FAB ACADEMY CLASSES AND ASSIGMENTS BY WEEK

Week 1: Principles of project management

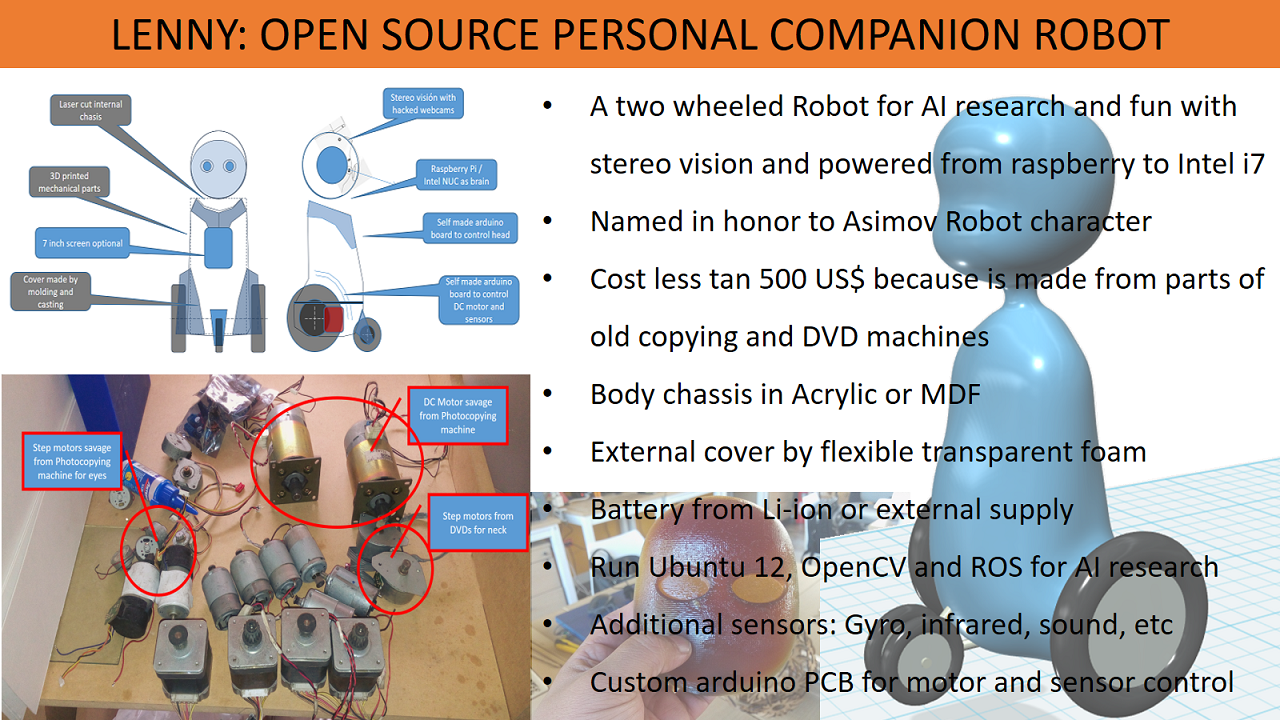

27 Janary 2017: As communications and computation went from analog to digital, resulting in PCs and the Internet, the digitization of fabrication is leading to personal fabricators that will allow anyone to make almost anything, anywhere.At the Fab Academy, we will learn how to envision, prototype and document your ideas through many hours of hands-on experience with digital fabrication tools. We take a variety of code formats and turn them into physical objects.

The job this week is learn how to use GitHub for control and document the projects and do a personal webpage about me, do a tutorial about Git or Webpage creation and upload all to the Git Hub repositorie. If you want to look into the details of this week assigment pls click the link.

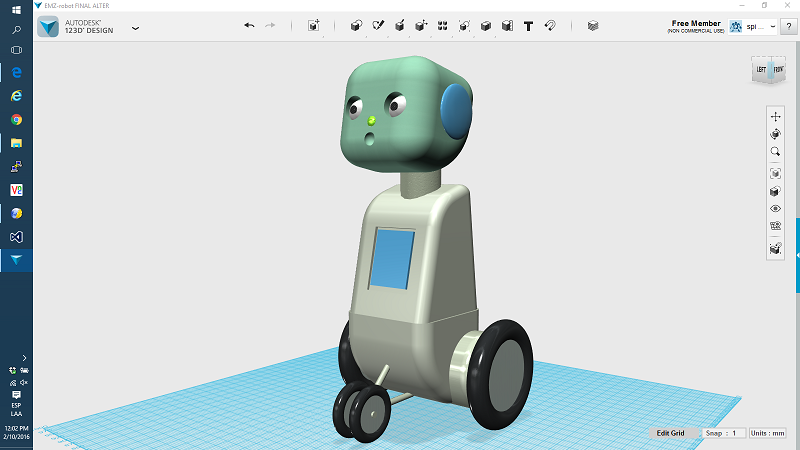

Week 2: Computer aid-design

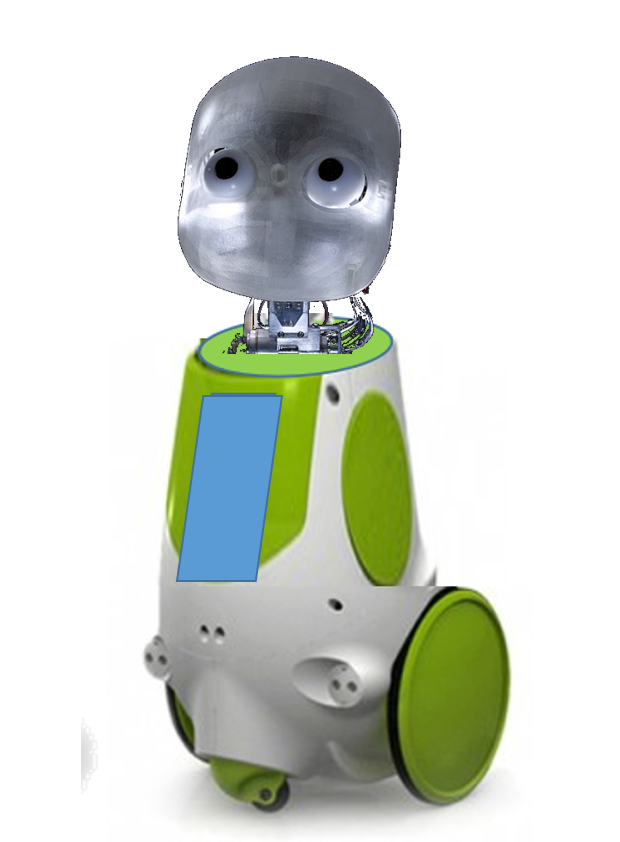

21 Febreary 2016: This week we start working in our projects. The first things to do is start the design process with Computer aid-design tools, so this week we explore several open tool options to design my robot. I will document the process of review of the 2D and 3D tools most popular that I found and, later you will see the preliminar design of the robot in 3D.

Week 3: Computer controller cutting

10 Febreary 2016: Now we start to play with th fab lab machines ... will be great

The assigment for this week is do a cardborard kit to snap together the pieces and form and object. In order to do this we need to learn how to made vector graphics, operate a vinyl cutter to do and sticker and operate a laser cutter for the cardboard model.

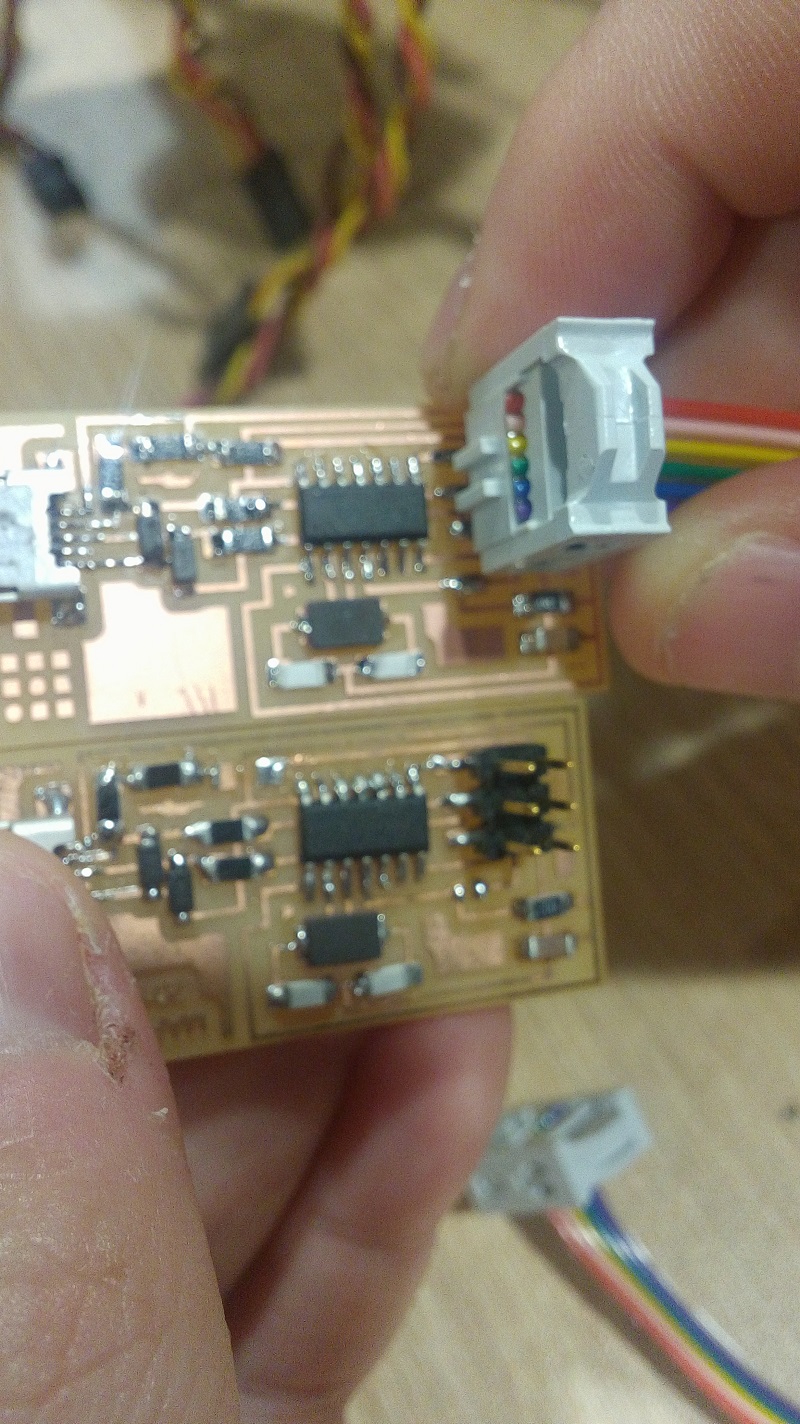

Week 4: Electronic production

17 Febreary 2016: This week we learn how make a PCB board to made our own electronic board using the Roland MODELA to grab in a PCB plate our design, then we learn how to program the board

Week 5: 3D Scanning & Printing

24 Febreary 2016: Now we start learning how scan objects to use in 3D printers and use the printer to make reallity our computer aid design. This week I will scan a mask which will be used as the face of my robot project.

Week 6: Electronic Design

March 2, 2016: Now we learn how design our circuits, and because we learn in week4 how to produce it, we are ready to create our own PCB designs

Week 7: Computer Controlling Machining

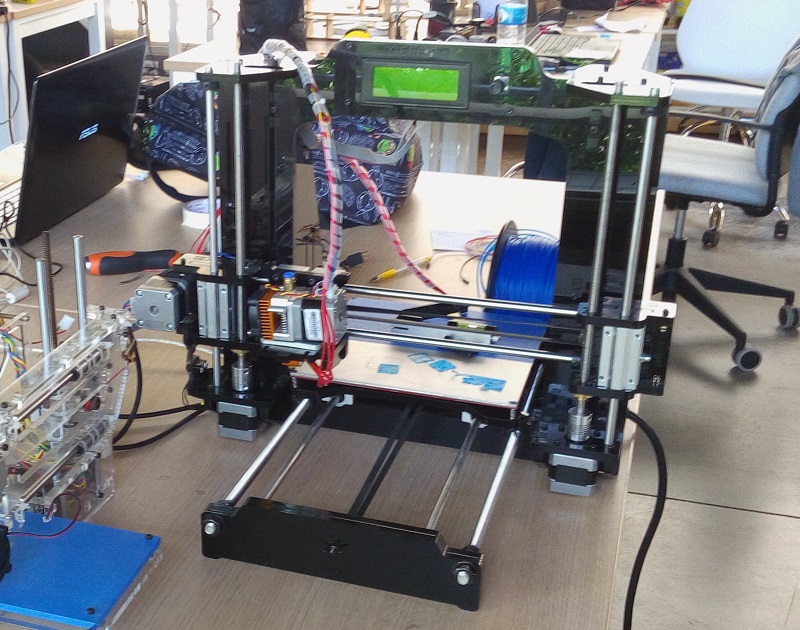

March 9, 2016, This week we learn how to make a big things with big toys, like the CNC ShopBot which can work pieces of 2.44 x 1.22 mts. Using this machine I will create a 3D printing station from MDF plates for my 3D printers and other devices I will build for my own mini fablab at home.

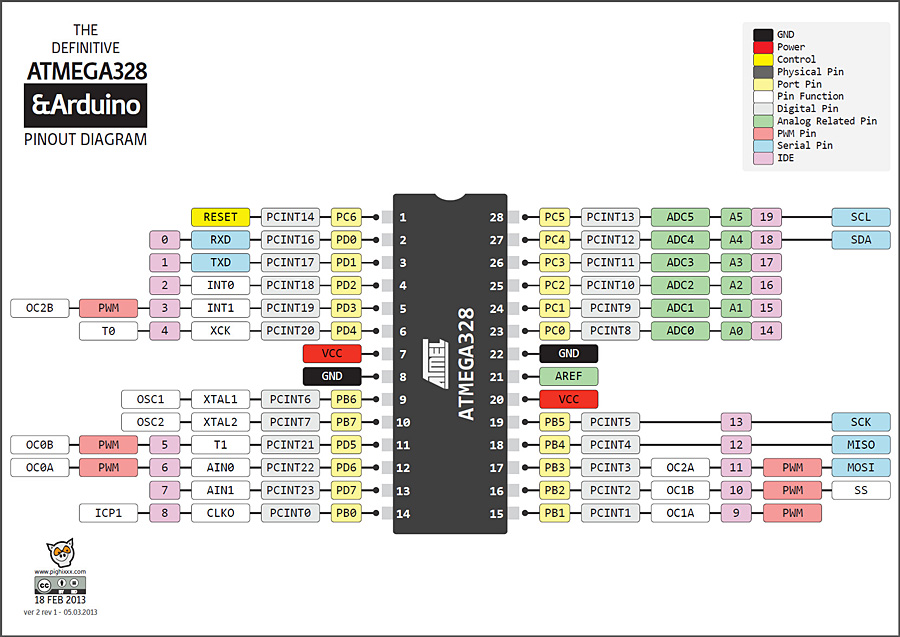

Week 8: Embedded programming

March 16, 2016: in week 6 we build an already designed PCB circuit with a microprocessor, but we really dont know how it works and how programming it, we just learn how to build the board. But now, this week we learn how to understand what capabilities have the microprocessors by know how to read the datasheet and programming it to do differente things

Week 9: Mechanical Design

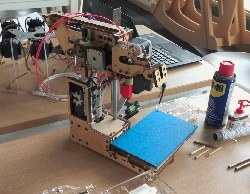

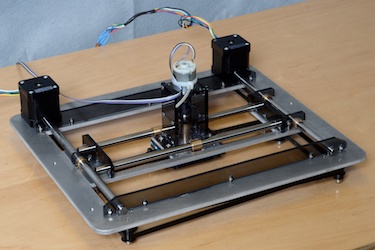

March 30, 2016: In this week we learn how create a machine which do a job for us, like a CNC, PBC milling, etc. The whole ESAN fablab group will work in this assigment, and I will be part of . This week we focus in mechanical design.

We choose made a design based in the COREXY principle and I will do the preliminary design of the chassis

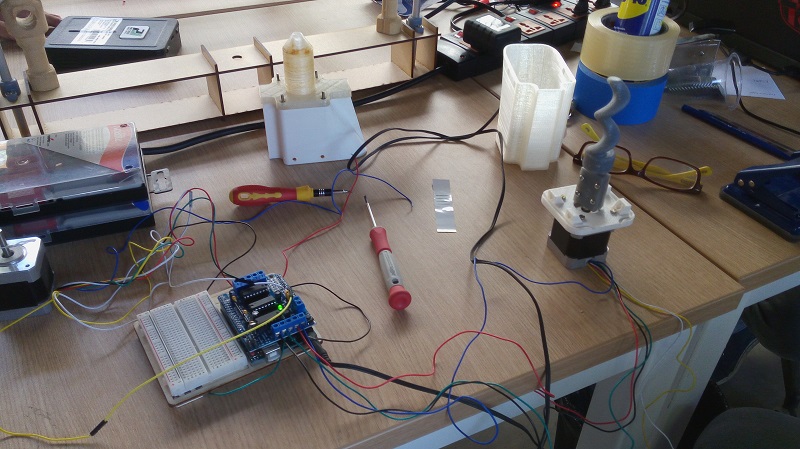

Week 10: Machine Design

April 6, 2016: This week we continue working in the team assigment by automating the machine with and Arduino PCB builded, some Step Motor and gears and motor drivers.

Week 11: Input Devices

April 13, 2016: This week we continue using microprocessors to sensing the world, This week we will learn how the sensors works and put to our previous PCB board a sensor, then I will program the board to do something woth the input... will be very funny.

Week 12: Molding & Casting

April 20, 2016: Now we will learn how to made molds for casting ANYTHINGS, for example I will use the 3D object of the face of my robot to create a mold in STL format to print in a 3D printing or milling machine, and them made the face in flexible silicon, just like a real face.... This part will be very funny

Week 13: Output devices

April 27, 2016: This week we will understand how output devices works and we attach an output devices or motor to a PCB and programming the board to do somethings. This week we will finish our own PCB milling machine using the motors.

Week 14: Composites

May 4, 2016: Now we learn what is, and go composites materials like fiber glass. This week I will do an 3/4 scale body test with cutboard, cloth and resin.

Week 15: Networking and communications

May 11, 2016: WIP

Week 16: Interface and application programming

May 18, WIP

Week 17: Applications and Implications

May 25, This week we think a lot about our project, the impact, applications and implications of it. We dont make any material job, but instead we think about it and answer important questions about our project.

Week 18: Invention, intellectual property and income

June 1, 2016: Now is the time to present a mature version of our project, an one slide presentation and 1 minite video about it. Enjoy...