Molding and casting

To do-

To make design for making mold, take mold and cast it.

What I am going to do-

I wanted to make rubber casing for fab ISP as I took lot of time to run my ISP

To make design for making mold, take mold and cast it.

What I am going to do-

I wanted to make rubber casing for fab ISP as I took lot of time to run my ISP

I prepaired 3d design for taking mold.In this week for designing 3D mold here I used 123d design software I am going to print it on Machinable wax using Modella MDX-20 and Fabmodule software.

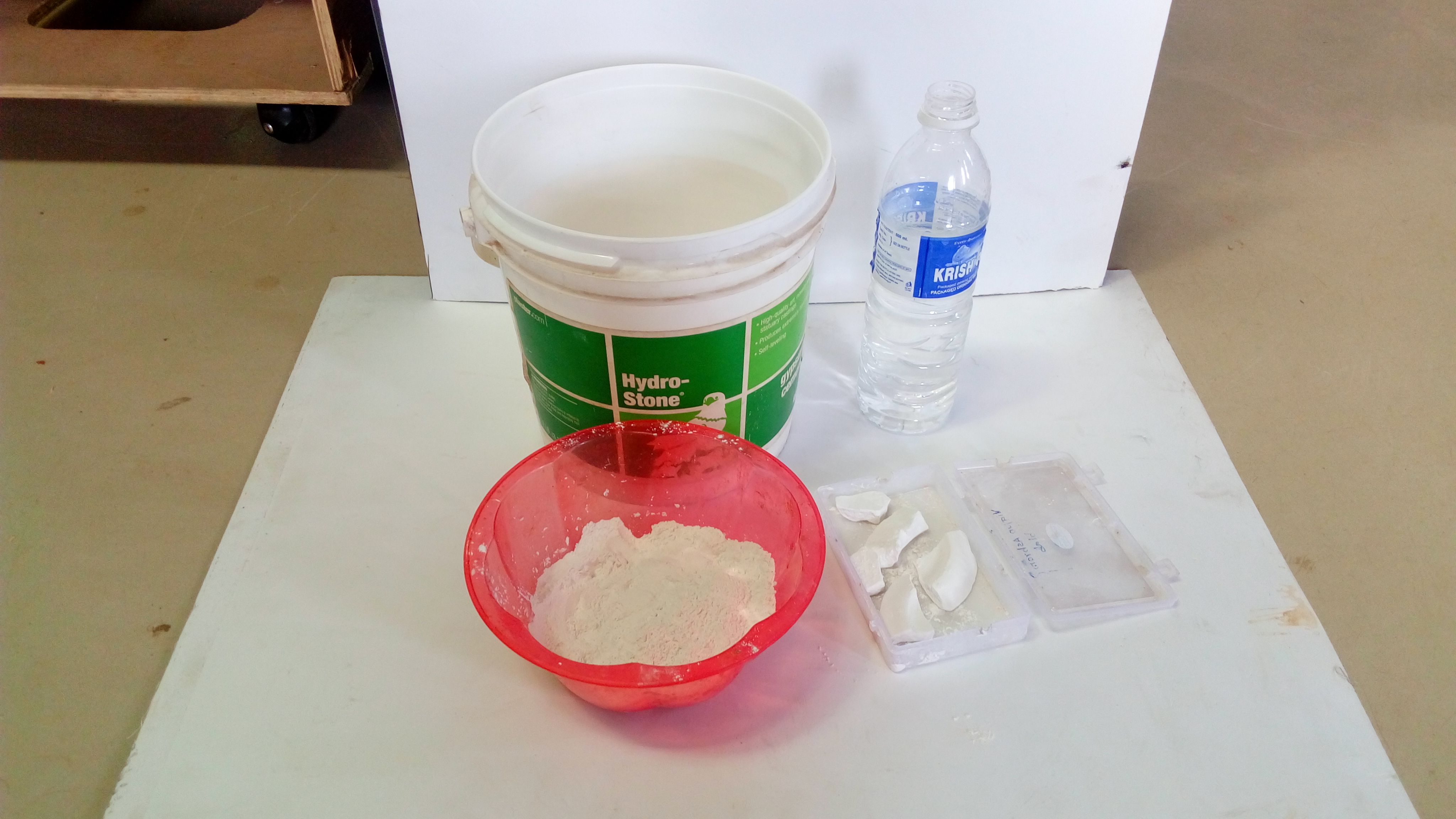

Material for casting-I an going to rubber solution and Hydrostone made casting object.

Software tools: 123D design

Mold Object: Fab isp casing

Material for casting-I an going to rubber solution and Hydrostone made casting object.

Software tools: 123D design

Mold Object: Fab isp casing

I want to make below casing in rubber material.

step1-I downloaded Fab Isp .stl file from website of my team member

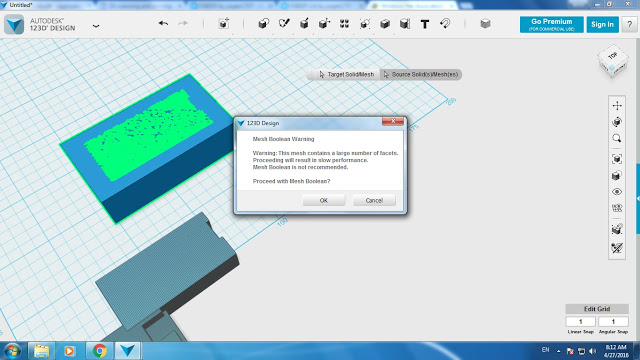

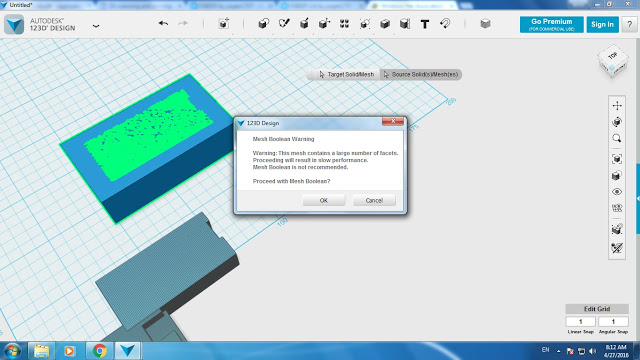

Step2-I import that .stl file in 123D design software for making mold design.When I went to subtract that that time I got some errors.It was showing warning as mesh contains large no of processing.proceeding will results in slow performance.mesh boolean is not recommended.

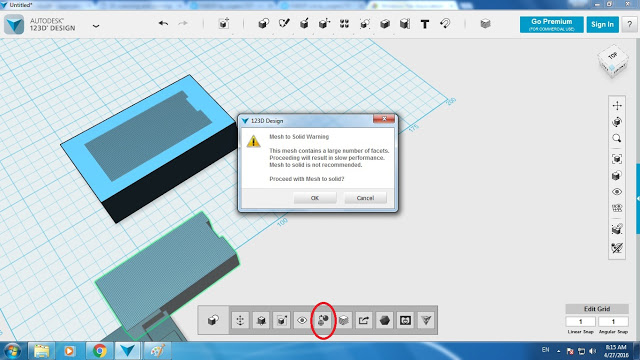

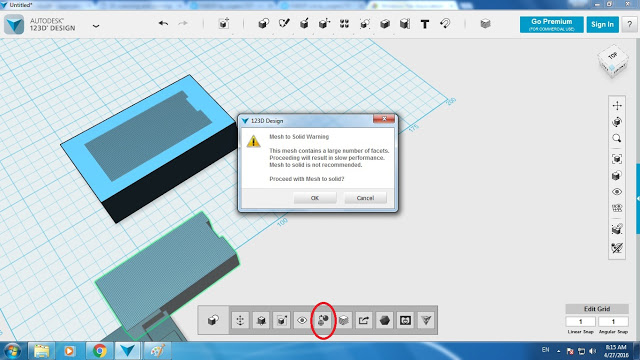

step3-Then I wanted to convert that mesh into solid.so there was one option for converting mesh to solid I selected that.

step4-Again I got one warning telling that this is open mesh.Mesh to solid is not possible.use meshmixer.So I downloaded and used meshmixer for mesh to solid conversion

Then I went to meshmixer.import file in it and made that object solid.Now my 3d design is ready only thing remained is to take mold.

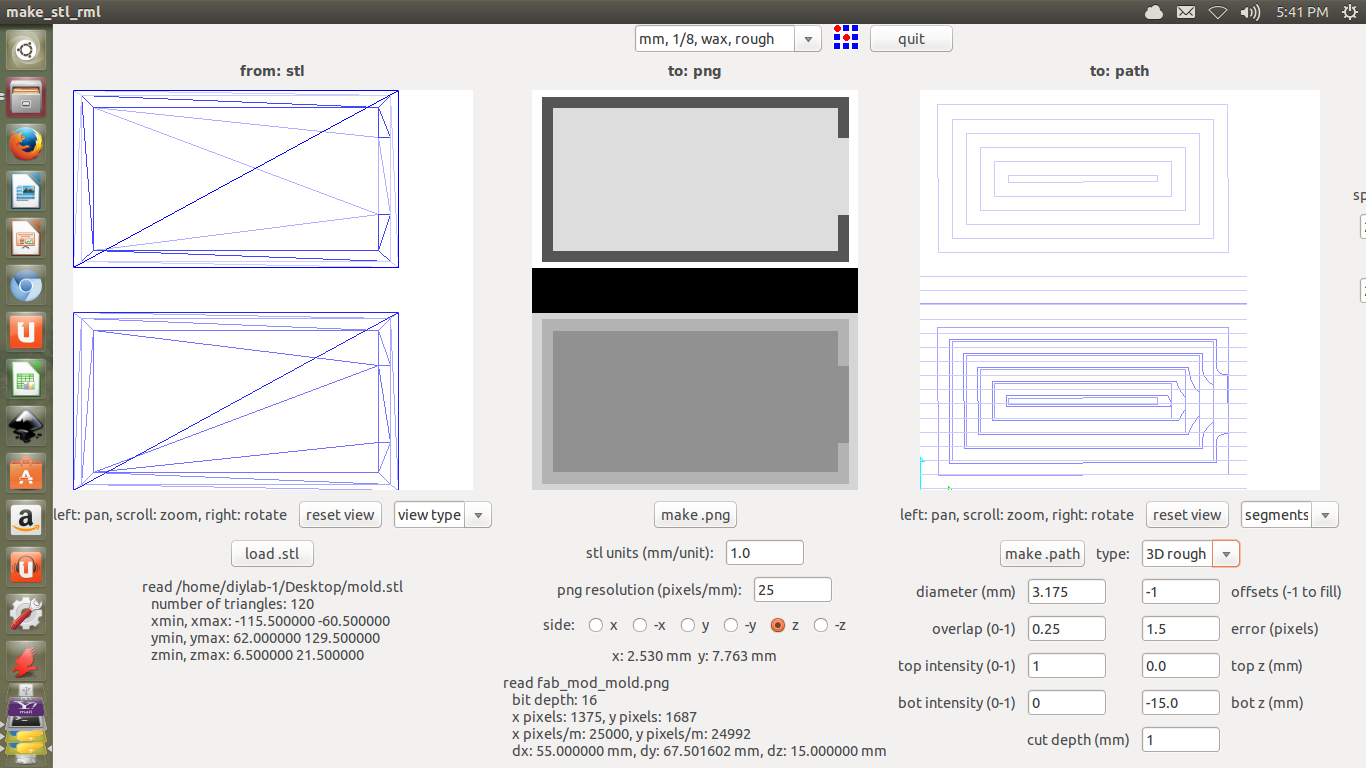

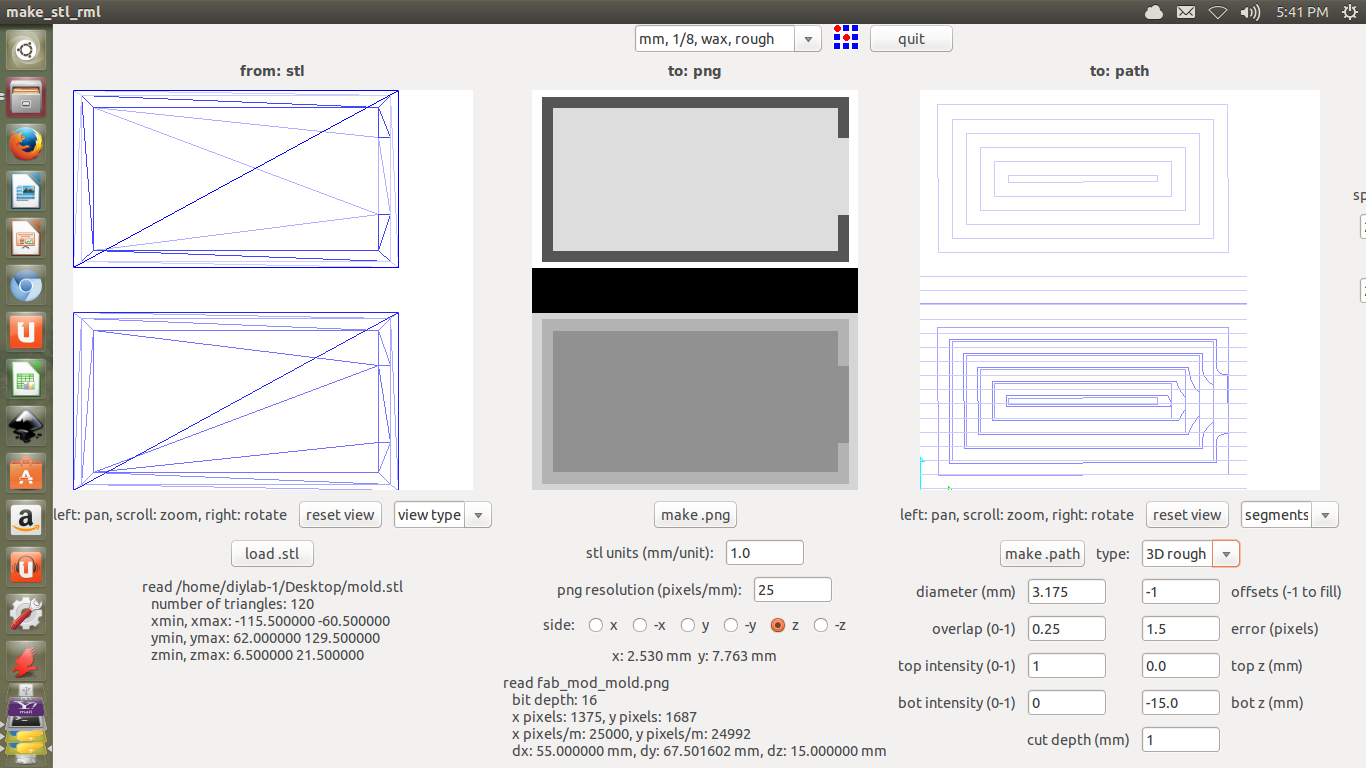

step5- I used fabmodules to mill the mold

But I got error.Machine milled first layer and suddenly start drilling

I thought it is communication problem.But it was problem of width of mild

thickness of mold should be more than the bit size which we are using

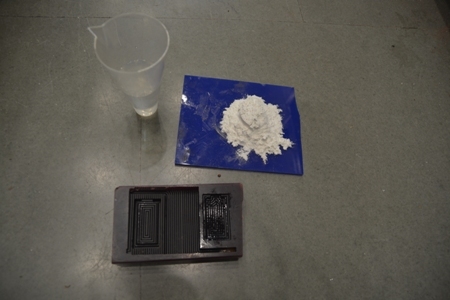

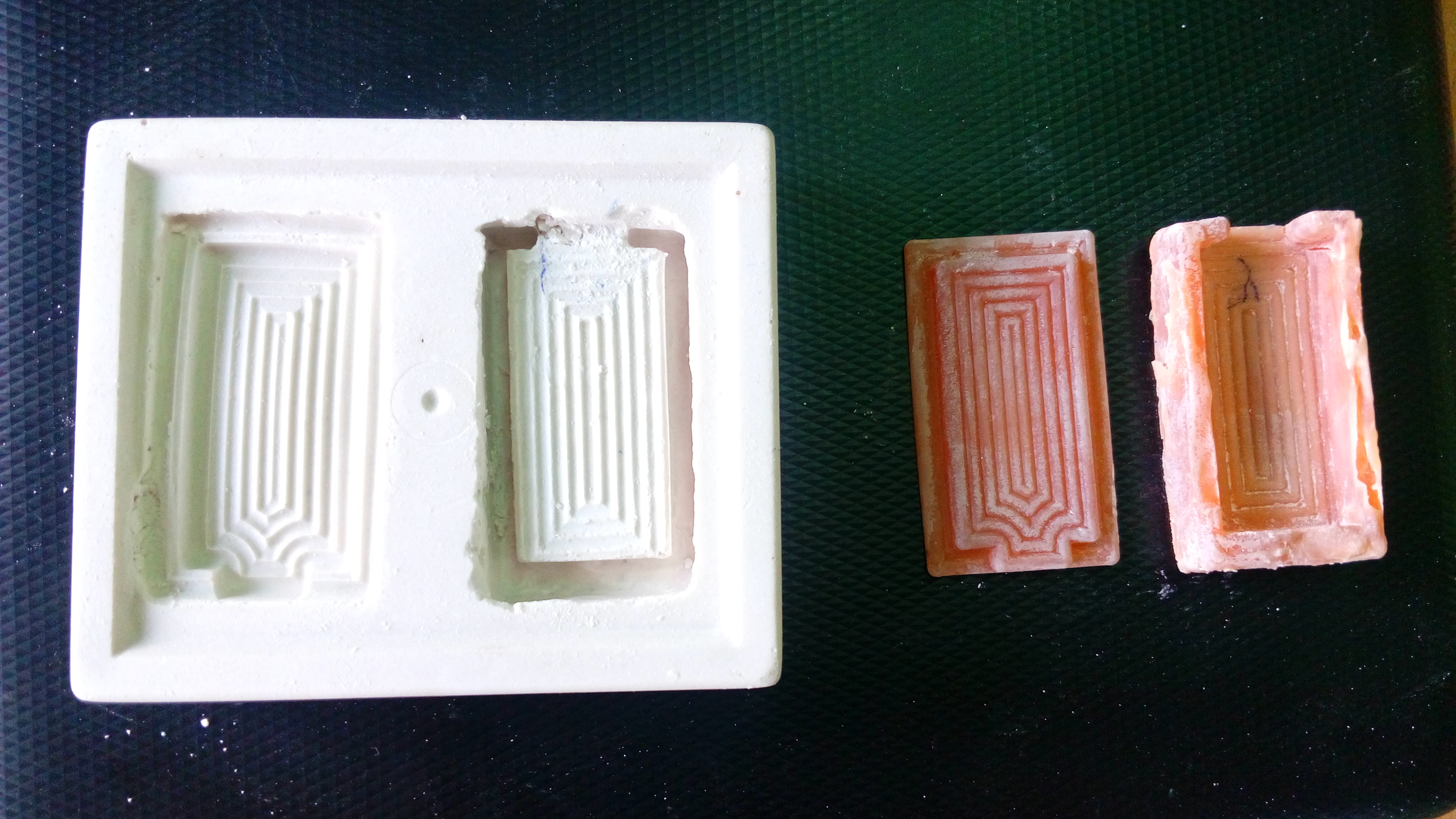

After solving the problem I Poure rubber solution to take mold.Due to bubbles my 1st mold was bad.But third one is better.

I also use Insta mold material for molding and casting also.It is soft material

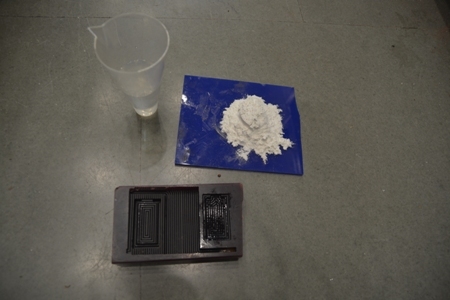

and we have to add only water to it.As much water we add it become more soft.First take Insta mold powder

Add water and mix it well

And take mold

or you can cast but insta mold mold unable to add quality

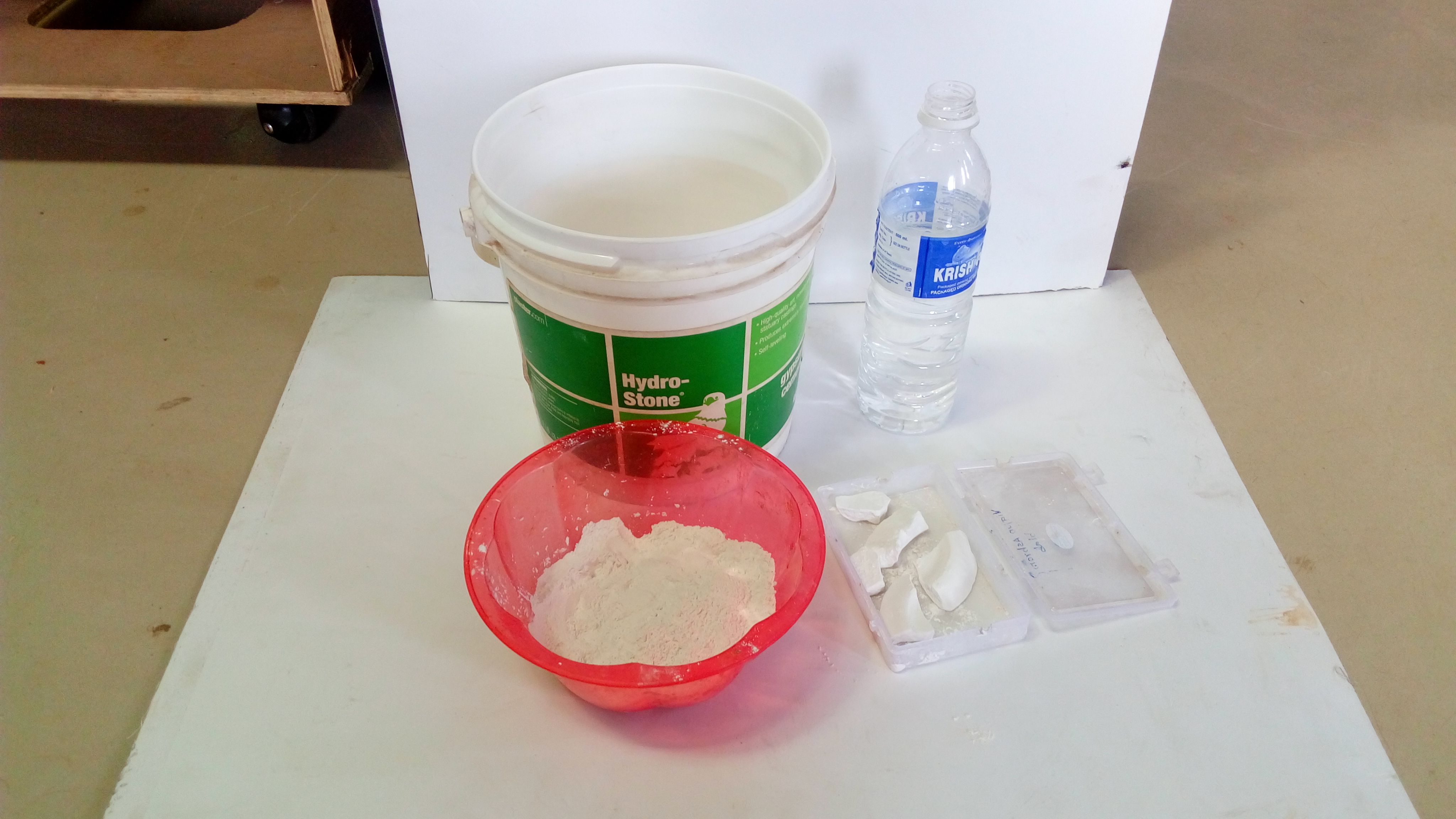

I did casting using hydrostone also.Used hydrostone and water combined it such a that it formed thick liquid.If there is stones of hydrostone then crush it make its powder and use it,Dont throw.After making thick liquid I poured in box and incerted rubber mold in that.After 2 hours it dried well,So I removed rubber mold from hydrostone.Molds made good impressions on hydrostone.Its quality is better than insta mold.

I tried another cast in that I put rubber moldes at the bottom of box and then poure thick mixture of hydrostone powder and water.After 2 hours I take out that hard cube from the box and then removed rubber mold from it.Some hydrostone material is sticked to upper side of mold but it easily get removed.Finally I got well finished cast.

step1-I downloaded Fab Isp .stl file from website of my team member

Step2-I import that .stl file in 123D design software for making mold design.When I went to subtract that that time I got some errors.It was showing warning as mesh contains large no of processing.proceeding will results in slow performance.mesh boolean is not recommended.

step3-Then I wanted to convert that mesh into solid.so there was one option for converting mesh to solid I selected that.

step4-Again I got one warning telling that this is open mesh.Mesh to solid is not possible.use meshmixer.So I downloaded and used meshmixer for mesh to solid conversion

Then I went to meshmixer.import file in it and made that object solid.Now my 3d design is ready only thing remained is to take mold.

step5- I used fabmodules to mill the mold

But I got error.Machine milled first layer and suddenly start drilling

I thought it is communication problem.But it was problem of width of mild

thickness of mold should be more than the bit size which we are using

After solving the problem I Poure rubber solution to take mold.Due to bubbles my 1st mold was bad.But third one is better.

I also use Insta mold material for molding and casting also.It is soft material

and we have to add only water to it.As much water we add it become more soft.First take Insta mold powder

Add water and mix it well

And take mold

or you can cast but insta mold mold unable to add quality

I did casting using hydrostone also.Used hydrostone and water combined it such a that it formed thick liquid.If there is stones of hydrostone then crush it make its powder and use it,Dont throw.After making thick liquid I poured in box and incerted rubber mold in that.After 2 hours it dried well,So I removed rubber mold from hydrostone.Molds made good impressions on hydrostone.Its quality is better than insta mold.

In this assignment I learned to make 3D design by subtractive method.Seen that how our design is responsible for quality output of machine.Learnt casting and things not to do while molding and casting

Download 3D mold design here