The unused gear

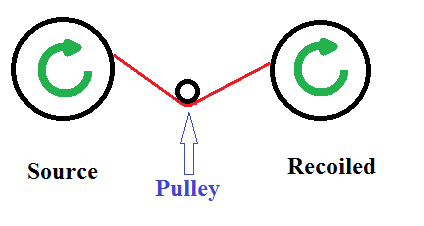

Since

the diameter of the cylinder formed by the recoiled wire increases as

the wire gets recoiled, counting the number of turns of the reel is not

the most precise way of measuring the length. So, my first idea was to

place a pulley between the two reels in such a way that its speed was

exactly that of the wire, thus providing an accurate measure of the

recoiled length.

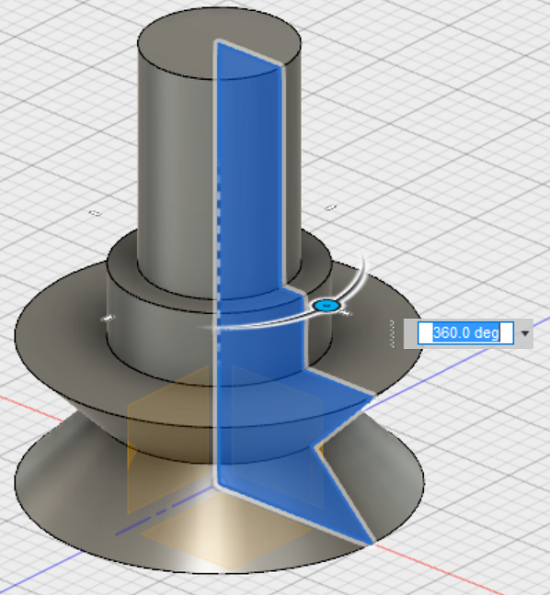

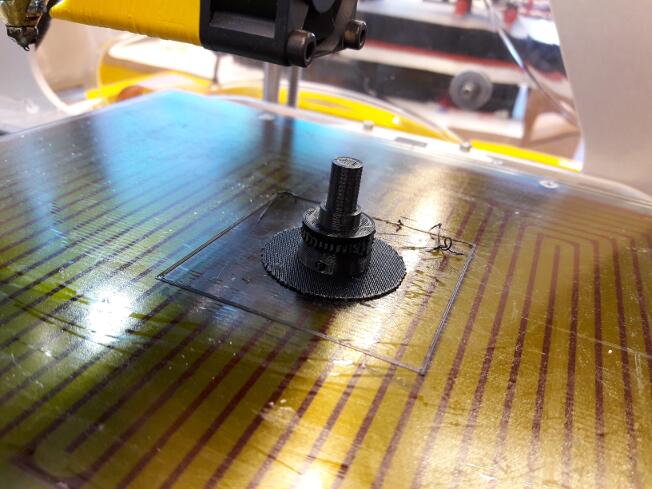

This is the pulley I designed, using Fusion 360:

The

idea was to fit a piece of wire into the pulley hole and insert the

pulley axis into a ball bearing, which in turn would be placed on the

physical structure. After 3D printing (files here, password abc123), this is what I got:

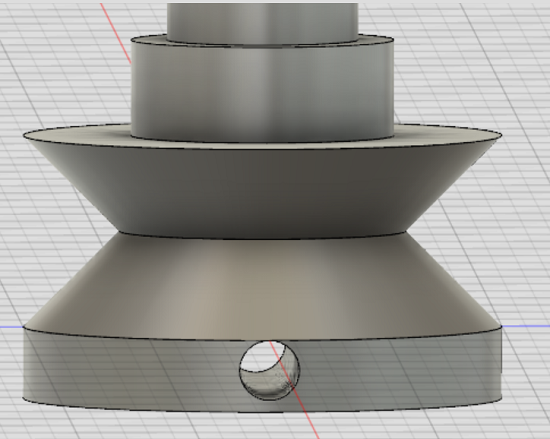

The piece was actually quite nice. But, I ended up not using it because of two problems:

- it added extra strain on the motor, which meant more current being drawn;

- the wire would slip relative to the pulley, so it wasn't actually measuring the recoiled length.

Since

I was on a deadline, instead of trying to solve these problems, I chose

the less precise (nonetheless, precise enough) solution: counting the

number of turns on the reel. You can see the details about the sensor I

used to do that here.