ShopBot

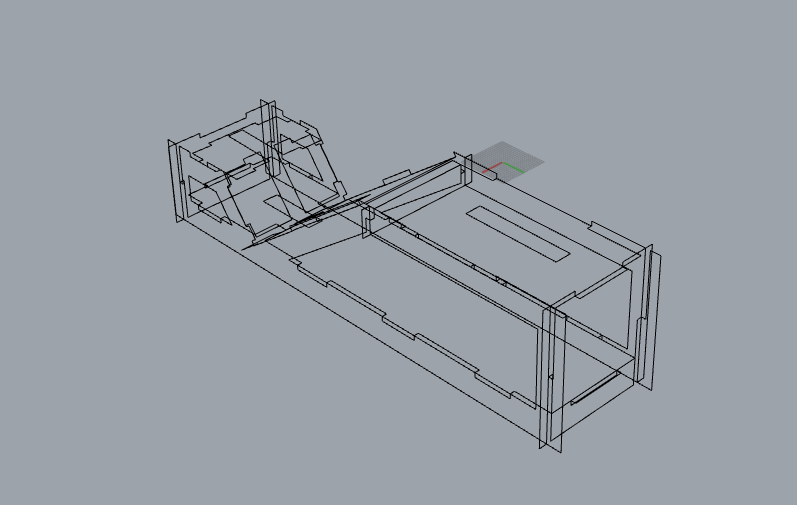

The assignment for this week is to build something big using CNC machine.

Machine Description

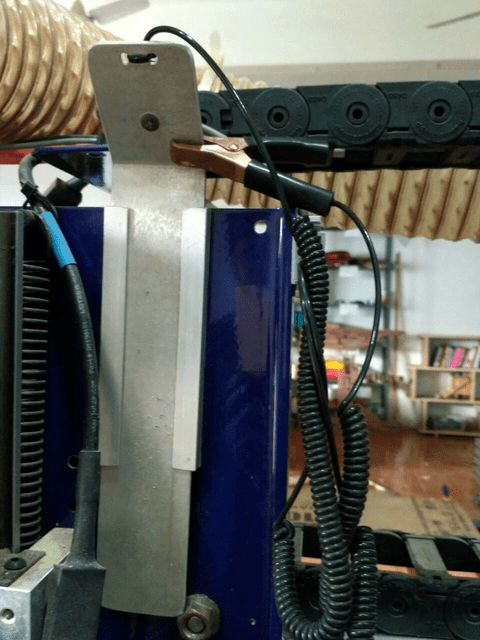

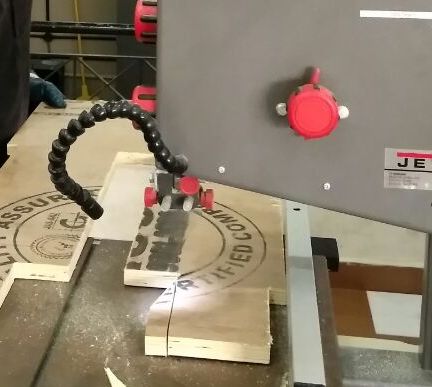

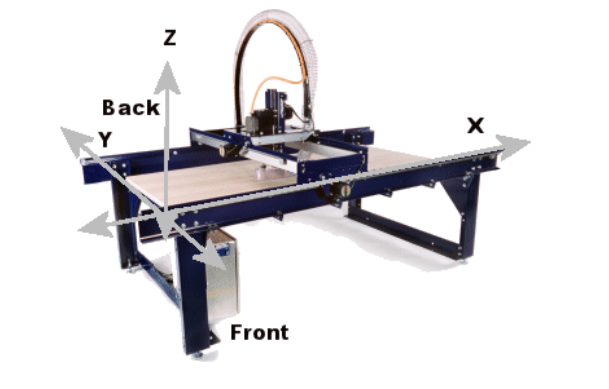

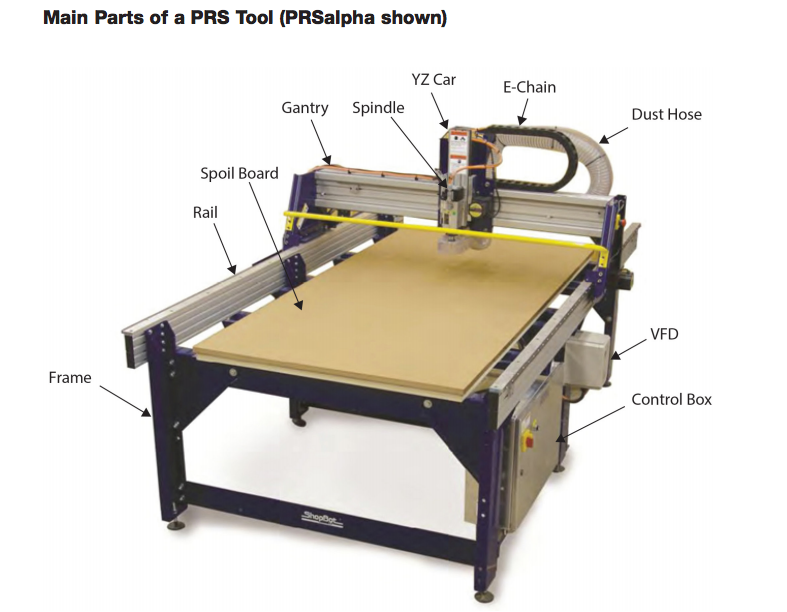

We have the ShopBot at our FabLab for this purpose. Its a large milling machine with a bed size of 8 x 4 feet which can mill wood, and plywoods. It base is fixed and the head has railings to move in x, y and z axes.

The CNC machine has a compresser attached to it, so that the cut particles do not fly around and mess up the lab. Its important to wear safety protection whenever using this machine, esp. eye gear and gloves.

Tooling Details

The following details are obtained from the documentation provided by Vishnu Easwaran

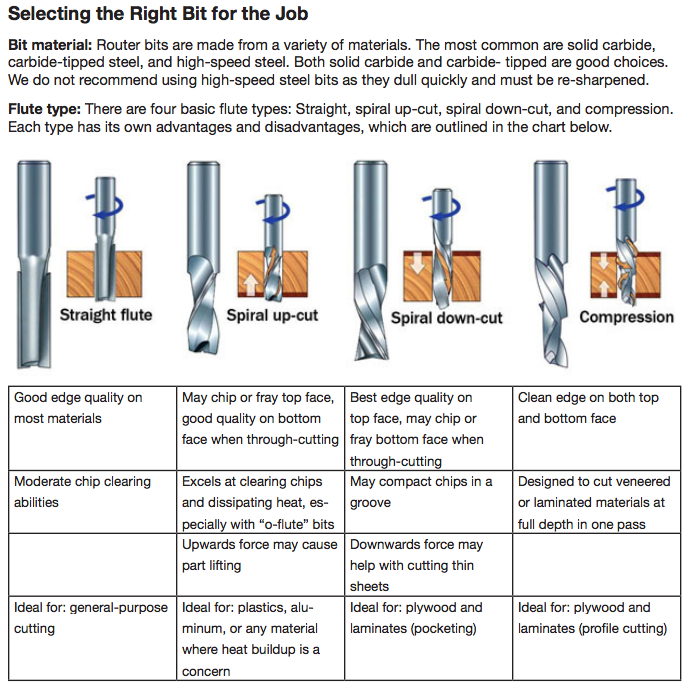

drill bit vs end mill :- Drill bit can be differentiated by its pointed tip which is for drilling into the object whereas end mills have flat tips and they are for milling away chunks from the object.

End mills give a flat cut while drill bit gives a curved cut.

flutes :- they are the spiraing sharp part along the surface of an end mill. They are for cutting through the object and for clearing the chips. Less number of flutes means chips will be cleared easily but the cut will be of rough finish. Higher the number of flutes we will get a smooth finish but the chips cut off wont be cleared effectively.

coating :- the end mills undergoes a lot of stress and strain while milling. So to provide extra strength, it is very common, to coat the bit in some ceramic bke nitrites which increase their endurance.

center cutting :- when you hold the bit upside down an look, if the flutes meet at the center then it is center cut and is good for cutting downwards but not for clearing the debris. If the flutes terminate before reaching the center it is non-center cutting and it is good for clearing the debris but not good for cutting downwards.

up/down cut :- if you hold the end mill by its head (the portion without flutes) and rotate it clockwise if you get the impression that the flutes are spiraling up then it is up cut and if it feels bke it’s spiraling down then it is down cut. Up cut is good for clearing the debris easily but results in a rough top surface while down cut is bad at clearing debris but gives a smooth top surface. Then there is something called center cut, where from bottom till middle it is down cut and from there till top it is up cut. This gives smooth top and bottom surfaces but very bad at clearing the cut out chunks.

flat/ball end :- flat end leaves flat surface and steps are formed when used for making cavities. Ball end leaves curved surfaces and forms curved finish while cutting cavities.

For Setting up the machine, ShopBot Documentation is all you need. It would only get repeative if I start going through it here. So I'm not.

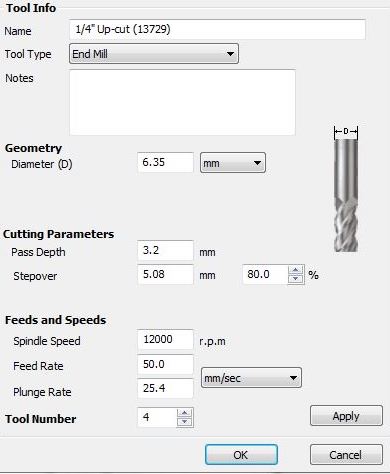

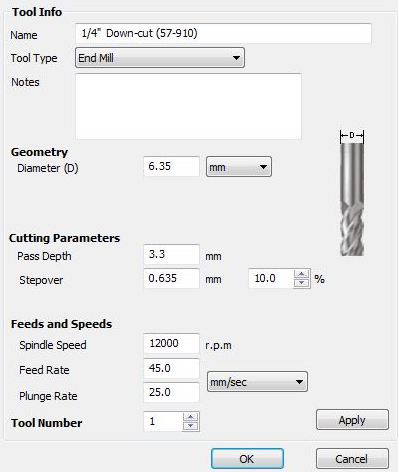

More details here on Feeds and Speeds Details

Chip load is a function of three different parameters: feed rate, RPM, and number of flutes on the tool.

Chip load is the thickness of the chunk of material taken by a tooth of the cutter. This is determined

by how fast the cutter is moving forward into the material and how fast it is turning,

Chip load = Feed Rate / [RPM x number of flutes]

Following is a screenshot from the documentation.