The assignment for this week was plain and open - Make something BIG

As a learner, I wasnt sure what I should make. I wanted to show a clear design of what I was planning to make. I decided to start the Webinar classes with Onshape and practice it well. My friend Frank and I could share a particular file of design and work on in concurrently. This really improved our skills on the same. We also realized the advantage of Filee sharing in Onshape as it comes with bigger storage capacity allocation as compared to private work

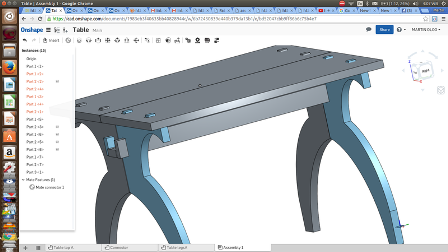

I decided to make a table. It looked simpler but it could give me adequate practical skills necessary

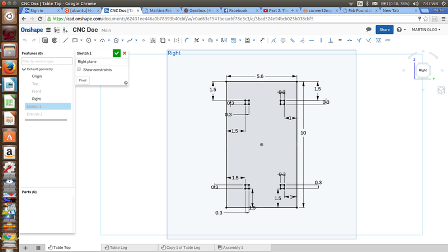

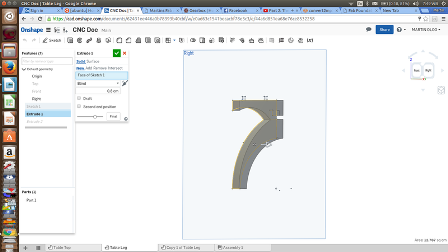

I made my first sketch. I had to work on various dimentions with an imagination of the 3D look.

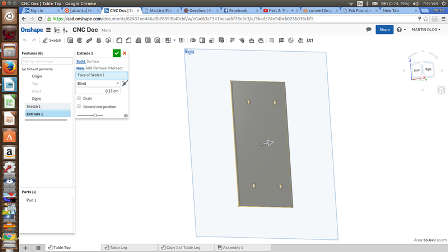

This is the Extrude of the sketch above. It gave me alot of hope of success with my design

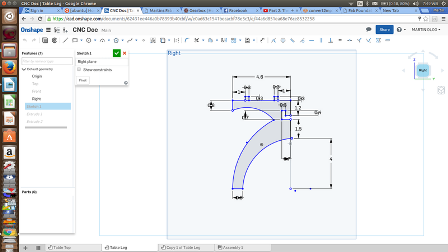

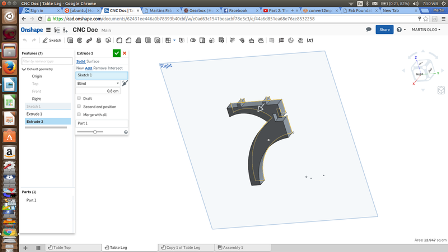

Now another sketch for would be the table leg. Here, I had to apply extra skill of curving out the shape from the rectangular sketch. More meaasurements had to be used

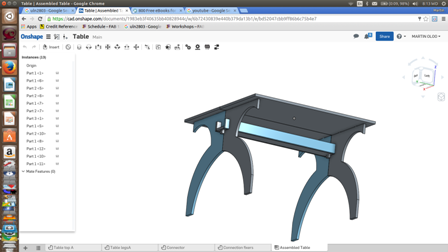

And so, it's extrude was out and it looked great

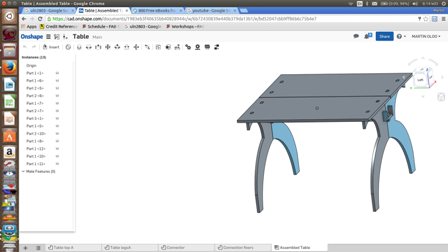

I had to rotate it through different views to confirm my work

And you can always refresh your Onshape page by clicking the Onshape logo on the top left corner

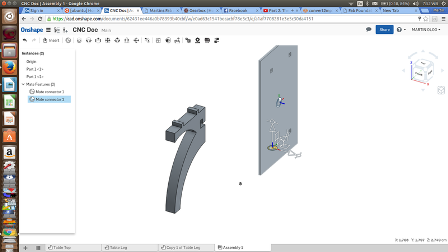

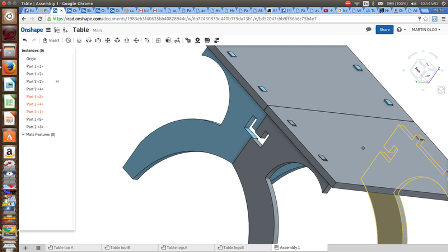

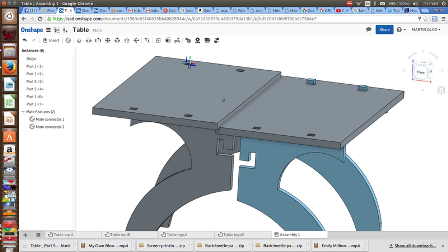

To start Assembling, you click on the Assembling, you can click on the Assembly button and Insert the various parts you want to assemble. You can rename these tabs as best suit you.

I was able to complete my design as expected and proceeded to the CNC Machine

Files

Download the Table partsDescription

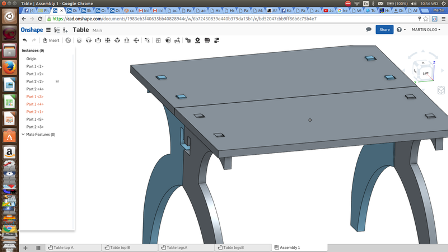

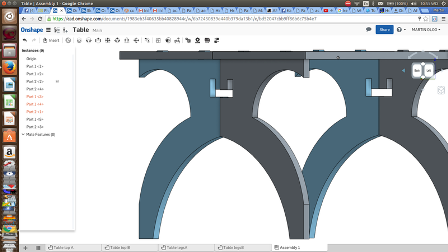

The table has for pieces of legs where each two are expected to fix to each other by a connector. The connector which has 4 holes 2 in each ending side will the fixed to hold firmly the table legs using the connector fixers. The table tops which are two in number will however be laid on top and using the their holes fix themselves on the protruding pieces of the legs facing up. There you have your Safari (portable) table

Assembling process

Assembling process contunues

Assembling process contunues and almost done

Final touches

Hurraaa!!!! See below wonderful images

CNC MACHINING

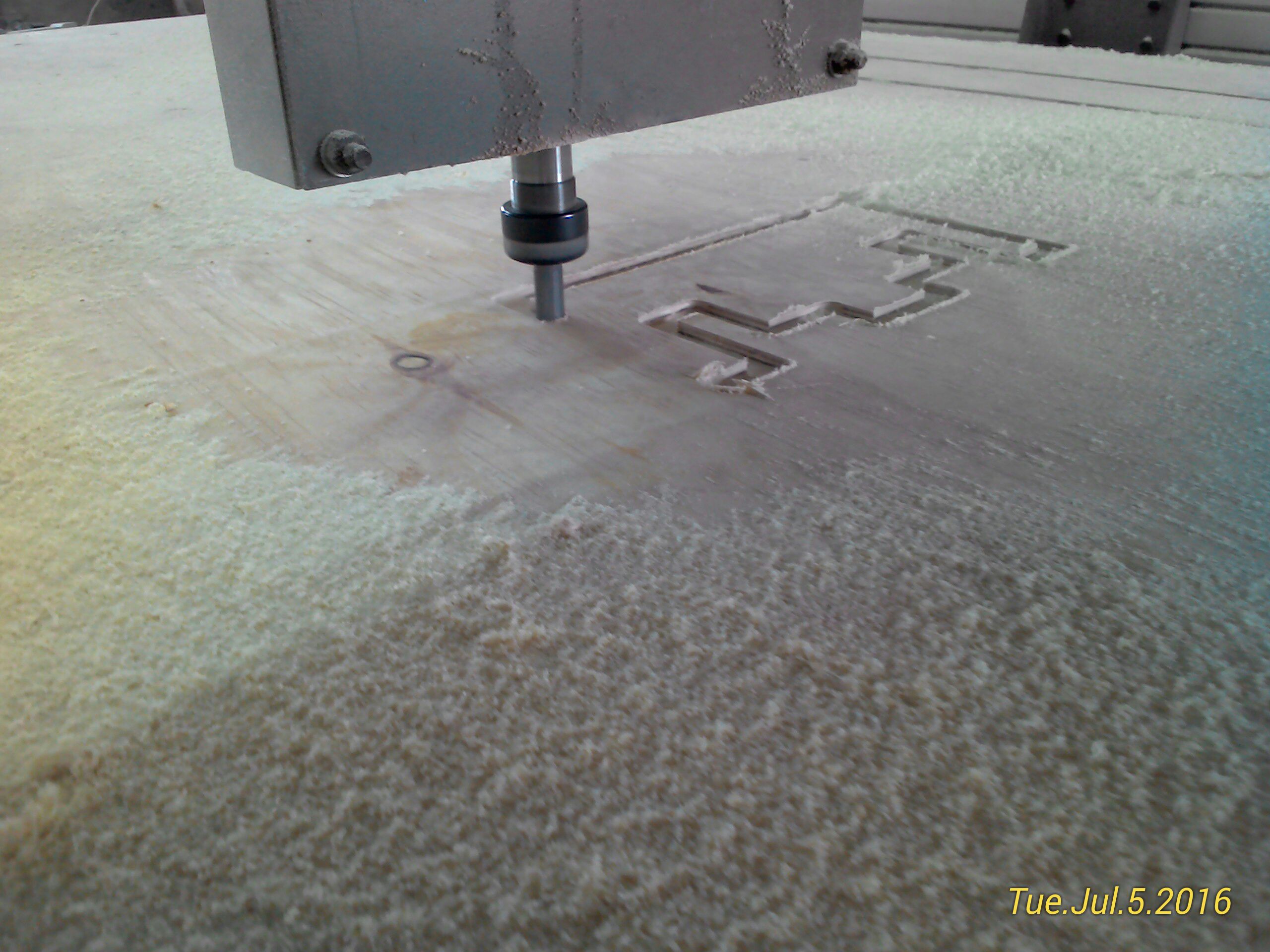

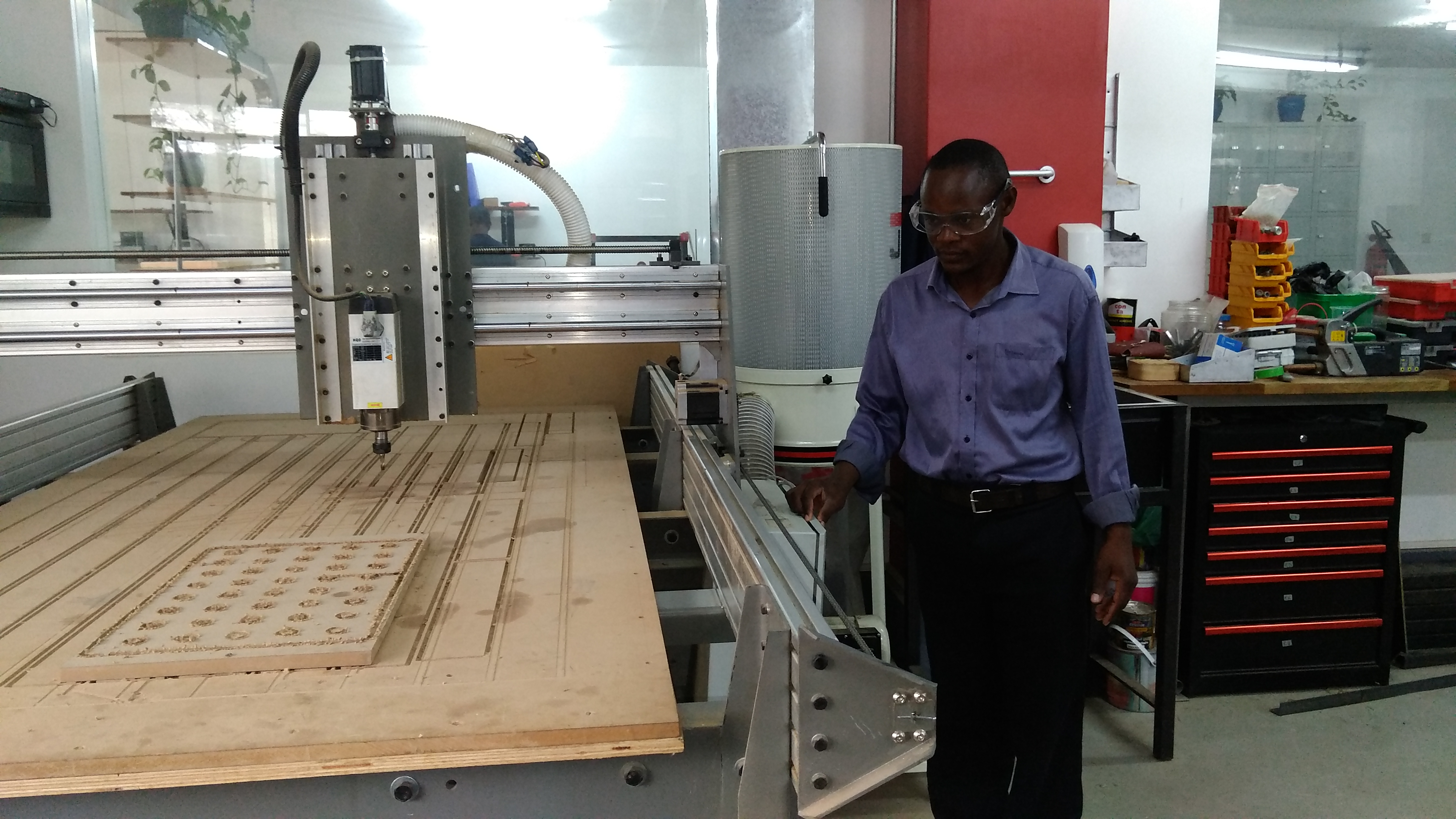

Now, I had to redo the work in a 2D in order to be able send to our CNC Machine. Meanwhile I have to understand the machine operation

It was a learning session first to understand the machine

The workpieace would be fixed on the table as this sample was

We had to do some test to understand the settings and Safety precautions

Drilling

In the event, some mechanical and electronics challenges were found and would be fixed by the concerned Engineer. These are common problems with locally made machines and so prone to some technical challeges