Week 14 - Composites

Design and make a 3D mould (~ft2 /30x30cm), and produce a fibre composite part in it

- SuperSap CLV Vlear Epoxy Bio Resin

- Jute fabric

- Hemp fibers

- Cotton fabric

- plastic food wrap

- Digital scale

- Edge clamps

- Brush, wood stick

- Vacuum bags

- Laser Cutter Epilog

- paper

Softwares :

- Slicer for Fusion 360

This week, as a physicist, I felt I needed to explore the mechanics of composite by making some experiments. I've always been fascinated by how Nature designs materials and mechanical systems and this for a variety of functionalities. Reproducing, exploring and understanding these mechanism and their associated functionality in the lab is part of my job. Digital fabrication clearly empowers the experimentalist to explore mechanical system by making them, feeling them and studying them. After the experimentation, I've decided to produce a wind turbine blade. I was amazed how fast I did that using 3D softwares and the laser cutter. Mastering the tools and practicing really make a difference. It is also remarkable that cheap and nature friendly materials can be used (quite easily) to produce extremely hard and large structure... Composites are amazing !

How nature uses composites ?

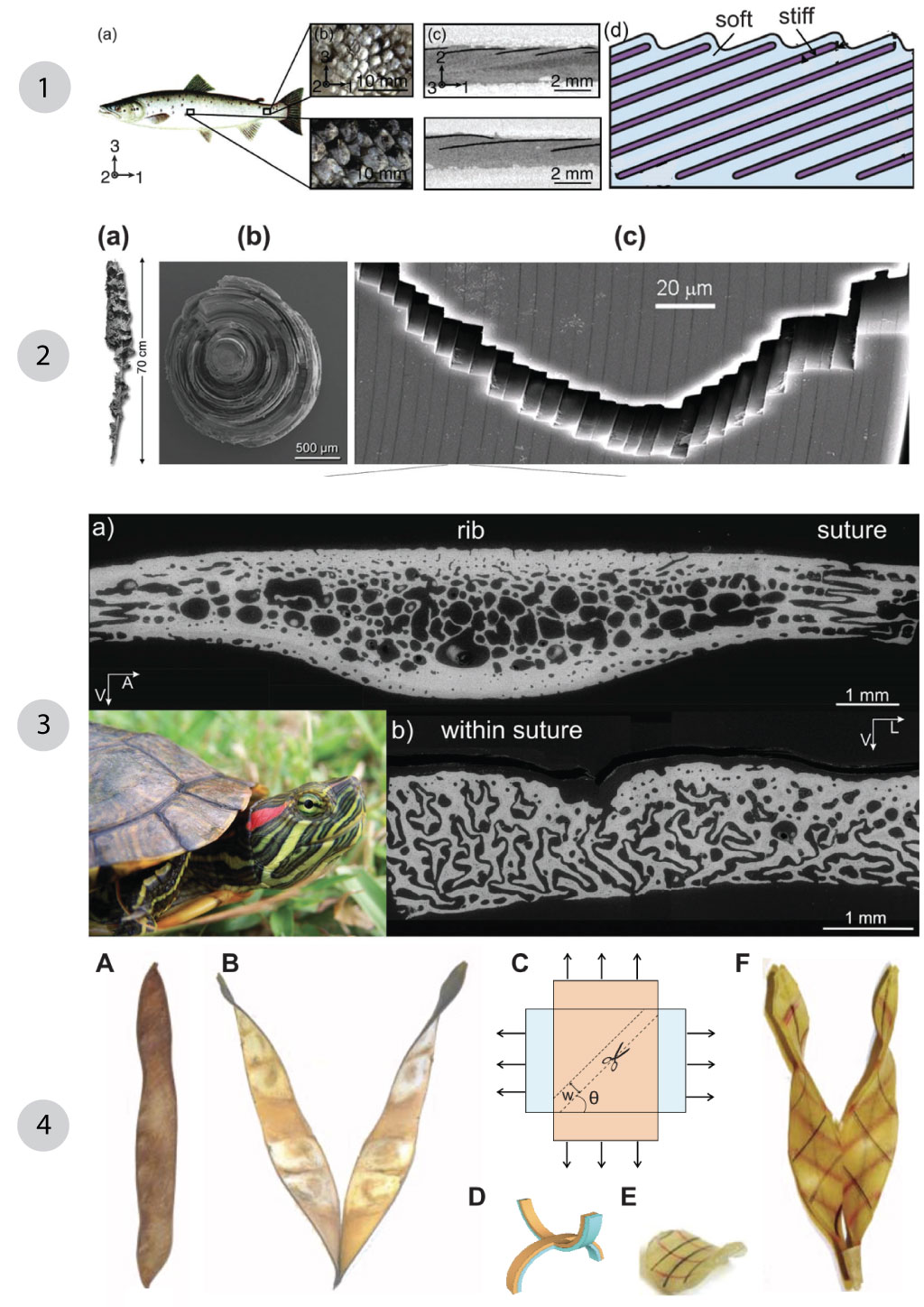

Composites are everywhere in nature. We all know composites for their increased rigidity but in Nature it can be used for much more. Here are some example from Nature on the figure below, (1) the fish scales of the Atlantic Salmon are composed of stiff parts embedded in a softer matrix which provide an armour against predator and flexibility for the fish to swim. (2) the multilayered silica spicule (skeleton) of the glass sponge provides a high strength material that makes crack really difficult to propagate; (3) The carapace of the red-eared slider turtle is composed of mineral ribs that are connected with other ribs through softer joint at the suture giving some flexibility to the carapace [Fratzl, Chem. Soc. Rev, 2016]. (4) The Bauhinia pods open when they dry releasing the seeds. It is the anisotropic arrangement of fibers in the vegetable composite that swell or shrink and is at the origin of the helical shape when opened [Armon, Science, 2011]

Let's explore composite

I will start by exploring and experimenting some functionalities of composites that are readily available around us.

Paper is a composite

Paper is made of cellulose fibers that were separate from wood or other fiber crops chemically or mechanically. In the paper pulp from which we make paper there is a components that is called lignin. Lignin is an important polymer for the structure of cell walls in wood as they give their rigidity (It's similar to the role of the epoxy in this assignment). In newspaper and cardboard the lignin gives rigidity and the yellow color. To avoid papers to turn yellow (with light and oxygen) lignin can be removed chemically which moreover provides some flexibility to the paper.

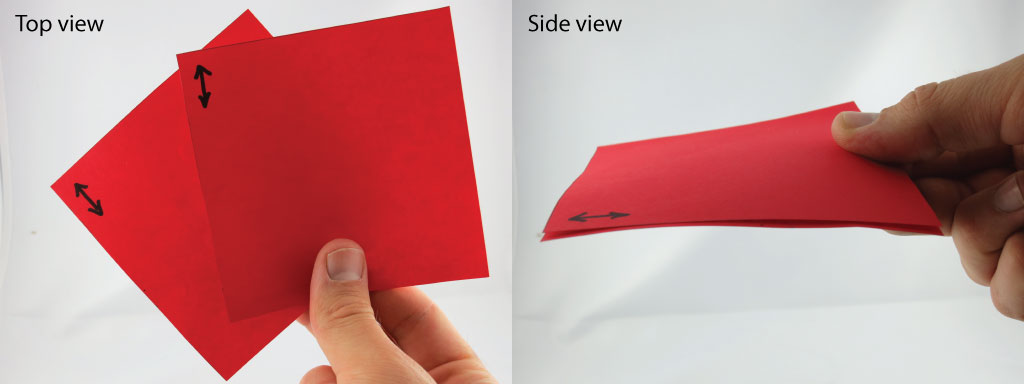

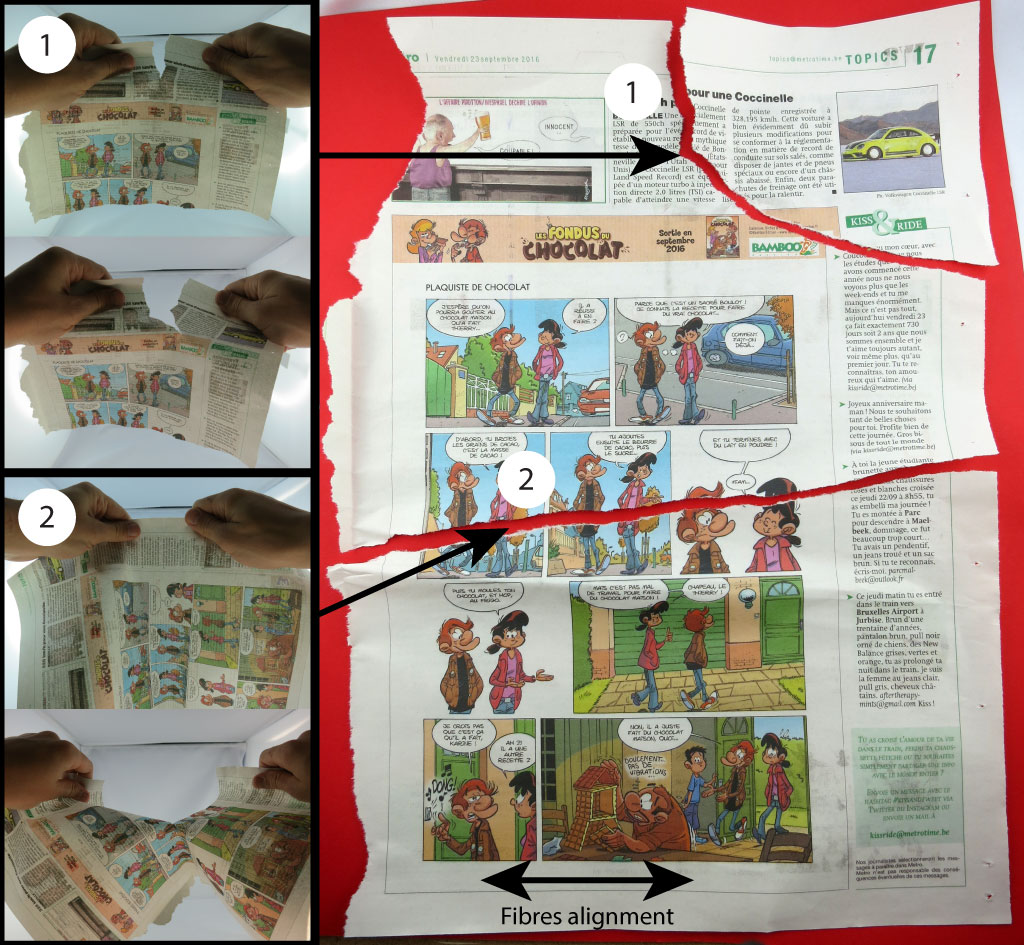

Paper is an anisotropic composite When stacked and hold perpendicularly to the gravity they stay horizontal./h4>

In the paper, the cellulose fibers are arranged in an anisotropic fashion. They are usually aligned to one of the side of any paper.

Increasing rigidity

I started by cutting to squares from a paper sheet on which I indicated the principal direction of the cellulose fibers (along the longer side of the paper sheet). When stacked and hold perpendicularly to the gravity they stay horizontal.

Then I turned the sheet below by 90°, the two sheets have now their fibers aligned perpendicularly. We observe that the under sheet falls in the gravity while the top one stays horizontal. This shows that the rigidity is different for the two sheets depending on how the fibers are aligned.

Hygroscopic properties

Natural fibers are usually hygroscopic. This means that fibers can swell and shrink depending on their water content. This can be widely use in Nature to make vegetable structure to change form when humidity is changed or when soaked into water.

By a sunny day, if you find a pine cone, you will see that it is open. If you soak it into water for a few hours, the cone will close. Put it out of the water, it will take 3 days to open again. This depends of course of the weather condition... If it's raining, pine cone will be closed.

This is because, at the base of each scale, there are fibers that increase their length by 20% when they are wet. This makes the scale to move and close the pine cone [Reyssat, J. R. Soc. Interface, 2009].

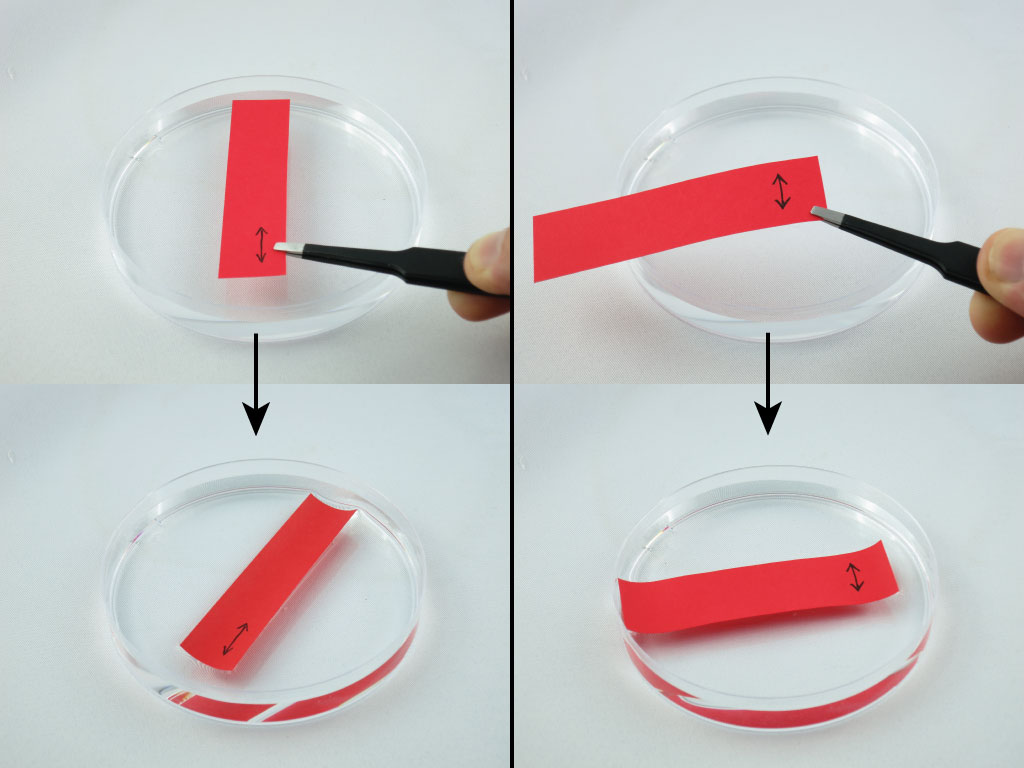

You can experiment the swelling properties of cellulose fibers by laying small strip of paper at the top of water. The water will slowly rise in the paper, the wetted fibers at the bottom of the strips will swell and the paper will bend. Note that the paper bend in a perpendicular direction of the fibers, fibers grow radially.

The package of a tea bag, is made of a paper sheet glued to a polymer sheet. When stripes are cut with different orientation and soaked in water, they will bend in direction depending on the fibers orientation in the paper sheet.

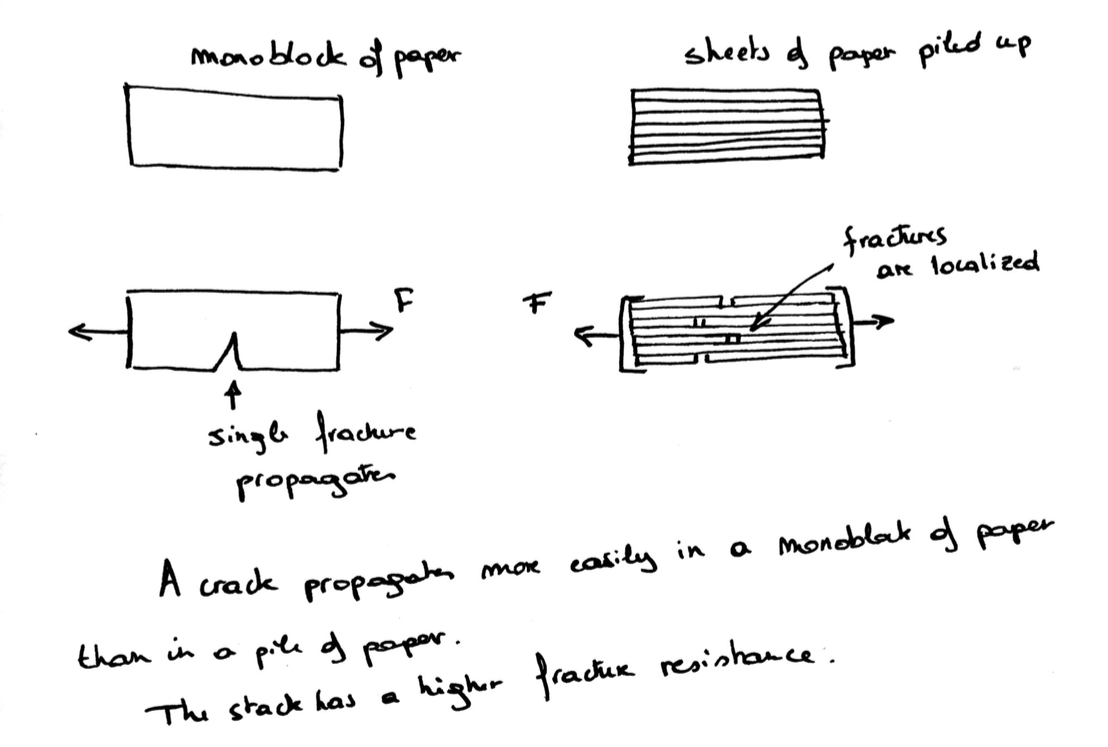

Fracture propagation and resistance

fibers in a composite will have a huge effect on how fractures propogate. When you tear a piece of paper, fabric or composite, the fracture will take the path that is the easier. I will thus propagate through the weakest past. In paper it is really simple to see it. By taking a piece of paper and tearing it perpendicularly to one side. The crack will go straight like in the figure below (2) or if the sheet of paper is turned by 90°, the fracture will bend and will align with the fibers. The fracture propagates and orients following the fibers orientation. The anisotropy of composites is a very important point concerning fracture and cracks in propagation in composites.

Why is it so hard to tear a book ? Using multilayered materials hold the cracks from propagating. As can be seen on the left figure below, if we take a monoblock of plain paper and stretch it it will break at some point. Once the fracture starts from one side of the block it propagates through the monoblock and break it. On the figure on the right, if we take a stack of thin sheets of paper which total size is equal to the size of the monoblock we just talked about, we experience that breaking the pile of paper is much more difficult. It requires much more energy than breaking the monoblock. It is because when a crack starts to propagate in one sheet of paper, it stops when it reaches the next sheet of paper and the cracks cannot propagate further. So all the sheets have to crack before tearing the entire pile.

Making and testing coupons

Natural fibers

Jute

I found a burlap made of jute fibers at a gardener's supply store.

Hemp

Hemp is used to seal threaded joint of plumbing pipes. The hemp fibers when soaked in water, swell and seal the pipe joints. This can be found in any hardware store.

Cotton

Cotton is widely used for clothing, bed sheets,... Here I used an old bed sheet that I teared into pieces.

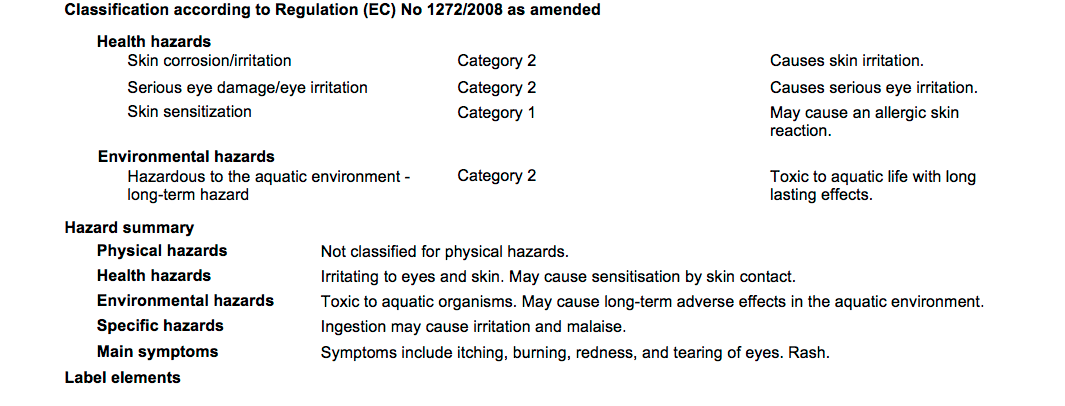

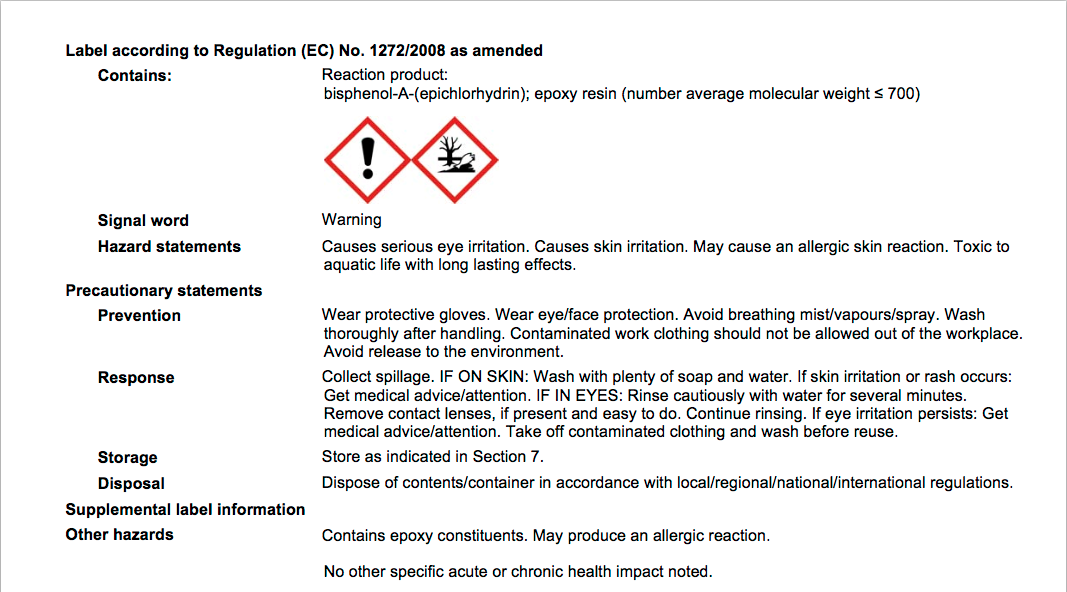

Epoxy

We chose to use SuperSap CLV Vlear Epoxy Bio Resin. There are no technical datasheet for this resin TDS. This is a high performance bio resin that is low viscous. It is thus easier to infused in the piece of fabrics that we will use to make our composite pieces.

Safety

Here is part of the safety datasheet (MSDS) that we have to read before using the resin. To handle this resin, we need to use gloves, eyes protection, protect the working area to collect the spillage.

Composite fabrication process

My working table.

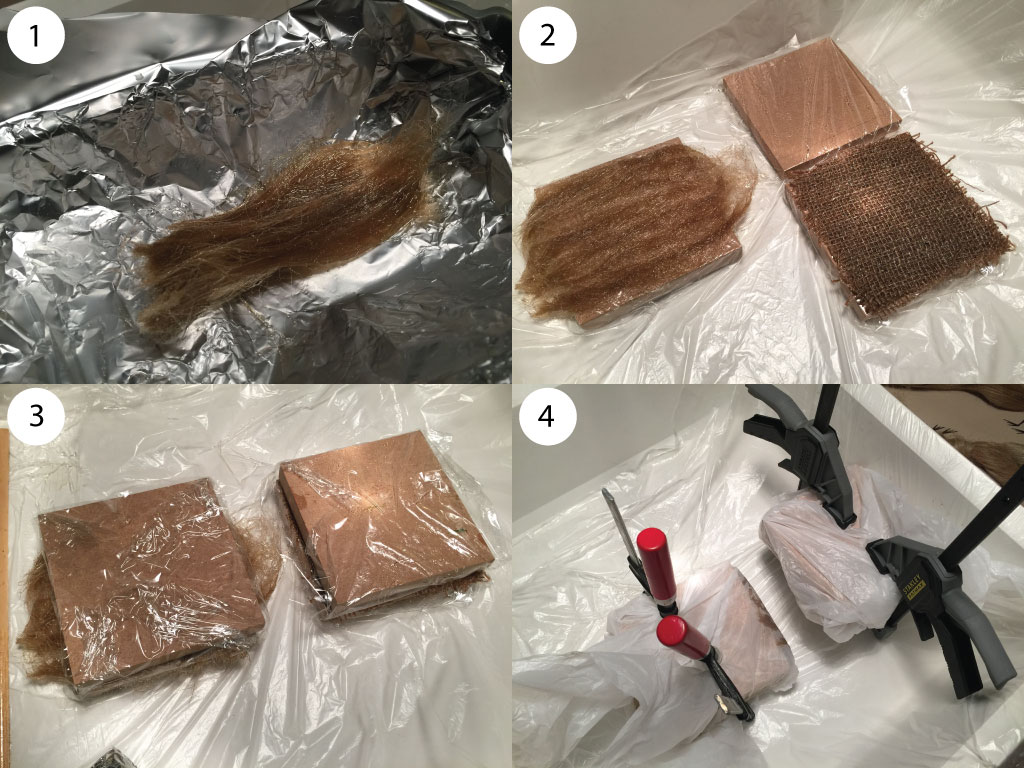

Here is the workflow I used to make the coupons in composites.

- Prepare the fabrics, the plastic wrap, the gloves, the mold, ... everything needed before starting mixing epoxy.

- Cover the mold with plastic wrap, it makes it easy to demold. Epoxy does not adhere to plastic wrap.

- Mix resin and hardener 100:40 by weight using a digital scale.

- Mix by hand for 2 minutes.

- Pour the mixed resin in a larger container to slow down the reticulation process due to overheat (reticulation is an exotherm process) (Fig. 1). Pot life is 25-35 Min.

- Use a brush to coat the mold surface with resin.

- Soak the fabrics in the resin (Fig. 1).

- Lay the soaked fabrics in the mold (Fig. 2).

- Make several layers (Fig. 2).

- Close the mold to apply pressure on the layed fabrics soaked in epoxy (Fig. 3).

- Use clamps to apply pressure (Fig. 4).

- Demold after 12h (cure time).

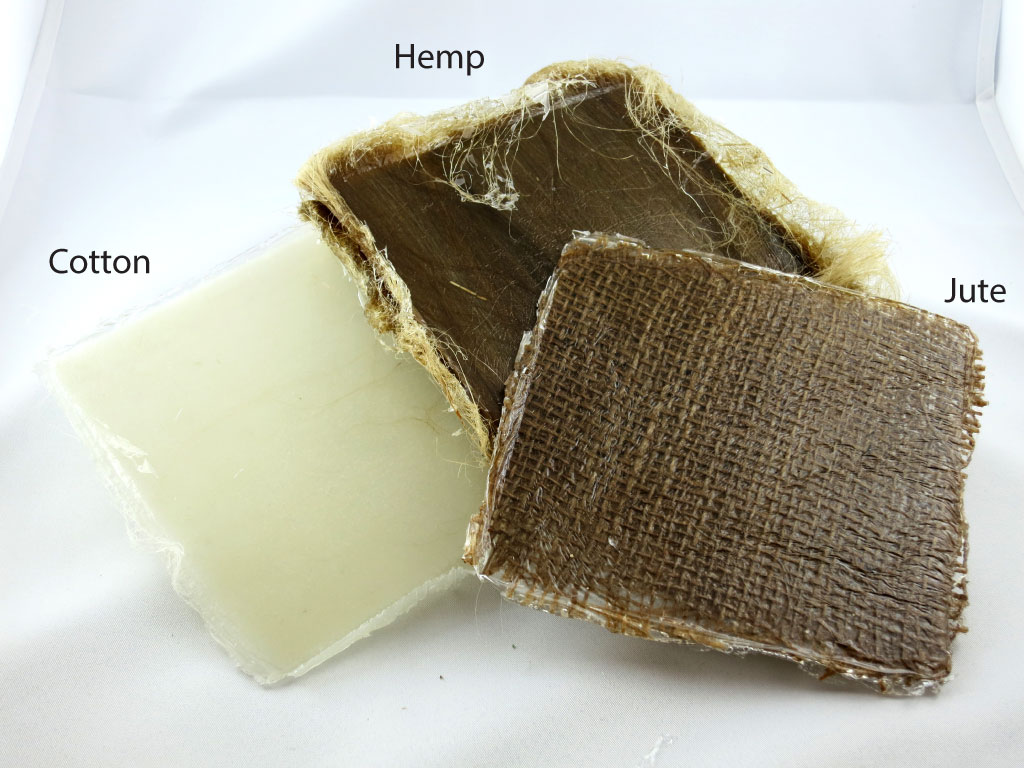

Here are some of the coupons I made. A 5 layers cotton coupon wich has the smoother finish, a 3 layer jute coupon which as a rough finish but feel resistant, a 2 layers hemp coupon with the first layer made of fibers aligned in one direction and the second layer made of fibers aligned perpendicularly to the one of the first layer.

Hygroscopic properties of coupons

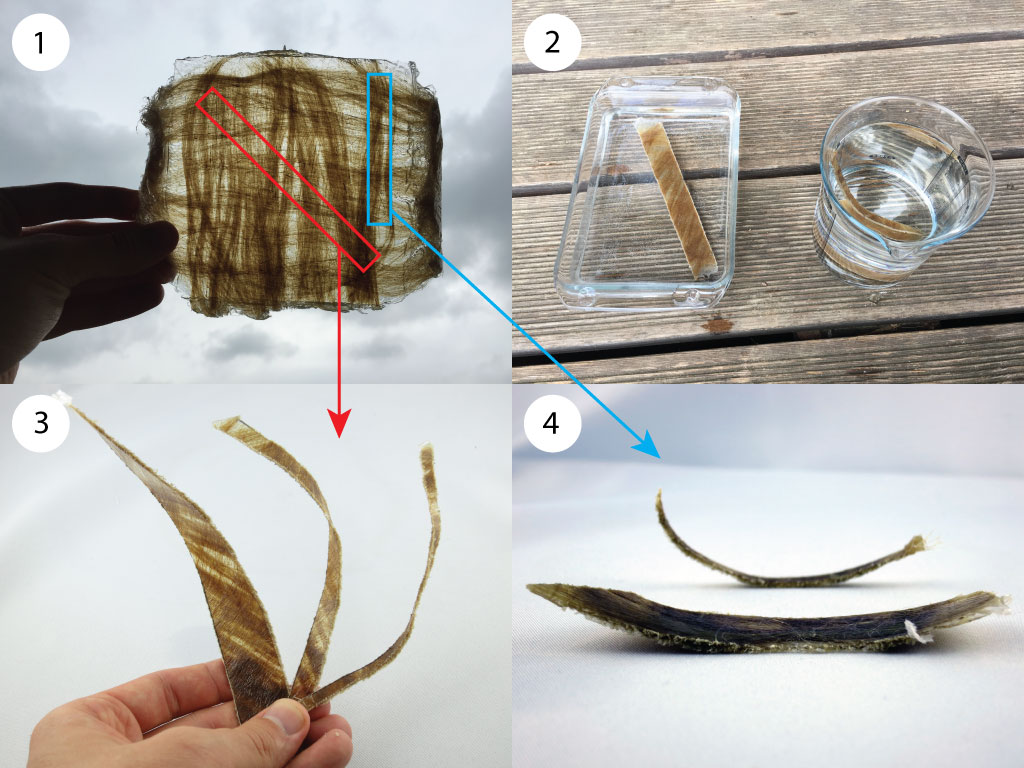

Understanding the hygroscopic properties of the composites with natural fibers is really important when you make this kind of composites.

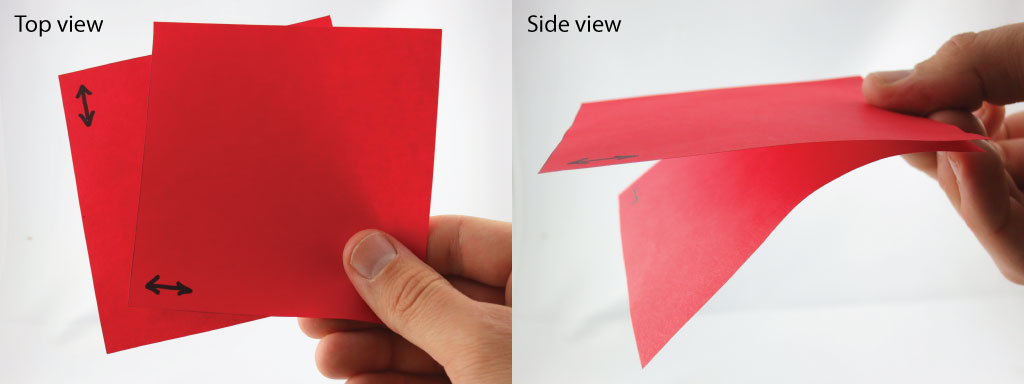

Using the hemp coupons, I wanted to test the effect of the hygroscopic properties of hemp on composites coupons I made. This is an original idea of a colleague of mine Antoine Leduigou (University of South Brittany) who is making flax composite with hygroscopic properties.

Here below on the figure are the results of the experiments I made.

- We see the 2 layers of hemp fibers that are aligned perpendicularly to one another. I've cut several pieces diagonally and several aligned with the fibers of one of the layer.

- I soaked the pieces in water for several hours.

- The diagonal pieces have deformed in a helical fashion. On each side of the pieces, the hemp has swelled and induces a swelling force that makes the 2 surfaces to swell in perpendicular direction. It results in a helical morphology. Note that the thinner is the piece, the more helical it is. It is really similar to what is happening in the Bauhinia pods when it opens as it is shown here above.

- When cut along the fibers of one of the layer, the fibers on the other layer are all perpendicular to the coupons and swell radially making the piece to curve longitudinally.

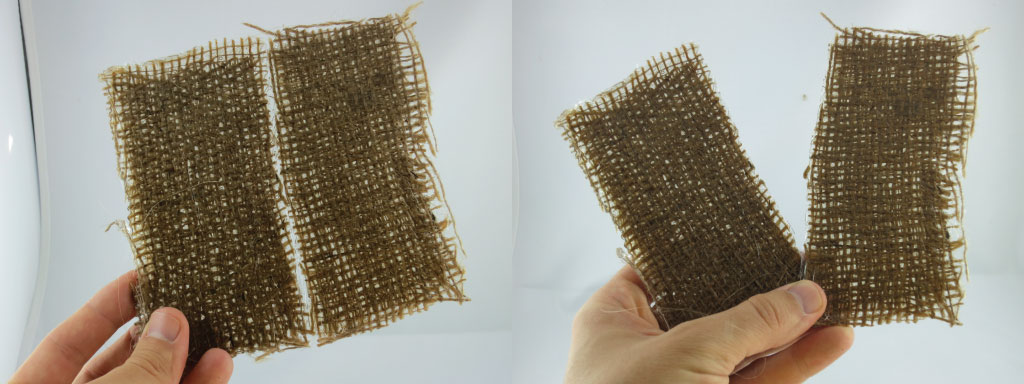

Fracture propagation

I did a coupon with a discontinuity in the jute fabrics to see how it will behave. I thought that, may be, I could create a flexible joint. But it broke directly when I bent the coupon. To create a joint, it might be an idea to get inspired from the turtle above and design a join with some interpenetrating fibers.

A wind turbine blade

Motivation

I've always wanted to build my own wind turbine. To feel (!) what you need to make to produce green energy and how effective it is.

How it works ?

Basically, wind turbine blades are based on the same principle as plane wings. A curvy blade design produces a lift force entraining the rotation of the blades while the drag is minimized. There are plenty of shapes that can be found on internet. Shape calculator softwares also exist which allow to calculate the blade shape as a function of the wind speed, the blade sizes and the height of the rotor.

Wind turbine blade production workflow

In search of a design

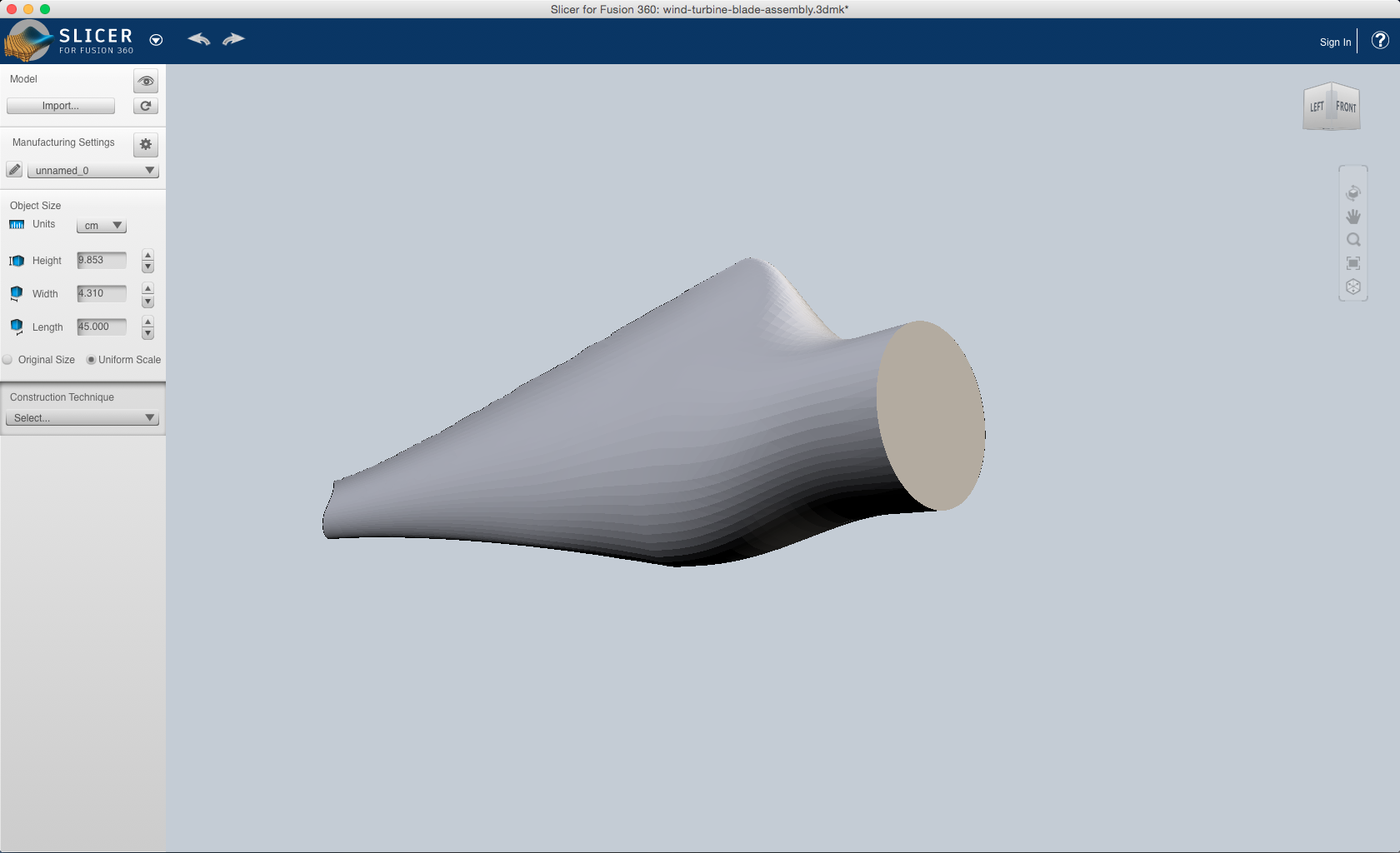

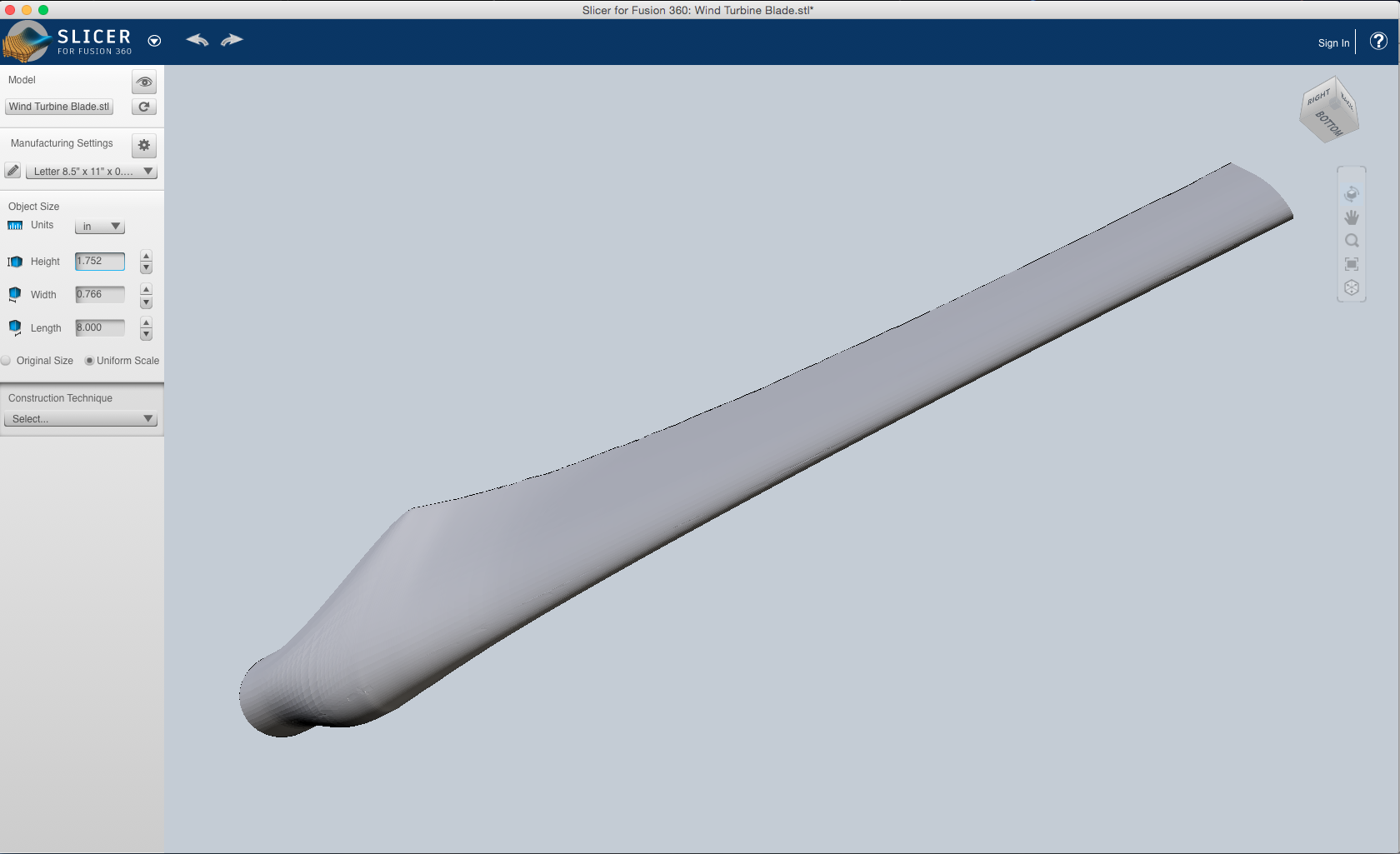

Having already learned the design workflow for 3D digital mold making (see assignment 12), I wanted to work on a workflow that would allow making windturbine blade effectively. I thus started by searching online for a model that is not too simple and that I can use as a test (here is the model I've found). It is a 3D shape with some subtle curves that I would like to see if I can reproduce. I opened it in Slicer for Fusion 360.

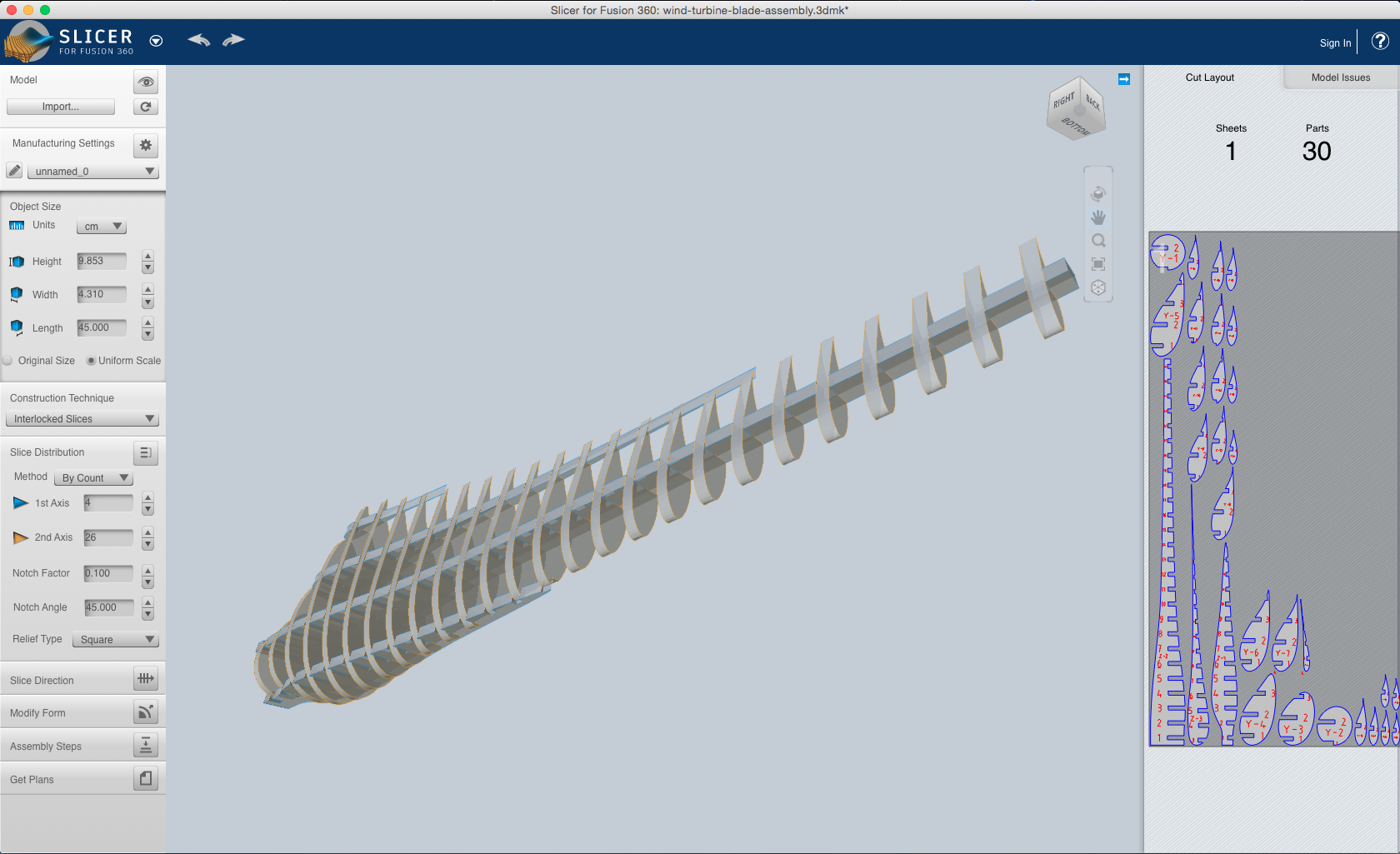

Designing the mold

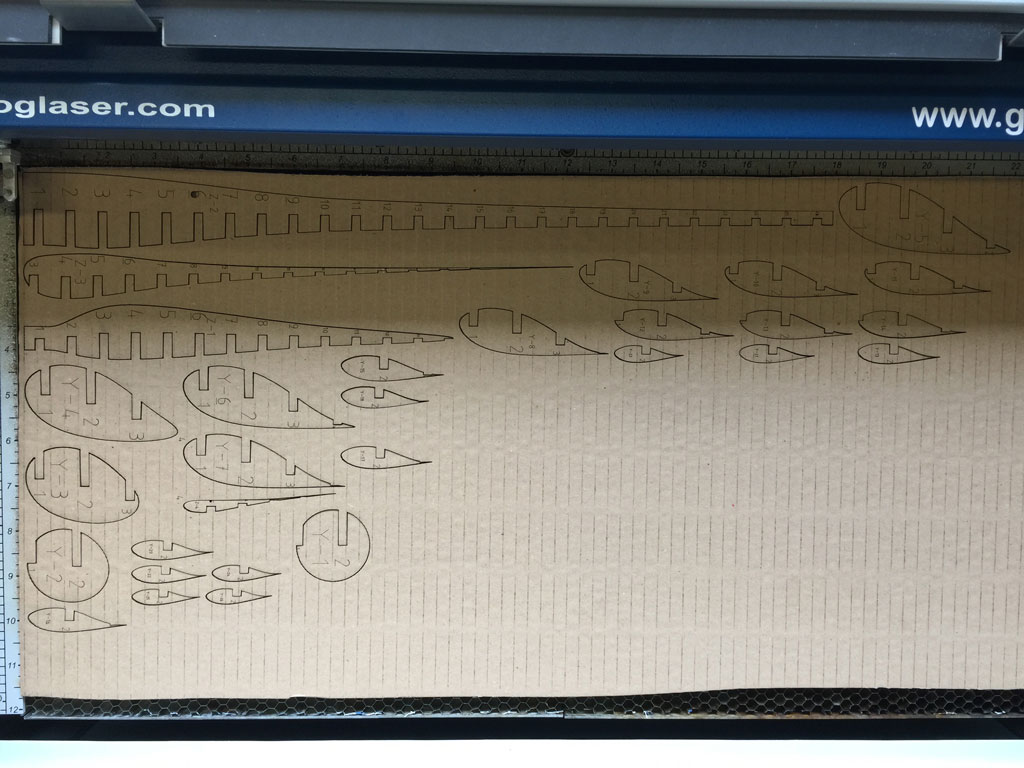

To make the structure, I choose to use 5 mm cardboard and a laser cutter to produce the skeleton of the wind turbine blade. This procedure can be easily scaled up with larger laser cutter or more pieces to assemble. Using Slicer for Fusion 360, I skeletonized the 3D design using interlocked slice, using a material of 5 mm in thickness and in a length of 45 cm which is a good size to start working on the workflow. Too big, I would used too much material and energy, too small I would have difficulties to make composite. Depending on the fabrics we use, composite has a minimum scale required to work at its best.

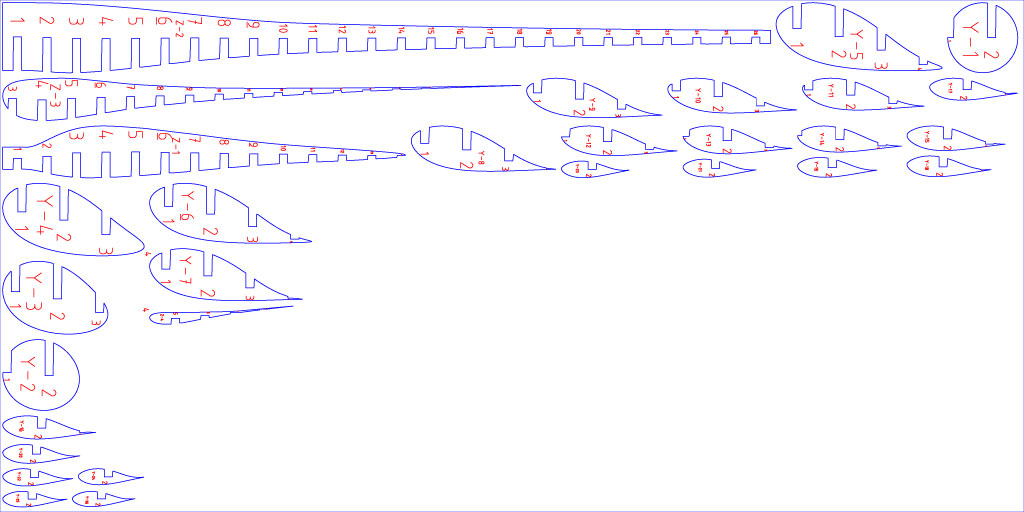

Here is the dxf file we will use to cut the cardboard with the laser cutter.

After having made some test I used an offset of 0.254mm to cut the pieces

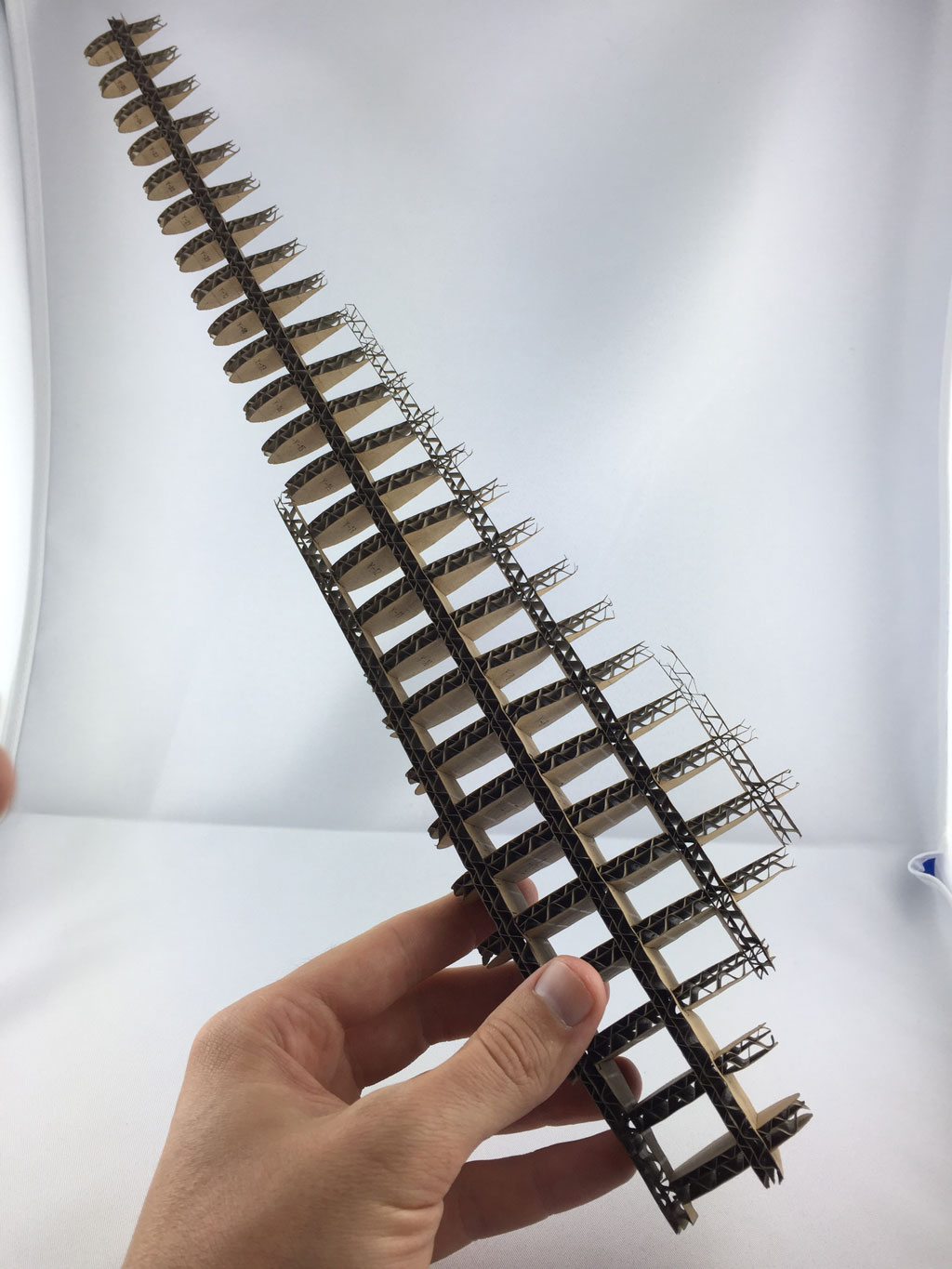

Assembling the structure. Some pieces are quite thin and I'll have to be careful when laying the fabrics. I'll let the epoxy impregnate the cardboard structure so it will harden the structure. Using cardboard seems a good option but care has to be taken, it is flexible and fragile. But it is a cheap and light material, easy to work with.

Making the composite

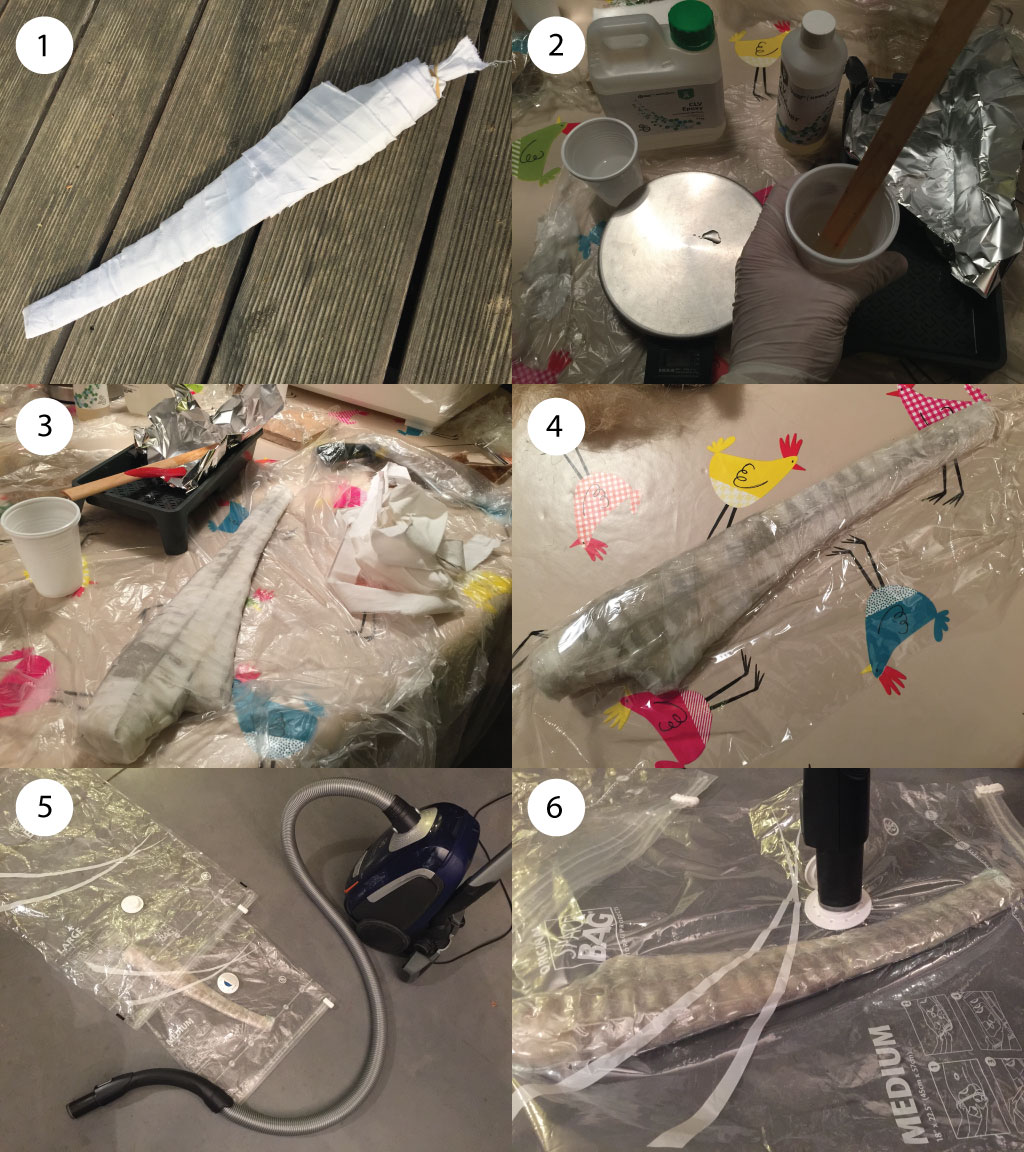

Here is the procedure I used to make my composite wind turbine blade.

- I used cotton strip to recover the structure and fill the gap in between the structure.

- I prepare the resin mixing as explained here above.

- I recovered the first layer of cotton with the resin and made sure the fabrics is completely soaked with epoxy. I then put more cotton strips (4 layers)

- When finished, I covered the blade using plastic wrap.

- I then put the piece in a vacuum bag (in fact I use two to avoid leakage)

- I made the vacuum, sealed the vacuum bags and let the part cure for more than 12h.

Hero shots

It's amazing to feel how hard is the composite after curing and demolding. I think I would need to polish the blade to have a smooth finish. On the figure below, we can see the "rugosity" of the cardboard structure which could be a problem. So next time, as an improvement, I might fill the holes in between the structure with CNC cut foam parts.