Computer controlled cutting

Task to do

To do 2D design and cut it with any computer controlled machine like laser cutter or vinyl

What I did..

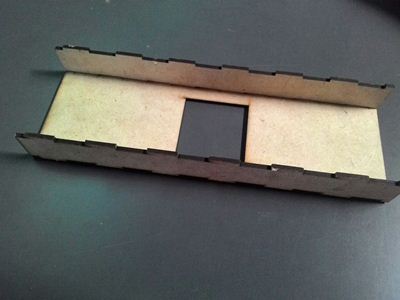

I decided to cut my 2D design file on laser cutter. I have designed motor hanger.Which has 2 wooden side strips virtically attached to middle strip which is horizontal.I have put one square slot to hang motor through it.You can see my design here.

I used STL Laser cutter for this design.In this laser cutter we can cut and engrave wood and acralic upto 6mm thickness.It gives precise laser cutting.RD works is a machine software for stl laser cutter.I followed below steps for laser cuting.

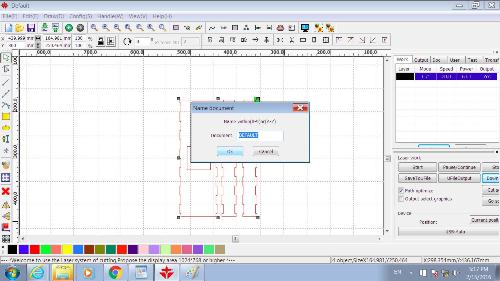

step1-As I am using laser cutter of SIL company and it uses RD works and RD works require .dxf file for processing so first of all I saved .svg file as .dxf

step2-When we save file as .dxf then it shows the window of desktop cutting poltter as below.Make base unit in mm.As I had pud all the dimension in mm.

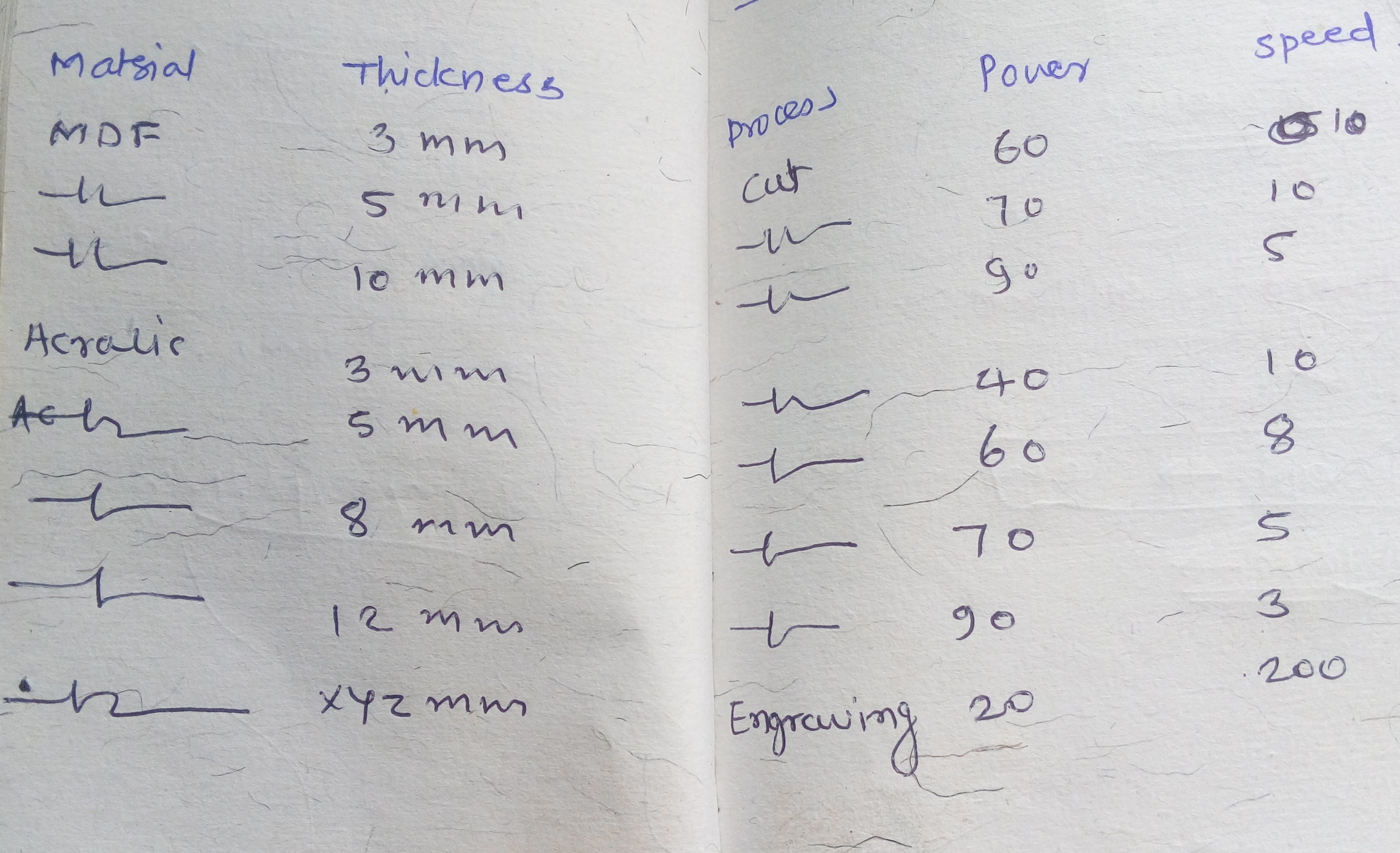

step3-Then I opened RD works.Put settings of power and speed in it.Settings are as below.

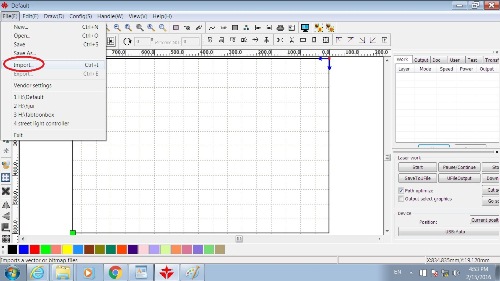

step4-Import .dxf file into it by going to the file in left corner and select import.

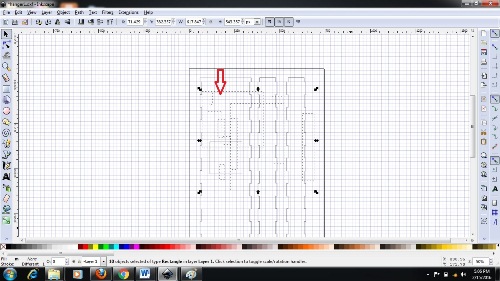

After this I saw many unwanted parts in my design.But if I see it in inkscape then there was no such sketches. I am unaware of the error coming in design.As I am not seeing unwanted part in inkscape but it is in RD works.Then I select design I draw in inkscape as below and surprisingly I saw the unwanted sketches in that design.I removed them and repeated above procedure.

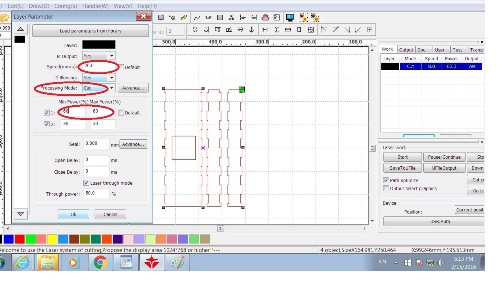

step5-Now select the line which you have to cut by giving it one color and give different color to the line which you have to just engrave.In right corner you will see black color and cut is written after that it means the line I have choosen with black color is going to cut.We can give different colors.then set power and speed of laser beam as shown below.

step6-Now switch on the laser cutter and connect it to your PC with USB cable to download your file.

step7-Now put sheet of material which you want use.I have used MDF material of 3mm thickness.Swich on air compressor and then switch on laser beam.

step8-Now we only have to attach the parts

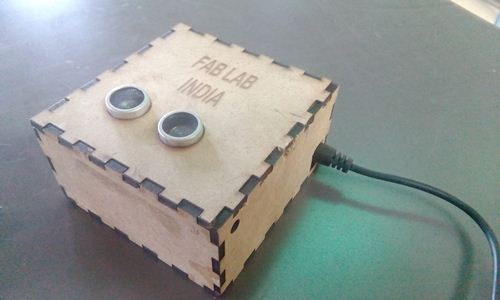

I also made below box on laser cutter

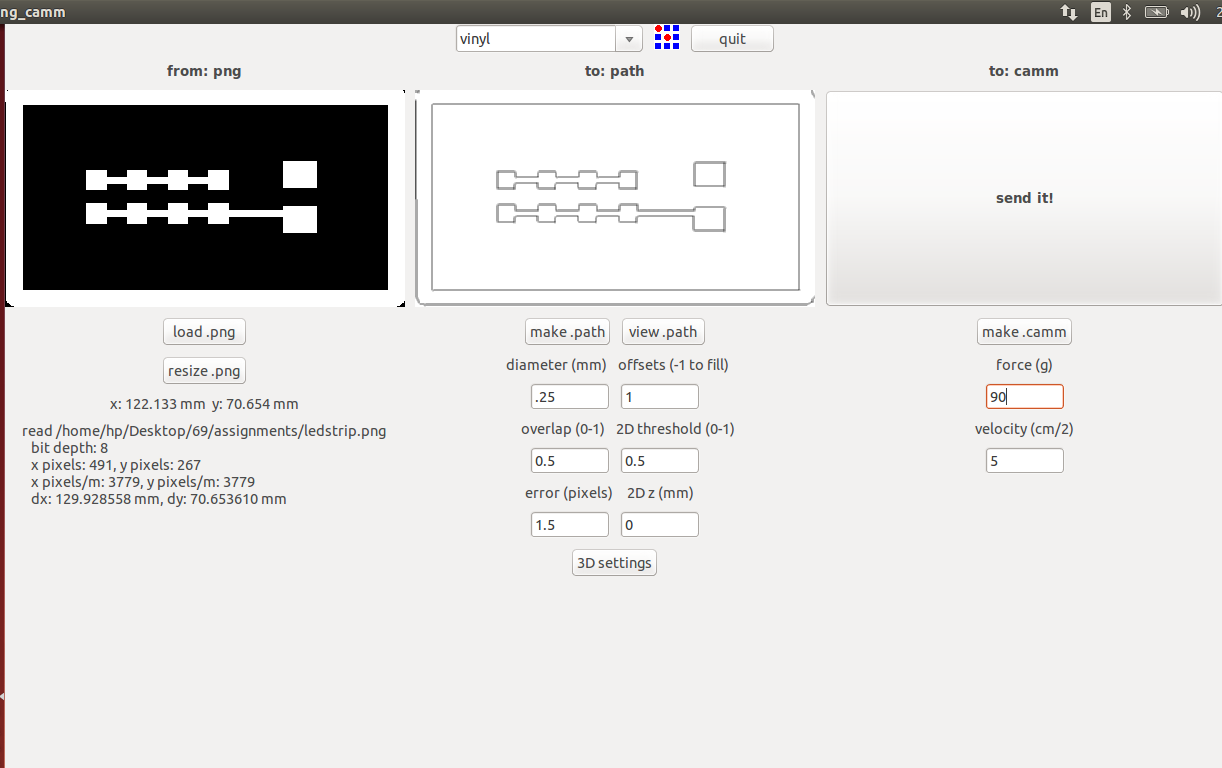

I started working on Vinyl machine by using fab module.For installation of fab module on ubuntu I followed tutorial of my Instructor.For opening fab module go to terminal,type sudo fab and it will ask your system password.After providing information you will find new window popped up.

There first select image format which you have i.e .png,jpg...etc. Then select machine you are going to use.Here I am going to use vinyl .so I selected that one.Then click on comm.path.You will see another window come up.Now load image, make path.

Vinyl plug in

Connect Vinyl to your system and give power supply through its power cord.There are sensors on Vinyl cutter to detect paper.As I am going to use copper paper and its width is small I stick masking tape above the sensors

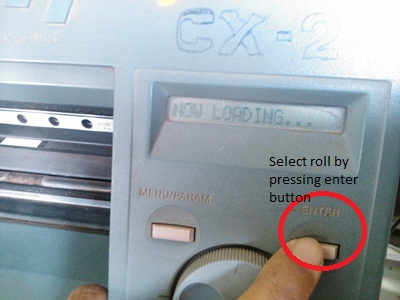

Switch on Vinyl cutter.and load roll by pressing enter butone at the right. we can test that whether force and speed of machine giving us good print or not.For that you have to rotate circuler button on vinyl cutter after switching on the machine,you will see option of 'test' press that and then machine will cut one small square.By observing that we will adjust force and speed of machine.For adjusting force and speed again rotate circular button there will be the option of force,then press menu button now LCD will show blinking cursor for editing value.Now rotate circular button to change value.Press enter button after adjusting the value.Same thing we have to do for changing speed by selecting the option'speed'

Then click the option saying 'send it ' in the fab module.We can adjust force in fab module also.I print parallel circuit on vinyl and made below hand belt of LED's using this flexible electrobics technique

I made one board of DIC(design innovation center) by using vinyl paper.Here I put force 110 gf.Made design in inkscape.Firstly I loaded roll and set origin to left most side.As the size of image is more than the size of set origin and border,vinyl cut only half of the portion.After that I corrected the mistake and set origine correctly.After finishing cutting I removed unwanted parts and pick remainning part with the help of masking tape,from vinyl paper to place where I want to stick cutting.

Trouble shooting

As per my experience,If we not getting any good print by adjusting force.We have to change blade of Vinyl cutter.For this first remove previous blade by losing the screw above blade.Note- we have to see for Speed,force,blade sharpness,paper fitting in machine.

In this assignment I learned to use vinyl and laser cutter,Its trouble shooting,Designs and its importance.

This was very good exercise to understand machines.

Download all files here

download vinyl file here

file for led strip here

file for motor hanger here