Week #2: Computer-aided design

The tasks for the second week were:

- Learn about different design tools

- Design a possible final project and post it on my website

I

had previous contact with the following softwares: Inskscape,

GIMP, SketchUp, CATIA and AutoCAD (a very brief contact with

the

last 2). But, I had never developed any 3D model for a printer and I

was told that SketchUp could be a not so great choice.

Since I

teach math and I am particularly biased towards parametric design, I

was told to try out Creo. And, as I would do if I was studying math, I

tried to learn something about 2D design before trying out 3D design;

so, I proceeded to download Creo Sketch.

Just to get the hang of

it, I tried to design a simple gear: 10 cm diameter, 20 teeth. It took

me about 20 minutes to draw my first conclusion: Creo Sketch is not

made for that! As the name says, it's for quick drawings, not for

precision. It's a really nice (and free!) substitute to Paint Brush,

since it allows for layers, but not what I needed.

Next try: Creo Parametric (30-day trial). Lengthy installation, seems

like a bulky program. After that, a warm welcome:

Well, ok... gotta make the most ot of those 30 days, right? As soon as

I downloaded the program, I got an e-mail with links

to a tutorial, so I thought this would be a good point to start.

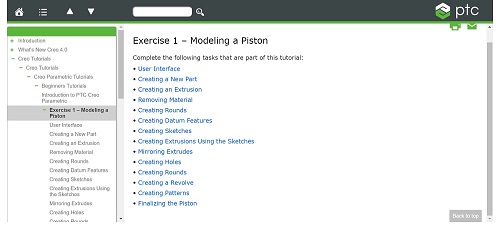

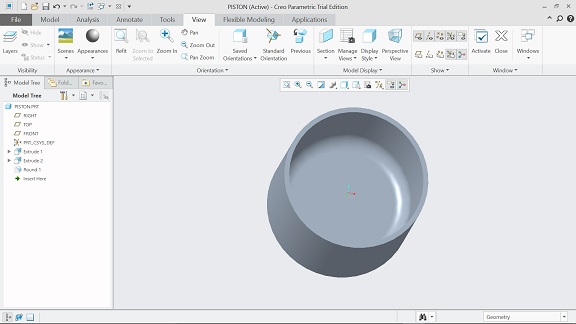

The tutorial is based on modeling a piston. The first step was to

create a new part:

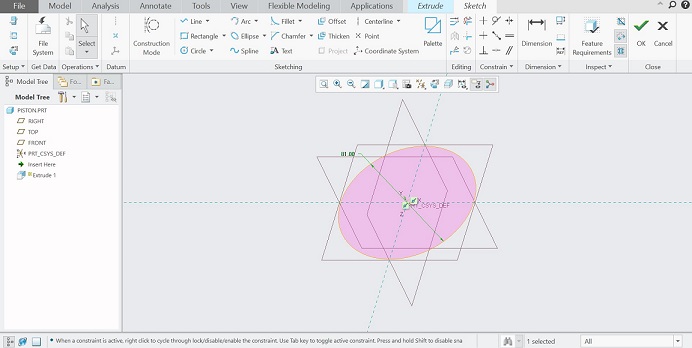

Now,

I will extrude something, which I believe (at this moment) is going to

be the piston head. For that, I use the center and point tool, and I

notice a major difference from what I knew about AutoCAD: you can't

type the diameter as you draw; you have to draw a circle with arbitrary

diameter and the double-click this dimension to reset it to the desired

value. Not too practical, but that's ok.

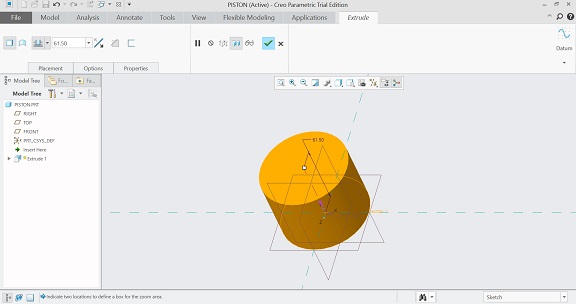

After you click "Ok", the circle is automatically extruded and you can

manually set the extrusion depth.

Then, after you click "Ok" again, you can manipulate the object.

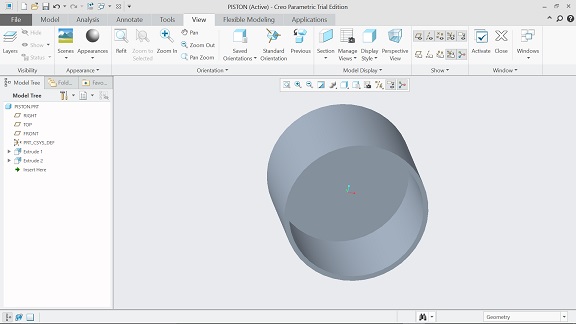

Ok,

now we're going to remove some material so that the connecting rod can

fit inside. It's pretty much the same process: extrude, circle. I took

me a while to figure out how to rotate the view dynamically,

but

eventually I got this:

Now, I have to round some edges. It's pretty straightforward: I just

have to click "Round" under the "Engineering" group.

The

next step was to create some datum features: a plane and an axis. I

must confess I did not get the point of doing this, but I think it will

be useful in a future step.

After

that, I felt the instructions got a little confusing, specially since I

don't have a third mouse button on my laptop (and no, clicking both the

left and right buttons at the same time does not work). So, I got a

little frustrated and decided to design something by my own: my final

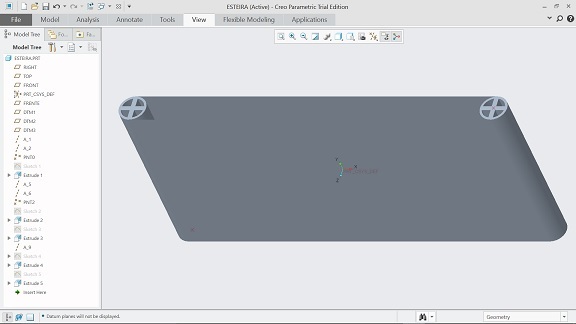

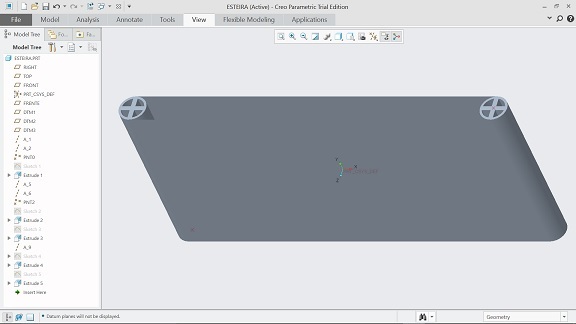

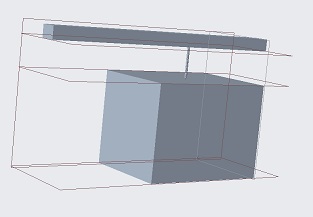

project conveyor belt. After some struggle, I got something like this:

I drew both the belt and the wheels as a single part. That's why they

look made from the same material.

Funny

story: on the next day, talking to a colleague, he told me that you

just CAN'T use Creo without a mouse. At first I was skeptical, but he

convinced me really quick. So, I got a mouse and started all over; this

time, however, I created each part separately.

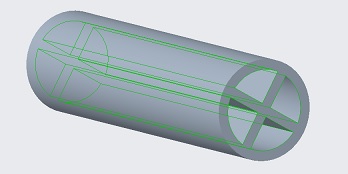

The first parts I

designed were the wheels of the conveyor belts, each one being

cylindrical with a length of 20 cm and a diameter of 5 cm. Here's what

I got:

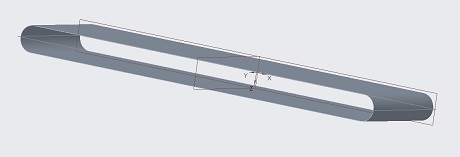

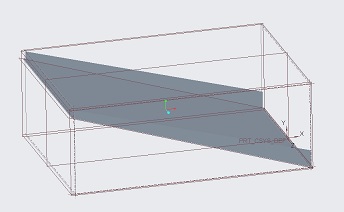

Then, I designed the belt itself, a sheet having a width of 1 mm:

As

the initial mixture rolls over the first conveyor belt, at some point

the ferrous pieces will be attracted to an eletromagnet and the rest

will follow it's way to the end of the belt. I want what is left of the

initial

mixture to roll over the entire length of the second conveyor belt; so,

both conveyor belts will need to be placed close to the sides of the

box.

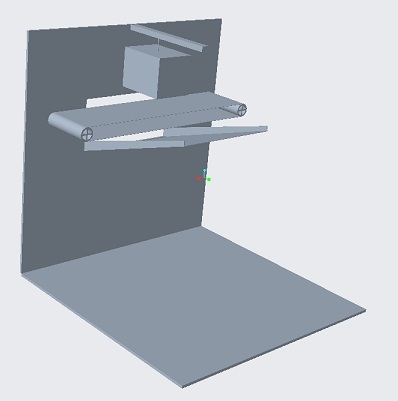

Thus, the

magnet has to move along a rail in order to drop the ferrous pieces in

an adequate container. It's kinda hard to understand the desing with

words only, so it'll all be clear when I show you the complete assembly.

Since

I still haven't calculated the necessary currents, it's hard to

estimate the electromagnet size. Being really conservative, it's safe

to say it'll fit inside a 20 cm x 15 cm x 15 cm box. This is what I got

for the magnet and it's rail:

After the ferrous pieces are picked up, they are dropped on a ramp (the

box shown in the figure is 40 cm x 55 cm x 20 cm) :

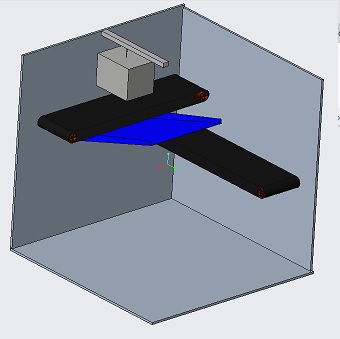

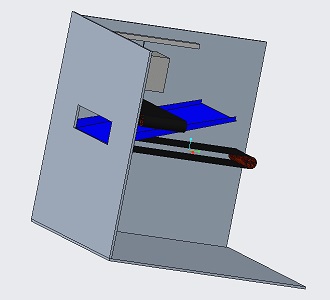

Now, I'm going to try to assemble together all the pieces I designed.

This is what I got:

As

you can see, this is far from a final design: the conveyor belt is

"floating" inside the box, and also it is not powered by a motor.

But, it's possible to get a flavor of what it will become :)

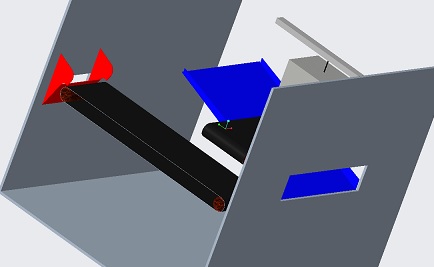

After

that, I added the second conveyor belt (the one where non-ferrous

metals will be separated from non-metallic materials) and put on some

colors to make it easier to tell parts from each other:

The

final part is another ramp, one that also serves as separator for

non-ferrous metals and non-metallic materials. The result was:

If you want to check out the 3D model files (parts and assembly), click

here

(the password is abc123).

*

UPDATE *

It

was only later during the

course that I noticed this week assignment

was also about 2D modelling. By the time this happened, I had already

changed (and, as a matter of fact, built) a different final project:

the Recoiler.

So, I am

going to describe the 2D modelling I did for my final project in order

to adapt the DC motor axis to the reel, using the laser cutter. For

that, I used Fusion 360.

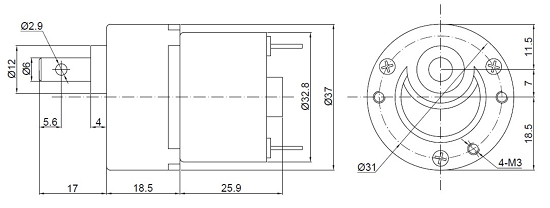

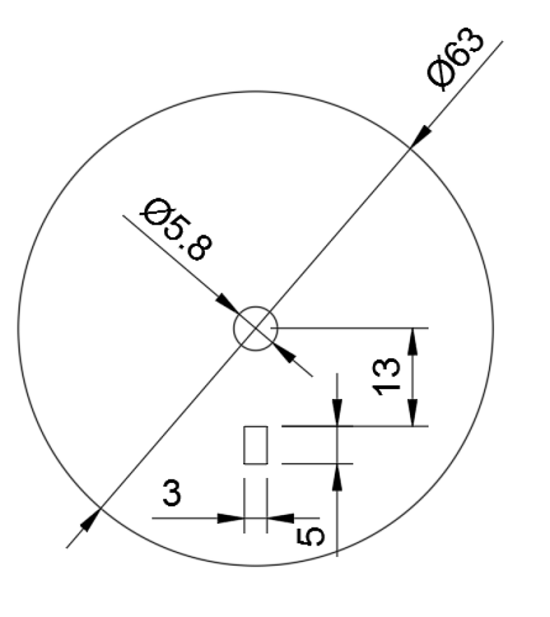

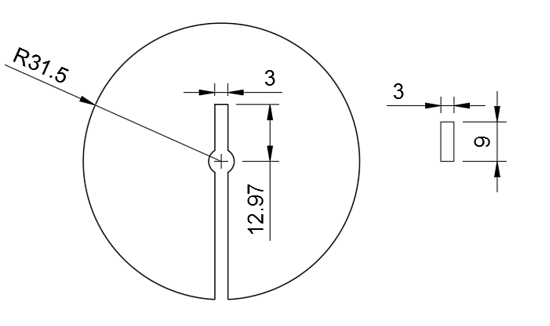

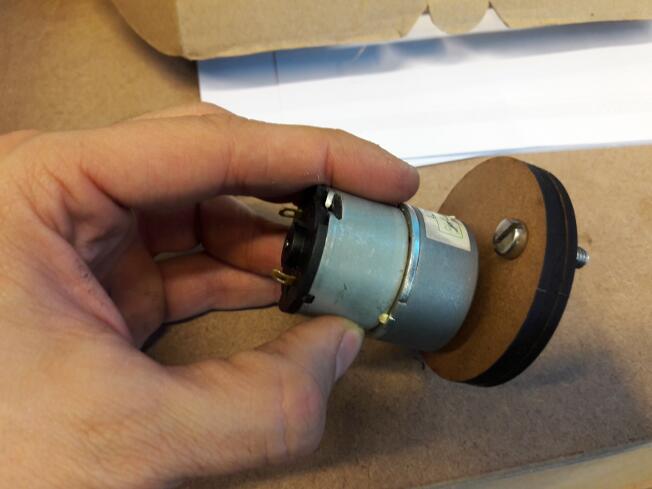

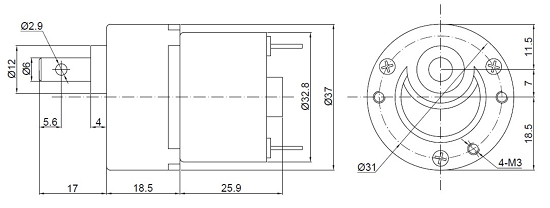

To understand the problem, look at the following figures:

,0

As

you can see, the motor axis has a hole. In order do adapt the axis to

the reel, which you can see below, I designed a piece made of three

layers of 3 mm MDF.

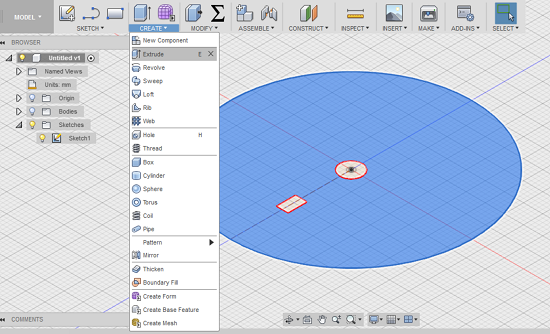

I am going to explain this piece as I show the design. As I said

earlier, I used Fusion 360.

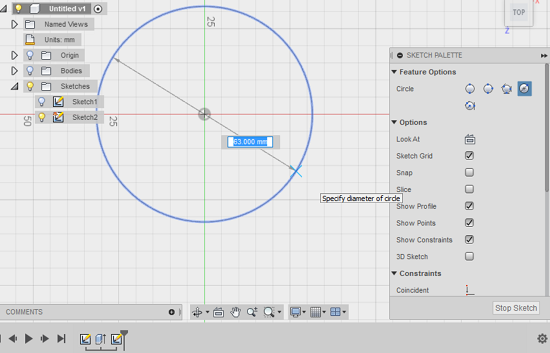

The

commands are quite practical: for example, in sketch mode, you press C

if you want do draw a circle, then you choose its center and type it's

diameter. Simple as that.

All the 3 layers that make up the

piece are circular and the DC motor axis goes through their centers.

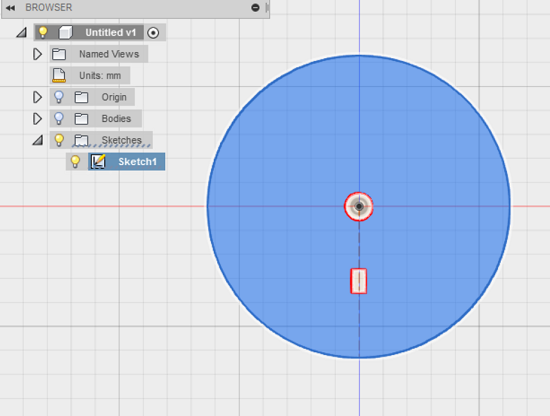

The first and third layers are simply a circle with one circular hole

for the motor axis and a recatangular hole for a pin that will hold the

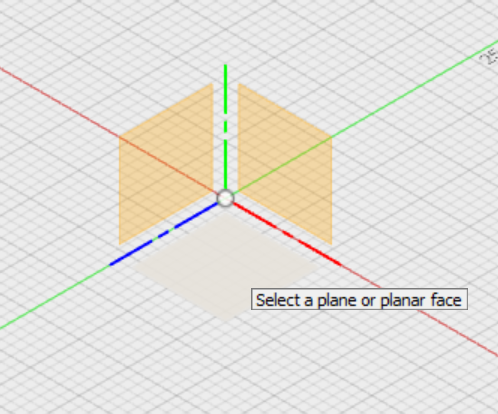

layers together. To draw them, I started by choosing a plane to sketch

and drawing a circle:

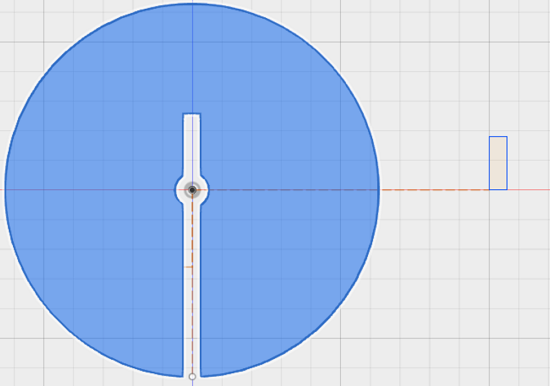

Then, I drew a circle for the motor axis and a rectangle for the pin:

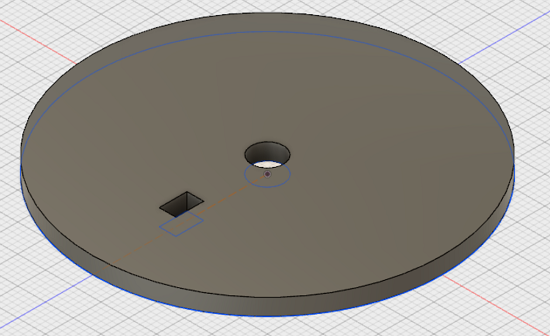

In

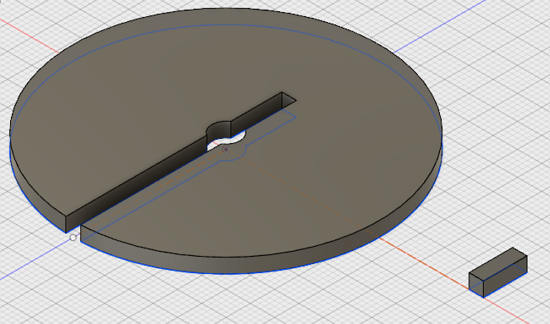

order to make a 2D PDF for the laser cutter, we first need to make a 3D

piece. In this case, I just had to extrude the above drawing for 1.3

mm, the thickness of the MDF board.

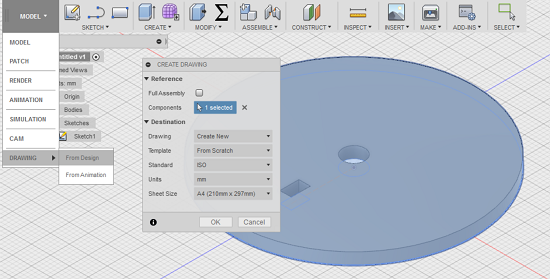

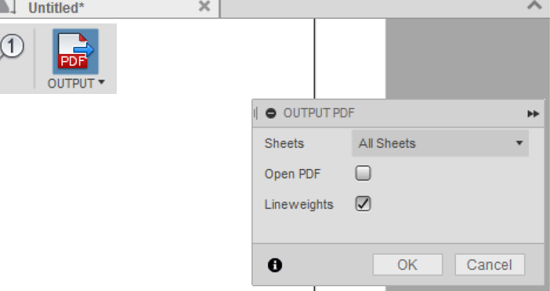

Then, to generate the 2D design, we click on Model -> Drawing

-> From design:

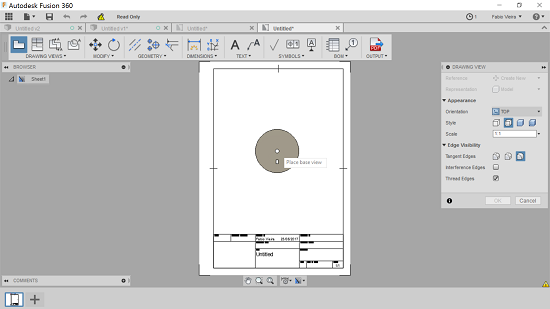

After that, Fusion opens a new window in which you can choose the

object view and place it on the drawing:

We can also add some dimensions:

Then, we simply click on "Output PDF":

The middle layer has a cut in which a metal rod (a cut rivet) will be

inserted:

On the right side, you can also see the pin. This is the 3D model:

And this is the 2D drawing with the dimensions:

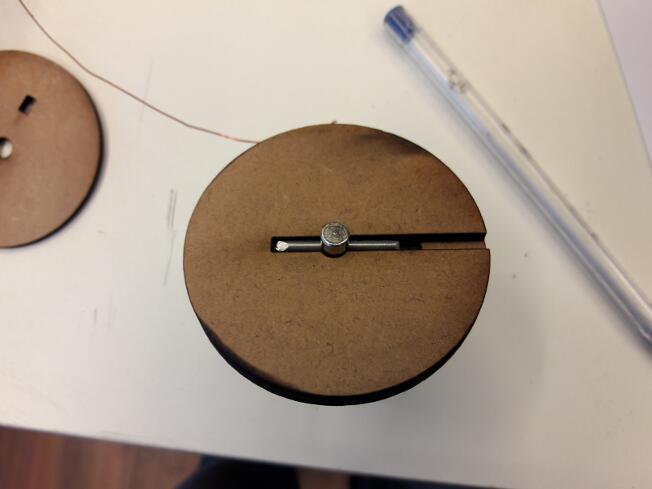

This is the assembly process after laser cutting the layers:

If you want to check out the 3D and 2D model

files, click here

(the password is abc123).

And that's my progress for the second week. I sure learned a lot, and I

also found out that 3D design is almost therapeutic.

,0

,0