Week #18: Applications and implications

Our tasks for the eigthteenth week were:

- Propose a final project that integrates the range of units covered, answering:

what will it do?

who's done what beforehand?

what materials and components will be required?

where will they come from?

how much will it cost?

what parts and systems will be made?

what processes will be used?

what tasks need to be completed?

what questions need to be answered?

what is the schedule?

how will it be evaluated?

projects can be separate or joint, but need to show individual mastery

of the range of skills covered

where possible, you should make rather than buy the parts of your project

As I said on earlier assignments, I changed my Final Project along the course. First, I started with an Automatic Recyclabes Sorting Can,

but then I changed to something that would actually help me on my daily

work. Since I teach Electromagnetism, I chose to build a device (the Recoiler)

that would help me to recoil insulated copper wire, which is a task I

need to perform several times before class experiments. You can check

the Final Project page for more detailed information (including a video!) on what exactly it does.

I'm

gonna fulfill this assignment on a Q&A fashion: for each of the

proposed questions, a section to answer it. The first one (What will it

do?) has already been answered, so let's move on:

Who's done what beforehand?

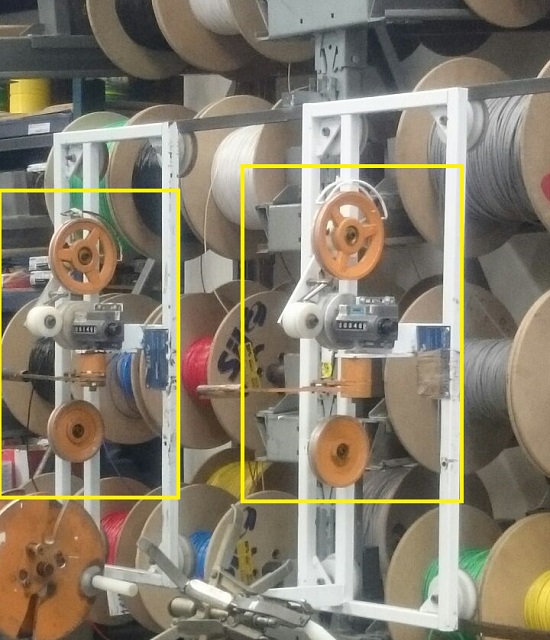

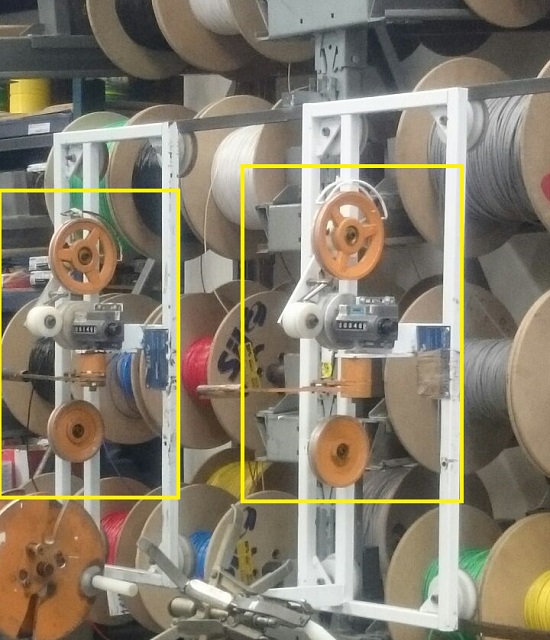

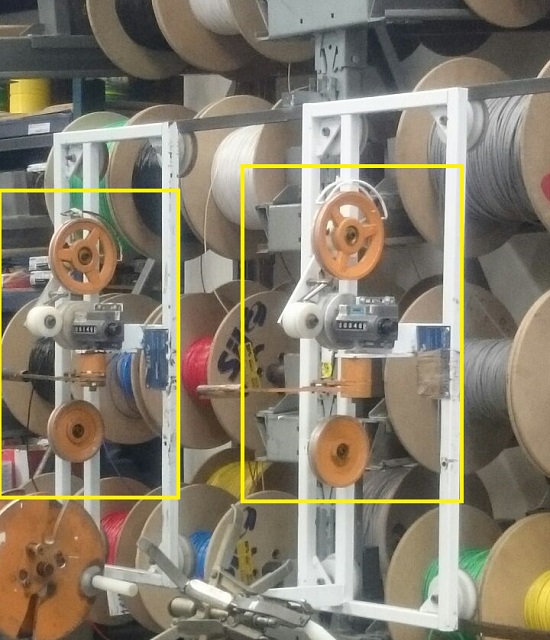

Well,

my idea is not exactly the new wheel, so someone must have done it

before, right? So, I wasn't quite surprised when our instructor Kenzo,

during a visit to Santa Efigênia, a neighborhood in downtown São Paulo

that specializes on selling electronic components, sent me this picture

These

devices do exactly what I intended for my Final Project, with the

exception that I wanted to use a laptop as control panel. But, I

couldn't find any information on the manufacturer (Concilab).

To

be quite honest, I did not spend much more time on findind out what was

done beforehand. Since I did not intend to make money and I thought the

learning process itself would be great, I went my own way and designed

my recoiler from scratch.

What materials and components will be required?

I will separate the components in two groups: physical structure and electronic components.

The physical structure will comprised, mainly, of 18 mm MDF, and 1 square meter is more than enough. You can see the details here.

Aside

from the PCB microcontroller, which was already built and whose design

and list of components have already been documented here, the other electronic components are quite simple:

- 1 DC motor with Gearhead (Jameco Reliapro 253471)

- For the driver:

- 1 NPN Transisistor that can output, at least, a maximum current of 150 mA (I used a BC-337)

- 1 1N4007 diode

- 1 1k 1/4W resistor

- PCB board (3cm x 3cm piece)

- 2 10k 1/4W resistors (pull-down resistors)

- 4 meters of standard AWG 22 copper wire

- Male and female conectors

Where will they come from?

All

the materials are readily available. The DC motor and the PCB board are

on the list of materials available to FabAcademy students; the

other components (wood and electronic) were "harvested" on the

university labs, but could have been easily (and cheaply) bought if

necessary.

How much will it cost?

Since I had all the materials, it cost me nothing. Had I had to buy all the components, the expenses would have been:

- DC motor: US$ 16

- Transistor, diode, resistors, capacitor and connectors, including those necessary for the microcontroller PCB: less than USS 3

- Wire: less than US$ 1

- AtTiny45: less than US$ 2

- PCB board: US$ 5 for a 15in^2 board, which is dozens of time more than necessary

So, around US$ 27 if none of the components were readily available.

What processes will be used?

- The button was silicone-cast on Week 13 assignment;

- The piece that adapts the motor axis to the reel was laser cut;

- The physical structure will be cut using the ShopBot;

- Both the microcontroller PCB and the driver PCB are examples of electronics design and production;

- 3D printing for the pulley used to measured the recoiled length;

What parts and systems will be made?

What tasks need to be completed?

By the time we reached Week 18, I already had built the microcontroller PCB, the silicon button (Week 13 assignment) and the sensor to count the number of turns (Week 14 assignment). So, still had to:

What questions need to be answered?

- How do I make it look good?

- Will it be able to withstand long periods functioning continuosly?

- How precise will it be?

What is the schedule?

Time is running out! I have less than a week to do the abovementioned tasks.

How will it be evaluated?

If it can recoil a desired wire length with an error inferior to 5%, it's a success!