Molding and Casting

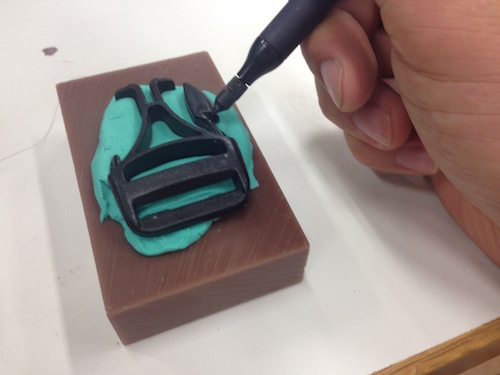

I want to fix strap buckle once broken.

◆Scan by Microscribe

First, I scaned broken one by microscribe, a kind of 3D scanner.

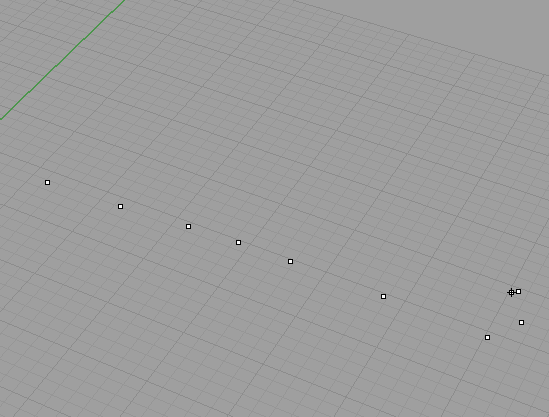

You can prot points on Rhinoceros with pen shape device.

After roughly scaned whole shape, fix and create 3D shape.

I use Rhinoceros commands below.

- InterpCurve

- CurveThroughPt

- Split

- Sweep2

- EdgeSrf

- etc...

※ I wrote detailed instruction on Fabble for other lab member.

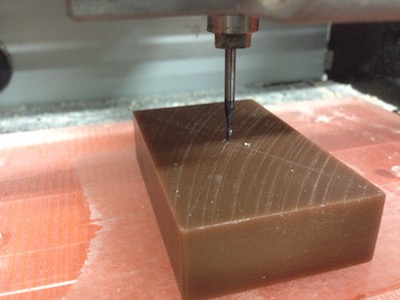

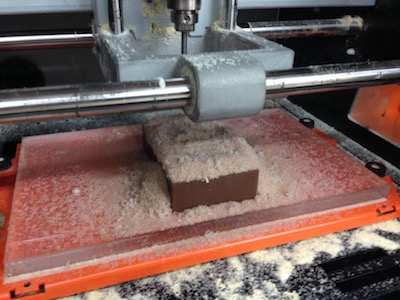

◆Milling by SRM-20

I used SRM-20 for milling modeling wax with 1/32 inch drill bit.- Open MODELA Player 4.

- Import stl file

- Select tool shape

- Generate tool path

- Set the center point on material by V-panel.

- Run the tool path

So I thicken them and create new tool path.

◆Molding and Casting

Let's work with clothes can be dirt.

This time, I use these materials below.

- Smooth on Silicone Rubber.

- Hobby Cast ーThis is Hard polyurethane resin.

- Make outer wall with laser cutted acrylic. Smear barrier coat on milled one.

- Measure and pour silicone rubber. Wait for 24 hours,,,, and got a mold!

Some place were not filled with silicone and has lack.

I guess measruement was a little incorrect.

- Pour cast material, and wait for a while...

It got be white and have heat!

◆Result

Finally, I got 3 types of buckle, original / 3D printed / casted.

I made them from scanned data, but their shape is little different.

I need to scan more correctly, or change model by each method.

(Ex. For casting, I think need a little bigger model.)

Sadly, casted model has no rigidity, broken.

But I think it's good try and want to use another material or new way!

Mold files is here.

FeedBack

・I can use glass fiber to reinforce.・Ex. FRP(Fiber Reinforced Plastic) → glass mat

・I can also mix strong / flexible materials.