Commuters Car Closet

For this week in Fab Academy our project is to create something big! I couldn’t think of anything to make with the size wood that was provided, but I managed to think of a project to make. So, since I am a daily commuter for my school I just stay in school for the most part of the day. This results of me turning my car into my own closer; however, everything mixes up in the back of my hatch back vehicle. It isn’t lovely when my longboard rub dirt against my clothes and how my shoes slowly get buried under everything.

I came up with an idea to where I create a car closet. This piece of furniture will have a place for shoes and shirts. I also designed it to have a cubbie for bigger objects because I am not just using it for school. I was drawing multiple designs to fit my needs and thinking of different ways to assemble my project together. At first I was thinking of a screwless design by using slots and t-bones to join my pieces together, but I wanted to practice my workshop skills. I changed my design a couple of times because the space off my trunk was limited and I took the dimension into consideration.

I used Adobe Illustrator to design a model so I can use the laser machine to produce cardboard cut outs to see how the design will look like in the end. This was crucial because I was able to see how the final result might of looked like and making a model gave me inspirations of how I was going to configure the final design in the end. I scaled my design to 4:1 when I was designing my model.

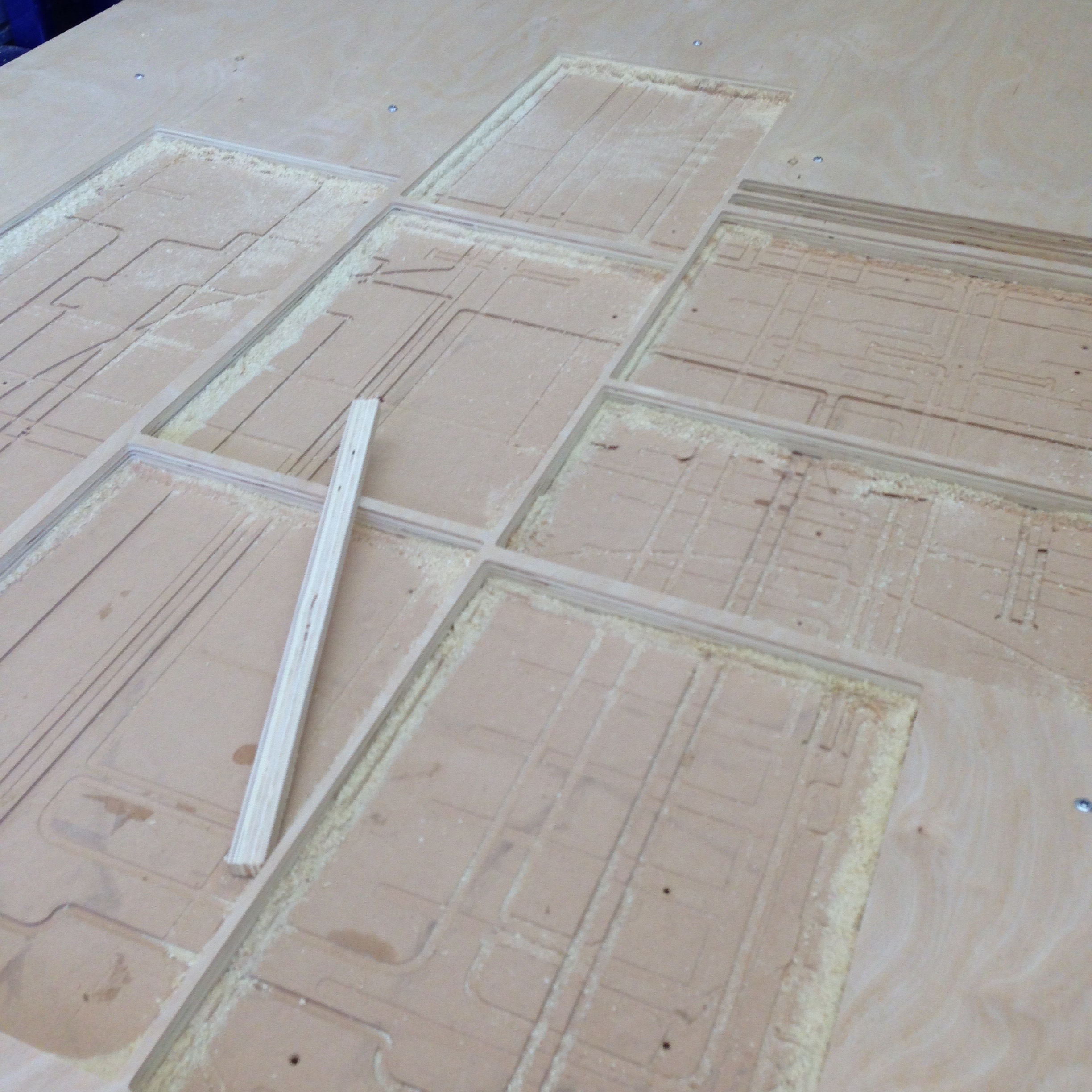

After I was satisfied with my model, I was ready to use our mill. Matt Chalker gave me detailed instructions of how to operate the mill and the safety precautions that came along with cutting out with the mill. We will be using the {add the programs} to send cnc codes into our machine. But, it is important to install hold down screws before continuing into the product. As a result, I had 2 different cutting procedures for my car closet. The first pattern was to create place holders for hold down screws and the other one was the actual instruction to cut out the car closet.

The cuts came out clean, but I was able to witness some of the machine’s limitations when it failed to cut a piece of wood that was only 1” wide. It deformed the shape when it was almost finished cutting it out. However, I decided not to use those components for my final design.

Finally, I installed each part accordingly and adjusted it in my car.