Well, there's one big issue with that idea: it relies on good education, a skill which is not always well developed in all groups of humans. And, as a result, its not uncommon to see the wrong kind of waste in each bin, which, in the end, accounts against the idea of cost reduction, since trash will need to be sorted anyhow.

Since effective sorting plays such an important role in recycling, there is a lot of reasearch in this field. Most technologies rely on refined methods, such as eddy currents, electromagnetic induction and infrared, and to this point none of them are available at household or, at least, building level.

My final project tries to aim precisely at this issue: the goal is to build an automatic trash sorting can, one which can work at a commercial or residential building level (i.e., at least a few dozen people).

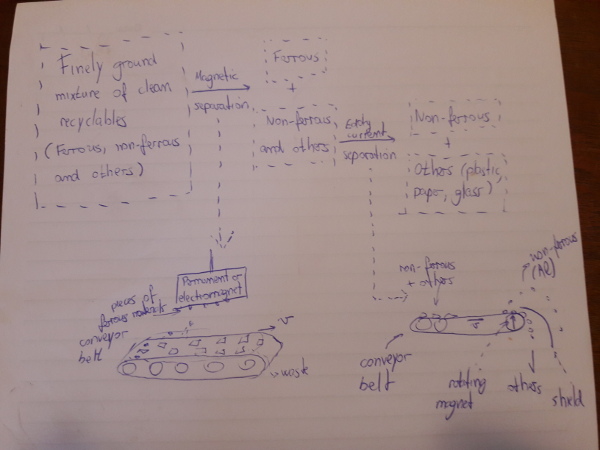

Here is my first handmade sketch:

Don't worry if you can't make out words from random scribbling, I'll present this in a while in a more adequate style.

After some research, I concluded that trying to automatically sort any kind of waste mixture would be a little bit farfetched, specially for a semester-long course. So, I set an essential goal, which is the absolute minimum I want my contraption to do; then, I set some complimentary goals, which will need significantly more time and resources to attain.

To clarify the outlining of those goals, I must first talk a little about sorting recyclables.

Around the globe, there are different ways through which recyclables are sorted. Starting with the extreme models, the sorting can be totally centralized, such that the common citizen need not worry about that and can throw all kinds of garbage in a single bag, or totally delegated to the common citizen, such that all the materials are already sorted at the moment of collection. And, as with most things in this world, there is a myriad of other models that lie in between those extremities.

The central fact is: the more precisely the recyclate is sorted, the greater the outcome. The problem with a totally centralized model is that, in a nutshell, it's really hard (by that, I mean expensive and time demanding) to separate the different materials that make up the recyclate. On the other hand, a totally delegated model relies too much on citizen education, which can be just as hard (again, I mean expensive and time demanding).

Regardless of the adopted model, any piece of equipment that can improve effectiveness in the sorting process while at the same time being unexpensive and easy to use is certainly welcome. So, that's what I'll try to create!

Ok, back to the outlining of the goals. Since sorting can be really hard, I'll set my essential goal as:

Essential goal

Starting from a clean and finely ground mixture of ferrous metals (such as iron), non-ferrous metals (such as aluminum) and non-metallic recyclables (such as paper, glass and plastics), to be able to separate these three components.

It may seem a bit modest, but it's actually quite the opposite. I'll get into that later.

The "previously finely ground" condition is by no means a major issue, and can be addressed quite easily with a lawn mower-like setup. But, since we won't be machining blades during our course, I'm going to focus my efforts on the separation part.

Before continuing, maybe it's time to define some terms. We can subdivide the trash according to the following types:

- "Organic" (I use the quotation marks because paper and glass are, from a Chemistry point of view, organic. But, here I'm going to use the word to indicate primarily rests of food).

- Clean recyclables (i.e., pieces of glass, paper, plastic and metal that are not covered with organic materials. For example, a washed bottle of soda is considered a clean recyclable).

- Dirty recyclables (i.e, pieces of recyclables that are, ate least, partially covered with organic materials. For example, a cheese smeared burger box would classify as a dirty recyclable).

So, IF I manage to achieve the essential goal within our course duration, I'm going to start working toward the second level goal:

Second level goal

To be able to achieve everything outlined in the essential goal PLUS being able to separate the glass, the paper and the plastic.

Well, from here on we start to dream a little. The advanced goal:

Advanced goal

To be able to achieve everything outlined in the second level goal EVEN with a dirty initial mixture. Aside from that, being able to also separate the organic materials.

Why do I call that "dreaming"? Well, organic materials represent a special kind of challenge in the automatic sorting process, since they can present themselves in various densities, colours, viscosities and lots of other physical properties. Even if we decide not to tackle organics directly, there's still the issue of washing dirty recyclables, which is not trivial. So, since the advanced goal will demand dealing with organics, I'm well aware that this is not feasible in a semester long course.

Finally, the ultimate goal:

Ultimate goal

To be able to achieve everything outlined in the advanced goal PLUS being able to also generate electric energy.

And that involves burning, pollutants and many other issues. But, a man can dream, right?

From now on, I'm going to target only the essential goal.

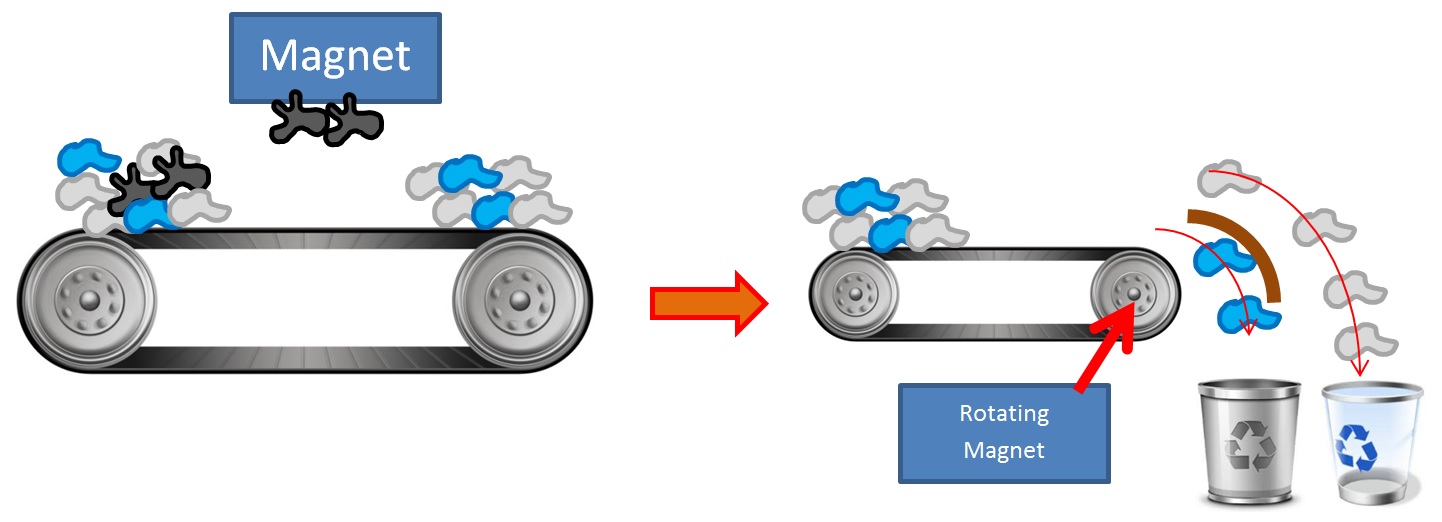

To separate the ferrous metals, I intend to use a permanent or electromagnet hanging over a conveyor belt. To separate the non-ferrous metals, my plan is to use an eddy current separator, quite common in the ore and recycling industry.