Molding and casting

Assignment for this week

- Design a 3D mold, machine it, and cast parts from it

- Learn how to mill wax on the ShopBot

- Learn how to work in PartWorks

- Link to this week’s home work page

This page is organized as follows:

Milling the mold

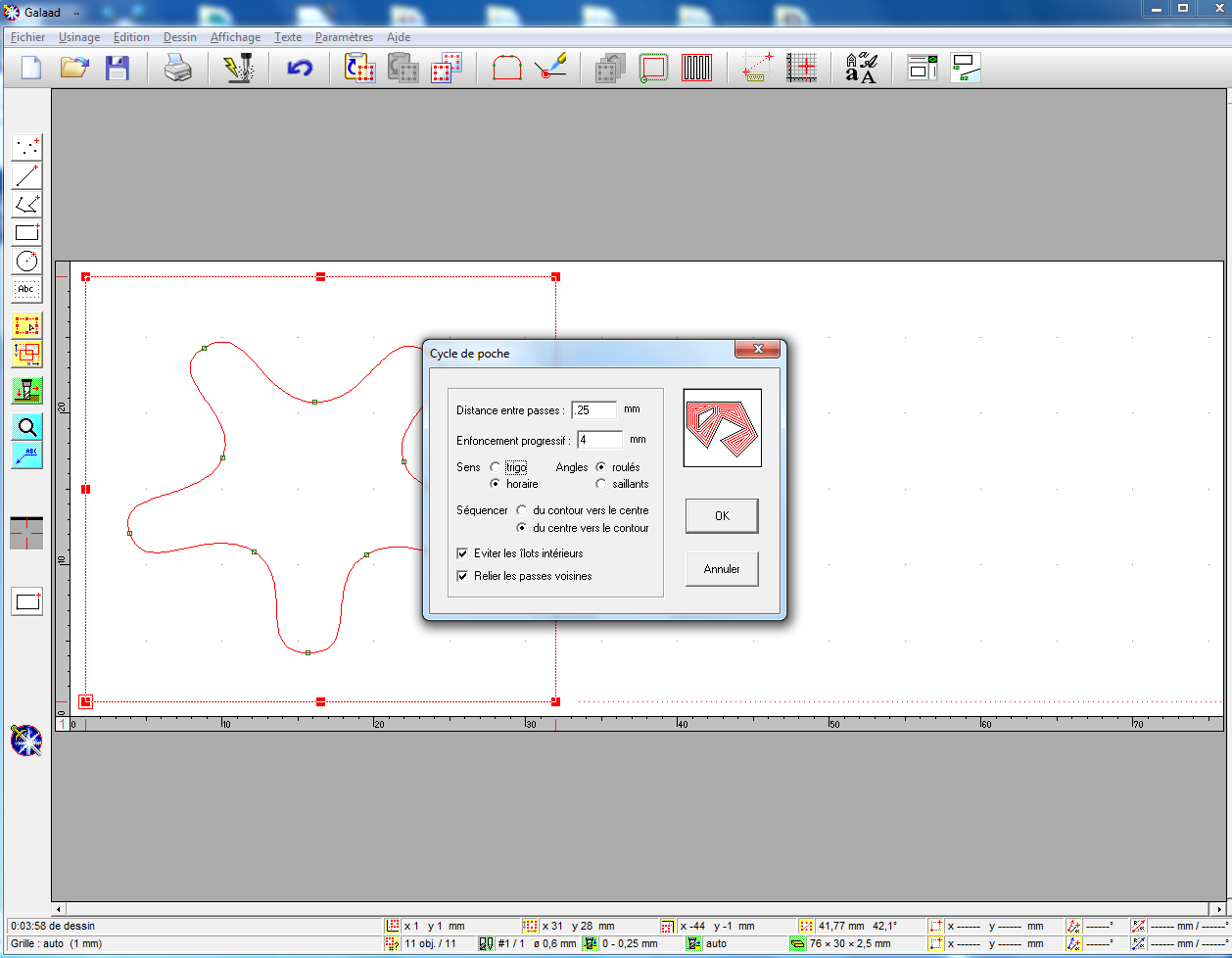

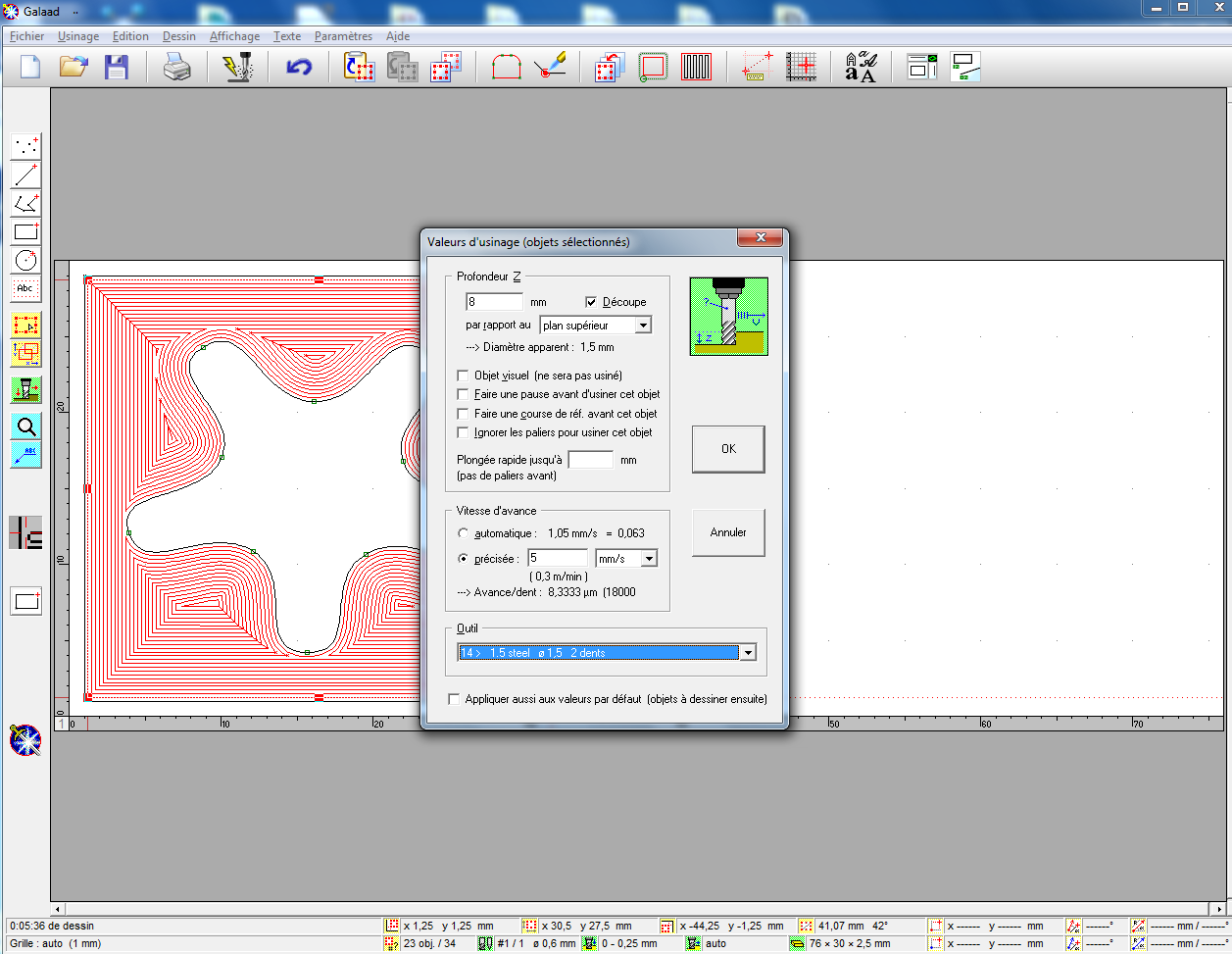

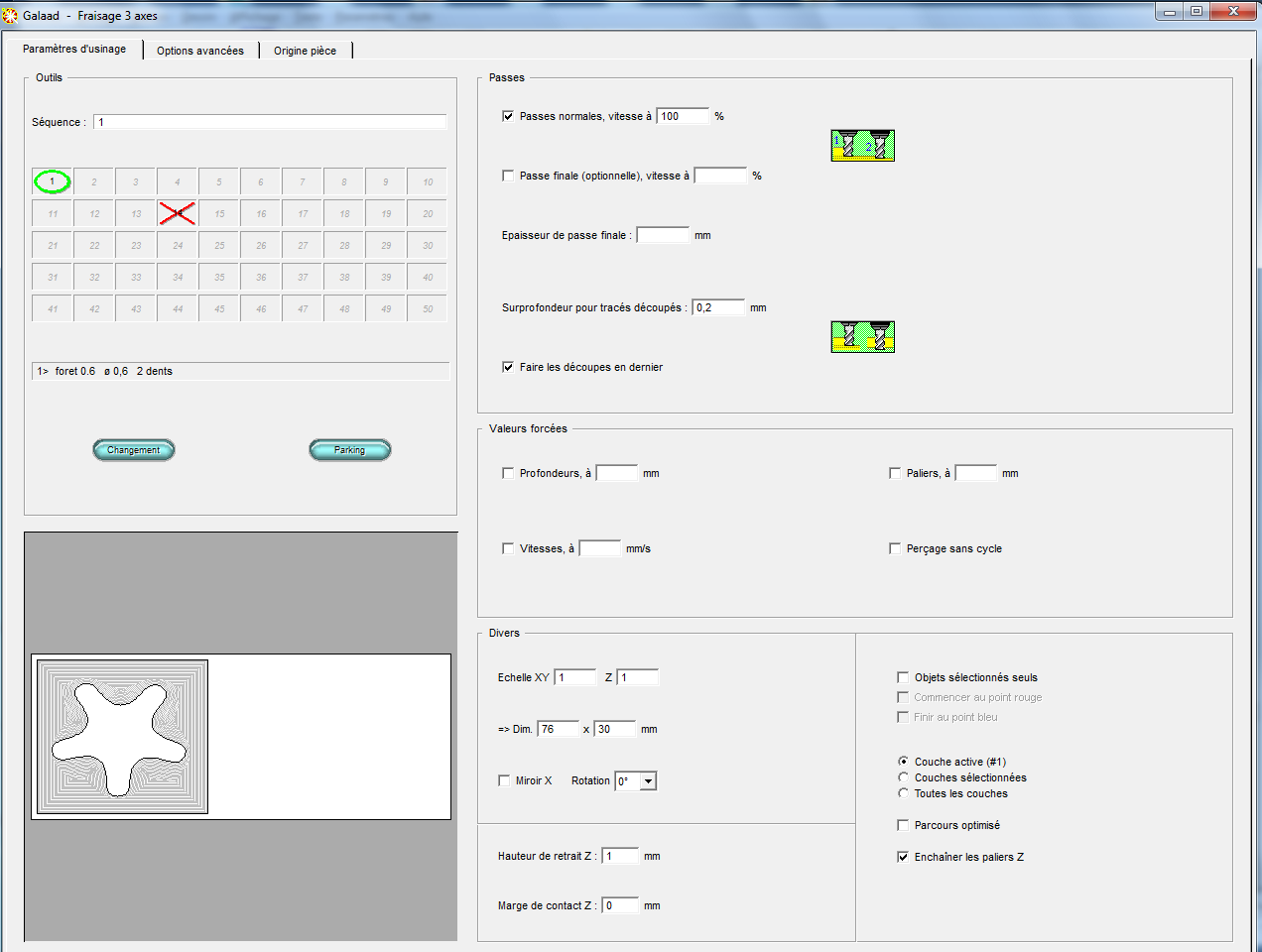

For this assignment, I decided to prepare a star shaped mold. The design was done in Inkscape, exported in dxf and imported in Galaad, the software used to drive our CIF Technodrill CNC.

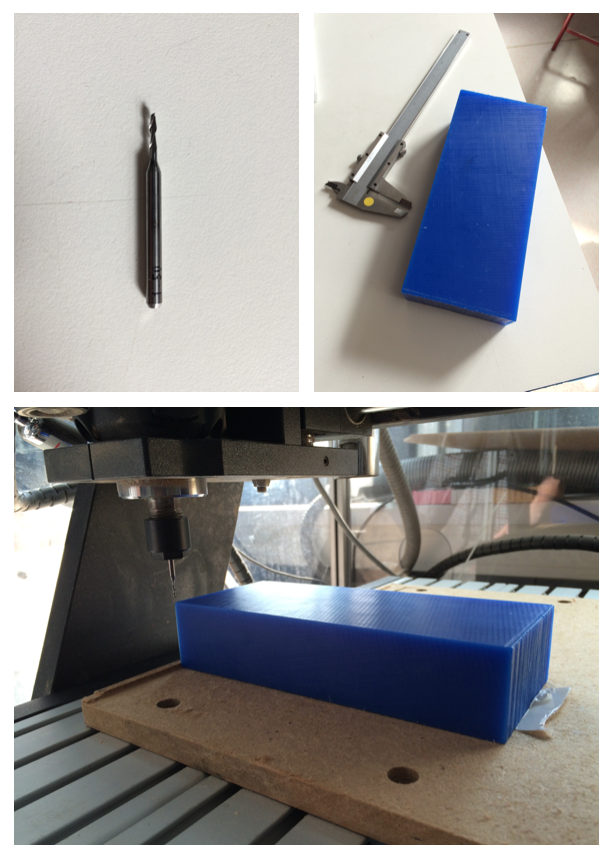

The mill is a 1.5 mm cylindrical mill. The distance between passes was set to 0.25 mm.

The total depth was set to 8 mm and the feeds to 5 mm/s.

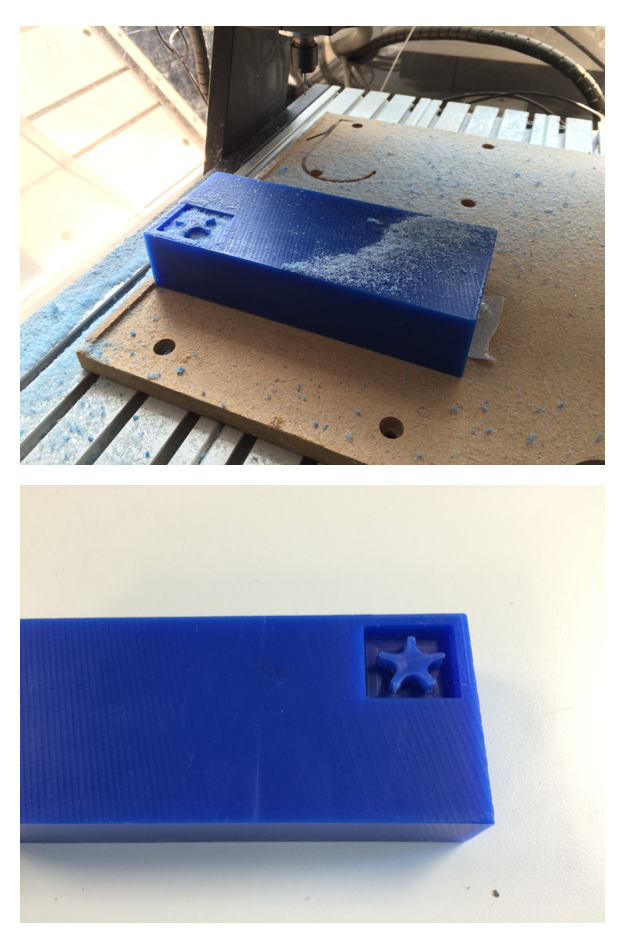

After installing the mill and the wax,

And zeroing properly the machine,

The milling process started and I obtained

Molding and casting

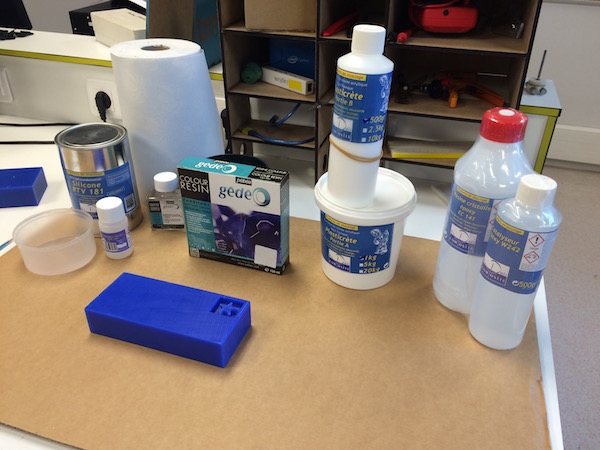

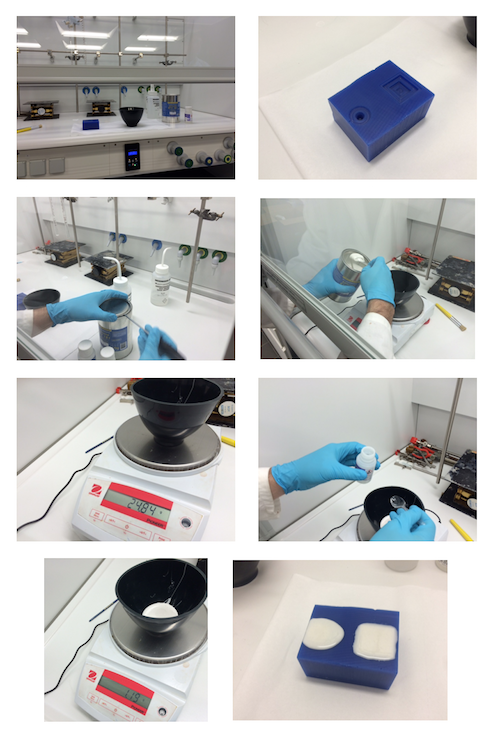

To prepare the mold we baught different chemicals:

- an elastomer solution silicone RTV181

- two catalyst solutions that can be mixed with the elastomer solution to obtain the soft mold: a slow catalyst with a 24h drying time and a fast catalyst with a drying time of 2h45 (for 5%).

- a thixotropic agent and silicon oil to adjust the viscosity of the elastomer solution.

- an acrylic resin solution Plasticrète that comes in two parts A and B that should be mixed (100g of A for 50g of B) to obtain the final product after 3h.

- 100 mL colour resin Farbharz Pebeo Lapis Blue A

- 50mL colour hardener Farbharz Pebeo Lapis Blue B to be mixed with A in a ration 2A:1B. Drying time 24h

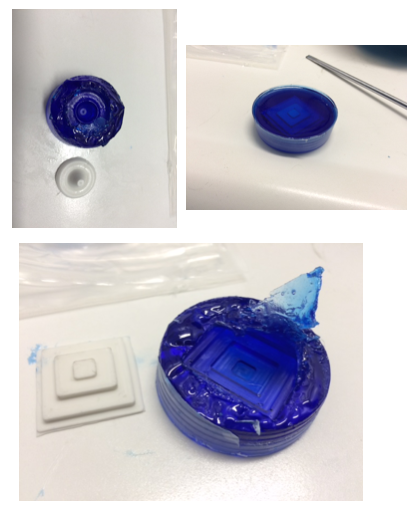

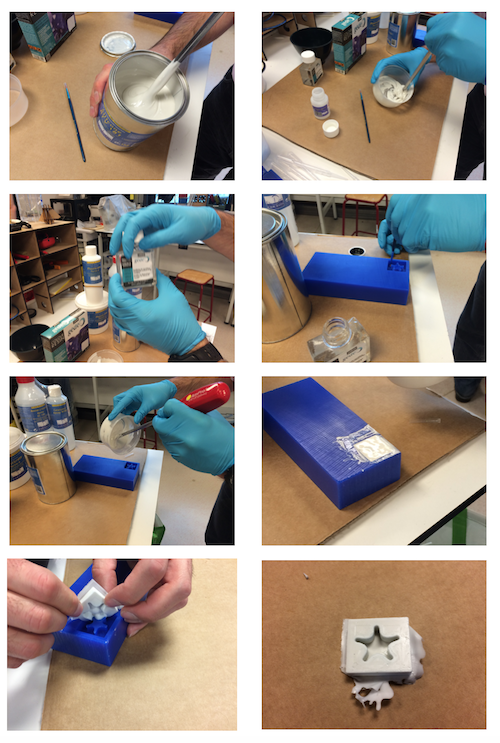

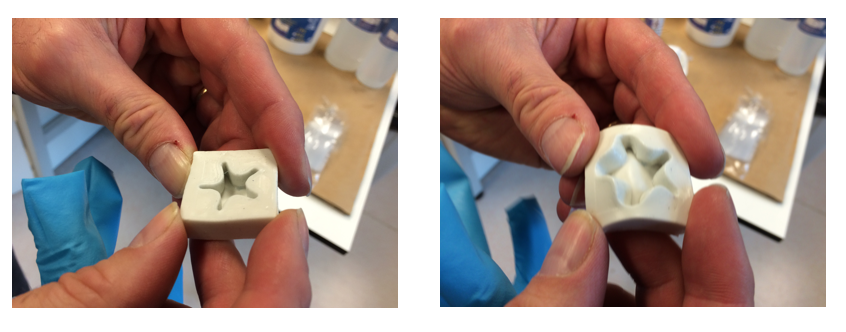

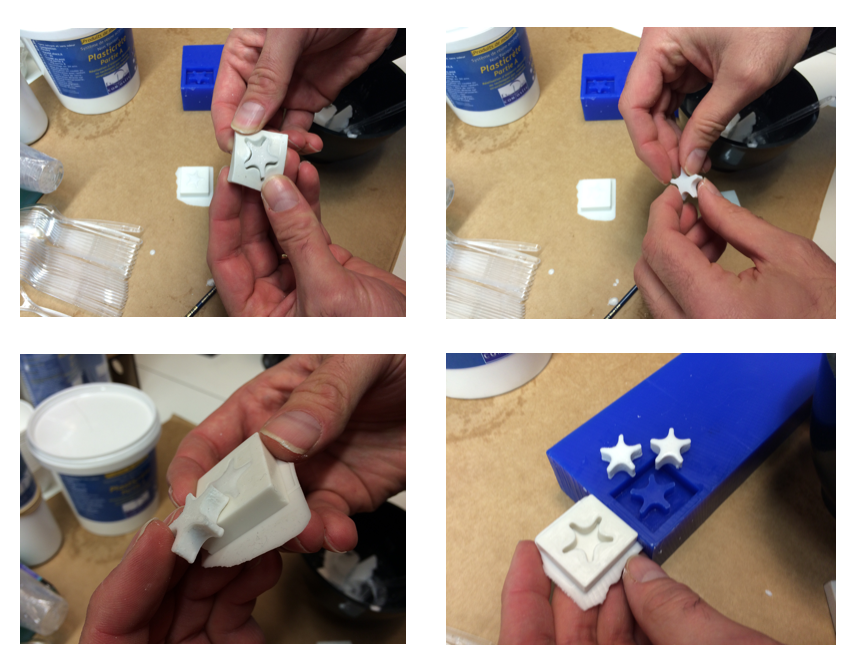

The preparation of the soft mold is pictured below.

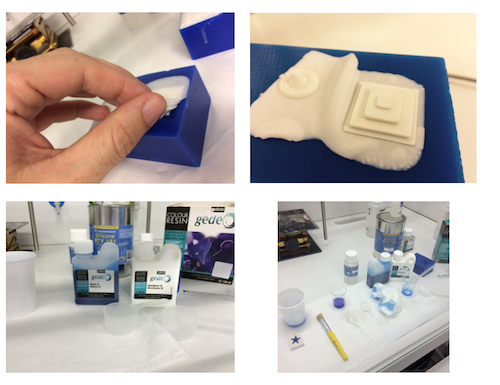

The soft mold is indeed soft.

Then we add the final resin and wait.

Molding and casting revisited

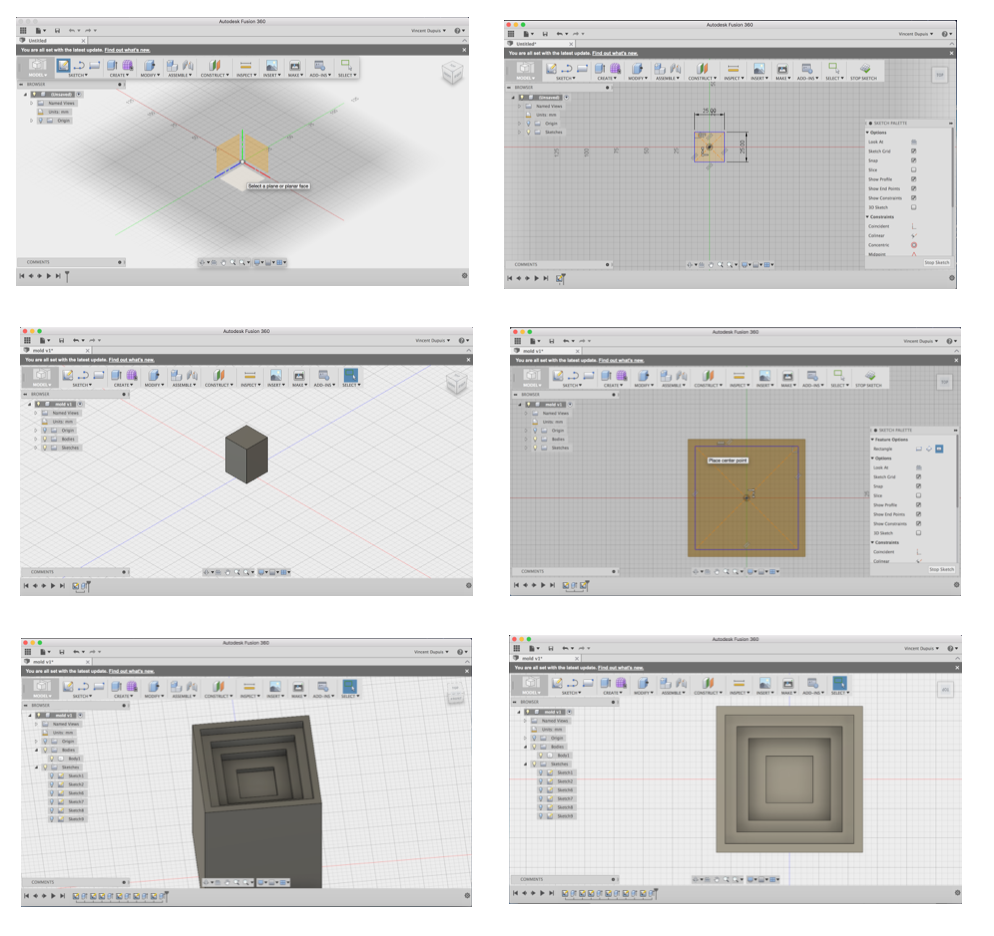

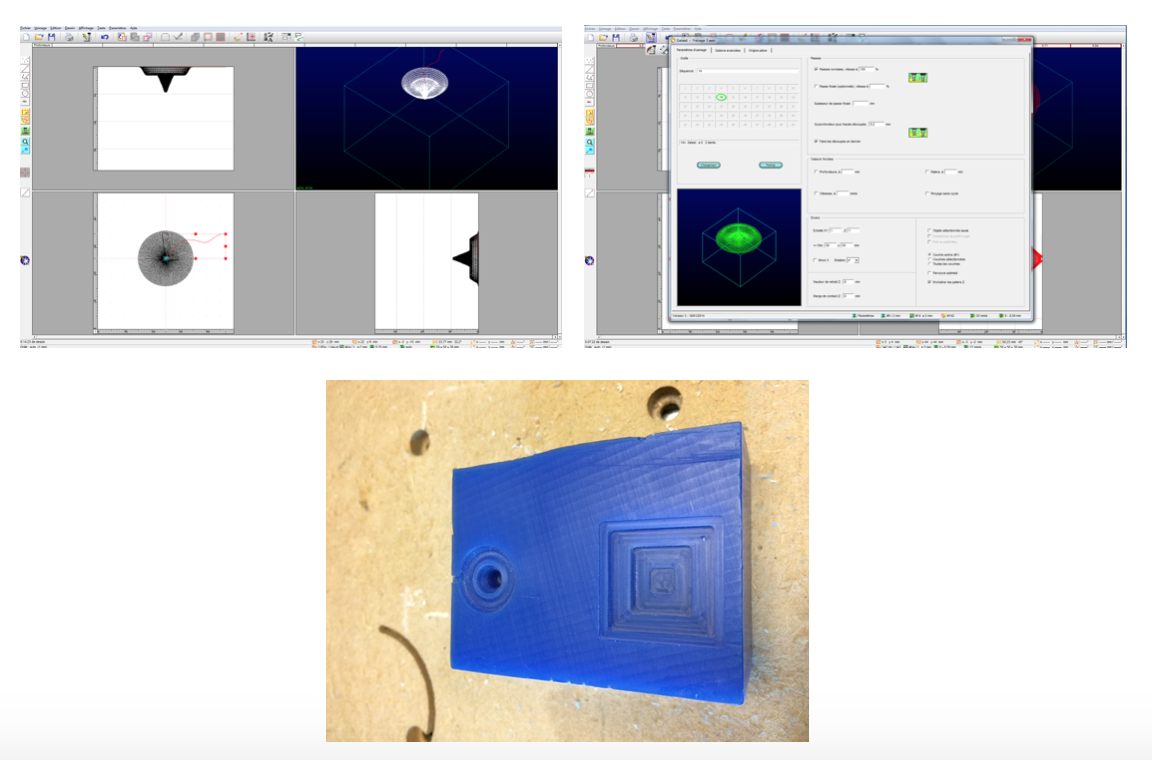

Since our instructor told us that we were not authorized to work in group, I repeated the assignment.I designed an inverted pyramid in Fusion360.

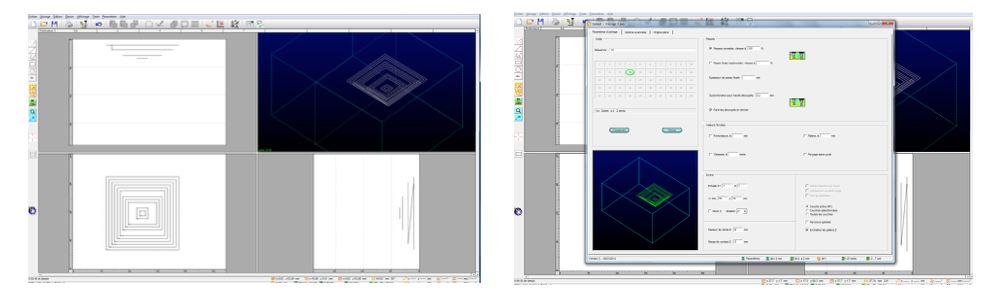

I exported into dxf and imported into Galaad, the software that controls the CNC.

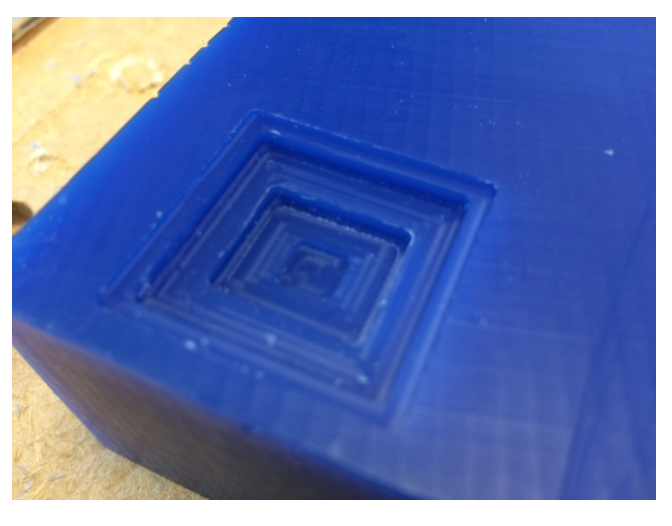

I milled the wax and obtained:

I also designed and milled another more rounded mold using Galaad:

I prepared a soft mold by mixing the silicon resin and hardener.

After one day I could demold the soft silicon mold and cast blue epoxy resin. I mixed the resin and its hardener. Contrary to the star, the soft molds are placed at the bottom of containers (cups here) and covered with the mixture of resin and hardener.

After a few days, I tried to demold. It was not easy and moreover I really that it was not completely solid. It worked but the process must be improved.