<-- Week 5

WEEK 6

[ELECTRONICS DESIGN]

Week 7 -->

WEEK'S GOALS:

IDEAS THIS WEEK:

ACHIEVEMENTS THIS WEEK:

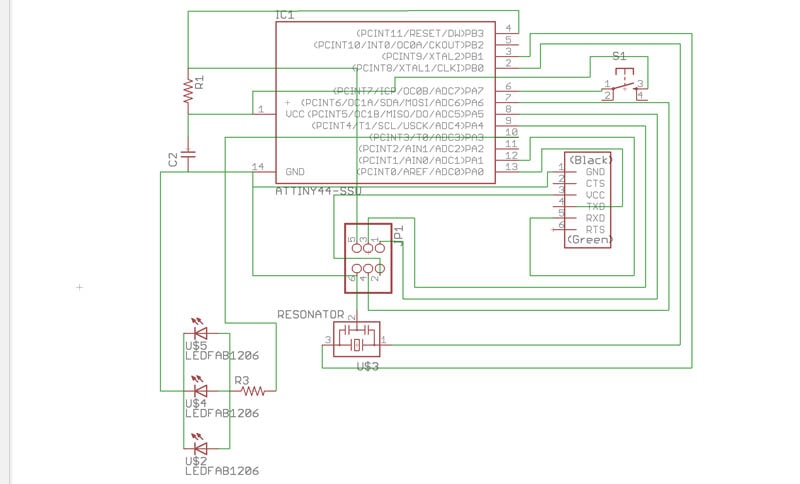

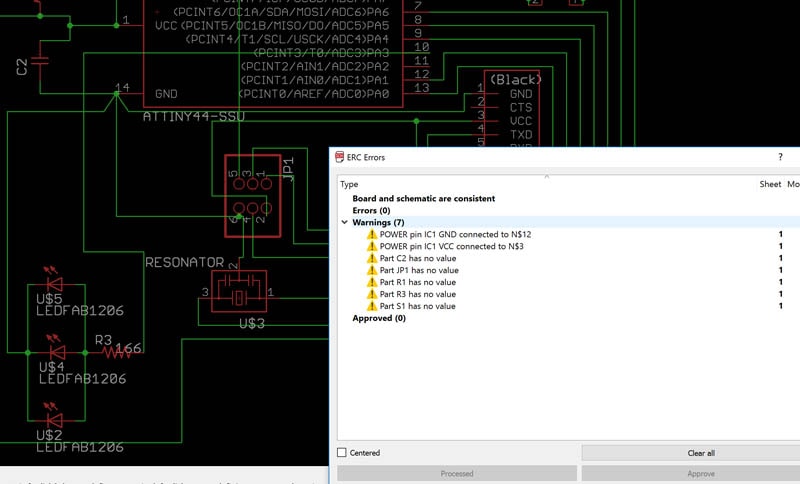

Electronics:1. Circuit Design

- Got refreshed with data on diodes, Leds, Capacitors, Resistors, ICs, Zeners etc. by our instructor

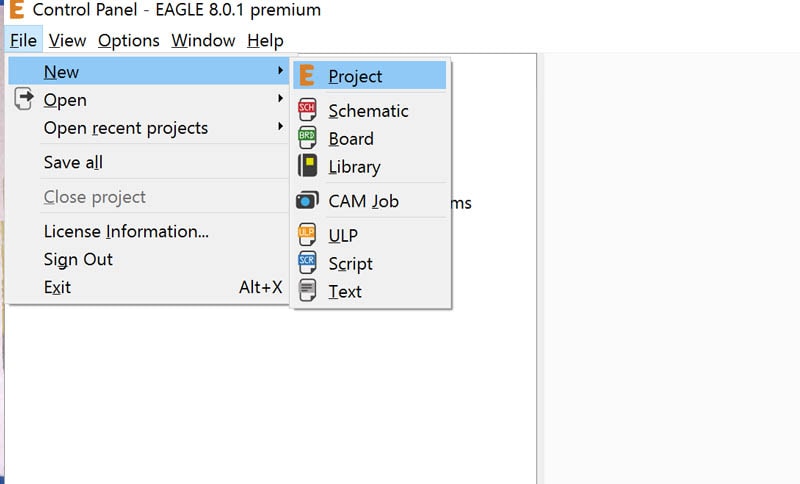

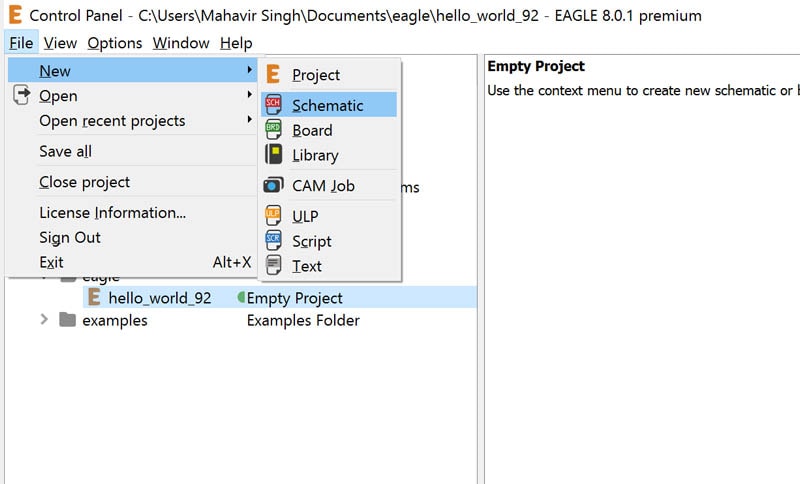

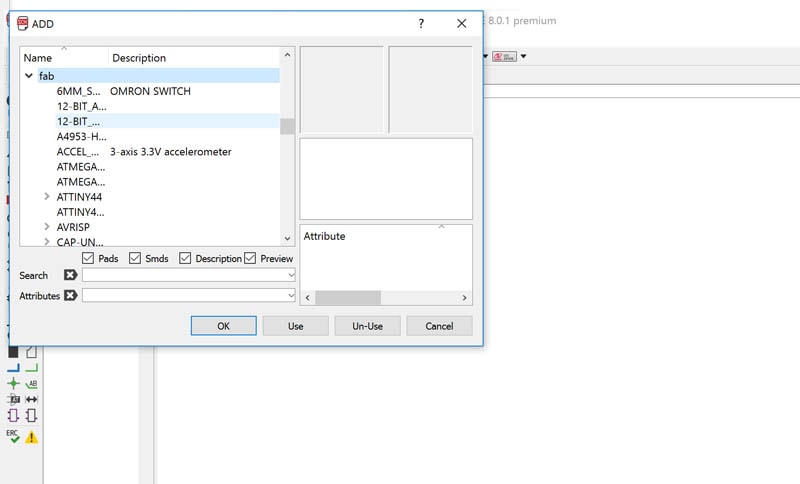

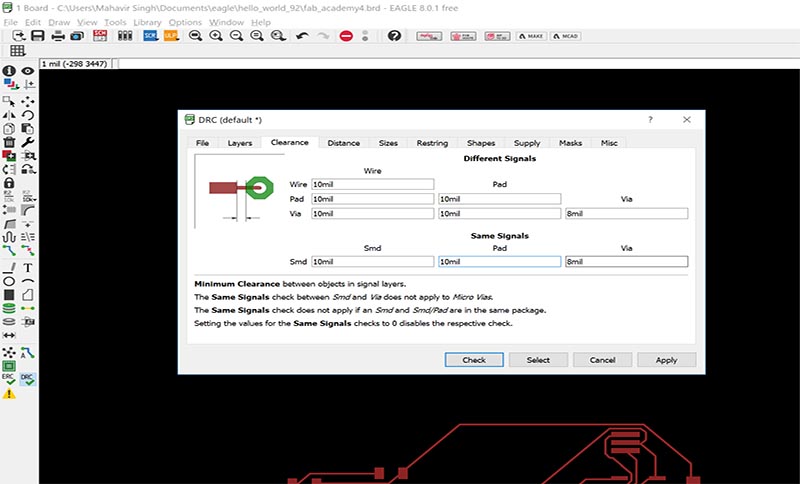

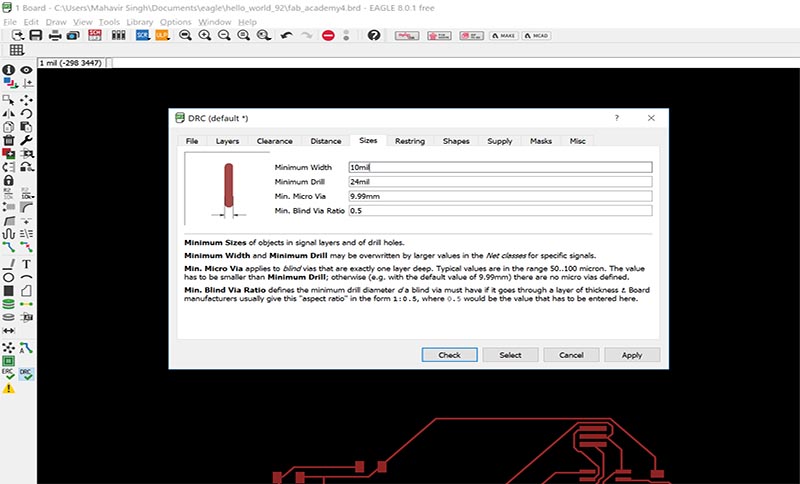

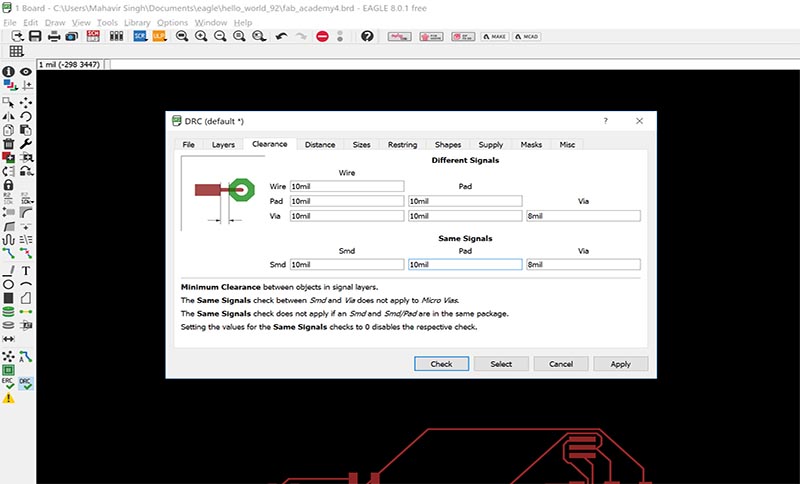

- Got familiarised with Autodesk Eagle by our instructor

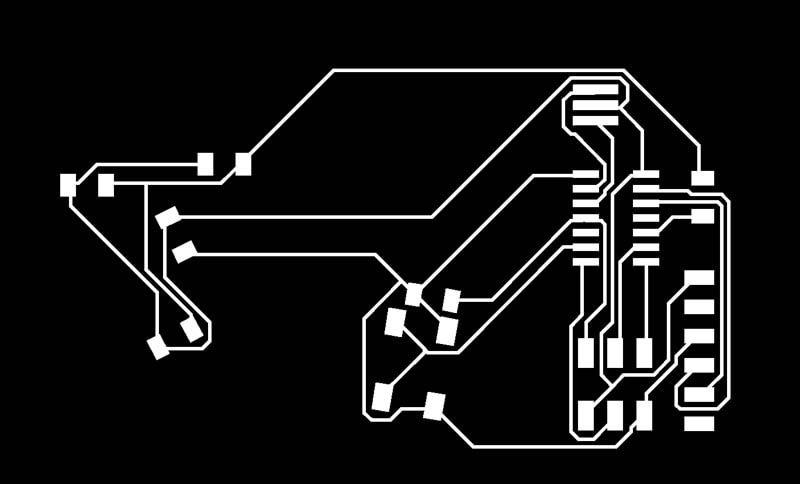

4. Board Routing

5. Populating of board

6. Try for Programming

TASKS AT HAND:

<-- Weeks Overview

Day 36

[ Preparing Files ]

Day 37 -->

1. Troubleshooting Laptops of my peers installing Ubuntu

2. Editing my Website

<-- Day 36

Day 37

[ Parallel Designing ]

Day 38 -->

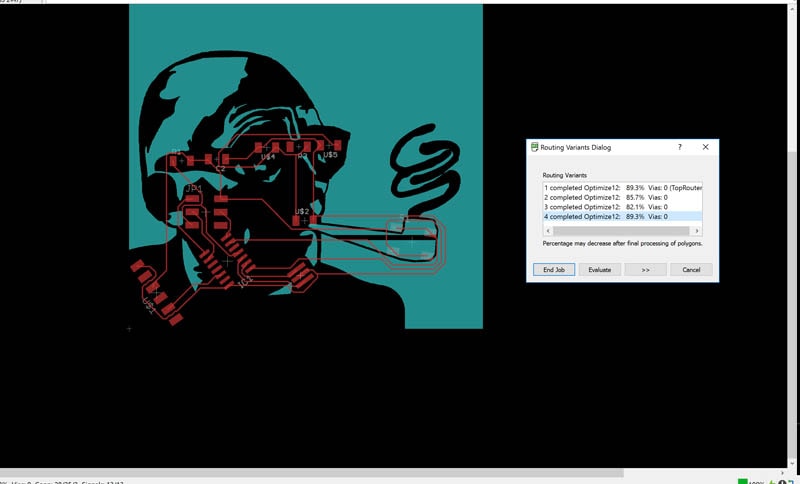

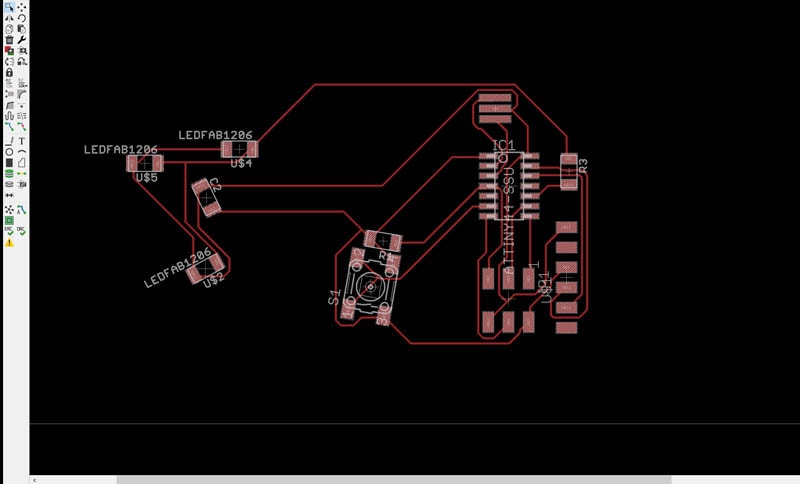

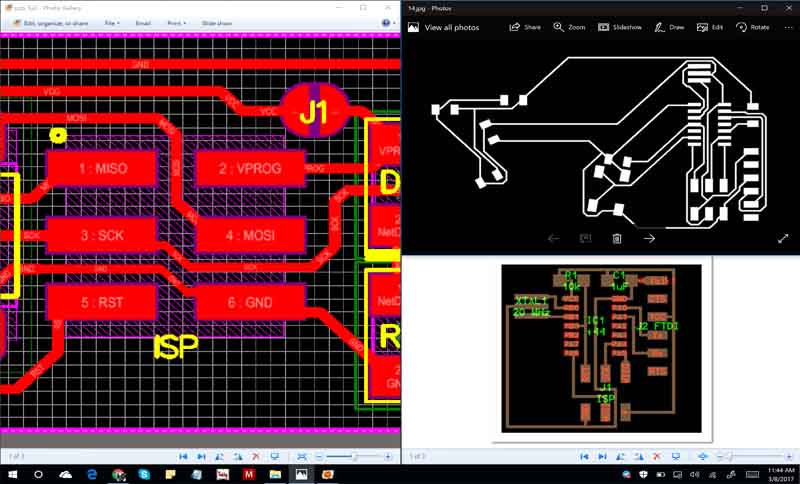

1. Autorouted with different orientations keeping the customised board shape in mind.

<-- Day 37

Day 38

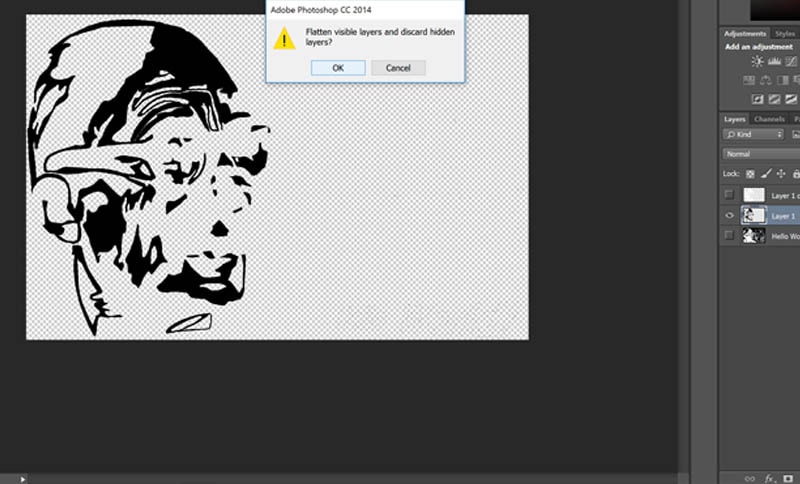

[ Photoshop Routing ]

Day 39 -->

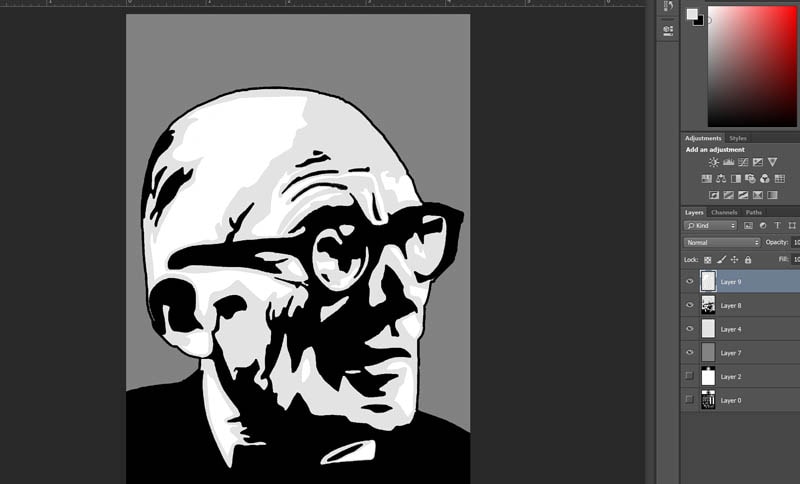

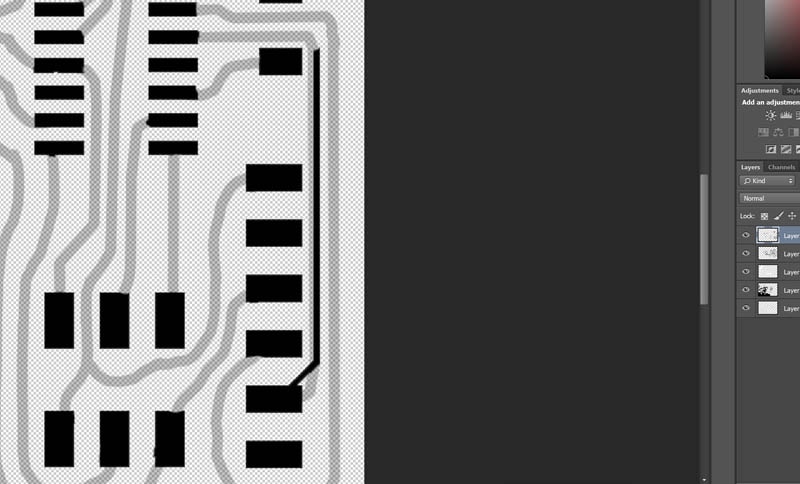

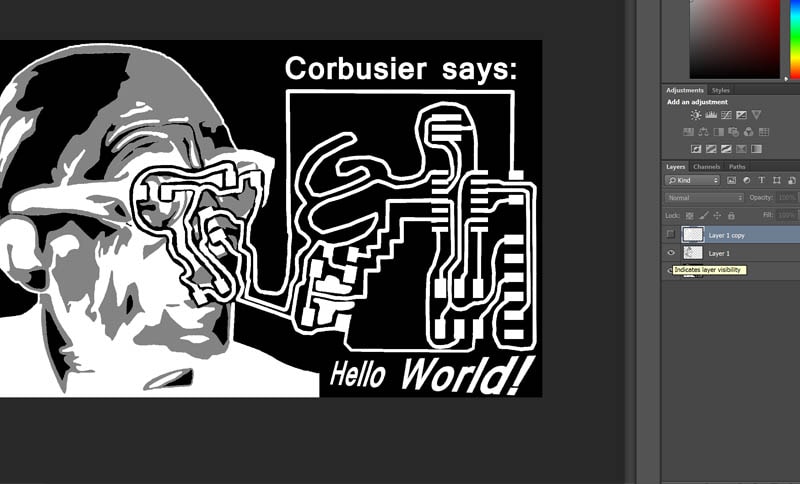

1. Imported Indexed PNG to Photoshop for Routing

2. Developed 3 layer routing image-Trace | Shine | Cut (Cut wasnt needed-file size just fit in the FR board)

3. Manual routing according to shape.

<-- Day 38

Day 39

[ Routing Time ]

Day 40 -->

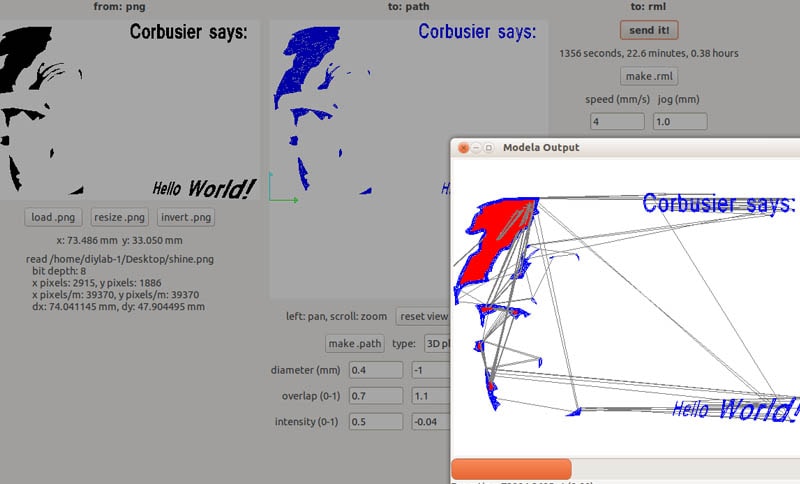

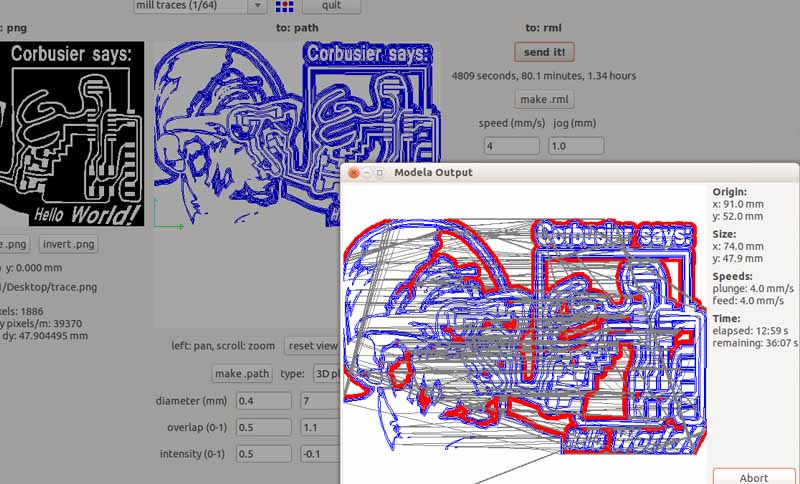

- 1.Tested my Shine Layer with 0.02 mm cut depth.

2. Went through the test board scanning for possible shorts and correctinng my trace file accordingly

3. Check list for routing-> bed leveling + more

So the order to achieve this shine layer and integrate it within your board is as follows:

1. We route the shine layer first (just in case so we know we will get it on our board without mistakes and copper coming out) @ 0.02mm cut depth

2. We then route the trace file @0.06 mm cut depth

3. Then the cut file @1.7 mm cut depth.

<-- Day 39

Day 40

[Populating time]

Day 41 -->

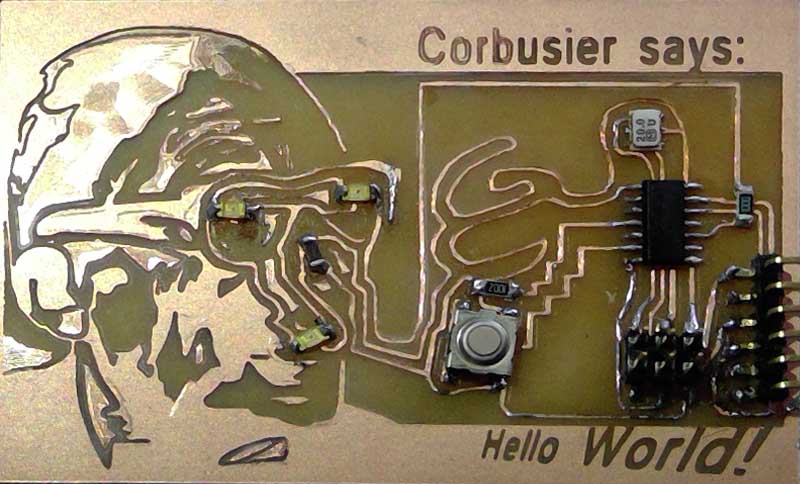

- 1.Gathered all components

2. learnt how to stuff it and solder

3. Learnt importance of Flux and how to add and remove solder

4. Loved arranging the components while soldering

I liked this week as it forced me to not sit on laptop whole day designing and working but also do hands on work . I discussed with Yogesh ji my final project and how i plan to improvise it with time and use Shopbot before the given week so that i am able to figure out ideas to improve my final project.

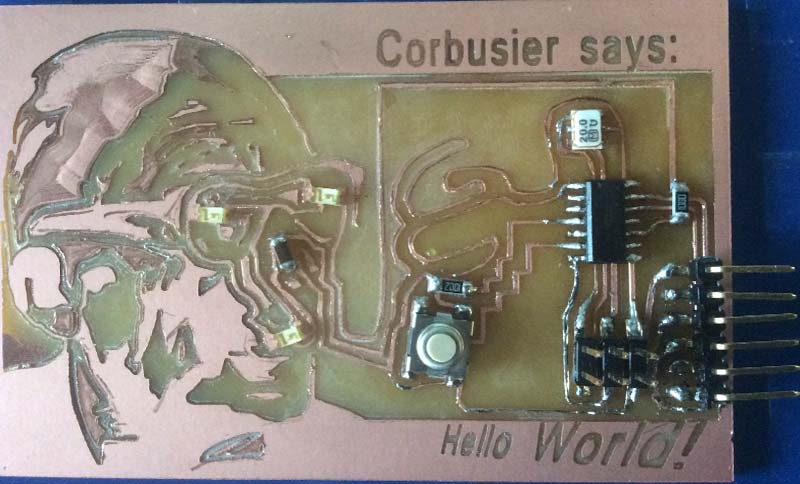

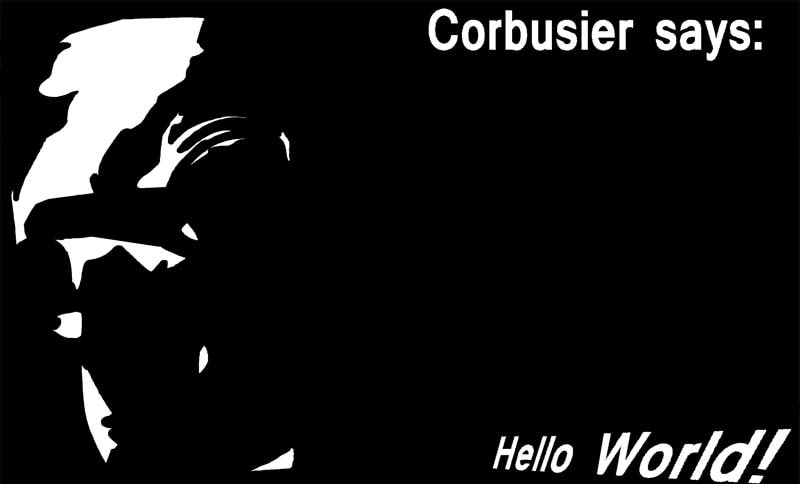

Do notice the slight shine layer on Corbusier's bald head. Under the right lighting, this whole board glows fantastically.

<-- Day 40

Day 41

[ Ready for Programming]

Day 42 -->

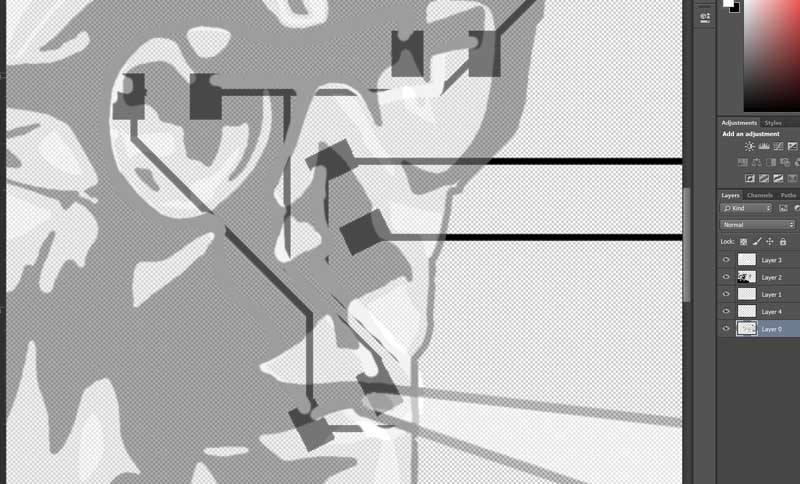

To help myself with connections, I put all three images i need to do the wiring together as a single pic.

Project Files for Week 6