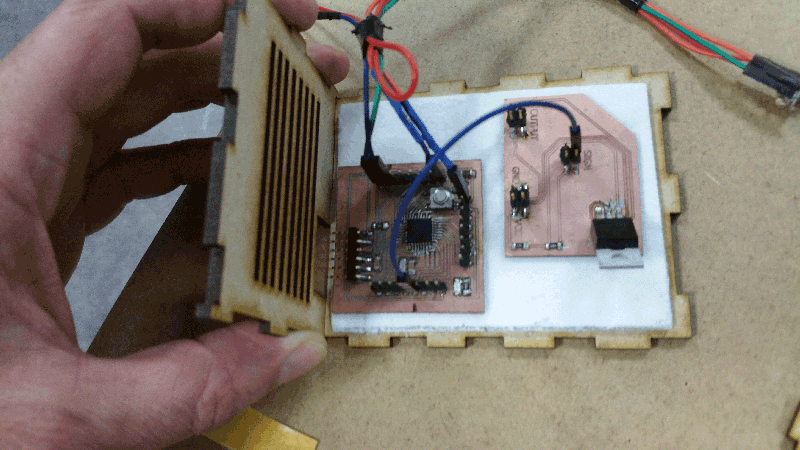

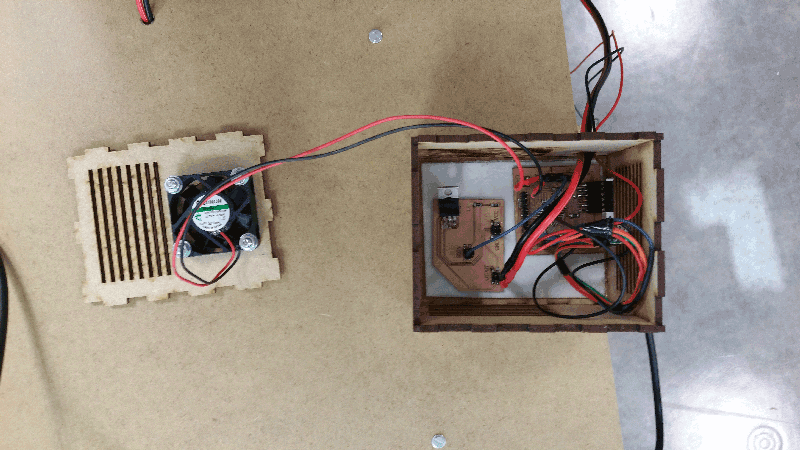

I built a Fabkit, and a Mosfet board and a temp sensor system. The full system is measuring the temperature in the box and if temp is to low, th heater starts warming up the air in the box

Fabkit link 1 Fabkit link 2 Mosfet Eagle Files Mosfet i used Code and Boards.txt file for Arduino IDE

I adapted this tutorial to my project to test another way to do a temp sensor

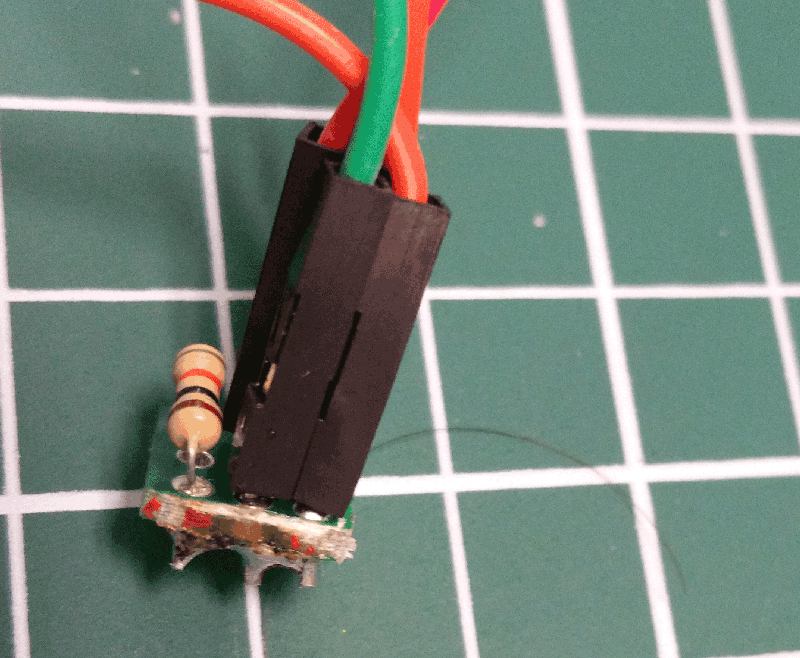

I had to build a little hand made circuit to get the 10k restistor, this could be add to a board later

Test of temp sensor and mosfet module wtih a fan

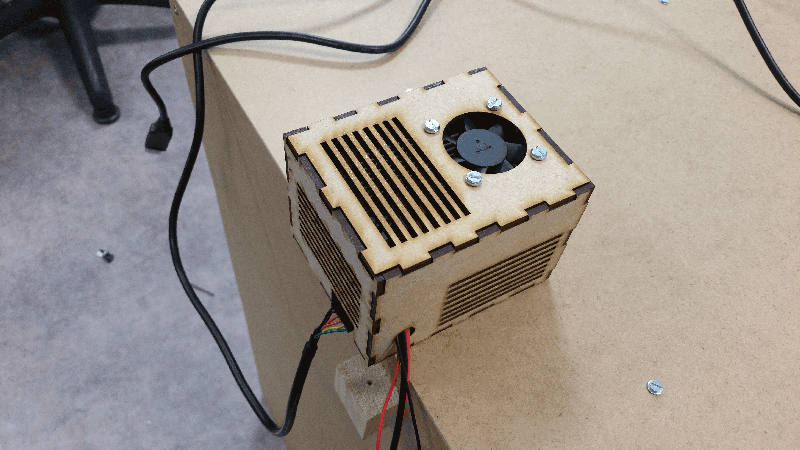

All the electronic goes in this box with a fan to refresh the Mosfet

Complete electronic parts

The first print test with the stove without electronic gave great results

Now the 100% made electronic with basic code is ready to adapt it self to any box.

The Ultimaker2 stove prototype itself gives great results

Everything is ready to start playing with settings

Questions :

Is one senor enough and where should it/they be placed to have a precise temperature ?

Wich system will i embed to cool down the Mosfet and/or should change the Mosfet ?

It is great fun, can't wait using it and upgrading it