Greetings, here lies my work-log at

______ _ ___ _ _____ _____ __ ______ | ___| | | / _ \ | | / __ \| _ |/ | |___ / | |_ __ _| |__ / /_\ \ ___ __ _ __| | ___ _ __ ___ _ _ `' / /'| |/' |`| | / / | _/ _` | '_ \| _ |/ __/ _` |/ _` |/ _ \ '_ ` _ \| | | | / / | /| | | | / / | || (_| | |_) | | | | (_| (_| | (_| | __/ | | | | | |_| | ./ /___\ |_/ /_| |_./ / \_| \__,_|_.__/\_| |_/\___\__,_|\__,_|\___|_| |_| |_|\__, | \_____/ \___/ \___/\_/ |_|

My final proposed project is a Compostiing bin which automates the process of agitatiting the compost for aeration, moisture control for odour-reduction, pH control and strives to gather as much data as possible to be interactive, insightful and entertaining.

Projects augmenting a WetGarbage Bin such as an automatic sorter? with spectral analysis capabilities perhaps (0_o) would be potential collaboration projects.

During the global lecture of week 9 (output devices) Fábio Pelicano borges vieira a student from FabLab Insper presented his final project which was a waste sorter! exactly what I presumed might be a potential collaboration. So, I decided to contact Fabio, but unable to find his contact details, I decided to email one of his classmates at random and emailed Victor Macul and never tell me the odds but Victor happens to be doing a very similar project as mine and we decided to help each other out with design issues and such.

Projects/Inventions augmenting a WetGarbage Bin such as an automatic sorter? with spectral analysis capabilities perhaps (0_o) would be potential collaboration projects.

NatureMill - Shortcomings identified

In-built agitator gets tangled with strandy and long items like a banana peel (a signature garbage item)

Low capacity

Expensive

requires manual pH-control and moisture control

Doesn't gather data

Not networked

In the first spiral of developing a robust composter, I've decided to complete the following simple components

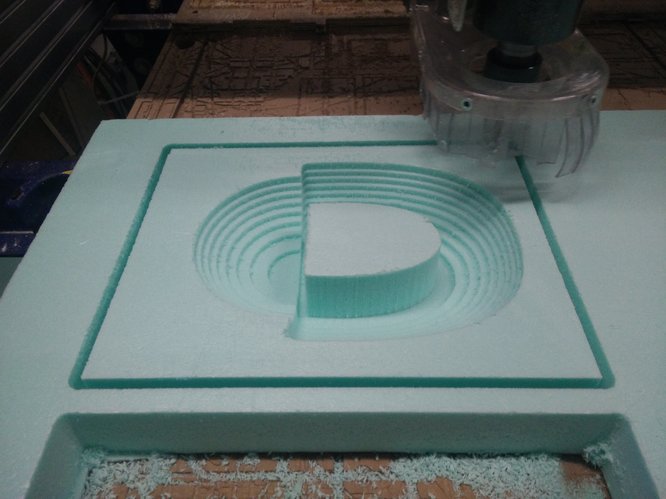

The design for the mold was milled in OnShape and milled out of XPS insulation foam, detailed workflow is documented in Composites week

The toolpath was generated in 'Partworks 3D' - more step by step documentation is in Composites week

After milling the layers of the mold, I used synthetic rubber based adhesives (Fevicol SH) to combine all the layers

Next steps were laying resin-soaked fabric pieces to form the composite part and applying pressure on the fabric layers using 2-part mold and clamps

the 2 parts are here temporarily joined by glue-gun magic, but a permanent fix would be laying strips of resin soaked fabric (the same kind used in the bin)

The coupler is intended to hold the acrylic brackets and couple it to the motor's shaft

It was designed in OnShape >> Exported to STl >> Imported in CURA >> exported as gcode and then printed in ABS material in an Ultimaker 2+

Input sensor - driven by attiny45

View post on imgur.com

Settings for MDF

| Speed | Power |

| 30 mm/s | 90 % |

Settings for 3mm acrylic

| Speed | Power |

| 20 mm/s | 70 % |

The motor board and the sensor board are not connected to each other, as I did not need to network them, the motor has to run in periodic intervals, and I'll be collecting the sensor data at odd intervals when I determine the need for it. The overall schematic of electronics is as follows.

The DC motor control board is embedded inside the bin-frame and the battery is located outside for easy replacement

void setup() {

// initialize digital pin 13 as an output.

pinMode(8, OUTPUT);

}

// the loop function runs over and over again forever

void loop() {

digitalWrite(8, HIGH); // turn the MOSFET-GATE on (HIGH is the voltage level)

delay(10000); // wait for 10 secondS

digitalWrite(8, LOW); // turn the MOSFET-GATE off by making the voltage LOW

delay(300000); // wait for 5 MINUTESThe temperature sensor board is attached to the lid of the bin, the idea is to have multiple sensor boards in further development, so another gas sensor board etc. When I have to take a reading, I insert the particular Lid i want.

#include //library to replace hardware serial

SoftwareSerial myserial(3, 4); // TX and RX pins (transmit and recieve)

#define tempPin A1 //Defining the pin A1 as the data pin

int val;

void setup()

{

myserial.begin(9600); //serial begins at 9600 baud rate

pinMode(A1, INPUT); //pin A1 becomes an input now

}

void loop()

{

val = analogRead(tempPin);

float mv = ( val / 1024.0) * 5000; //mapping analog values to relevant temperature readings

float cel = mv / 10;

float farh = (cel * 9) / 5 + 32;

myserial.print((char)cel);

delay(10);

}

Reasons for choosing the 'LM35' sensor over the one in the Lab-inventory

Senor integrated in the project - intent - is to use the project as a desktop composter (data collector) and have multiple lids - each lid with a different sensor but same FTDI RS 232 protocol communication.

final-project.zip

OnShape document holding all design files

Output-motor-controller board code

LM35 code input board