Week-4 ELECTRONIC PRODUCTION

ASSIGNMENT

1) Make the fabisp in-circuit programmer.

2)Solder the components on the PCB.

STEPS INVOLVED IN MAKING THE FAB ISP-

1)Preparing the .png files to be milled.

2)Milling the Board.

3)Soldering the components on the board.

4)Programming the board.

1.Preparing the .png files to be milled-

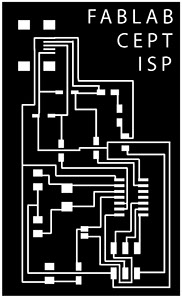

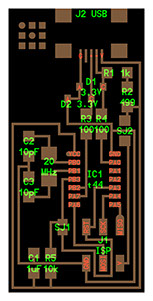

Image for milling the Image for cutting the outside Image showing the

circuit with 1/64 inch bit border of the circuit with 1/32 inch bit components of the circuit

2.Milling the Board-

Steps for milling-

1)Preparing hardware for milling the circuit

2)Cleaning the bed

3)mounting the workpiece

4)Changing the bit to 1/64 inch for circuit milling

5)setting origin and setting z-zero

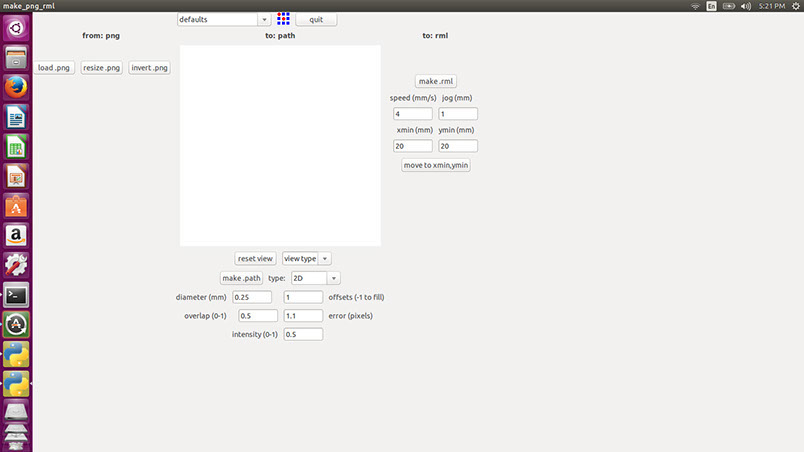

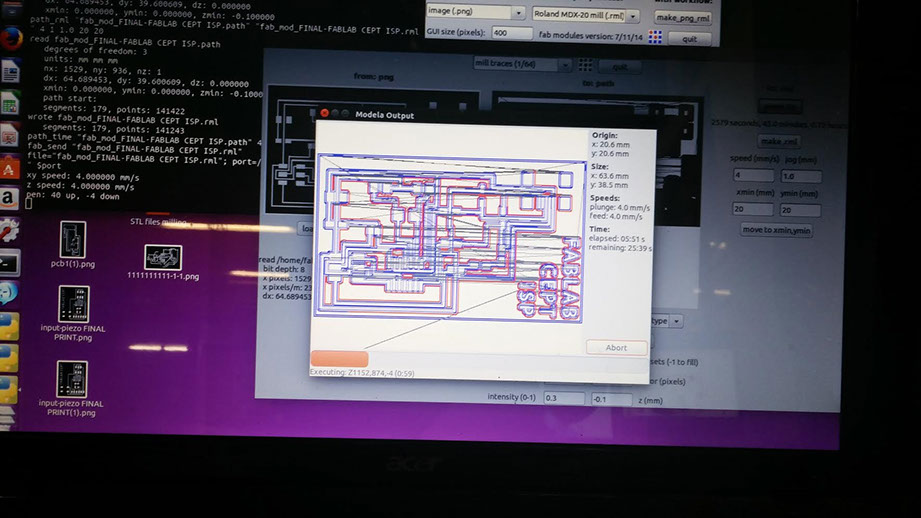

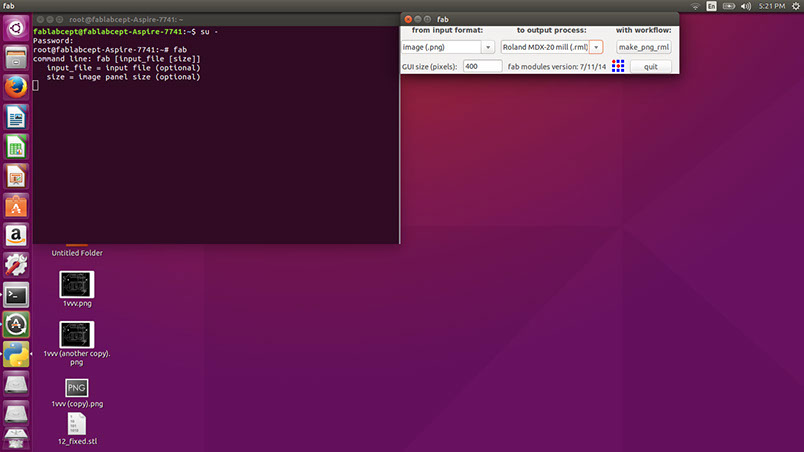

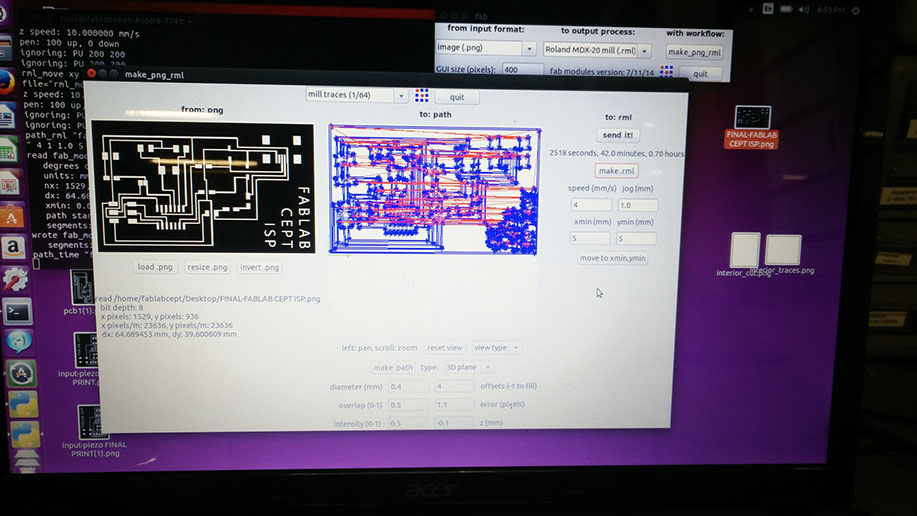

After doing the completing the above steps open terminal and type su - , after that you will be asked for password, add the password twice and a new window opens up asking the file type to be loaded.

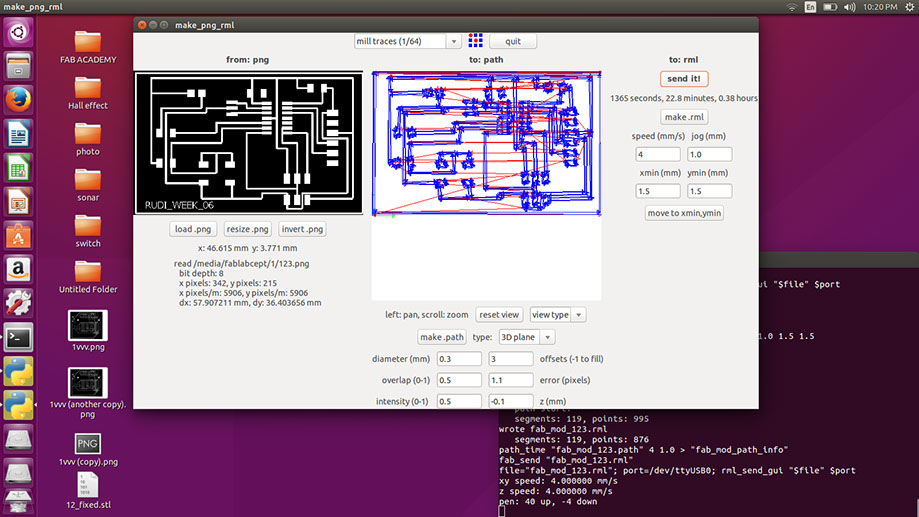

After the tab opens, select the file format to be .png and select the Modela model and click the make_png_rml button.

Now a new tab will open which has all the details of what and how you can mill. In the window click the load.png button and load the png file to mill.

After you have loaded the png file, click make .rml. Now path for the milling will be made.

After that we need to set the 1/64 bit on the circuit and set all the parameters in the window

that is open and click send it.

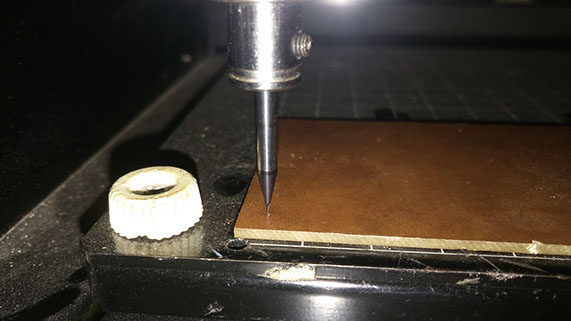

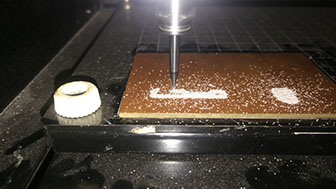

Now we are ready to begin with milling!(Setting the 1/64 bit on the board using allen key)

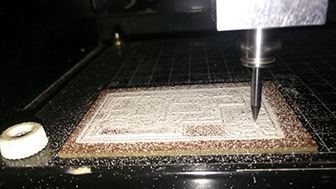

Once we begin with milling, we can have a look at the status of the task given.

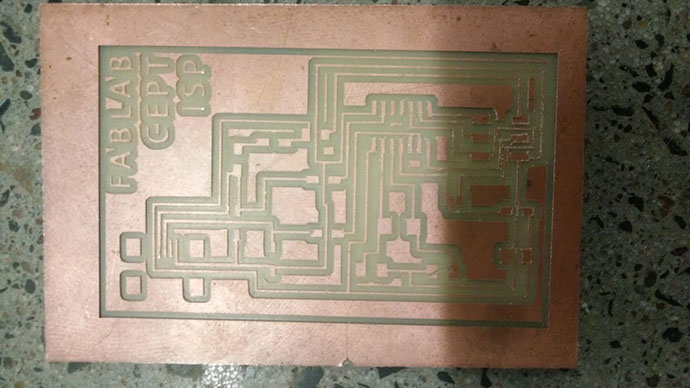

The milling is happening quite well. The desired depth of cut is being obtained.

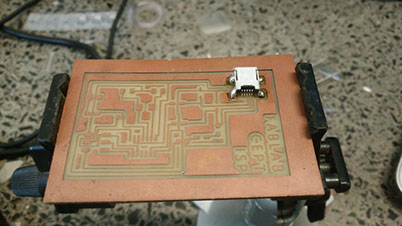

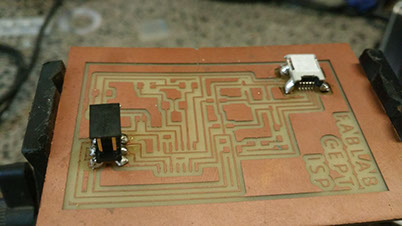

3)Soldering the components on the board

Components needed:

1) Micro-controller

2) crystal

3) USB connector

4) ribbon connector

5) Zener diode

6) jumper wire

7) firmware

8) Resistors

9) Capacitors

Equipments needed:

1)Soldering machine

2)soldering material

3)magnifying glass

4)holders for PCB

5)flux

6)small tips of soldering machine

.jpg)

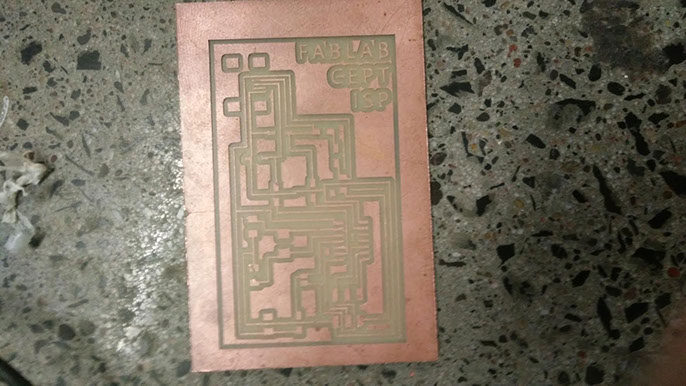

After the circuit is milled, clean it with a brush so as to remove the copper and wood dust remains from it.