ADITYA BHATT

Week- 7 Computer-controlled machining

ASSIGNMENT

-Make something big.

.

This week's assignment is to make some thing big using the shopbot cnc machine which is in our fab lab.

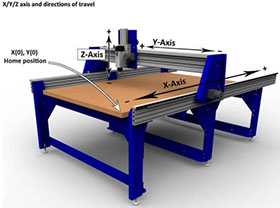

Computer Numeric Control is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command module, usually located on the device) as opposed to controlled manually by hand wheels or levers, or mechanically automated by cams alone. Most NC today is computer (or computerized) numerical control (CNC), in which computers play an integral part of the control.

Planning

I thought a lot on what to make but this was the first time I was using CNC machine so I thought of making something which is not too complex and at the same time fits the requirements of my assignment. So finally I decided to make a sign board for our fab lab.

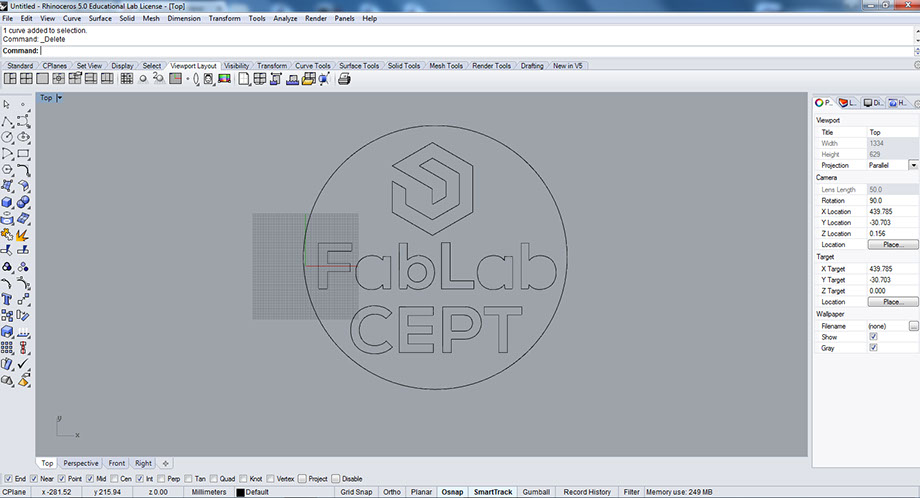

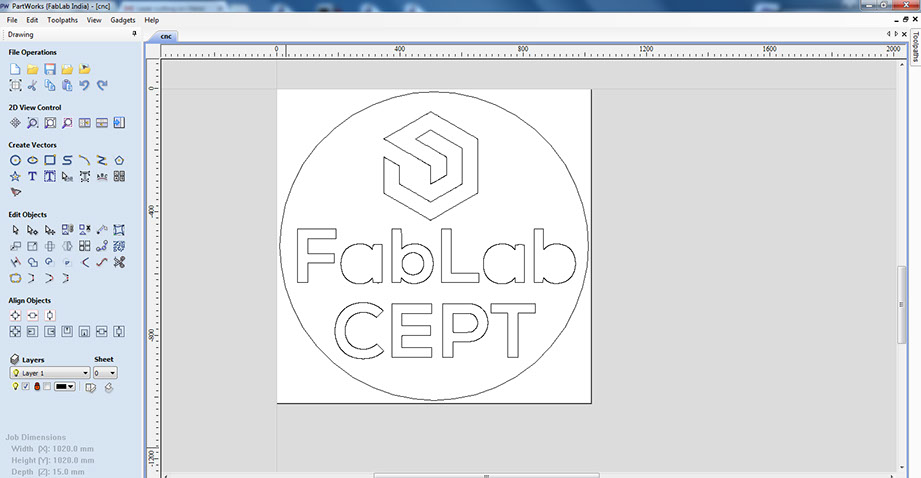

I designed my file in Rhino. The link to the file is given at the end of the page.

After my designing was over, I exported the file in .dfx format so that the software partworks accepts it.

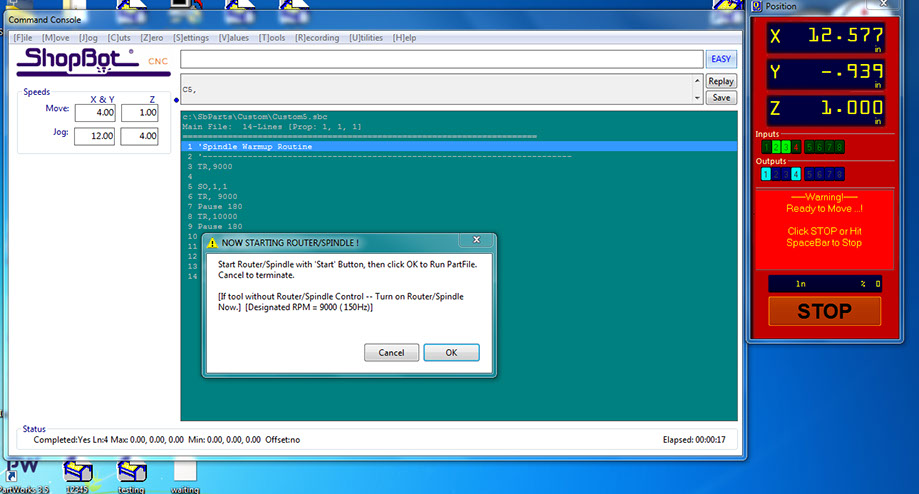

Before we start printing our file a bit of warmup needs to be done for the machine. Just like we racer starts his race with with warm-up we need to warmup the spindle too!

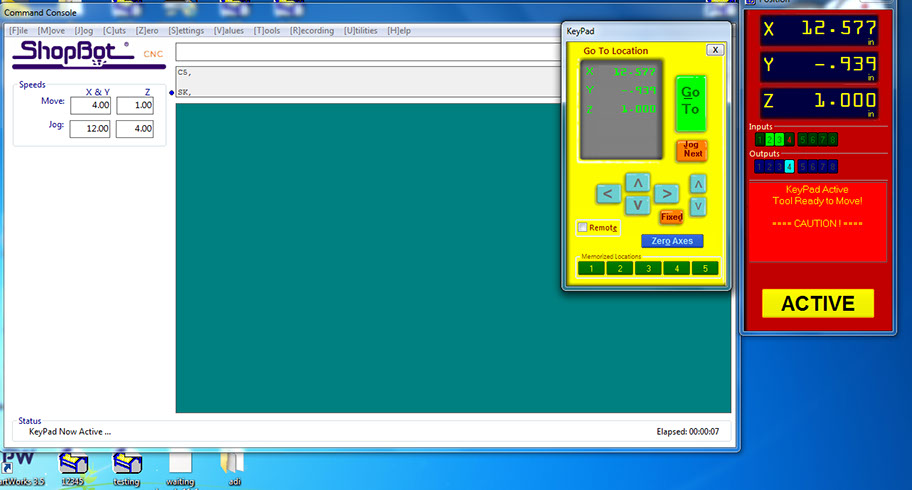

After doing this much we need to set the X,Y and Z axis of the machine at the points we want.

STARTING TO USE SHOPBOT-

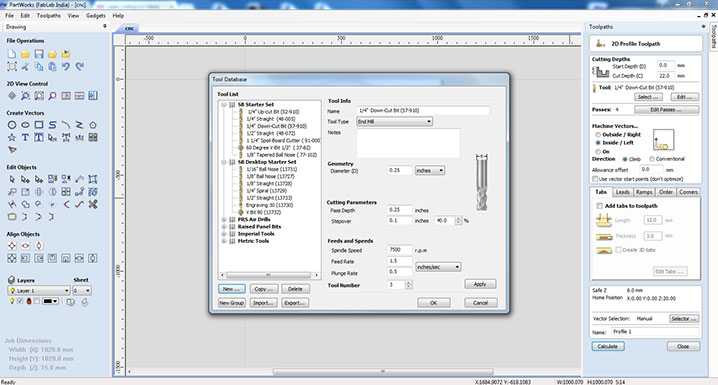

Now the next task is to load the file we want to cut, in the part works software and set the respective parameter.

In this cutting process we are going to use 1/4drilling bit, which is downcut bit with 2 flutes.

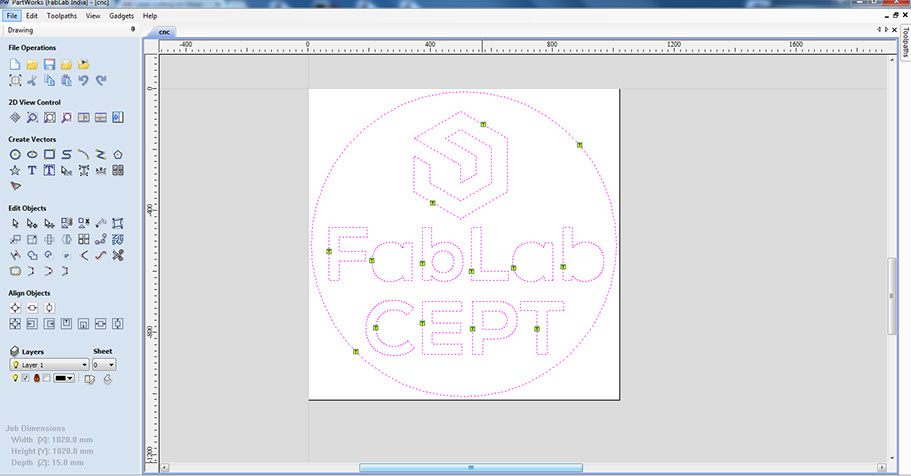

After we load the image and set parameters according to our drilling with we select the TAB areas so the while drilling, a few areas are not fully cut which reduces the pressure while cutting and makes our cutting safe and secure too. The screenshot below shows the places where I have put my tabs.

Now we are all set to load the G-code and start cutting!

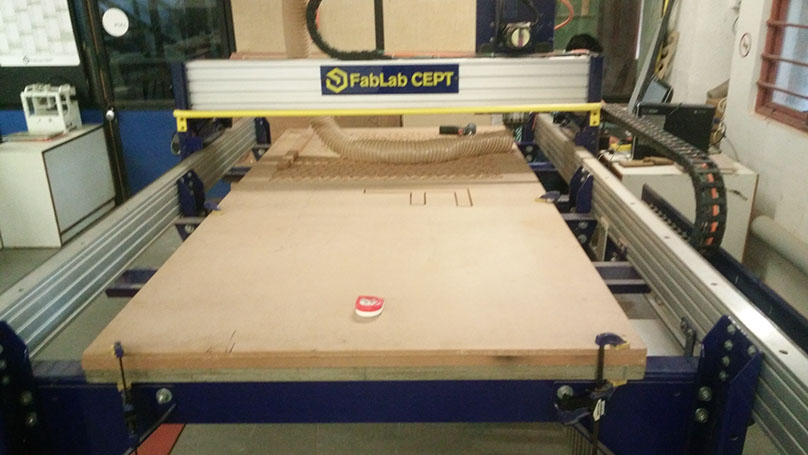

Before we start the cutting we need to place clamps which will tightly hold our cutting bed. I have used 15 mm mdf wood for this cutting.

We also have an emergency button for or cnc machine, incase something goes wrong just press it.

The last thing to be kept in mind before cutting is to see that our cutting bed is all clear with nothing lying around it as it may be dangerous.

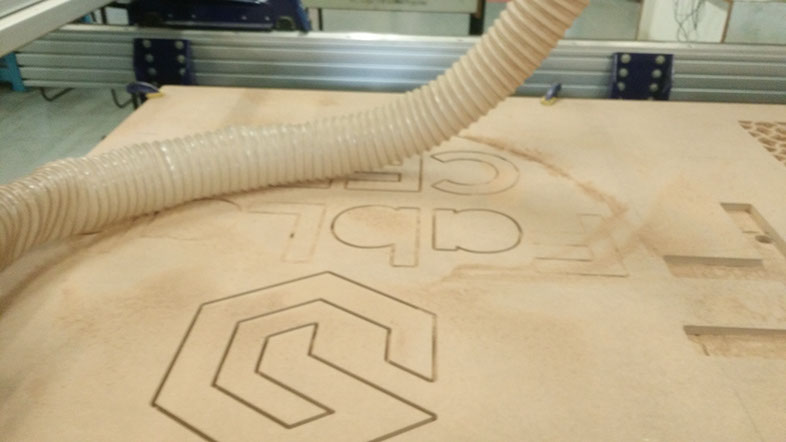

You can now have a look at the cutting process below-

After my file was cut I had to do a bit of post processing to clear off the left out TABS(I spoke about it earlier).

After post processing I took help of tapan bhai to hang the sign board outside our fab lab. I just manaually drilled 2 holes on the board so that I can hang it using a strong steel cable.

After this I went and hanged the board with the help of tapan bhai. Later on, to make the board look attractive I painted it.

CNC CUTTING FILE-