Applications and Implications

For Project development please go here

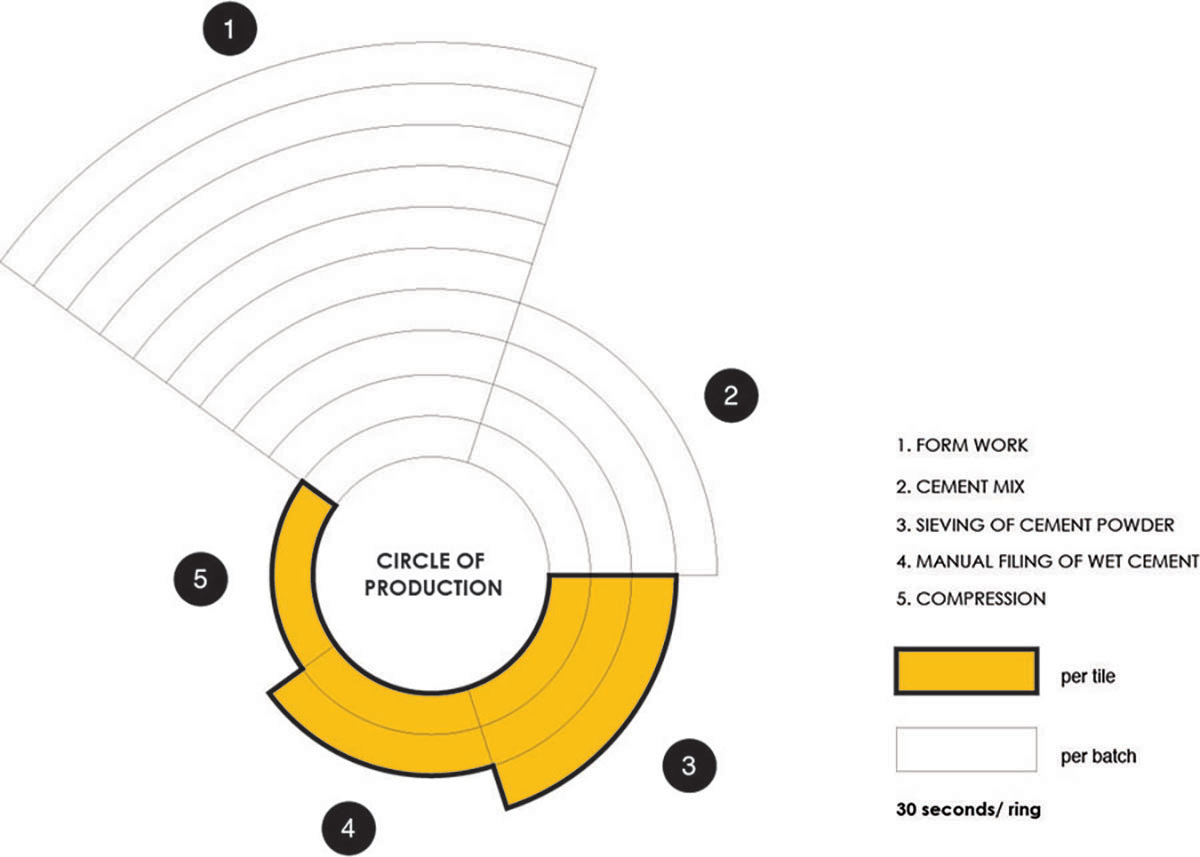

Hydrobot is an initiative to develop the manufacturing process of hydraulic tiles. First references of such tiles date back to 1857; yet its popularity started when presented as an alternative product to natural stone (marble mainly) at the Universal Exhibition in Paris in 1867; presented as a kind of tile that did not require cooking but was consolidated by pressing . The process and design stem from the art nouveau period : the drawings representing geometrical, floral or vegetable forms. Today such tiles are still widely popular especially in certain parts of Europe. However the trade is diminishing; and left in the hands of small family business's that still manufacture in a traditional manner. With the rise of digital tools and digital processes such as parametric design and cnc tooling in the context of fab labs; new craftsman are born; allowing the opportunity for more research and experimentation in variation and customization.

Preliminary concepts..

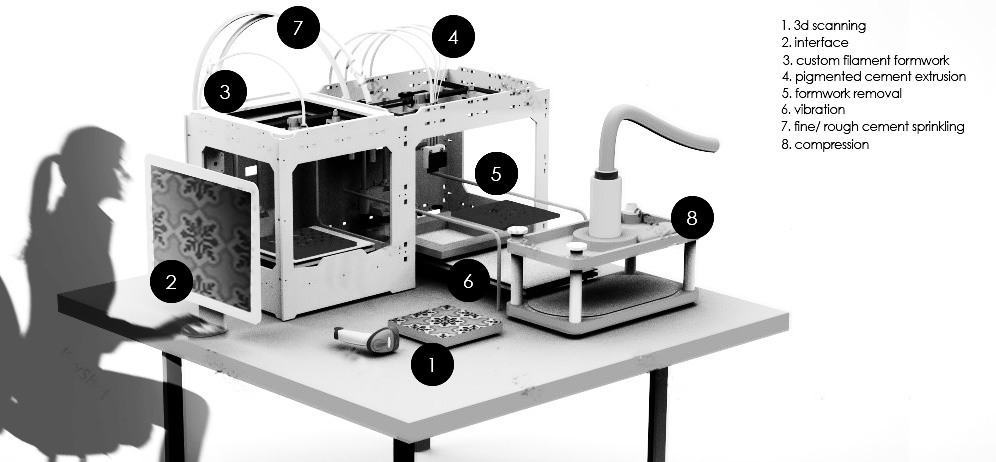

The Machine could include a user friendly interface allowing for different customizable patterns and work as a multi-tasking 2d/3d printer. The main challange is create a user friendly machine that can work with other tools found in a fablab and reproduce similar monotonous tasks that the craftsman does (i.e. placing of cement, removal of frame, sieving and compressing...) Thus expanding the possibilities of a fablab.

The idea is to develop my own my machine based on existing systems from mechanics to electronics. Therefore giving the project a unique application within the concept of digital fabrication.

There are many projects attempting to 3d print ceramics and cement mainly using robotic arms; however this is a unique application as it attempts to merge the ideals of ngos like Anda together with fablabs agenda of emporing through technology. Anda Project is an initiative that aims at repairing the relationship that communities establish with common spaces by creating situations where artists, architects, students and neighbors design and build cement tiles with the purpose of placing them within their local communities- i have been in contact with them to bring this project forward; hence moving into a fusion of education; digital techtonics and craftsmanship.

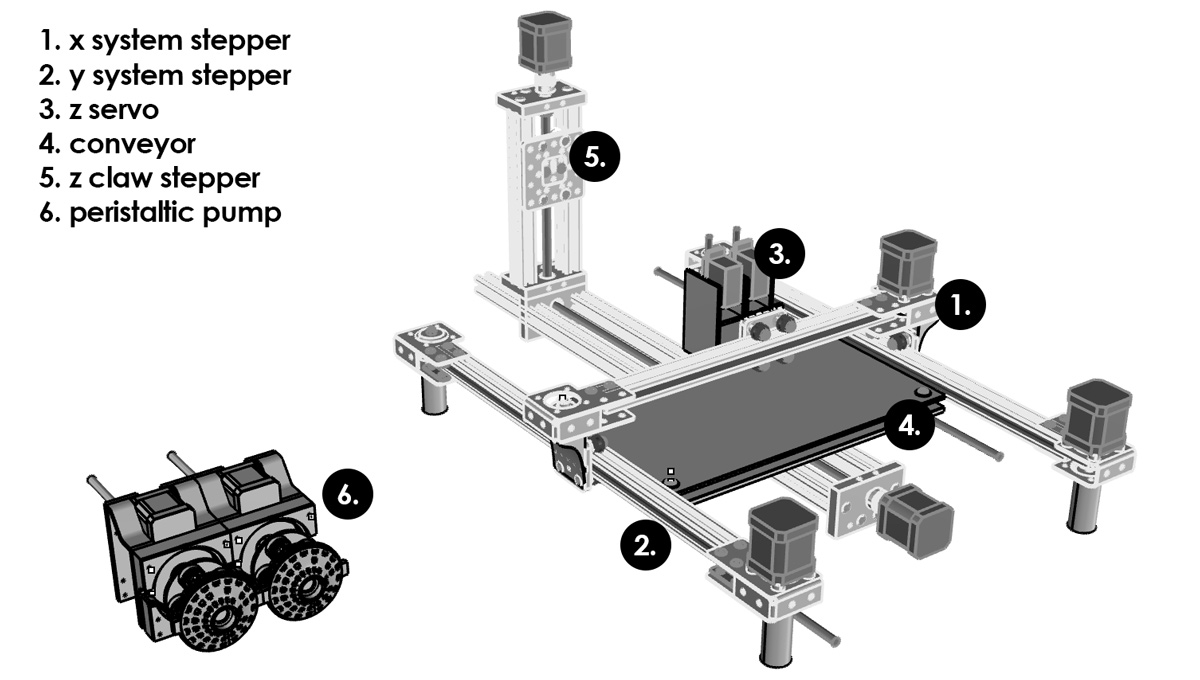

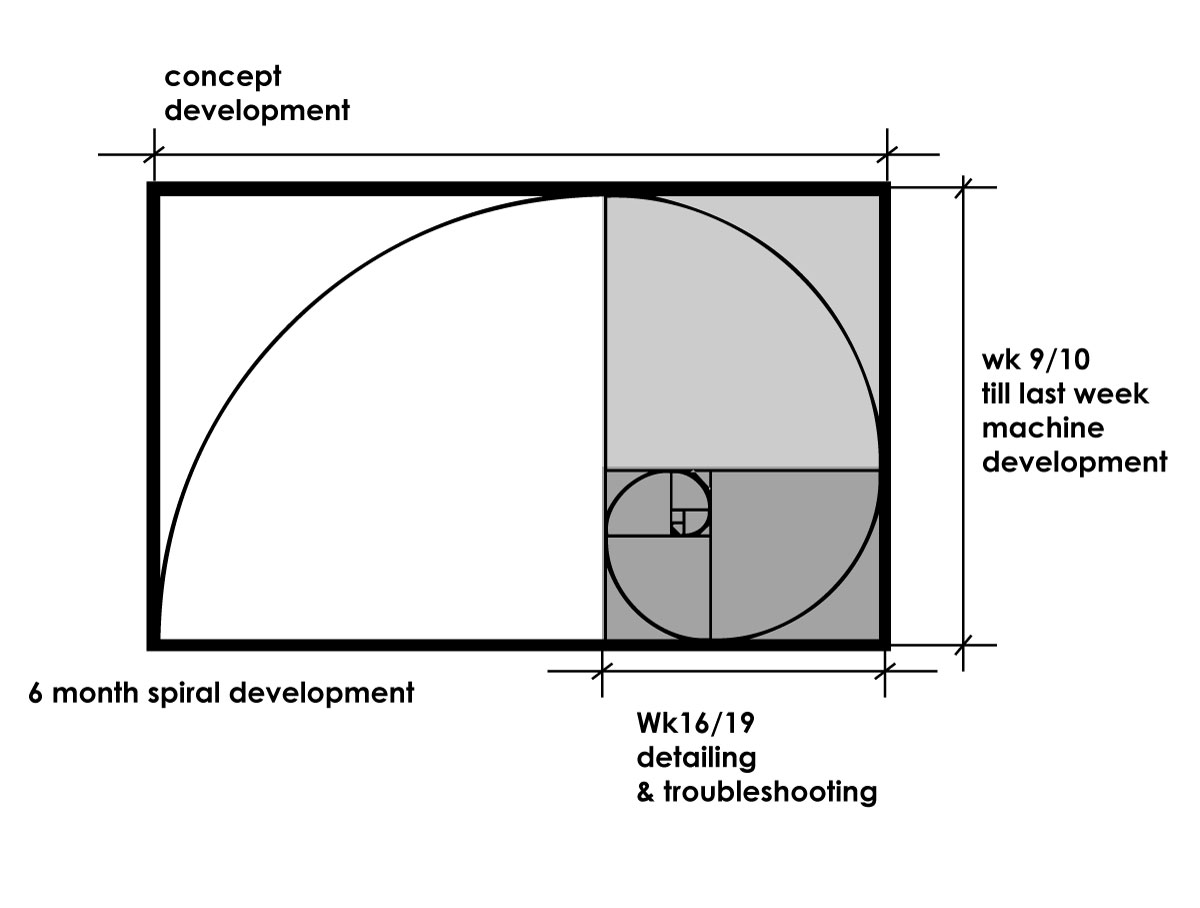

To finish the final project I have developed a spiral plan. The goal is to develope a cnc which would have peristaltic pumps as extruders and have a vibrating table. The gcode of this could be developed using grasshopper3d and then sent to the interface.

Up until week 16 I managed to have the new cnc and peristaltic pump designs ready. Therefore I had from May 25th till 21st June to fabricate and troubleshoot.Spending one week on fabrication; one week on electronics; one week on coding and trouble shooting and halve a week on presentation. | More info here|

As i needed to order some things for the project i made this quick list; most of the equipment was taken from dismanteling an existing reprap. and the rest was bought from placed like bcndynamics and in the case of electronic components; digikey .

go to hydrobot page

I decided to make all the joints for the cnc and design the pump myself. The joints would be laser cut for time efficiency and the pumps 3d printed as opposed to being cast or cnc cut.

The main questions to be answered will be dealing with enough accuracy to get precise flow at the right positions using semi viscous materials. This means obtaining the right gcode; pumping strategy; and cnc linearity.