Mechanical design & machine design

To do-To do mechanical design and machine design

What we have done-We have decided to make rangoli making machine.Rangoli is a

art in which granular flour of marble is used to draw picture and different

designs. In India it is tradition to draw rangoli on special occasions .

In some village areas early in the morning people showers water on floor in front of

house and draws rangoli. Specially ladies does this task.

But now a days there

are professional artist who makes beautiful rangolies and most of the artist

are gents. Making of rangoli consumes lot of time if there is no practice

also it is a part of skill.

This machine

Save time to draw Rangoli

We can draw any desgn we want in rangoli

no deed of rangoli drawing skills

limitations-

area of drawing the rangoli is restricted up to frame size of machine

This machine

Save time to draw Rangoli

We can draw any desgn we want in rangoli

no deed of rangoli drawing skills

limitations-

area of drawing the rangoli is restricted up to frame size of machine

Everybody wants to draw beautiful rangoli in front of their house but most of the time ,due to scarcity of time and skill they unable to do so. That’s why we want to develop rangoli making machine in make a machine assignment.

I also like to draw rangoli.Below rangoli is drawn by me.It is also one of the reason to make this machine.

I also like to draw rangoli.Below rangoli is drawn by me.It is also one of the reason to make this machine.

Work flow of our work-

first we discussed on which machine we have to do

after deciding machine we find out possibilities to make x-y movements and find out things to be consider while designing.We thought for 3 different designes then we list out drawbacks and benifits of each design and finalized one which is most strong and steady.

My role in this assignment-

Project discussion and documentation

Making 3d model of machine

list of material andMaterial transport

Searching for Electronics Design

documentation-In this assignment I helped for documentation.We desided to work on rangoli maker but I searched for types of rangolies and possibilities to add features in it.I collected data about how we can simplifie manual rangoli making work with the help of machine.I sent data to yogesh as he was managing machine web page.

Made 3D model

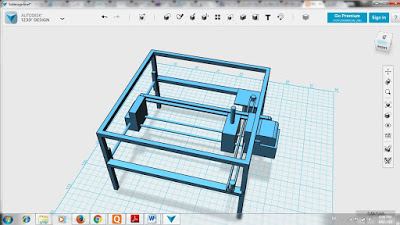

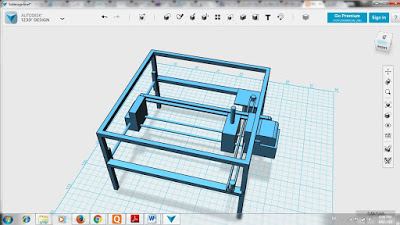

After finalizing the design of machine and its mechanism I made 3D design using autodesk123D Design software. I surprised by my design speed as I took only half hour for making this design.Due to practice I did that very fast.

I Also tried to make list of material.

1.rod (diam=8mm)33.5cm -2

2.rod (diam=8mm)30cm -2

3.linear bearing -4

4.allen head(m3) -30

5.allen head(m2) -20

6.hex nut -4

7.timing belt

(width-6mm,length-130cm) -1

8.cable tie -1 pack

9.wire protector

10.stepper motor

(42.7mm*47.2mm) -2

11.pulley (verticle treads) -2

Material transport

we gone through different parts of machine.One of our guide Mr.Rabade, helped us to list out the specifications of different parts.Then Yogesh purchased material which was I listed and then I bring that from yogesh to the vigyan ashram where we were going to make machine.

Searching for Electronics Design

At the end of week we started working on electronics things and programming.We desided to use rambo board and marline firmware.In this assignments I learnt time management and team work

Made 3D model

After finalizing the design of machine and its mechanism I made 3D design using autodesk123D Design software. I surprised by my design speed as I took only half hour for making this design.Due to practice I did that very fast.

I Also tried to make list of material.

1.rod (diam=8mm)33.5cm -2

2.rod (diam=8mm)30cm -2

3.linear bearing -4

4.allen head(m3) -30

5.allen head(m2) -20

6.hex nut -4

7.timing belt

(width-6mm,length-130cm) -1

8.cable tie -1 pack

9.wire protector

10.stepper motor

(42.7mm*47.2mm) -2

11.pulley (verticle treads) -2

Material transport

we gone through different parts of machine.One of our guide Mr.Rabade, helped us to list out the specifications of different parts.Then Yogesh purchased material which was I listed and then I bring that from yogesh to the vigyan ashram where we were going to make machine.

Searching for Electronics Design

At the end of week we started working on electronics things and programming.We desided to use rambo board and marline firmware.In this assignments I learnt time management and team work

Machine Design

and also discussed the future scope. made 3D design of machine to see that how it will look.

In this week -

- we made 3D design for parts of machine.

- Made mechanical assembly

- Did programming

- Discussed on various types of systems like close loop,open loop system,PID controller

As all team members were not together we used to make telephonic discussion or hangouts to communicate for further step.It is very good to see that everyone is performing his role neatly.

Threads-

We stuck to programming part.As before this I made mechanism for single directional movement but did not made any machine which required no of joints and movements. So while making material list we faced problem for nomenclature of machine parts. We were not completely blank about specifications of part as in lecture of mechanical design assemble it with designes cut in laser cutter.Some times we change previously cut designes.We connect our assembly with controlling board and finally our worked and made beautiful rangoli

Making frame of machine

2D Deasigning of requird parts

making mechanical structure of machine

Making frame of machine

I mainly contribute for mechanical assembly.At the time of doing prototype Initially we decided to do metal frame but when we started to do that time we realize the problem of welding and it was too much time consuming.Then we shifted to wooden frame.We cut designes on laser cutter and used 3mm mdf sheets.

2D Deasigning of requird parts

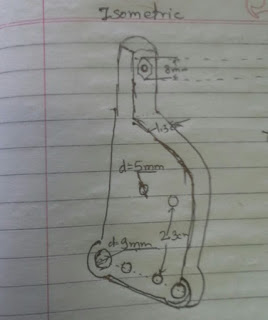

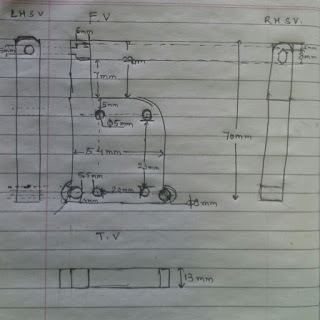

I made 2D sketch of 3d part required and send it to Akshay for making its 3D design

Did assembling,Designed 2D files in inkscape required for assembly making.

making mechanical structure of machine

I did assembling of all parts of machine and designed some parts while assembling ,whenever required.It consumed lot of time.but I enjoyed for thinking of machine mechanism

It was very nice learning experience for me.I have very much interest in Making machine.While doing this assignment I enjoyed learning from finalizing design of machine to fixing the problems in final assembly

I am very happy for our machine performance out of the lab

Download all files made by me on make a machine page

My role-

Making frame of machine

2D Deasigning of requird parts

making mechanical structure of machine

Making frame of machine

I mainly contribute for mechanical assembly.At the time of doing prototype Initially we decided to do metal frame but when we started to do that time we realize the problem of welding and it was too much time consuming.Then we shifted to wooden frame.We cut designes on laser cutter and used 3mm mdf sheets.

2D Deasigning of requird parts

I made 2D sketch of 3d part required and send it to Akshay for making its 3D design

Did assembling,Designed 2D files in inkscape required for assembly making.

making mechanical structure of machine

I did assembling of all parts of machine and designed some parts while assembling ,whenever required.It consumed lot of time.but I enjoyed for thinking of machine mechanism

I am very happy for our machine performance out of the lab

you can see everything about our machine here

Download all files made by me on make a machine page