Week 6

Electronics Design

Assignment

- Redraw the echo hello-world board, add (at least) a button and LED (with current-limiting resistor)

- check the design rules

- Make it

- simulate its operation

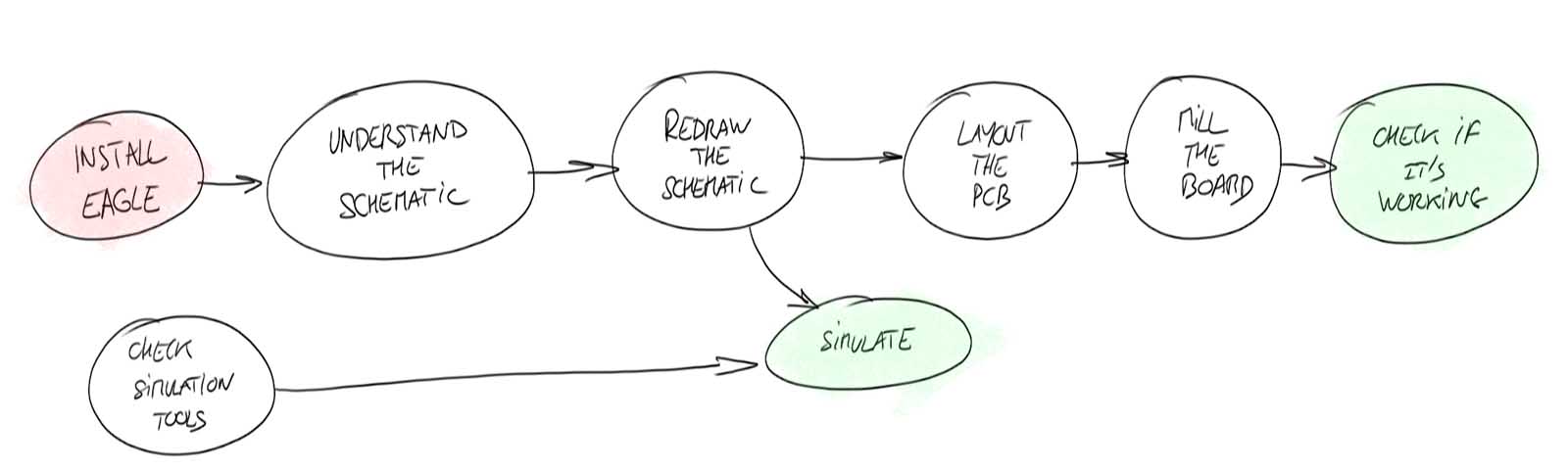

Week workflow

Here is how I see the week's flow :

Flow chart for this week

Table of content :

STEPS

Drawing the schematic

First We download and install Eagle.

Eagle Logo

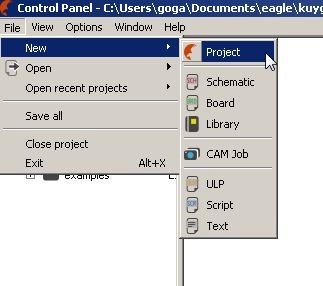

After we've done that we start a new project.

I'll name mine "My Echo HelloWorld Board"

Starting a new project in Eagle

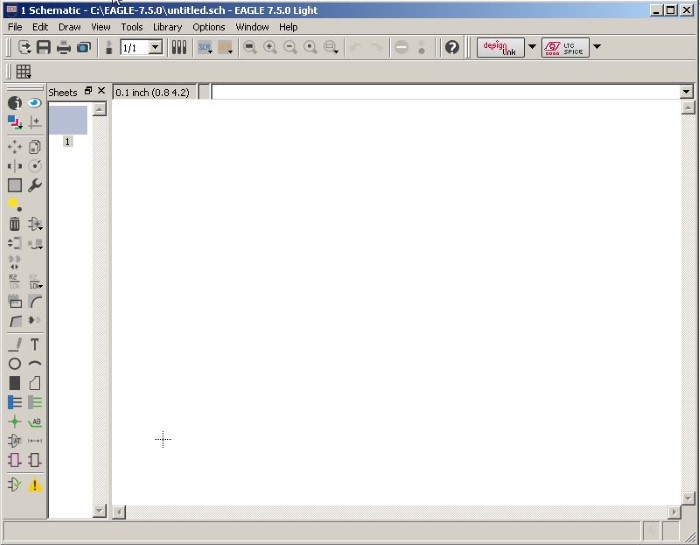

And in this project, we create a new schematic :

Starting a new Schematic in Eagle

We get the schematic interface :

Eagle's schematic interface - White Canvas

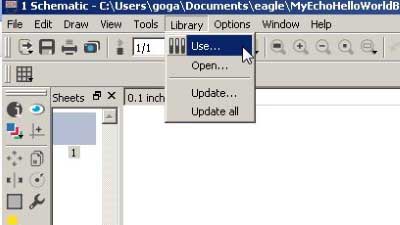

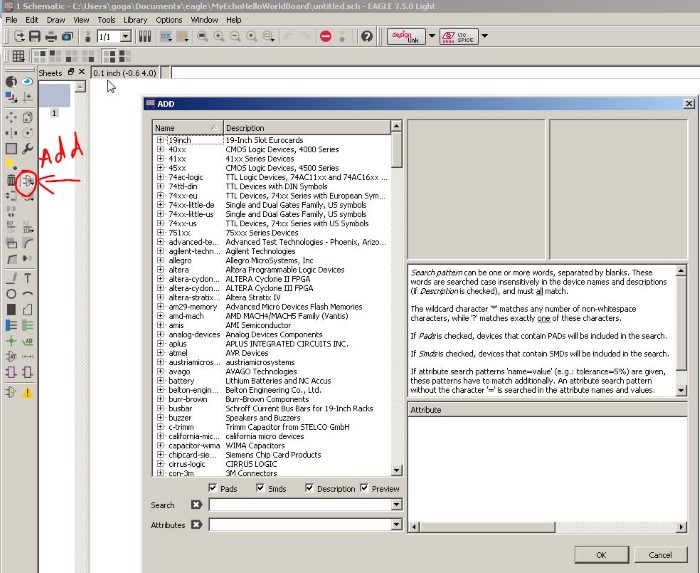

Then we have to add our components.

But before we do that, we need to add the library that contains our components. The fabacademy provides us with a nifty

fab.lbr

library that has all the components we need.

We import it in the install folder of Eagle, for me it's C:\EAGLE-7.5.0\lbr.

Then we tell Eagle to use it :

Specifying the use of the fab library

Once we've added the fab library we can go fetch them and add them on the canvas :

Adding components

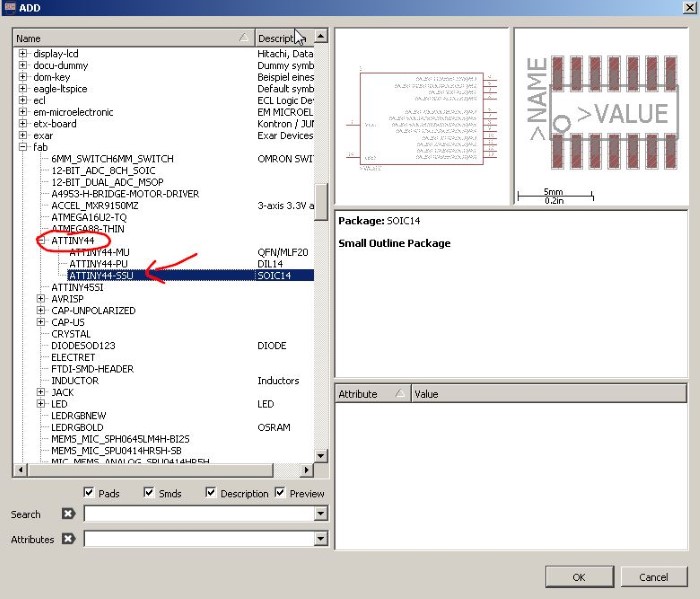

We then go to our fab library and add the components we need :

Selecting the t44 and adding it to the canvas

Sometimes there is several choices for the parts, for ex the LED :

Several choices for the LED

I choose the LEDFAB1206 cause I like the idea of being able to put a trace in between.

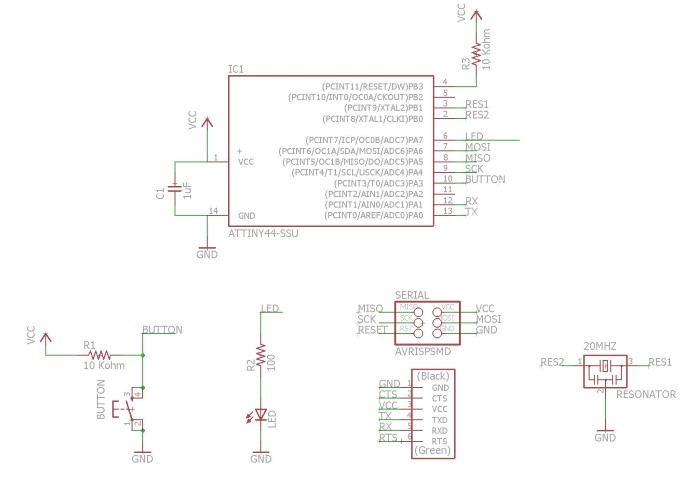

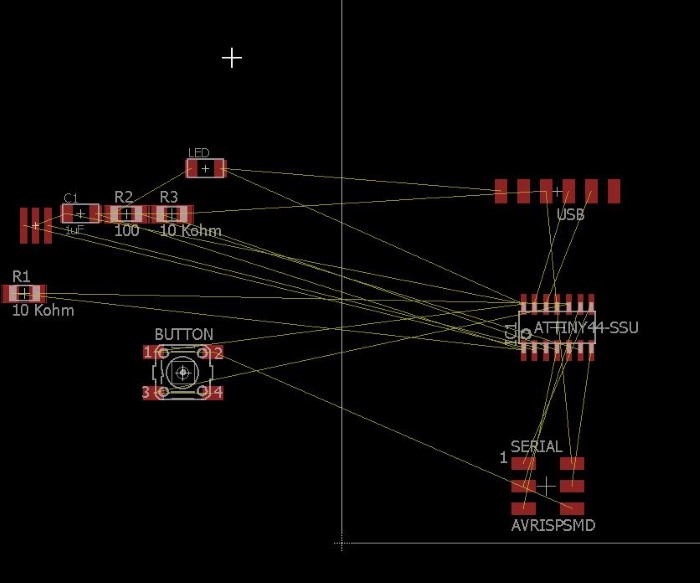

As required for this week's assignments, I add a button and a LED :

Schematic completed with added button, pull-up resistor and LED

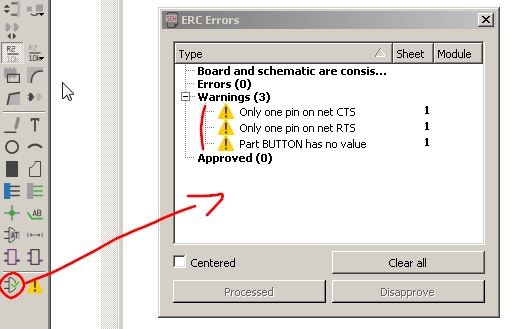

I check the ERC errors (I guess that ERC stands for Electrical Rules Control or something like this) :

Checking the ERC errors

Two warnings are just telling me that there unconnected pins, which is indeed the fact.

And the button warning is ok I guess since there is no value to this button component

Now has come the exciting time of the incredibly more fun game than tetris or sudoku : routing and PCB layout

Laying out the PCB

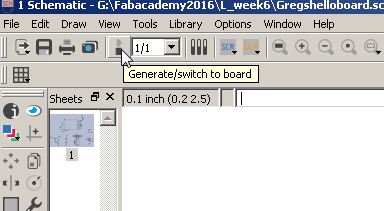

Clicking on the "board" button brings us to the PCB layout window :

The board button in the schematic window

The PCB layout working space canvas

Let me see, do I feel confident ?... hmmm. Alright, I decide to try to make my own design.

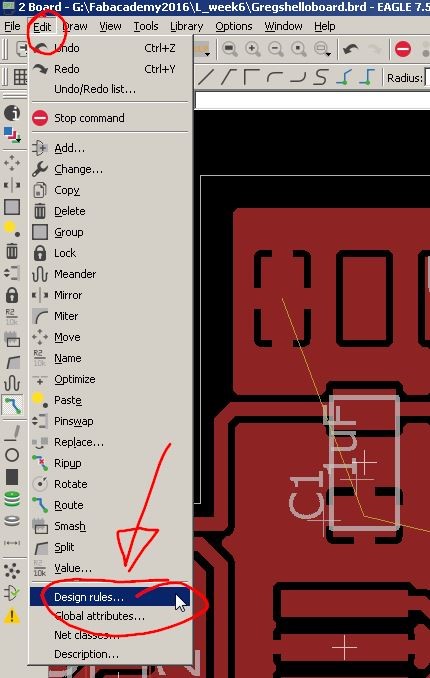

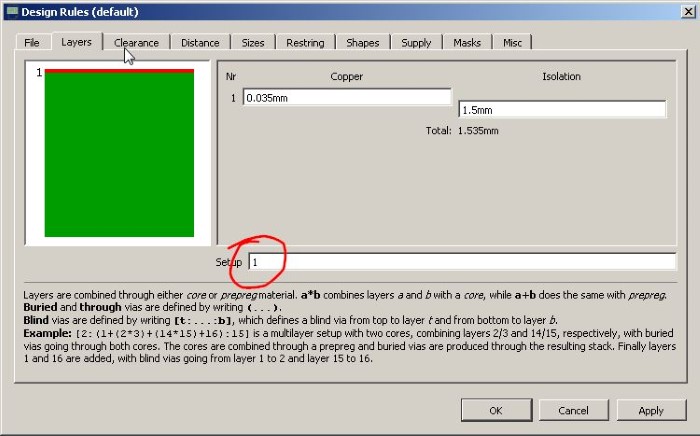

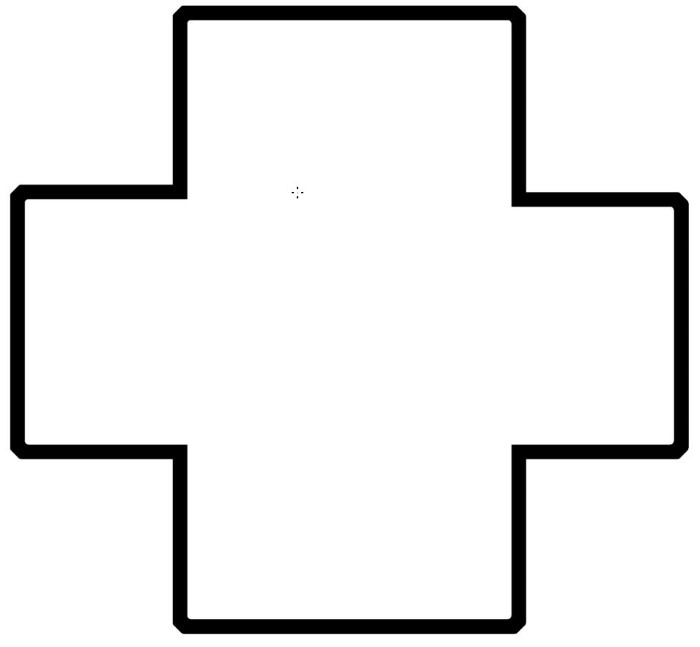

First I set up my design rules :

Checking and setting the Design Rules

I want only one top copper :

Only Top Copper

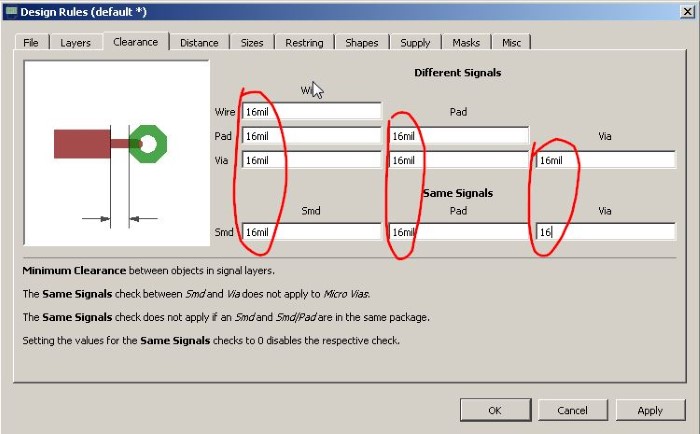

Because we use a 1/64 mil bit for milling the traces, which is a shy 16 mil, I define my clearances to 16 mil :

Setting the clearances to 16 mil

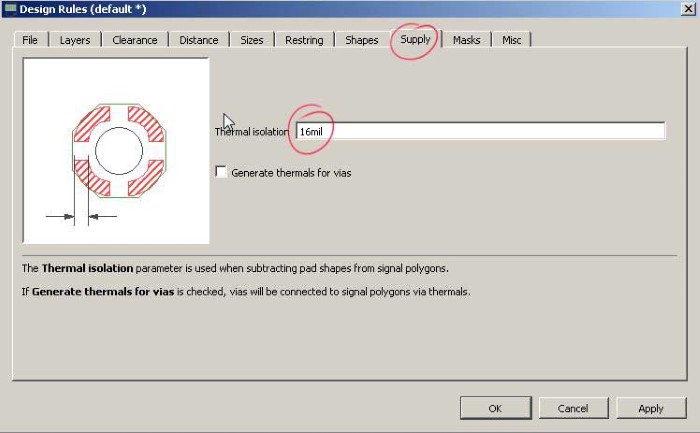

Since I'll be doing a ground plane, I need to define the clearance also fo the heat dissipation restriction feature :

Setting the clearance for thermal isolation

Since I'll be doing a ground plane, I need to define the clearance also fo the heat dissipation restriction feature :

Setting the clearance for thermal isolation

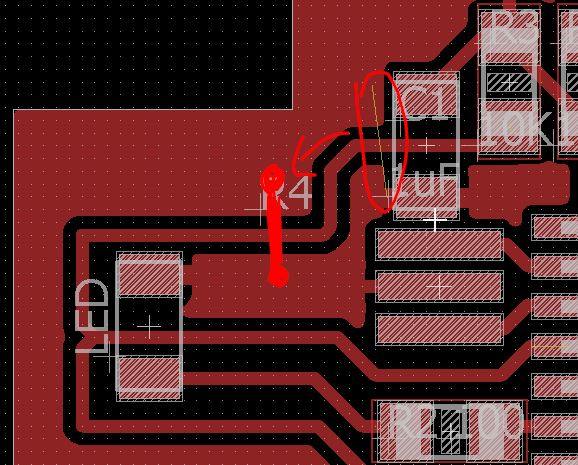

I get to a point where I need to connect two ground planes over a trace :

How to connect those grounds?

I decide to add a 0 ohm resistor.

I feel like I'm cheating but I decide to live with it, there's more profound issues in life.

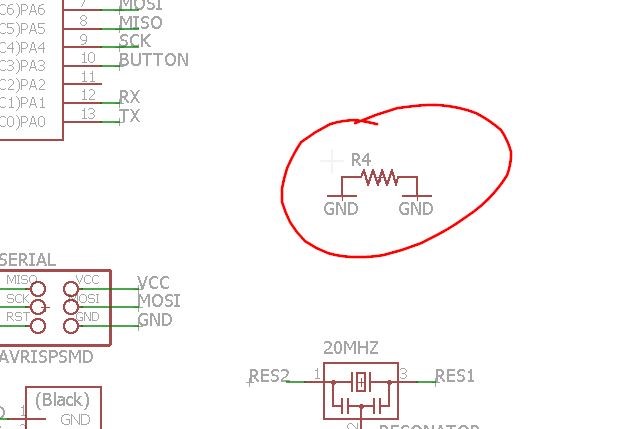

I need to add the fake resistor to the schematic :

Setting the clearance for thermal isolation

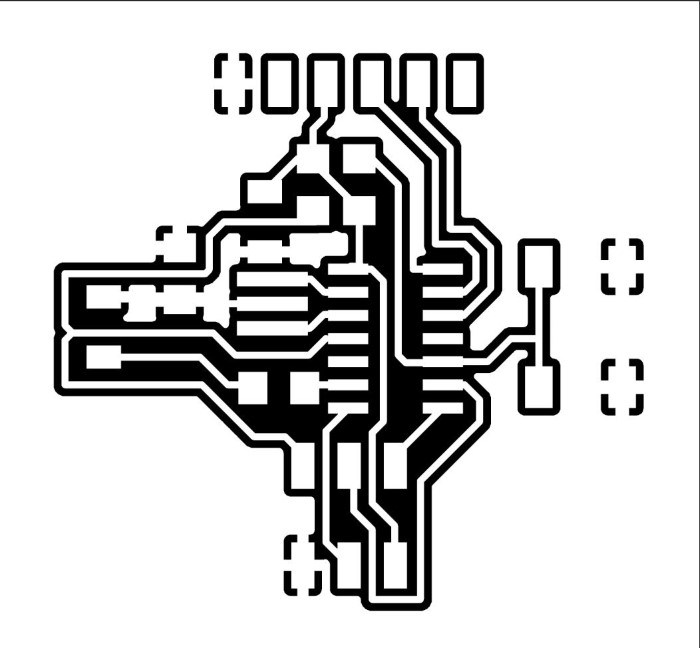

Then I place it on the completed layout, tada ! :

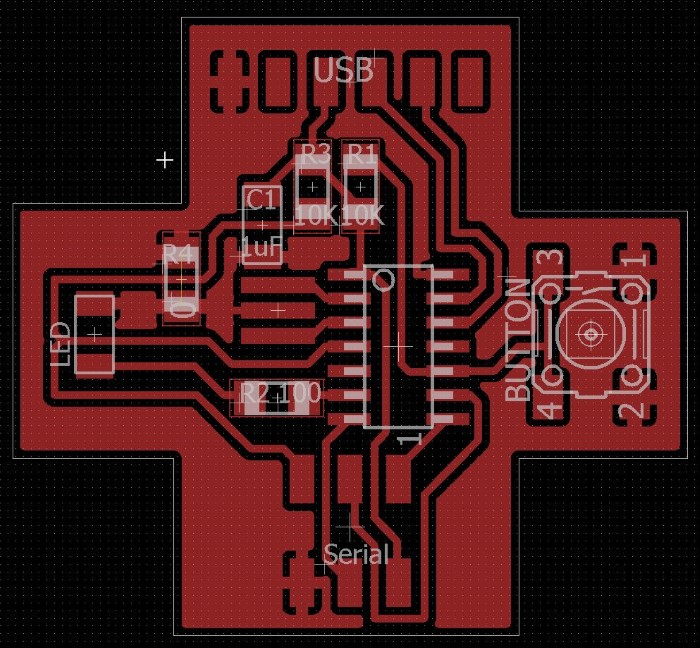

Completed pcb with the zero resistor

I check if everything is okay according to the design rules :

Checking the design rules

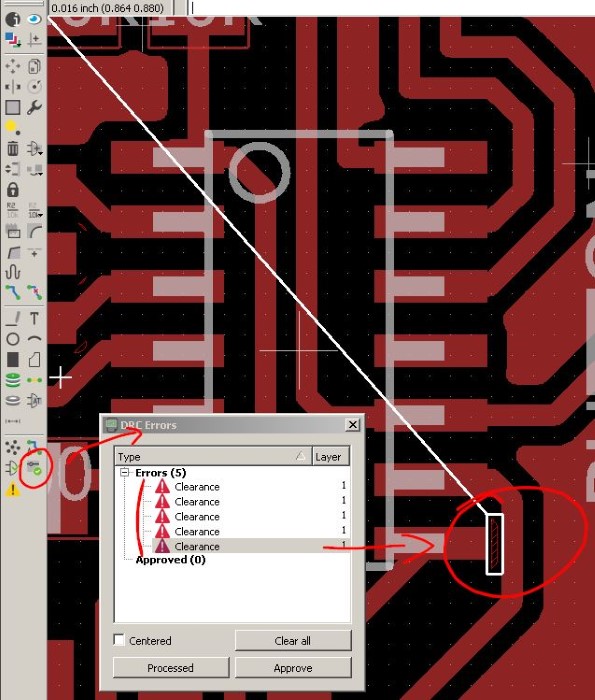

What??? Errors :

Design rules check errors

Oh! Okay I know how to fix this! Just a little bit of moving around for our milling bit to be able to cut here

There's still a yellow line between the pads of the resistor but I feel lazy to struggle. I know it's okay.

I feel happy and I'm all excited about milling it!

I first need to generate my PNGs

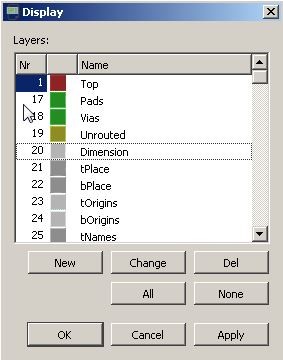

>I then select only the copper layer :

Selecting the top copper layer

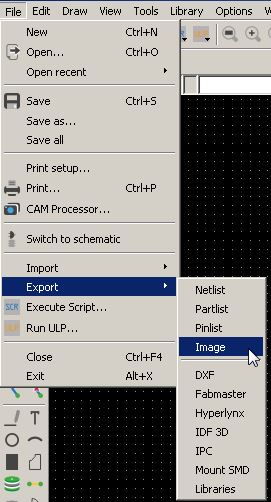

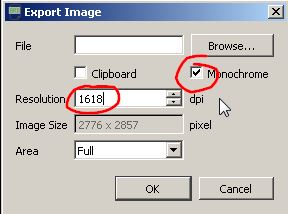

And export as an image :

Exporting as a PNG

In monochrome mode. I also choose a golden 1618 dpi just to bring me luck

PNG settings

Some basic raster image editing to generate the outline, and I'm ready with my two PNGs :

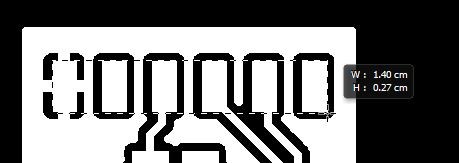

I'll just make sure the scale is alright :

Checking the Scale

1.4cm around the FTDI pads, exactly what we want. Good!

Milling

I'm then going to go through a process that has been documented in detail during a previous week : Electronics production

I'll just put here the important steps

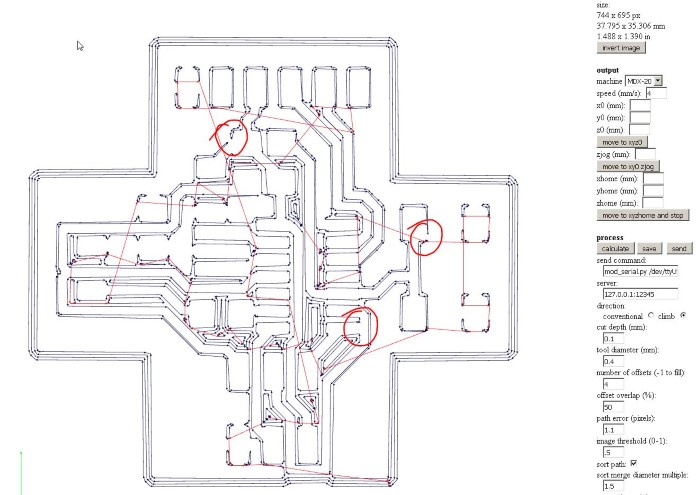

First, generating the path in the fabmodules didn't work completely. There was some merging :

Merging problem

Why is that? I don't really know since we have a clearance of 16 mil everywhere and the bit is 1/64 = 15.6mil.

Maybe something to do with the "path error" parameter

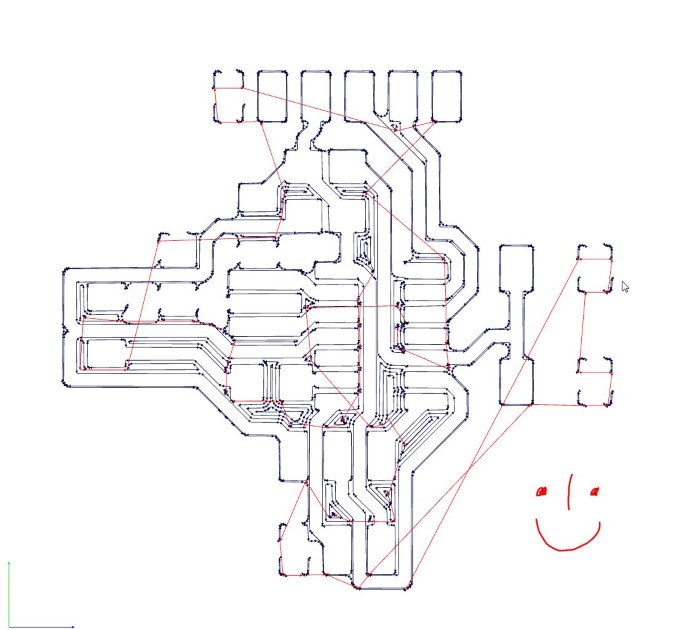

I decide to fix the problem by editing the image. I expand the black area in the traces PNG by one pixel. It works.

Merging problem adressed

Let's go for some milling on our Roland Modella MDX-20

Milling our board

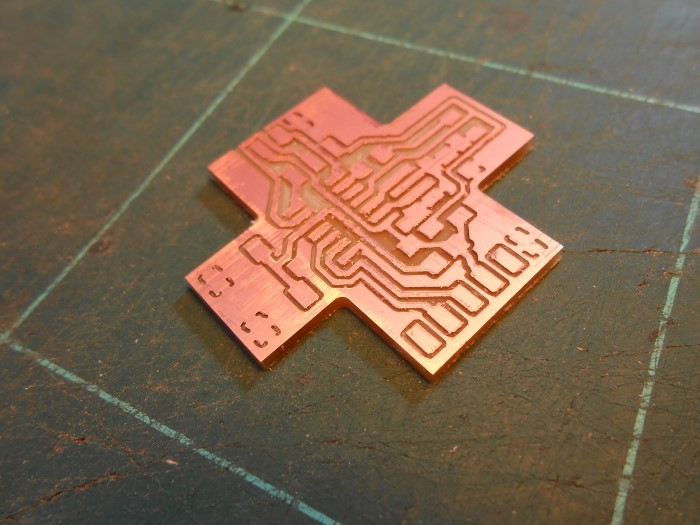

And there we are :

Board freshly milled

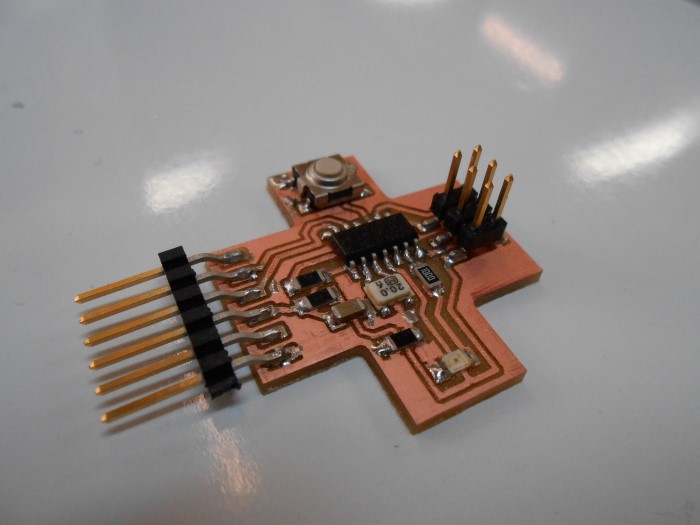

Soldering

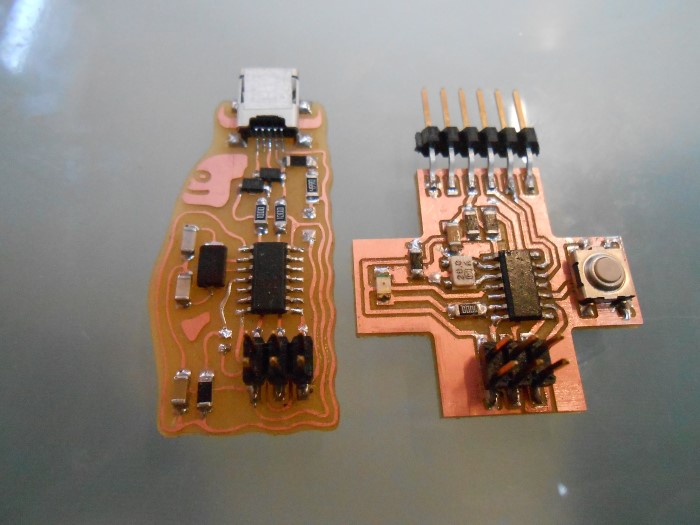

A little bit of soldering and...

Hero shot of the board

Just two notes on the soldering :

I had a doubt about the 10k resistors in the drawers, so I checked :

Making sure that we have a 10k ohms resistor

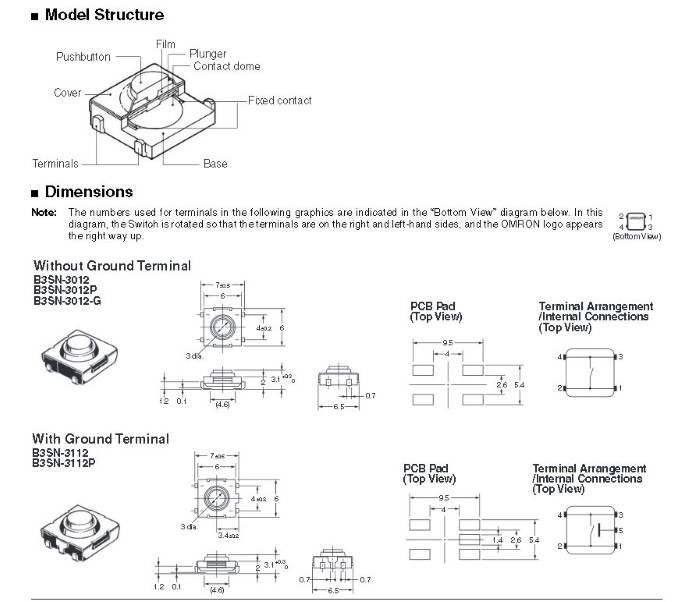

Also, I was unsure about the orientation of the switch, so I checked the datasheet

Checking the datasheet of the switch

At this point I can't resist the temptation of checking if the board is working so I try to do basic communication with it

Testing

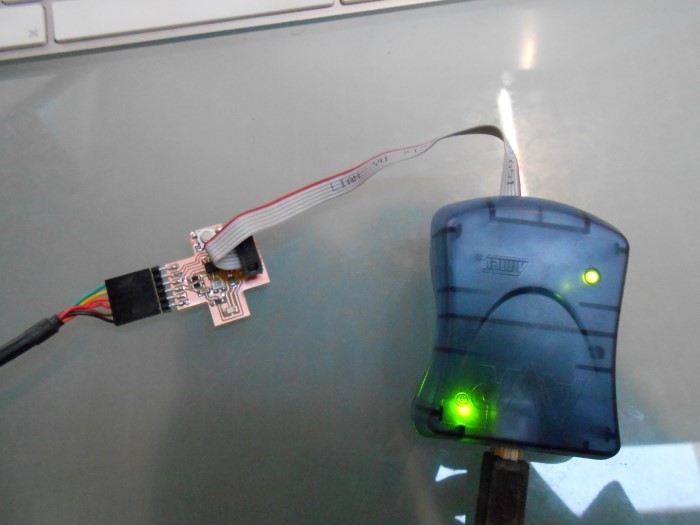

I then hook it up to the avrisp as follows :

Establishing connection through Avrisp

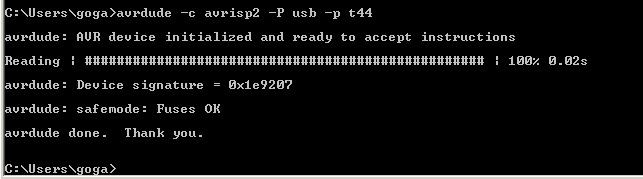

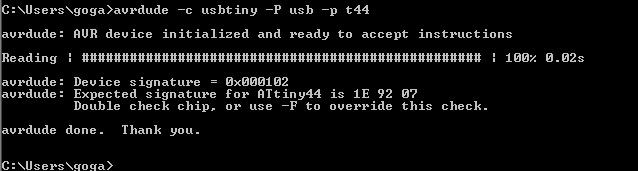

and type in a terminal :

avrdude -c avrisp2 -P usb -p t44

And it works ! :

Working connection through AVRisp mkII

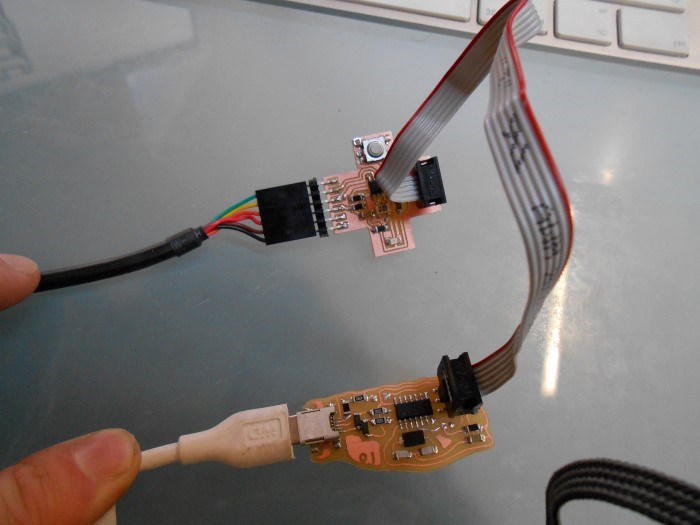

same thing with my FabISP :

avrdude -c usbtiny -P usb -p t44

Establishing connection through the USBtiny

Working connection through the USBtiny

I notice however something weird with the signature. I'll invesrigate thsi later

Happy family board shot

Happy Board family

Simulating

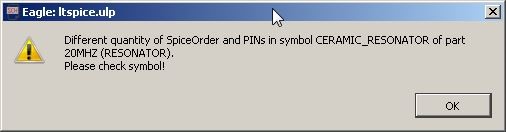

Finally I wanted to try the simulation from Eagle but I get a error message :

Error when simulate

I quickly check on forums about this error, and it looks like it's not something obvious.

I decide to give that up since I don't have the time right now

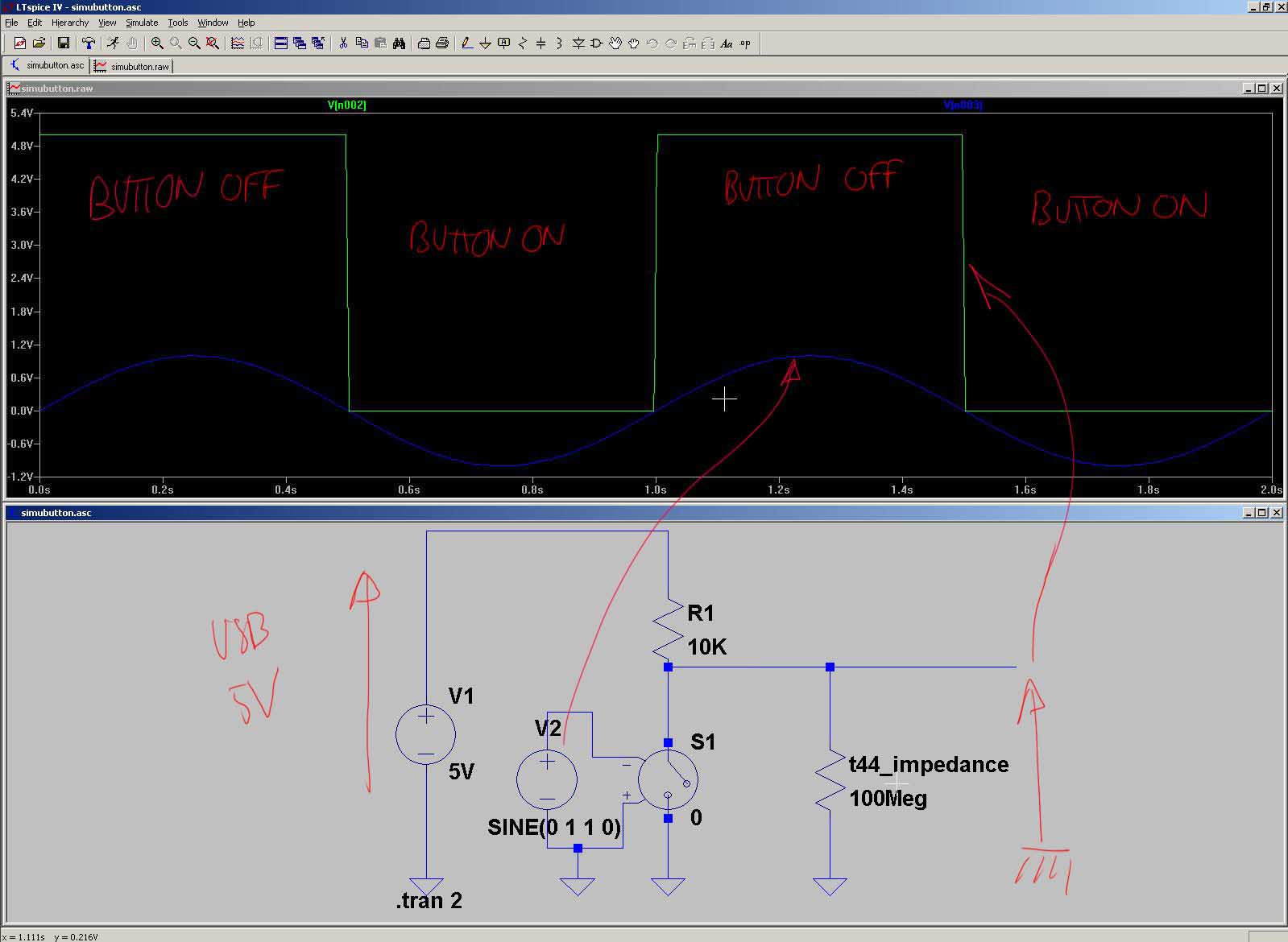

I still wanna play with the simulation tool though. So I draw and simulate the pull-up resistor system in LTspice :

Simulation in LTspice

To emulate the button ON and OFF I didn't find anything better than hooking up a sine to the driven switch.

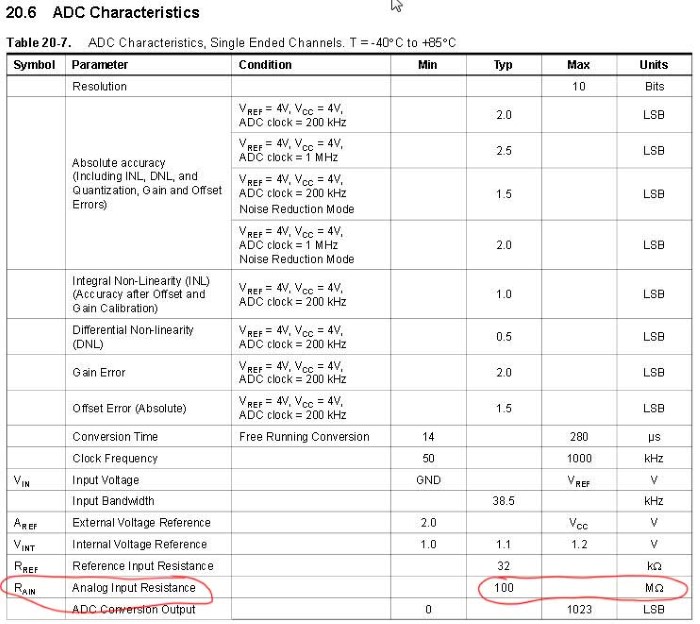

And I think I found the impedance of the t44 on the datasheet, p 177 :

Impedance of t44 in pin

We can see that as soon as the Button is Off, the voltage read by the t44 is quasi-5V, i.e. "High", pulled-up by the 10k resistor.

It is in fact, since we have a voltage divider, expressed in kohms : 100000/(100000+10) = 4,99V. Perfect "High" state

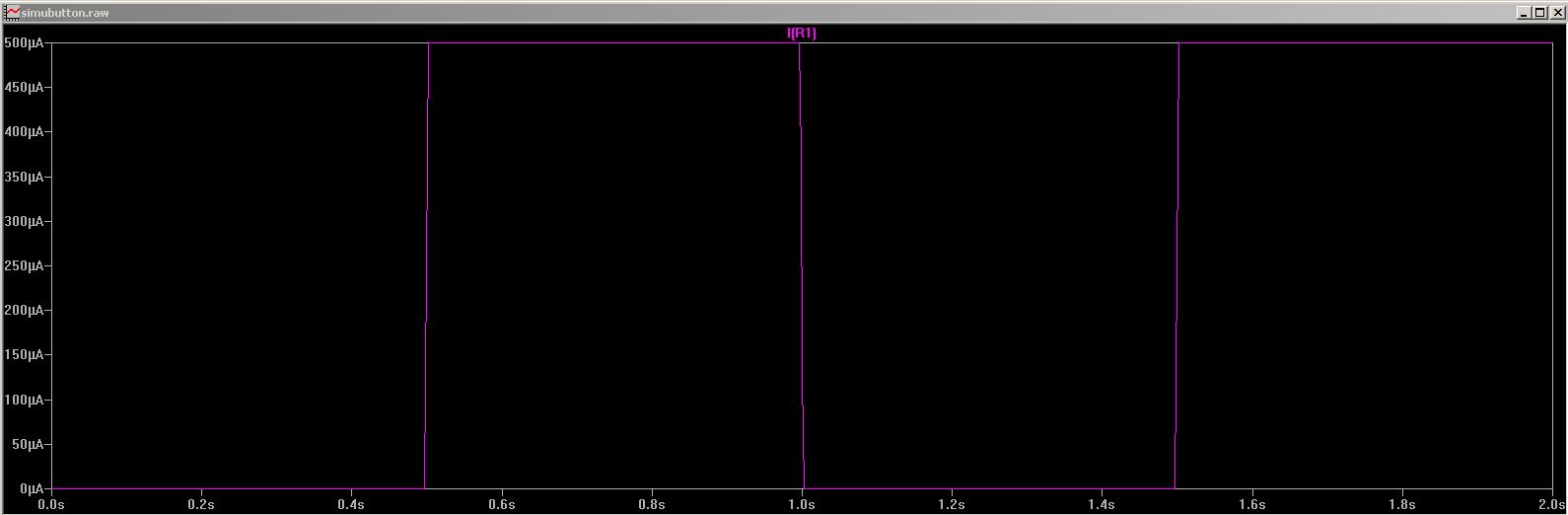

If we check the current when the button is on to make sure we don't use too much power :

Current in pull-up resistor

We read 500uA, which is exactly what ohm's law says : V = R.I => I = 5 / 10000 = 0.00005 A

That means P = R.I.I => P = 10000*0.00005*0.00005 = 25 micro Watt.

I think we won't blow the house's fuse...

Sources Files

Here are the sources files of the projects I talked about on this page :

EAGLE - Schematic

EAGLE - Board Layout

PNG - traces

PNG - Outline

LTSPICE - Pull-up simulation

Conclusion

***