Week 9: Design the Poor-Mans-Mill

Welcome to the legendary MTM-Week!

MTM stand for "Machine-to-make", and the goal is to build a machine for your lab that helps you do some thing.

This SHOULD be a group-projekt, and we SHOULD use the FabAcademy kits.

Well...

In my project-sketch-book is on one of the first pages a wooden mill. Since years i wanted to build such a machine

to mill wood and hdpe. I think, thats the chance to build this mill, i named it "The-Poor-Mans-Mill".

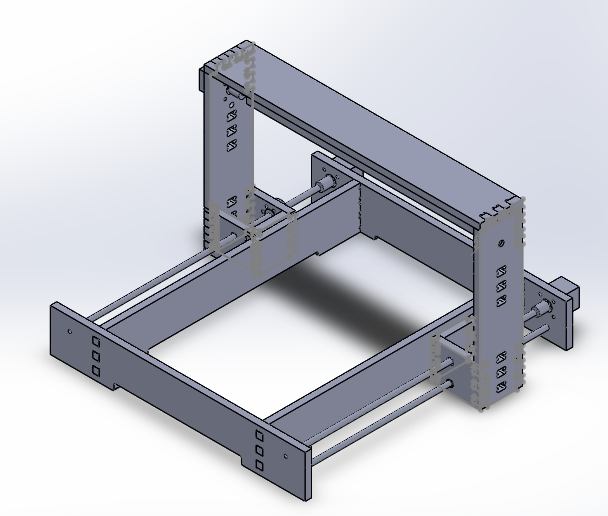

The structure is made out of 15mm multiplex-wood, milled on the big CNC in Kamp-Lintfort (see week 7 for details about the mill).

Cause its a low-budget-project: approx. 40$ for the multiplex...

For the drives i shot a bunch of steppers on ebay: 5x 17HS4417 for 35$. They have a step-angle of 1.8 degree at 1.7A current.

The bearings comes from IGUS and are normal plastic-bearings. From IGUS are also the trapezoidal screw (10mm dia, 2mm pitch) and the nut.

Summed up:

All in all 80$ for IGUS...

As rail i use 10mm V2A rods. They aren´t as stable as supported rails, but they are much much cheaper! Poor-Mans-Mill, you know ;)

I got the rod by some metal-seller around the corner for about 10$ (2100mm).

The mill is a classic construction as a portal-mill. The "build-space" will be around 50cm X 50cm X 30cm.

After i sketchted the whole mill i drove to our friends in Kamp-Lintfort to mill the parts...

Let´s say, i tried to mill the parts.

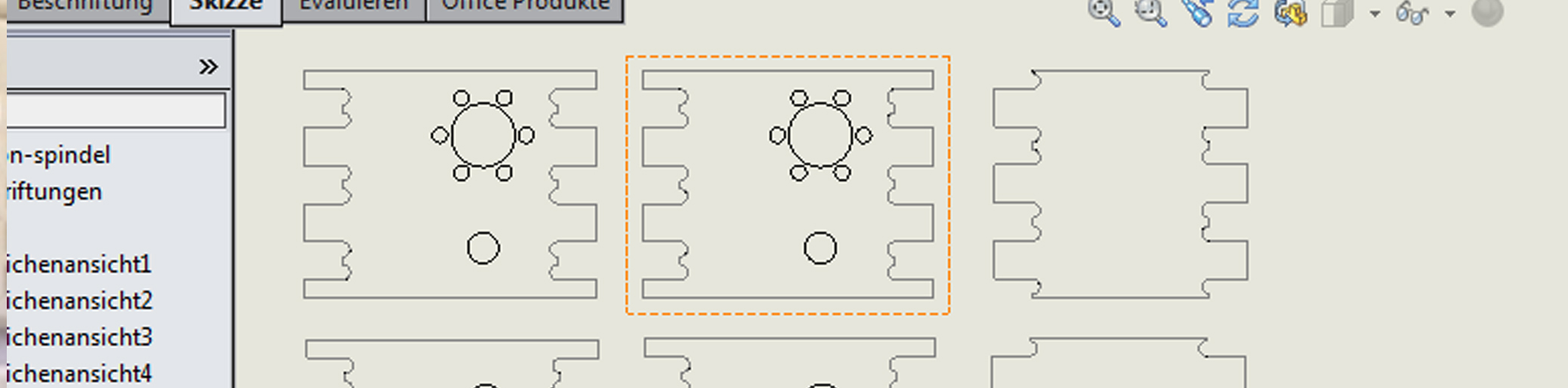

I sketched all parts in SolidWorks, as i´m familiar with this program for some years now.

The mill in Kamp-Lintfort just takes R12-DXF files.

In the "Build something big"-week this was not a big problem: export as dxf, open in Rhino, lay the different steps in different layers, put it all in the mill, finish.

This time the parts have much more circles in it, and it seems that this will make problems in Rhino...

The mill just accepts closed polylines as path, but somewhere between SolidWorks and Rhino the single polylines became overlapping in many points. As a result, Rhino can´t joint them together in a single polyline...

ARGH!!!!

I´ve spend some hours in working this out, but the only way i´ve found till now is to redraw every sketch.

Till i´ve got the parts milled i can just show you a STL-Model:

And for those of you that wants to rebuild the Poor-Mans-Mill, here is a zip with all files i´ve got till now: CLICK

Money thrown for the mechanic parts: 165$

Don´t be supprised, the Z-Axis isn´t sketched already, due to the mill-problem.

In the next week the Poor-Mans-Mill will get its electrical-background.

I will spend it a Smoothie-Board with RepRap-Display...

If you are also a poor man, and you want to build a mill, then maybe my files can help you...

But be patient, the files are not well ordered ;)

ZIP-File

Till then, have fun!