composit

This week I made mock up of my final project. I plan to make a sphere and dome aruarium and cover it for reinforcement and decoration. I made small model of that cover.

download file- voronoi_sphere(mold parts fudion360 3d model)

Process

first try

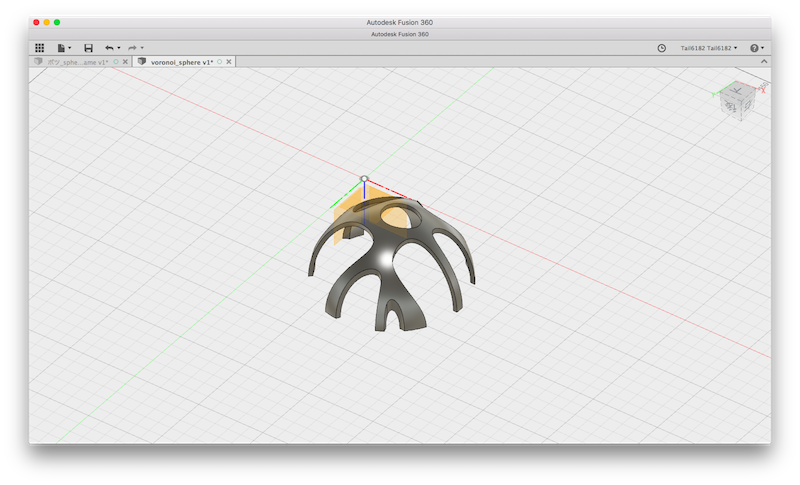

First, I try modeling by grasshopper but I could not.So I use Fusion360.This model is positive.

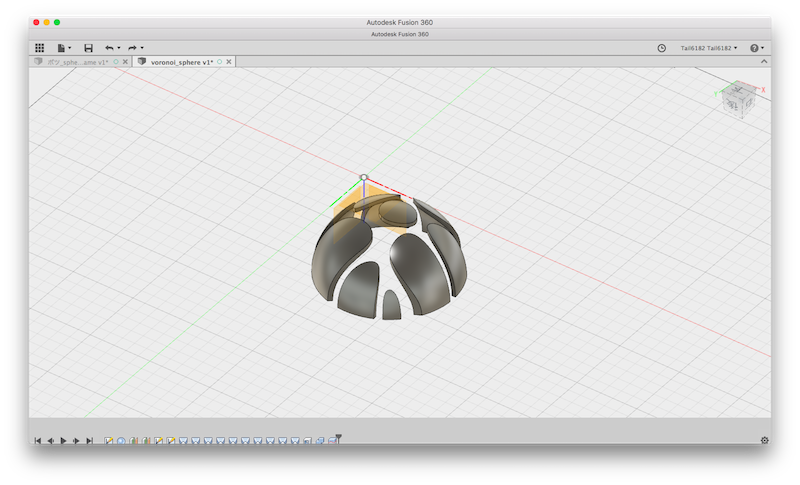

This model is negative. model is here

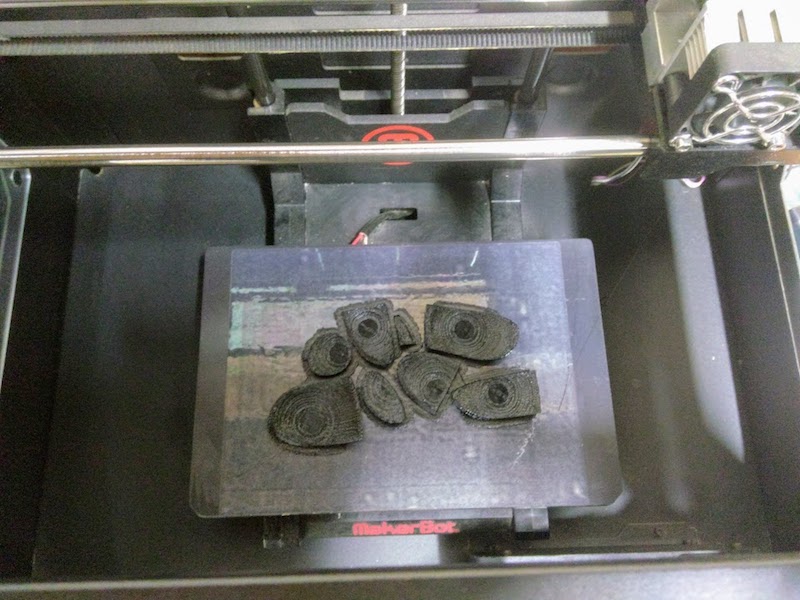

3D printing by Replicator2X.

I sticked parts to harf sphere of Styrofoam.

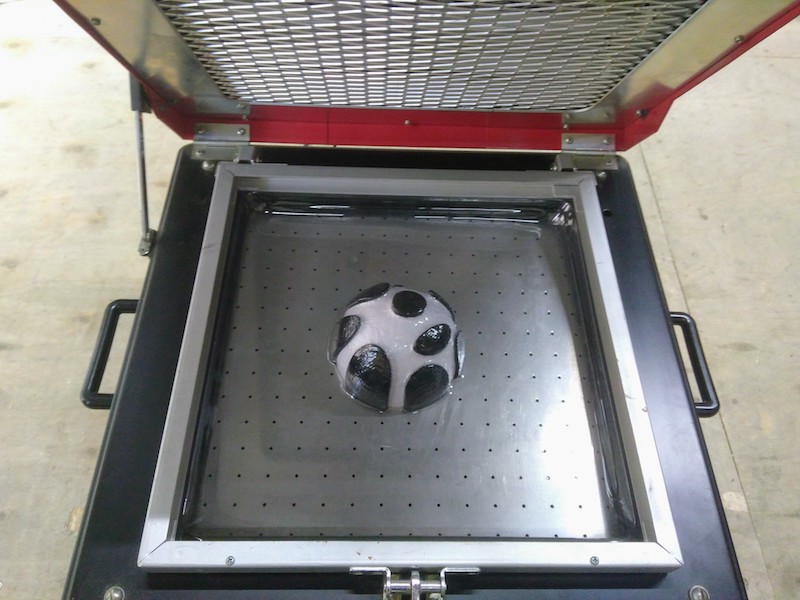

In this state, the material bite mold and it becomes difficult to peel off, so vacuum the styrene sheet to make the mold.

Styrofoam shrank due to heat.It copied to the surface roughness more than I thought.

I used a thin towel. I wanted to cut the laser, but because I could not make the developed data well, I cut it by hand.

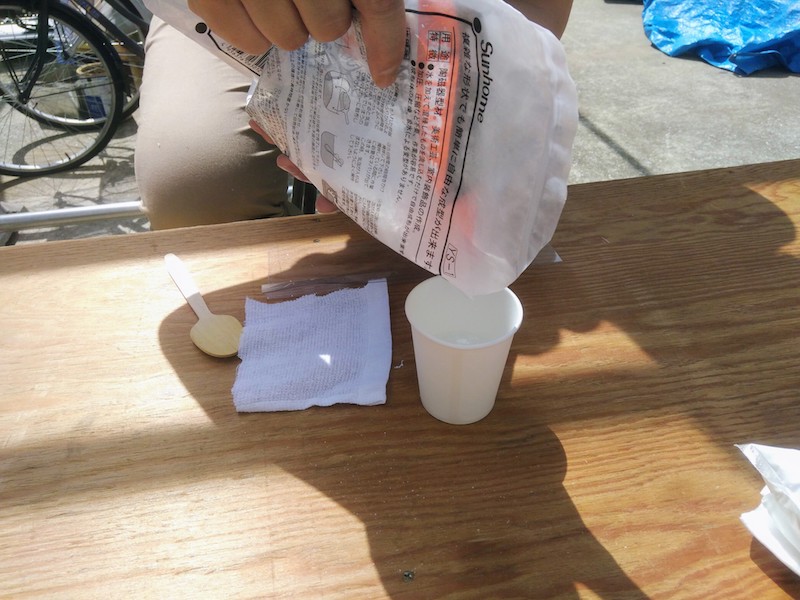

I used this gypsum.

SDS data sheet is here.Instead of MSDS,SDS is used in Japan.

I dissolved gypsum in water. Gypsum and water are the same amount. Gently slowly add gypsum to water.

Stirring to eliminate rash. Fill it in a mold with a brush, put the towel on the mold, and infiltrate the liquid so as to knock.

It took a long time because it did not penetrate easily, and the plaster started to solidify. Failure.

Gypsum is not sufficiently penetrated.

second try

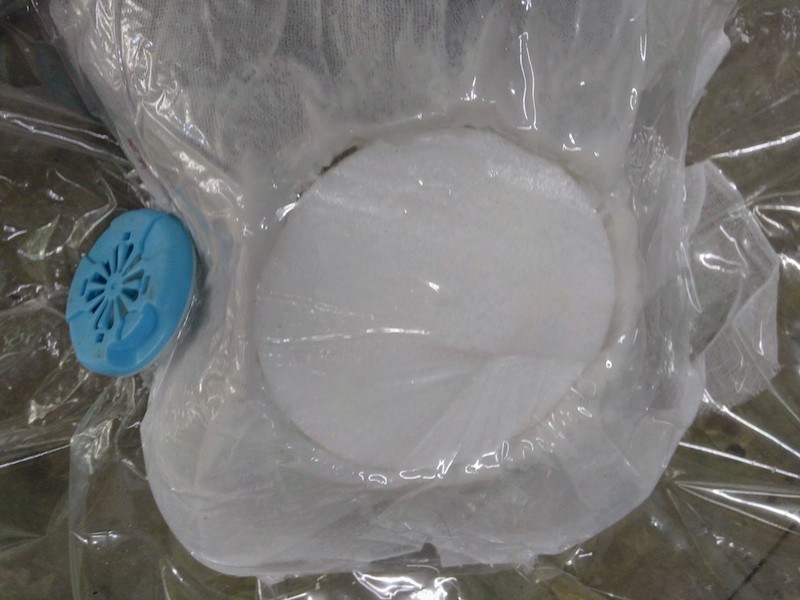

This time I used three pieces of gauze with incisions.I used the same mold as a female.

After gypsum was painted, the hemisphere of the styrofoam was pushed in and vacuumed.

I did not model it so that it could be removed, so I cut it out and came out.like this.good.