Composites

Assignment

- Read the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that you're using.

- design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it.

Learning outcomes

- Demonstrate workflows used in mould design and construction.

- Select and apply suitable materials and processes to create a composite part.

Have you

- Shown how you made your mould and created the composite.

- Described problems and how you fixed them.

- Included your design files and ‘hero shot’ photos of the mould and the final part.

- Read and linked to the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that you're using.

Materials

Files

Small button openSCAD file

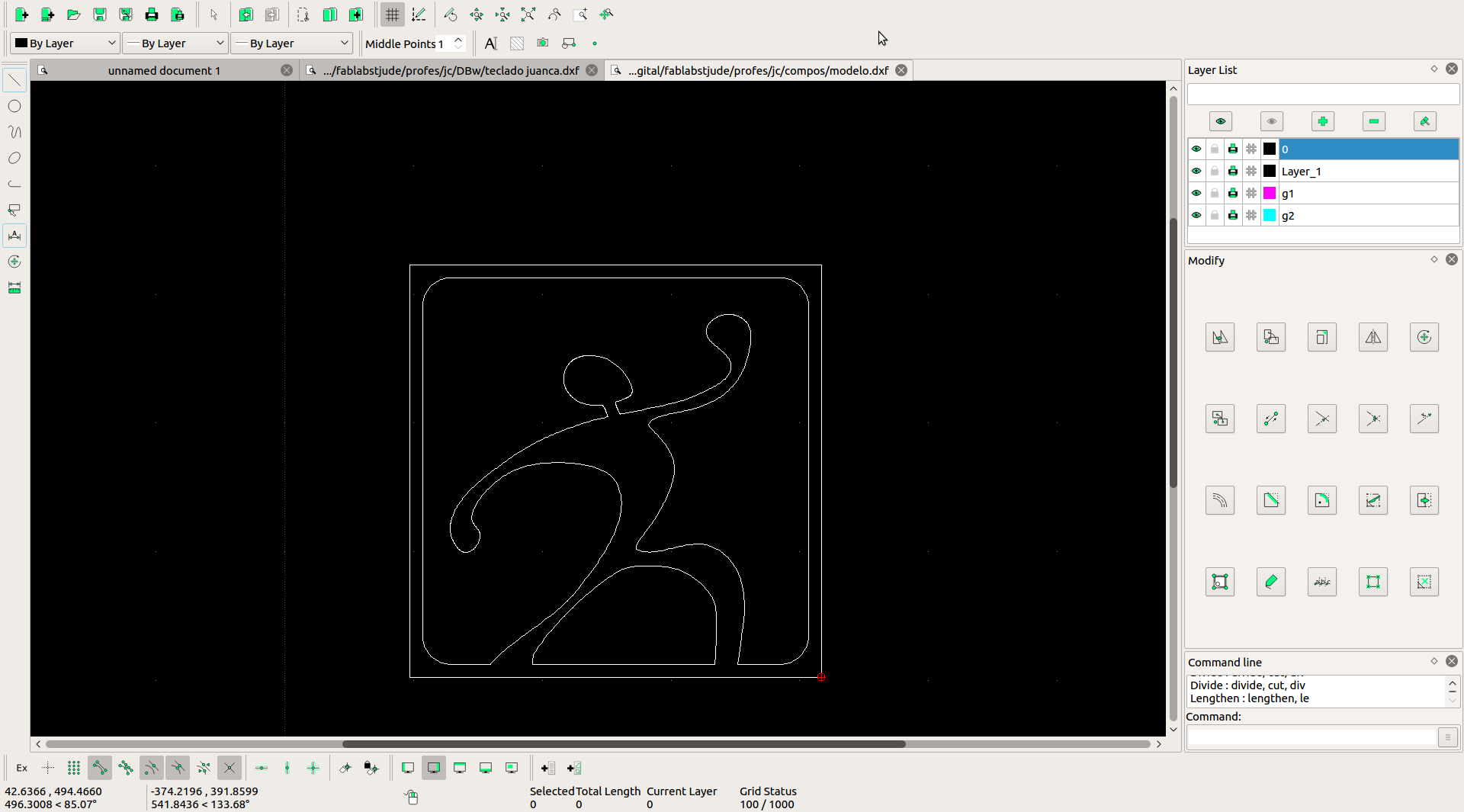

Button mould LibreCAD dxf file

Human figure mould LibreCAD dxf file

Design a mould

-

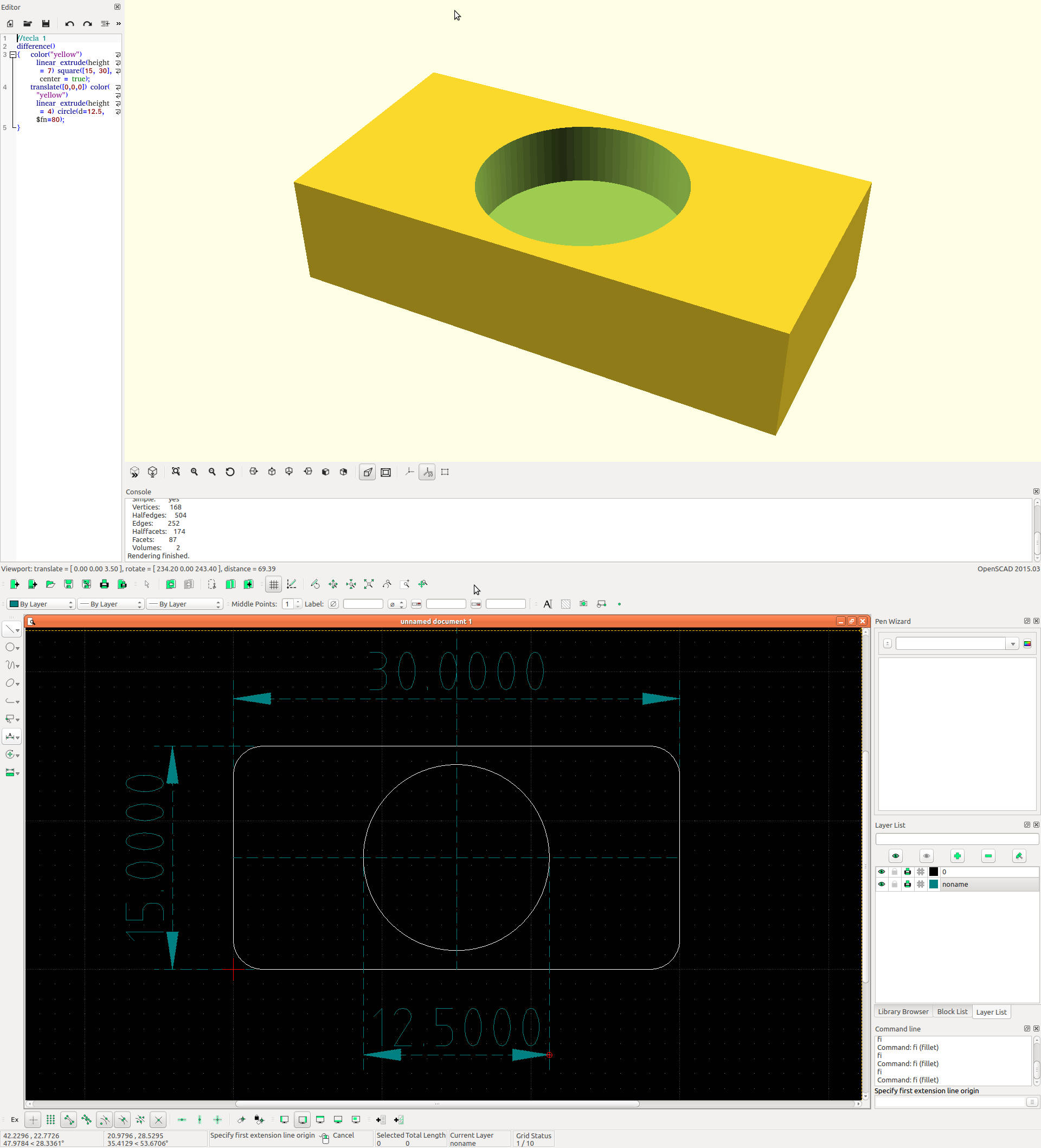

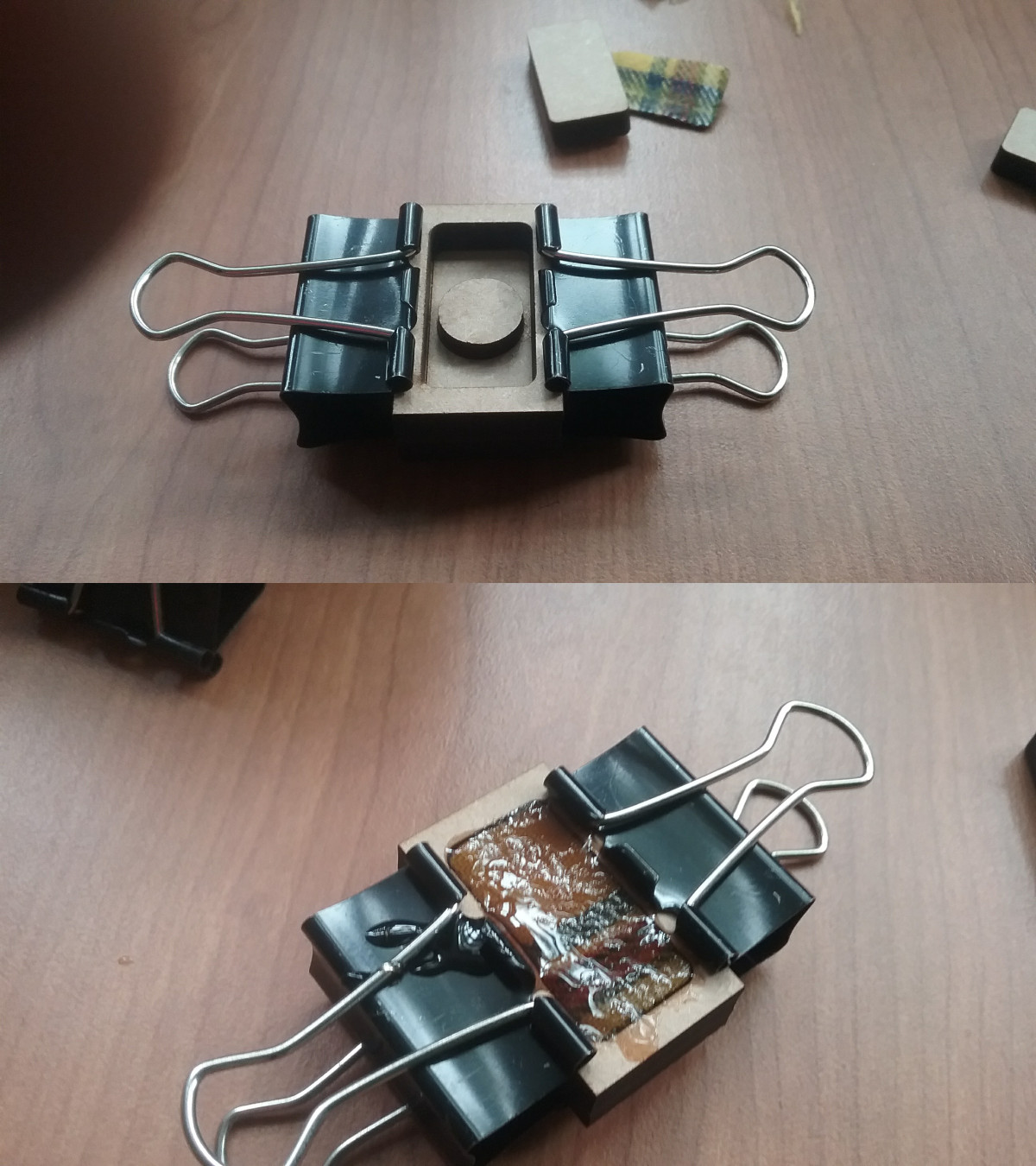

I wanted to try another fabrication method to make the buttons for my project. So, I started by making a new version of the button previously designed, with rounded corners. I used LibreCAD for this:

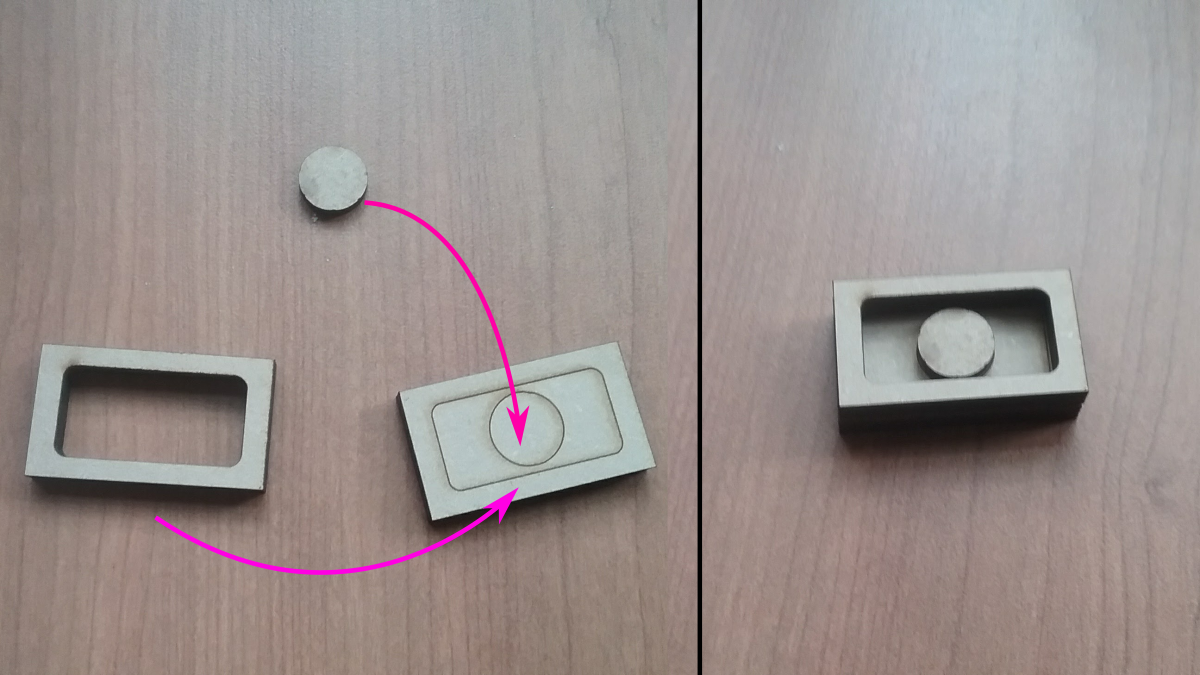

Then, with the laser cutter I made the mold for the button out of mdf:

I also cut a fabric piece with the same shape for the composite of the button: -

We have no access to vacuum bags, so I also prepared some fabric pieces to make a test coupon using compaction to remove extra resin.

Materials

-

For this assignment I will be using unsaturated polyester resin. These are the links to the MSDS and TDS of the material:

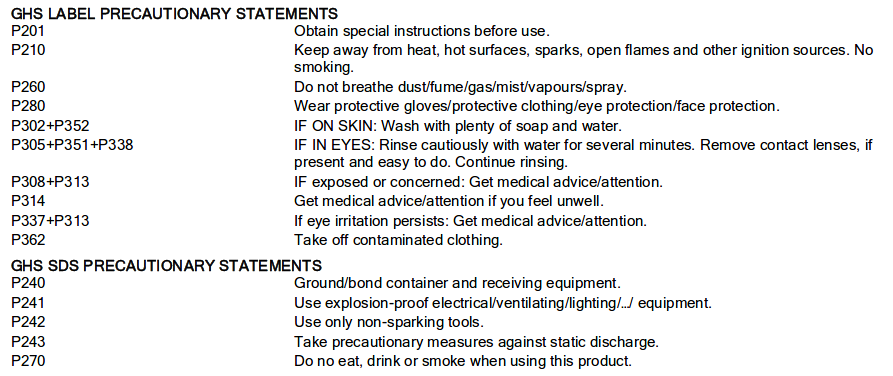

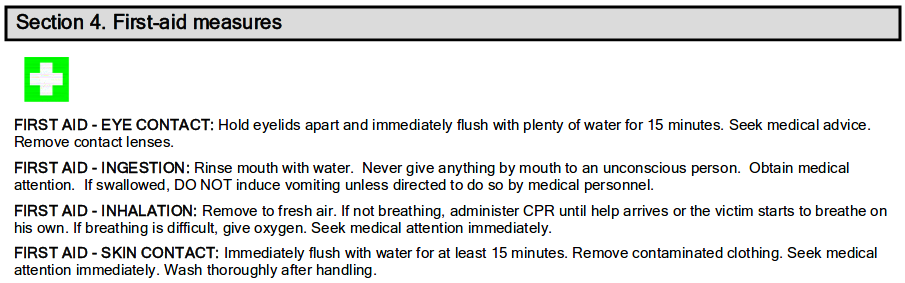

The main points to consider after reading the documents are:

- Flammable Liquid, category 3 H226

- Skin Irritation, category 2 H315

- Eye Irritation, category 2 H319

- Reproductive Toxicity, category 2 H361

- STOT, repeated exposure, category 1 H372

Other information to be aware of:

Composites

-

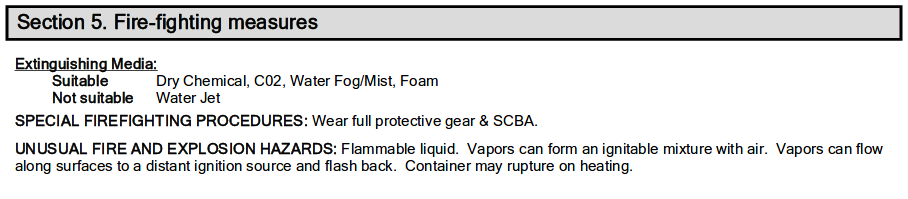

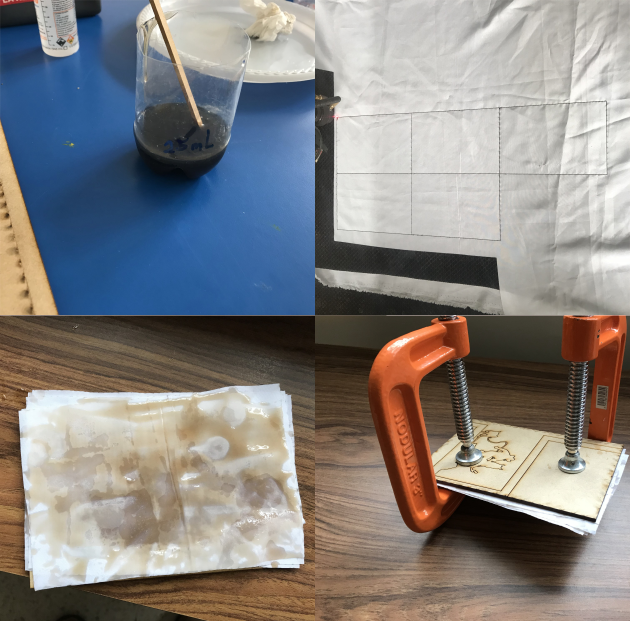

Then, I prepared the resin for the composite. The inidcation is 1% catalyst for the mix. I prepared just a small amount of resin, about a tablespoon, with a drop of catalyst.

Then, I poured the resin onto the mold, added the fabric piece and let it rest:

Then, I set the other fabric pieces for the test coupon, with some baking paper to prevent the resin from sticking to the plates:

Results

-

After taking the pieces out of the molud, and a little sanding, these are the resulting parts.

Button:

The pattern of the fabric can be seen in the picture:

Test coupon:

-

The button came out very well, but for future projects I would like to use a clear resin, so the mateial inside can be appreciated. Also, the mdf doesn't work well as mould material, it sticks to the part and requires some sanding.

The test coupon was fine, but it can be a little thicker.

Second try

-

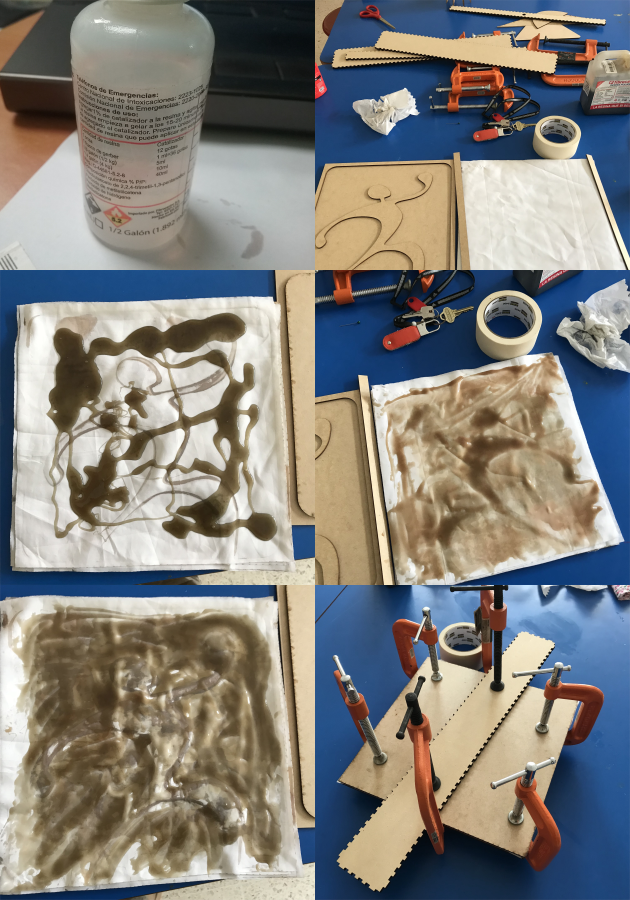

I designed a new mould. It is 30 cm x 30 cm. It is part of the school logo. Then I cut the mould and assembled it. I also cut 5 30 cm x 30 cm pieces of white fabric.

Then I prepared the resin. According to instructions, I need around 9 drops of catalyst for 25 ml of resin (25 ml = 0,85 oz). After that, I poured the resin over the first two layers of fabric, then repeated for the other layers.

I made also a test coupon with five layers of fabric.

Results: the coupon and the model had some bubbles of air, but otherwise, the results are good.

Back