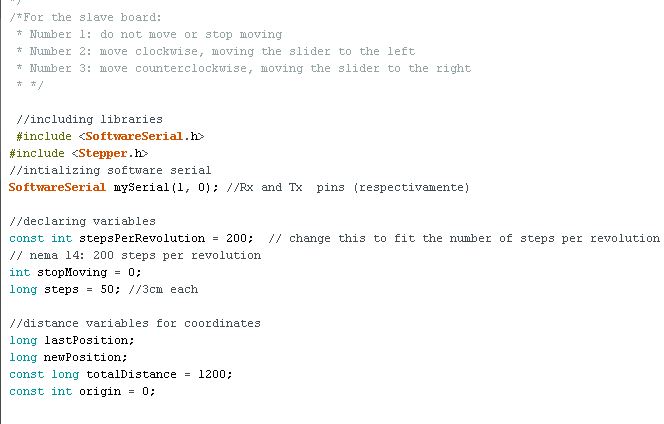

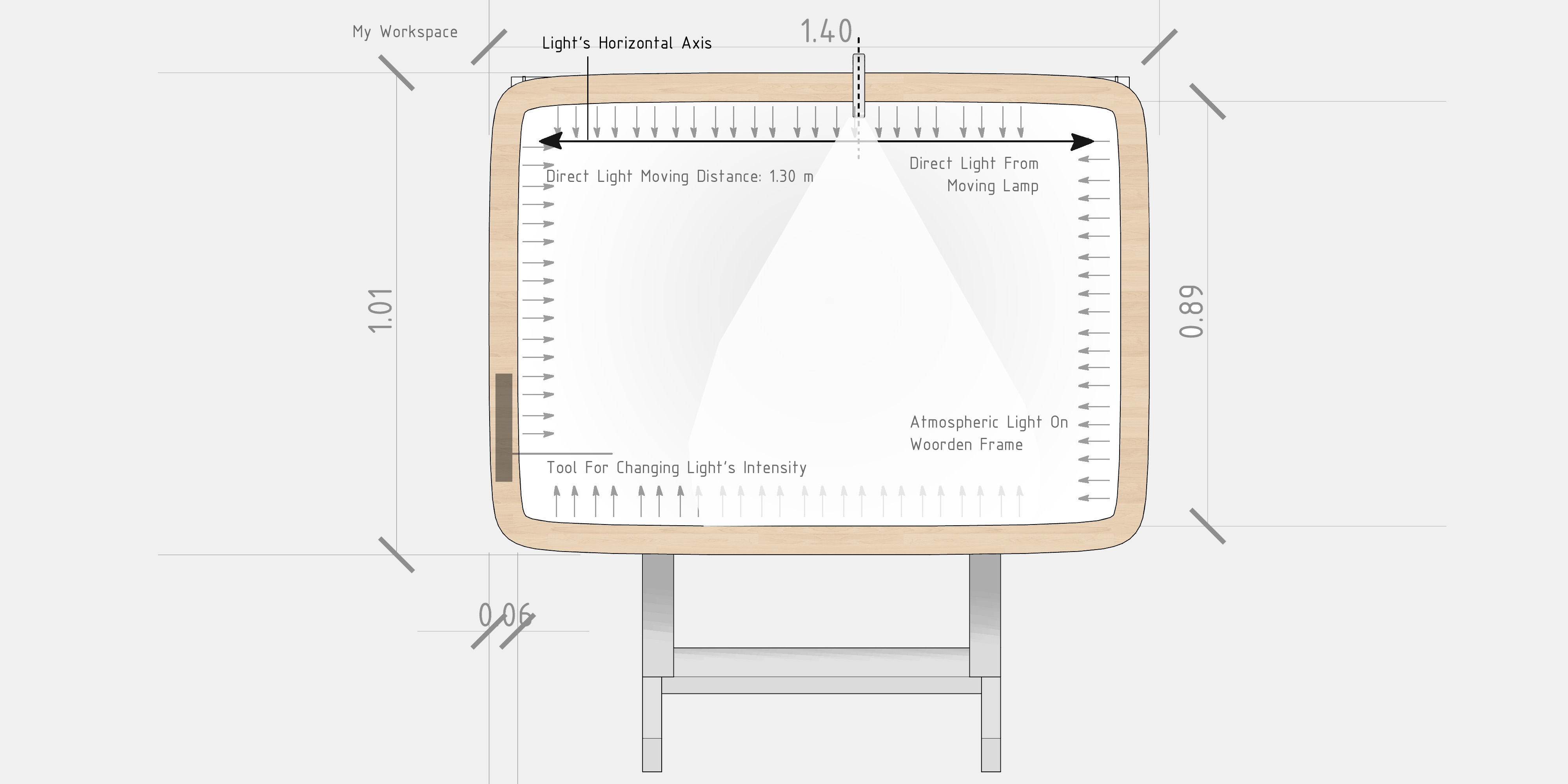

2.e - Embedded Programming: The Final Code

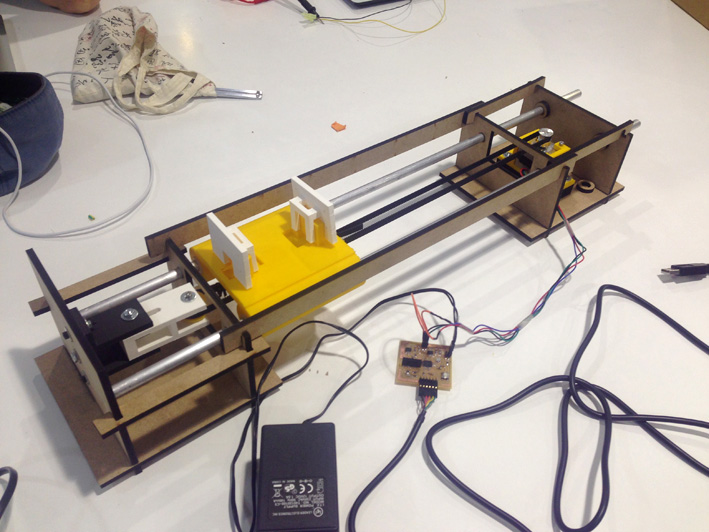

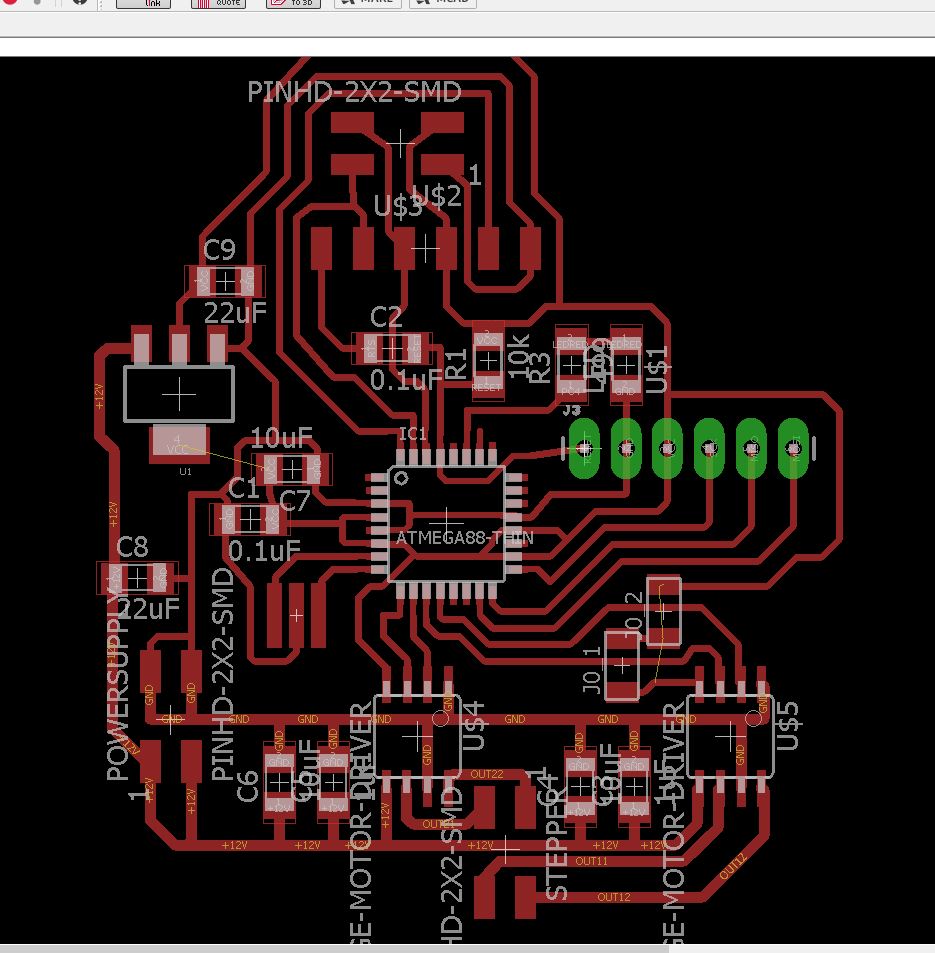

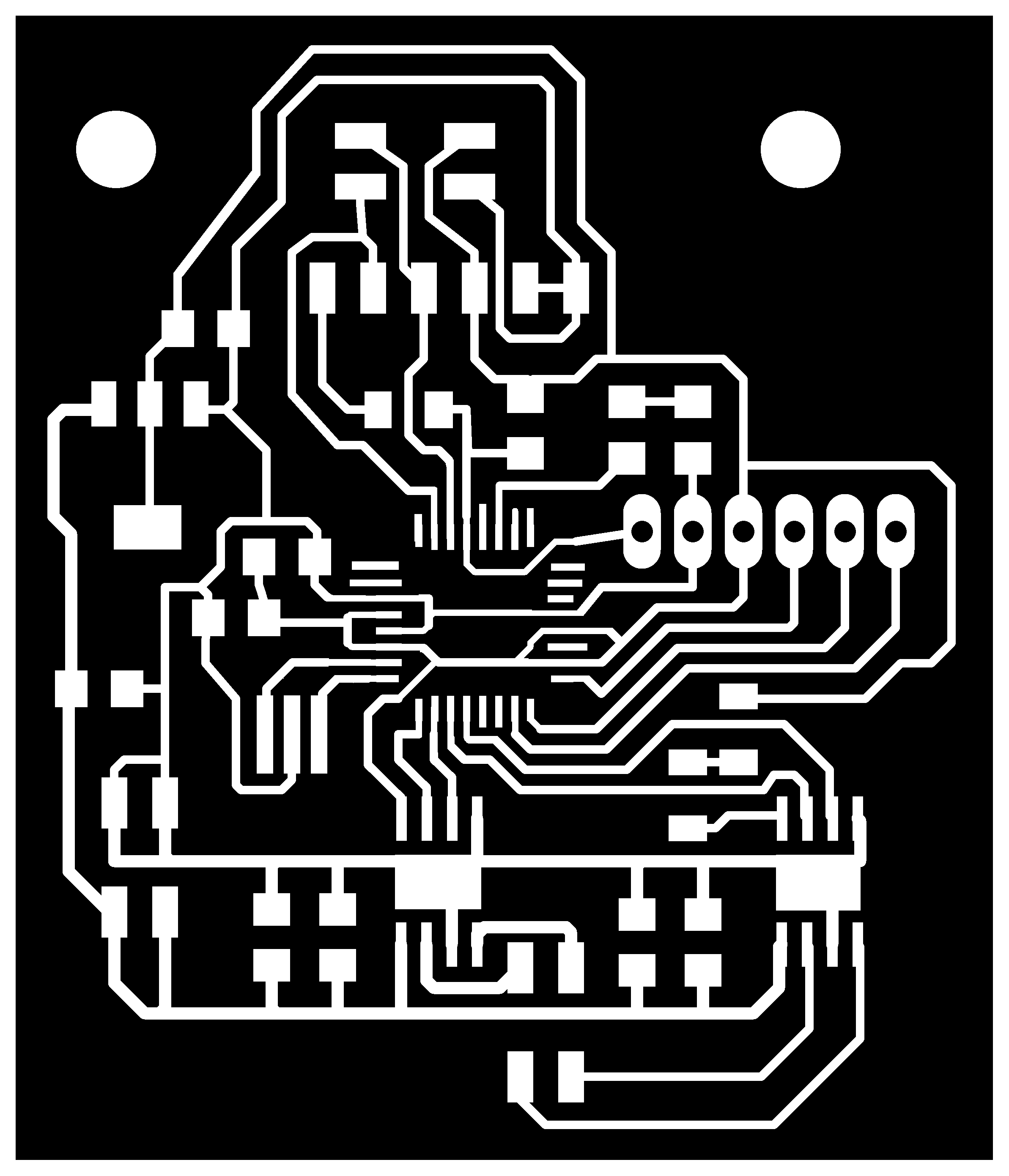

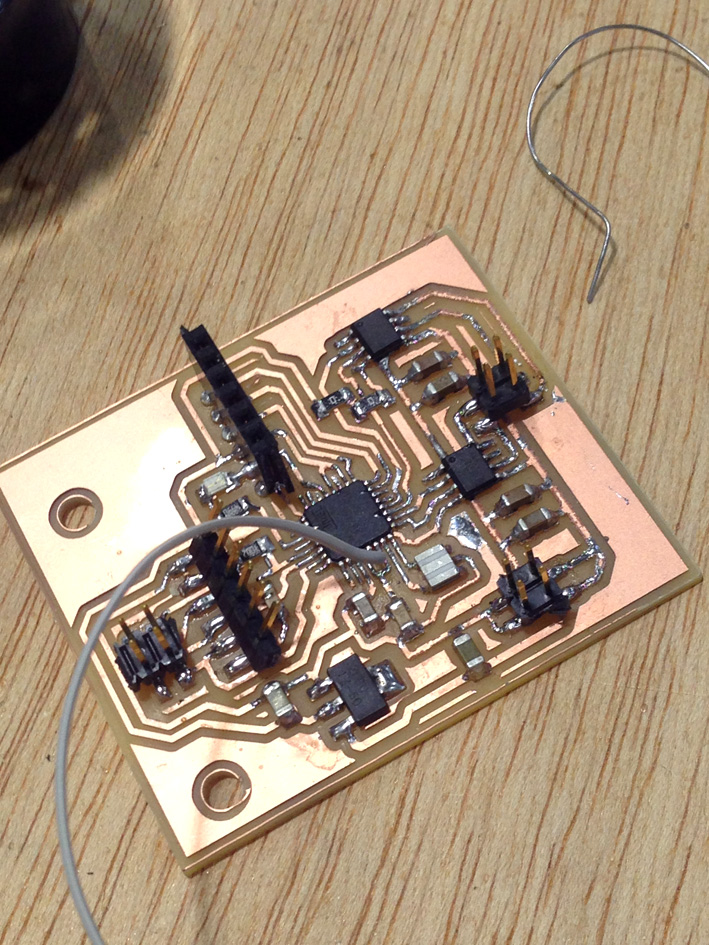

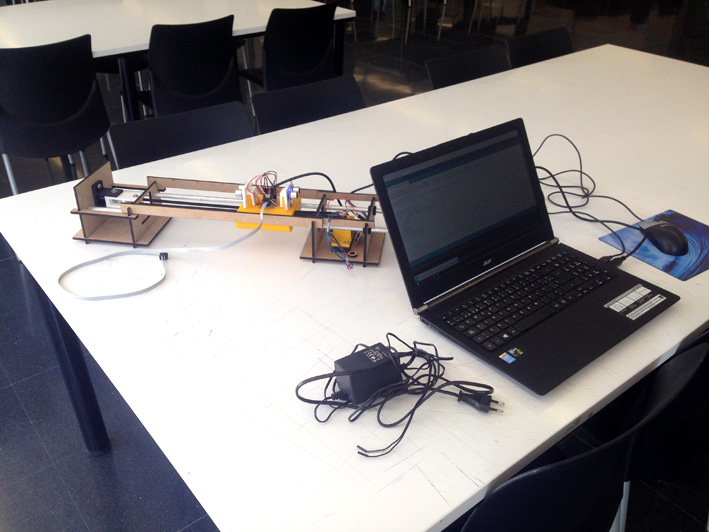

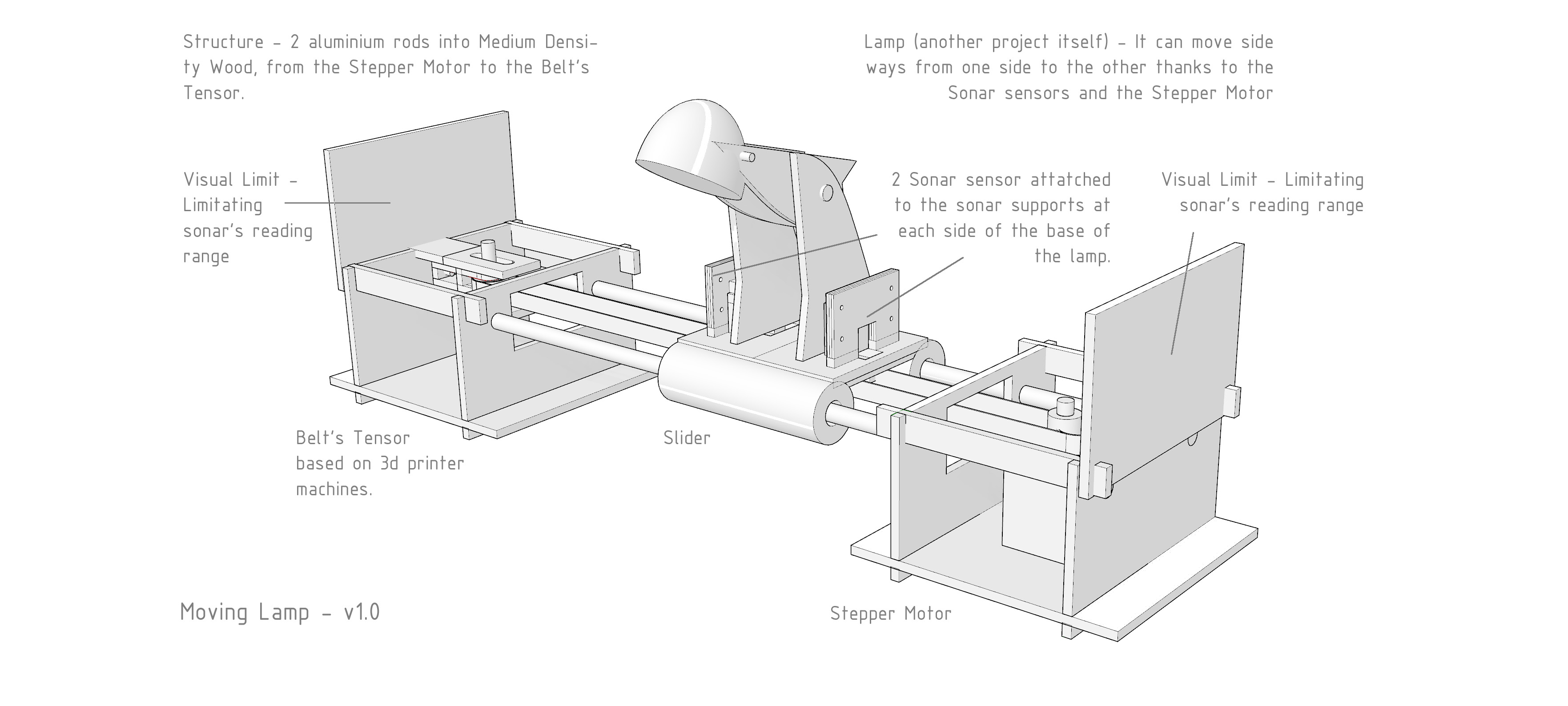

I have two boards that connect with serial communication. During the programming, I had to face up several problems:

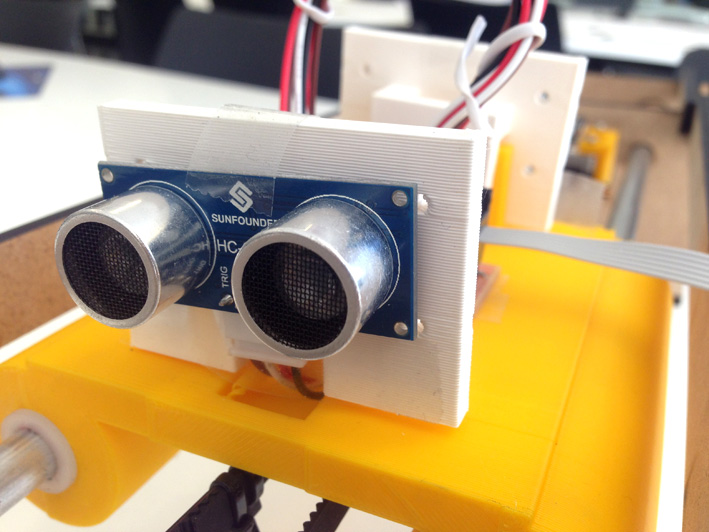

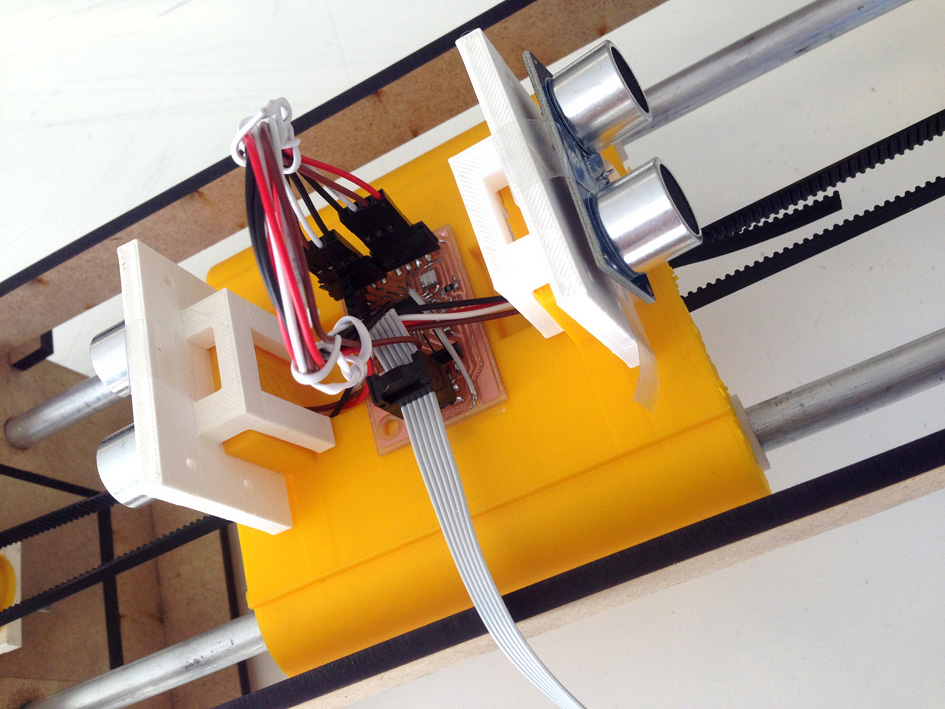

-analyse the four different situations that can take place with the two ultrasonic sensors used.

-make sure the slave board does not saturate from infinite commands sent by the master board.

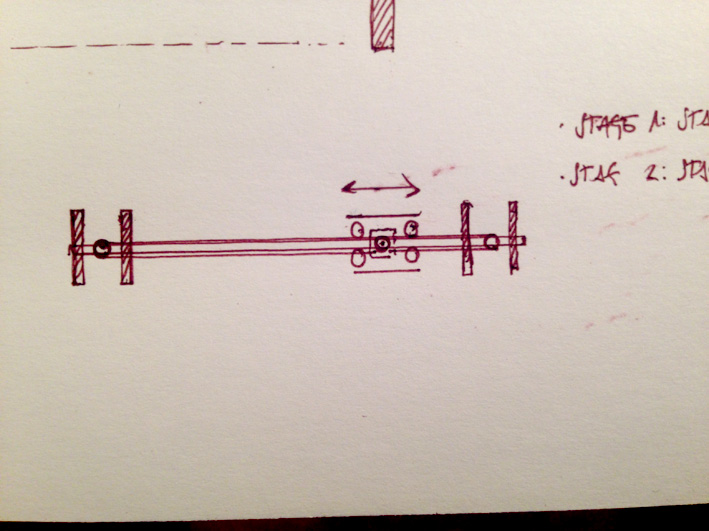

-the slider's position: the system needs to know where exactly the slider is at, what distance has left to both sides.

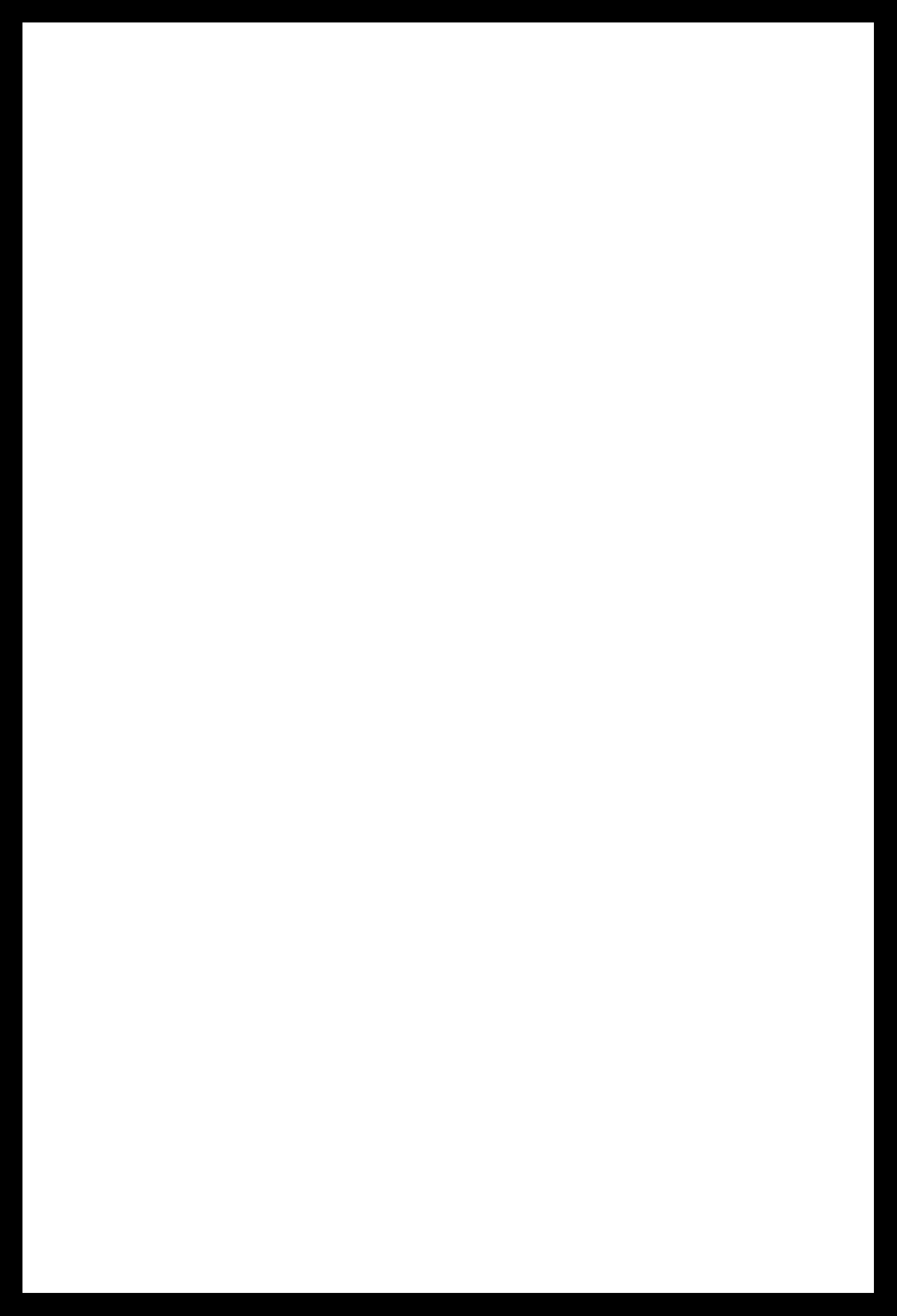

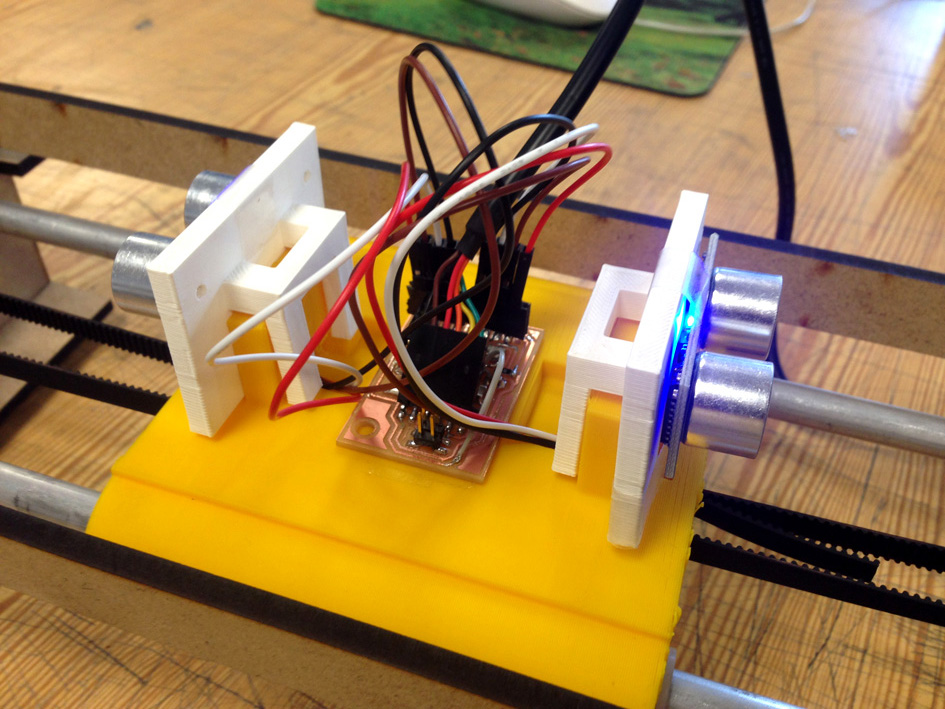

Input Board:

Its responsibility is to analyse if there is an object (my hand) under 10cm. If this is true, then move the slider to one side. Depending on which sonar detects this obstacle, it moves to one side or the other.

The input board is the master board of this system, having the responsibility of:

-send the order to the slave board

-consider all four situations regarding the sonar's readings.

-do not saturate the slave board with orders

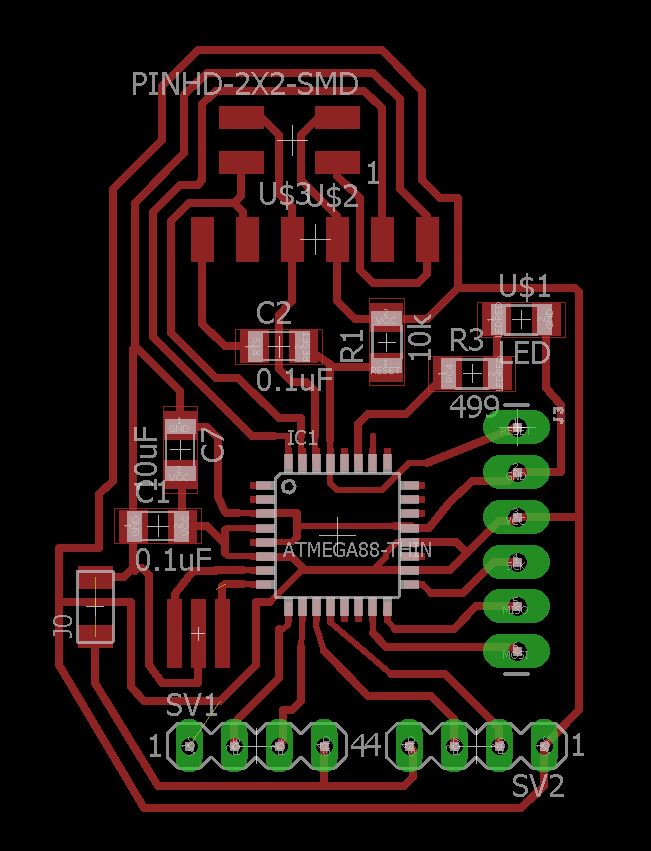

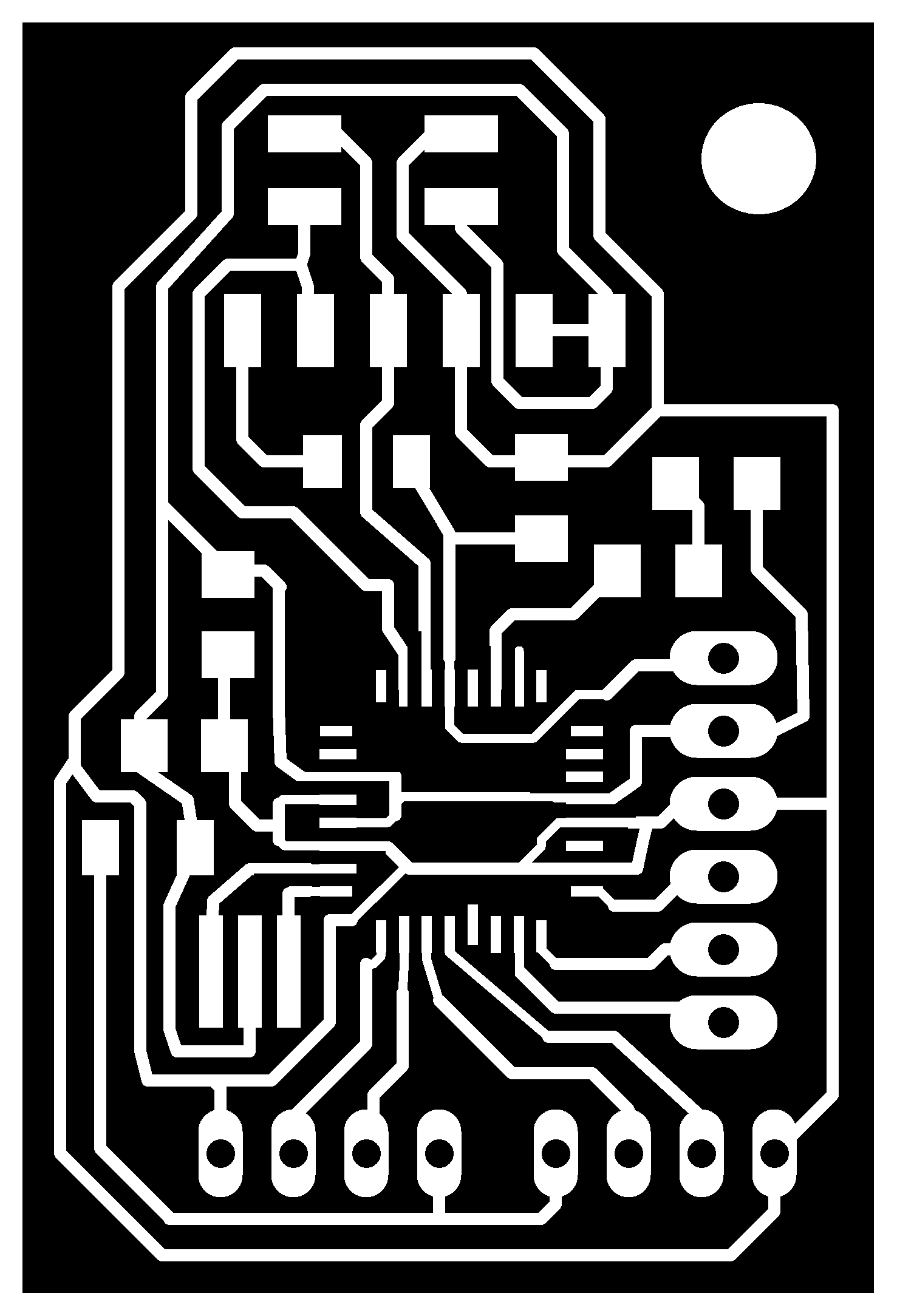

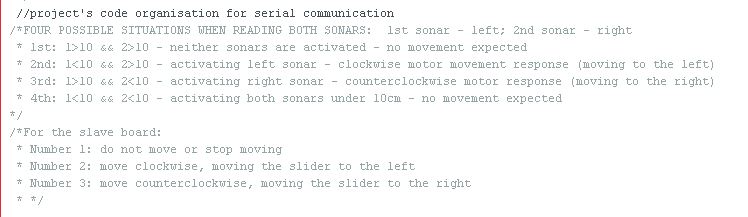

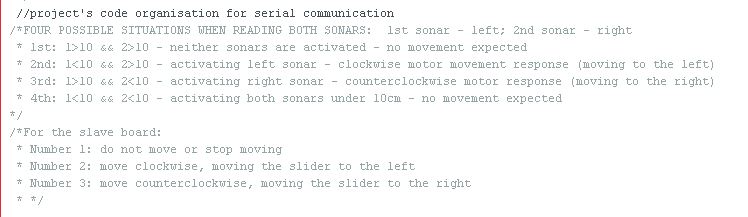

Just below, there are two pictures with the most important parts of the input's code. They solve what was written above.

(code for having an obstacle in sonar1, sending to the slave board number 2)

Sending The Order To The Slave Board

For the board to send the order to that slave board, it uses the command 'mySerial.println(n)'.

Number n can be:

n = 1 - Sends the order to the slave board to not move.

n = 2 - Sends the order to the slave board to move the stepper clockwise, moving the slider to the left.

n = 3 - Sends the order to the slave board to move the stepper counter clockwise, moving the slider to the right.

Analysing The 4 Possible Situations

As you can see on the picture, the first 'if()' is activated depending on the variables 'distance1' and 'distance2'. Each one of this variables have been previously declared assigning them 10. This number 10 refers to the 10cm distance where I will be operating the device. Therefore, if I have my hand under those 10cm, the board will send an order to the salve board. There are four different situations:

-Not reading anything: 'distance1>10' and 'distance2>10', both have measures above 10cm.

-One of the sensors reads an obstacle under those 10cm: 'distance1<10' and 'distance2>10'.

-The other sensor reads an obstacle under those 10cm: 'distance1>10' and 'distance2<10'.

-Both sonars read they have an obstacle under 10 cm: 'distance1<10' and 'distance2<10'.

Depending on each possible situation, the board is going to send one of the number explained before.

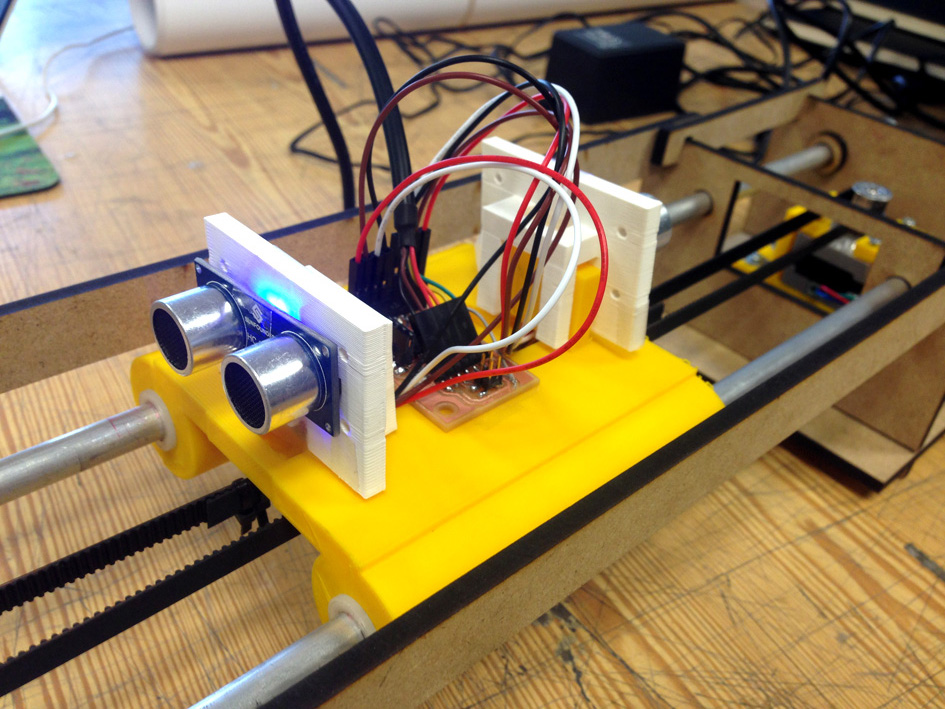

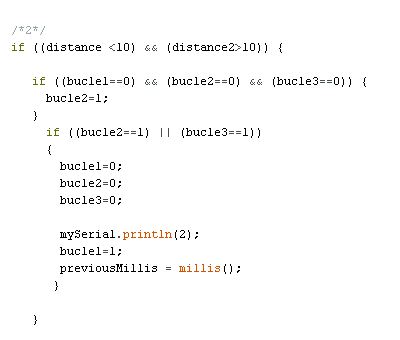

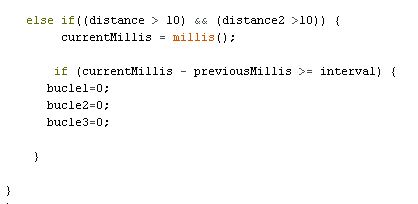

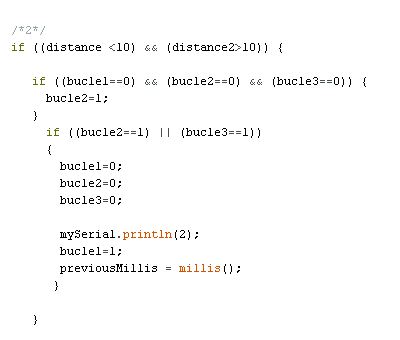

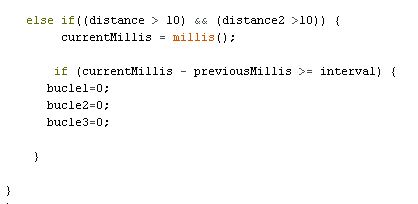

How Not To Saturate The Slave Boards With Too Many Commands

Just below, plus the previous image, you have the code I have used:

(code when both sonars do not have any obstacles and reassign variables 'bucle1', 'bucle2' and 'bucle3'.)

For the board not to send infinite commands, I have used the function 'millis()' to make sure that same command is not repeated all the time. I declare the variable 'interval' (take a look to the code, the image only shows some of it), where I decide how much time it needs to pass so the board can send the same order again.

Initially, 'bucle1', 'bucle2' and 'bucle3' are the variables that make it possible to not send all the time the same command, and the three of them are assigned number 0.

The way it works is very simple: once activated a possible situation, one of the variables changes from 0 to 1. When the loop starts over again, for the same possible situation, there is an initial 'if()' function. This if() function reads: if one of the two other variables are 1, the same command can be sent again, if not, continue with the next part of the code.

Here is the tricky part, I need to wait for the interval to take place so the variables go back to 0 and the same command can be sent again.

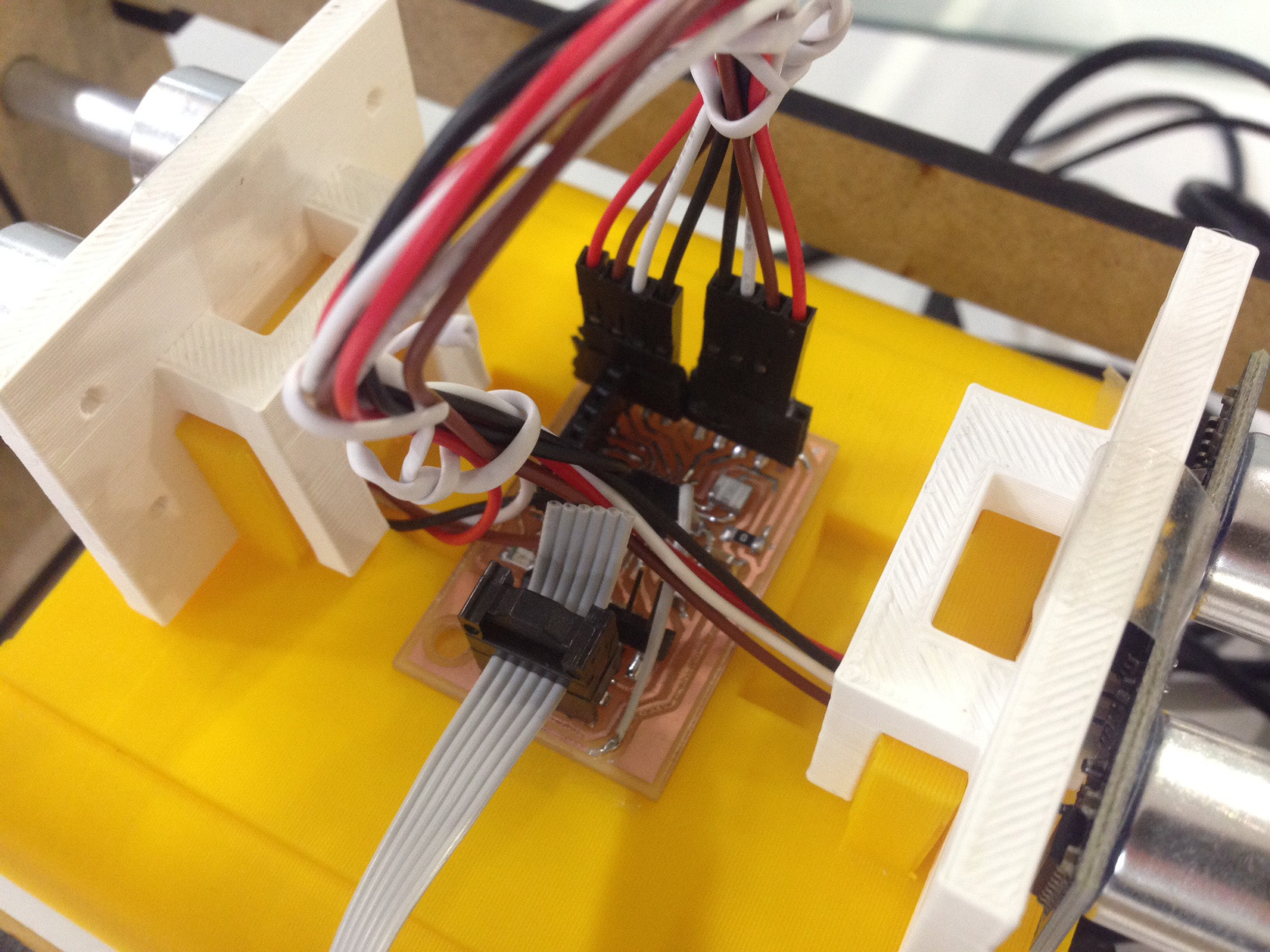

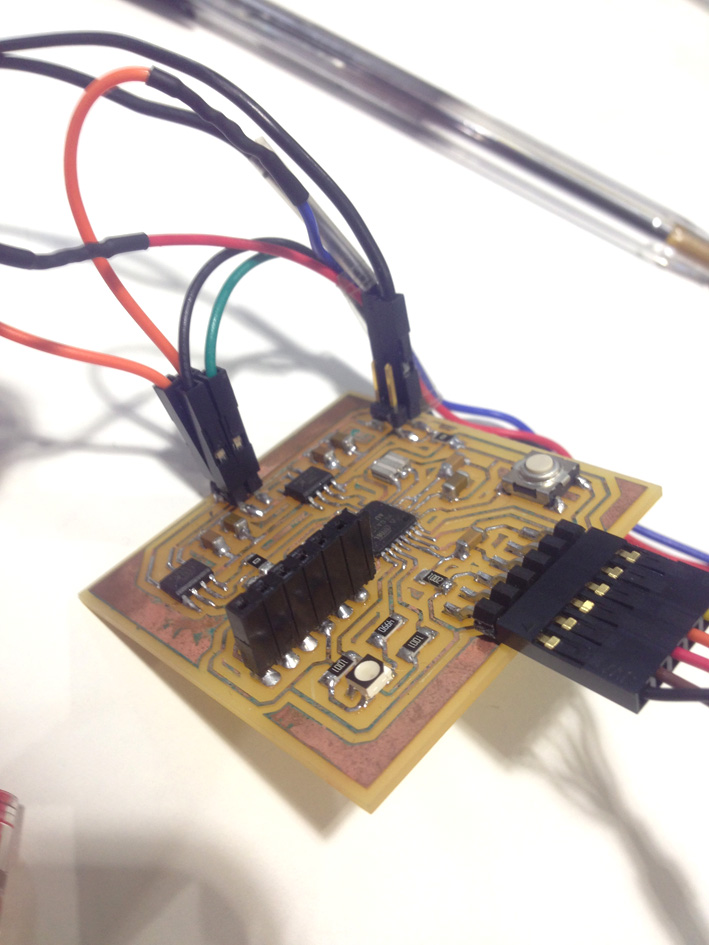

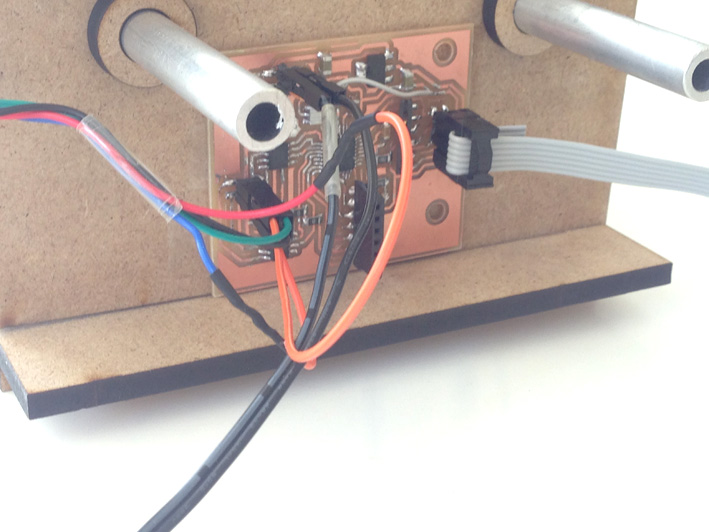

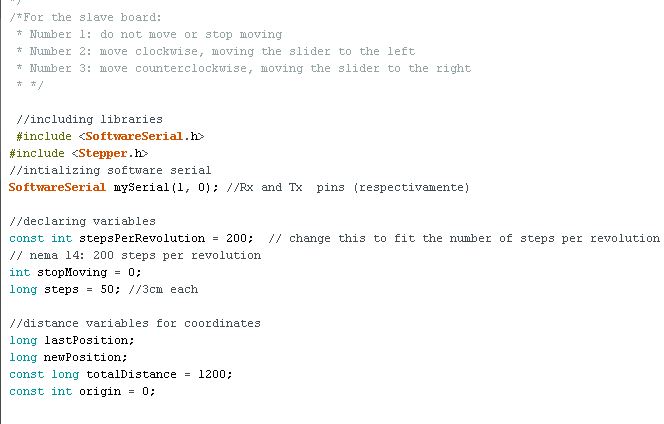

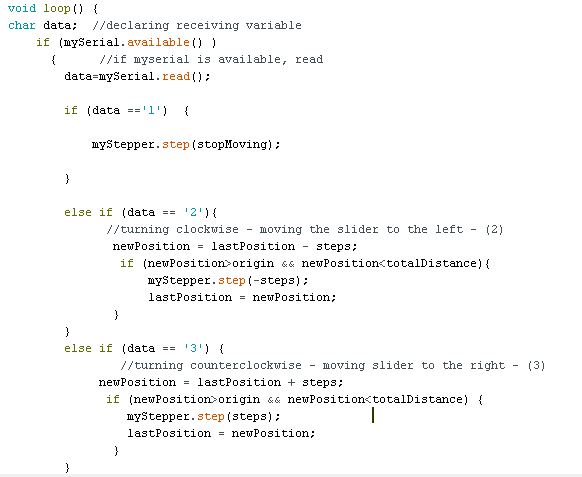

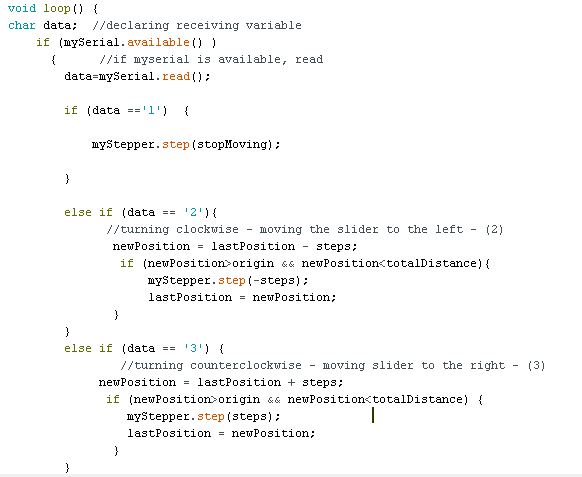

Output Board

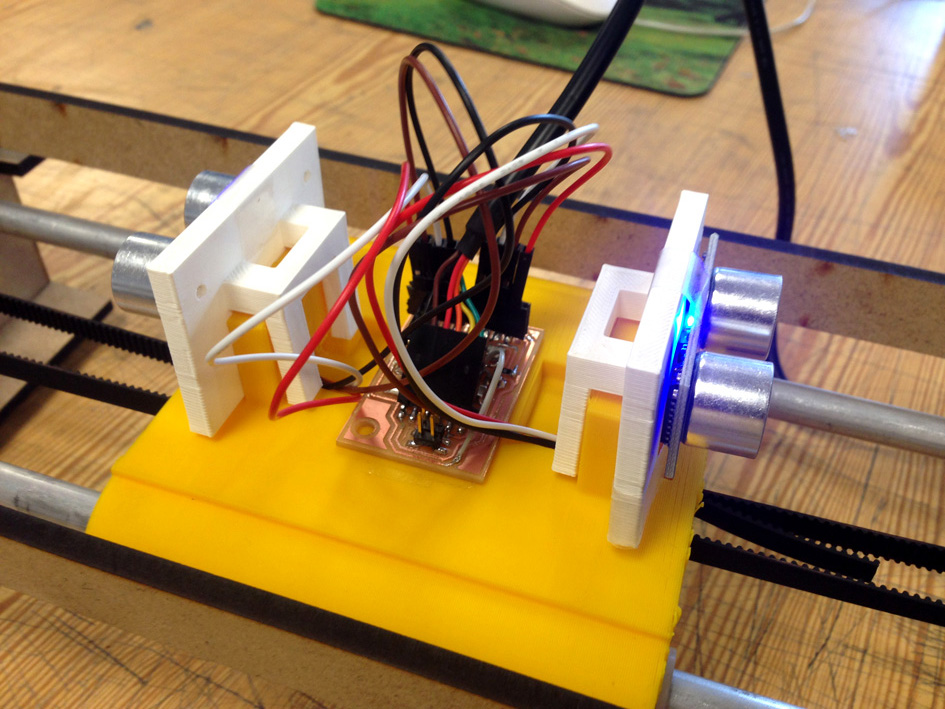

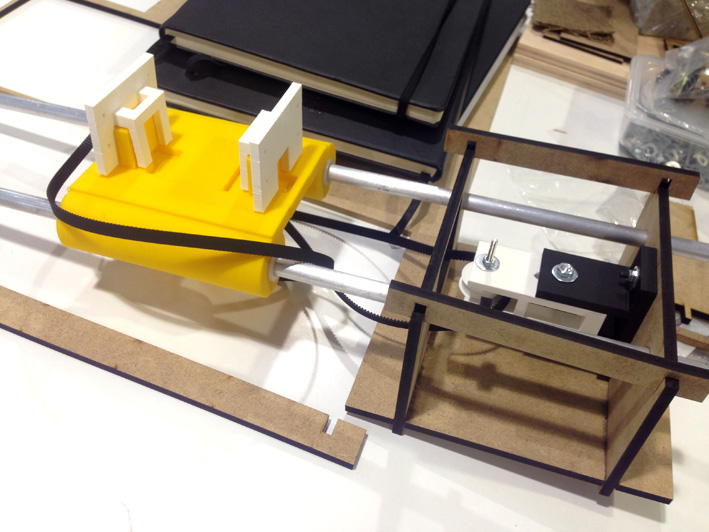

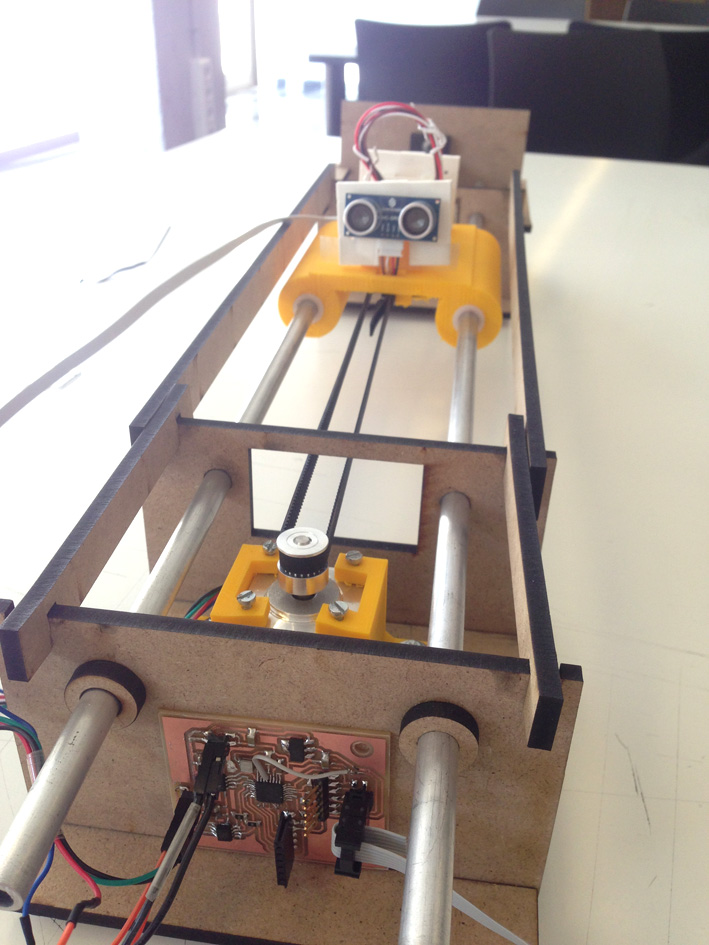

For the output board (the slave board), receives through serial communication the order. So, depending on the possible situation with the sonars, a number will arrive and activate the stepper motor.

The responsibility of this boards is:

-move the stepper motor so the slider moves to the direction I want to.

-know exactly at what position the slider is so it does not crash to one of the sides.

The orders the board can receive are:

-number 1

-number 2

-number 3

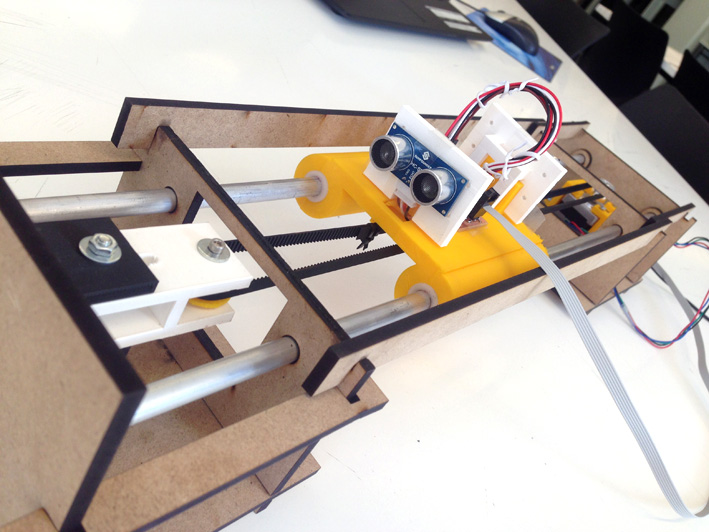

Moving The Stepper Motor

In order to move, I used the command 'myStepper.step(the order. This order can be:

(stopMoving)

(steps)

(-steps)

My strategy is that the motor will move the slider a certain amount of distance each time it receives a number. A non-continuous movement is caused.

My strategy is that the motor will move the slider a certain amount of distance each time it receives a number. A non-continuous movement is caused.

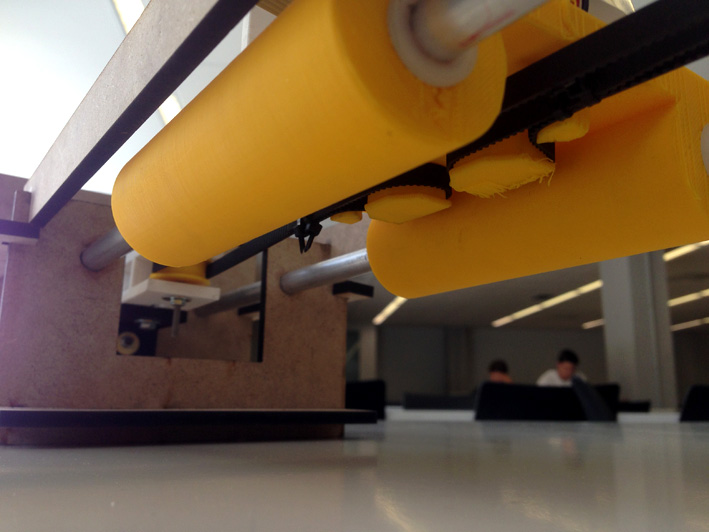

-'stepsPerRevolution': the number of steps the nema-14 stepper motor has are 200.

-'steps': the number of steps I want the stepper motor to do when executing the command: 60.

-'stopMoving': making sure it stops.

As well, there is another command that needs to be declared: setting the stepper motor's speed: 'myStepper.setSpeed(60). In this situation, I decided to have

(a part of the output's code, please check the full code either with the file or next chapter).

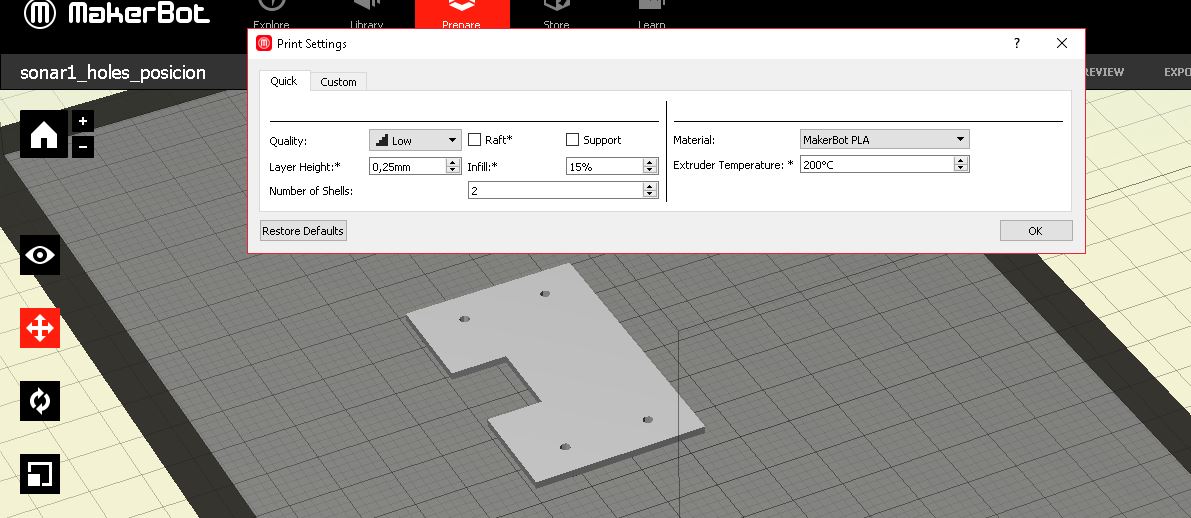

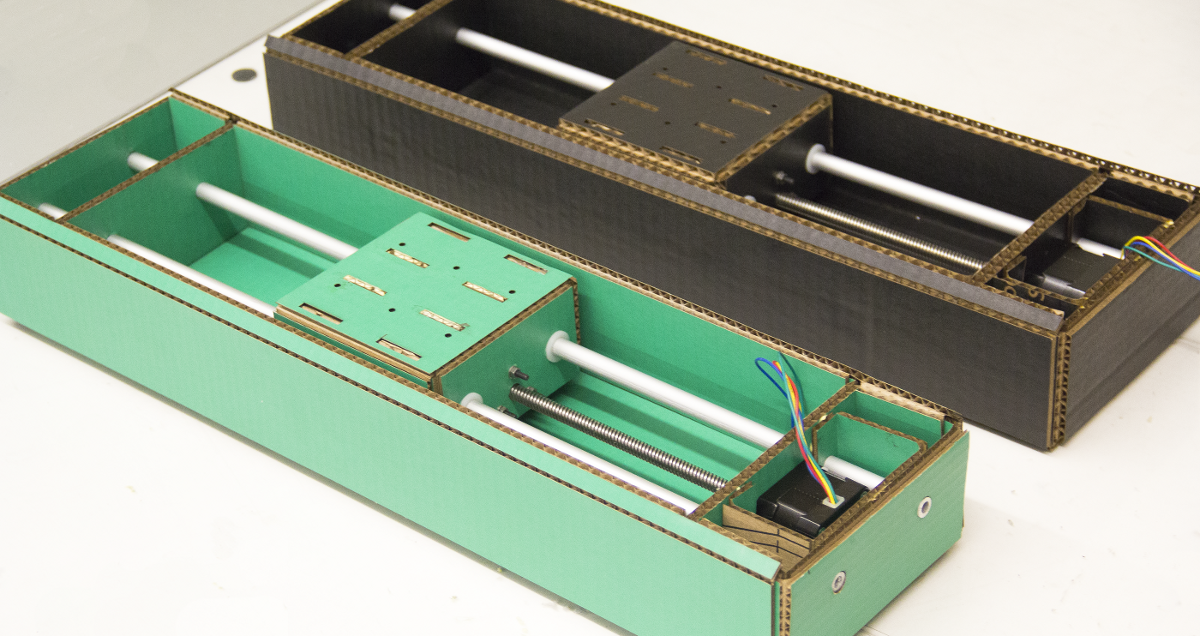

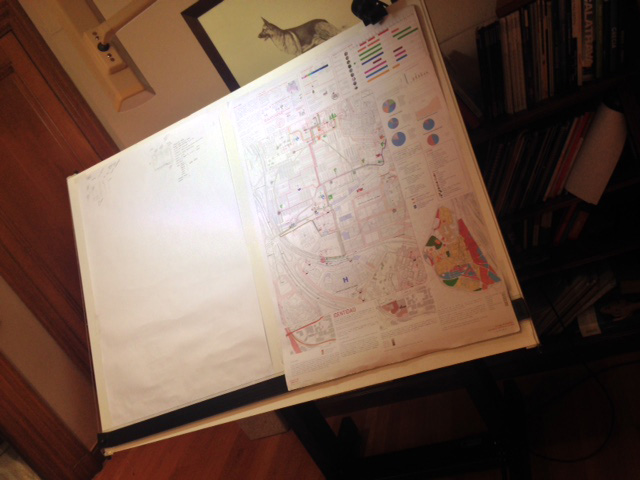

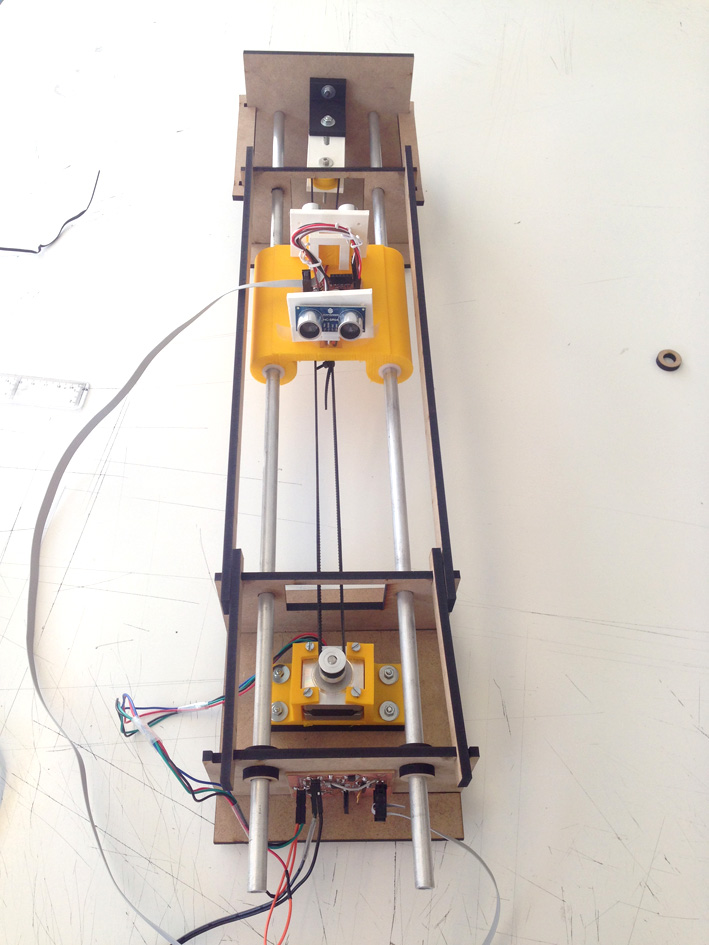

Position

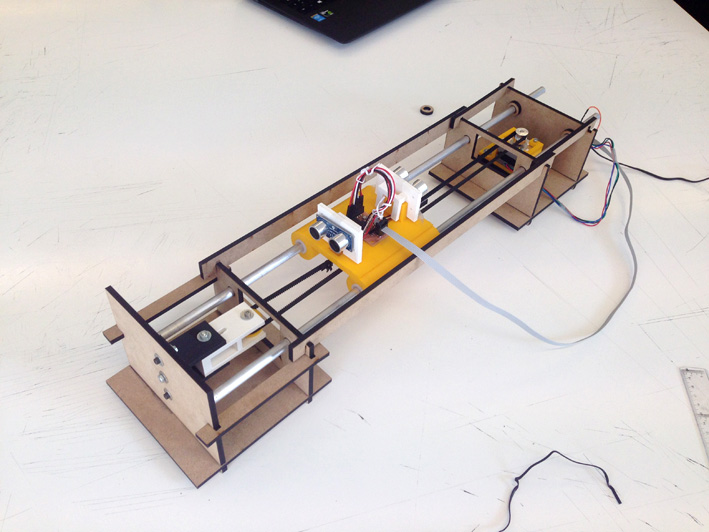

To make sure the slider does not crash onto one side, the board knows exactly where the slider is positioned. To do this, I store its position every time the loop has been executed.

Previously, I have declared these variables:

-origin: constant variable with assigned value 0.

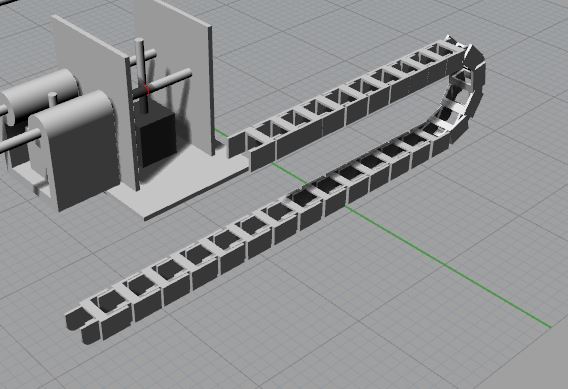

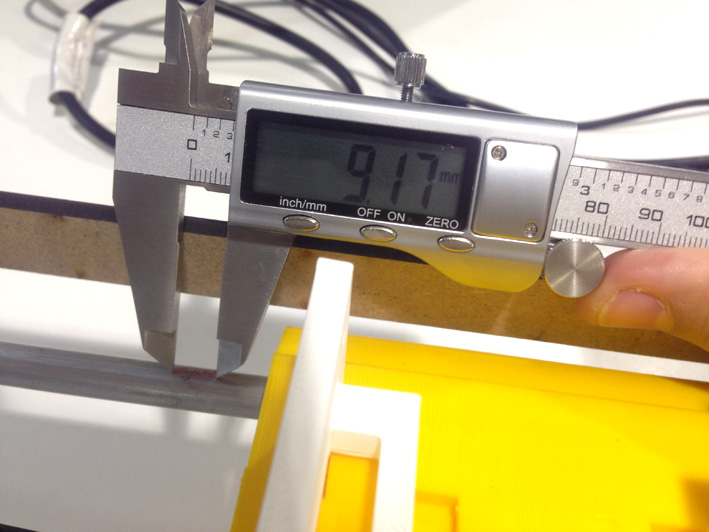

-totalDistance: after testing it, that horizontal axis has a total of 1200 steps.

-lastPosition: it stores the last position the slider was at.

-newPosition: with the number of steps, the slider knows its position.

When number 2 or 3 arrive from the master board, the slave board has the order to move when this condition takes place:

-it calculate what will be the 'newPosition'.

-if the newPosition goes beyond or under the 'totalDistance', it does not execute the command 'myStepper.step(steps)'.

(Check on the images above the code or go to next chapter to see the complete code)

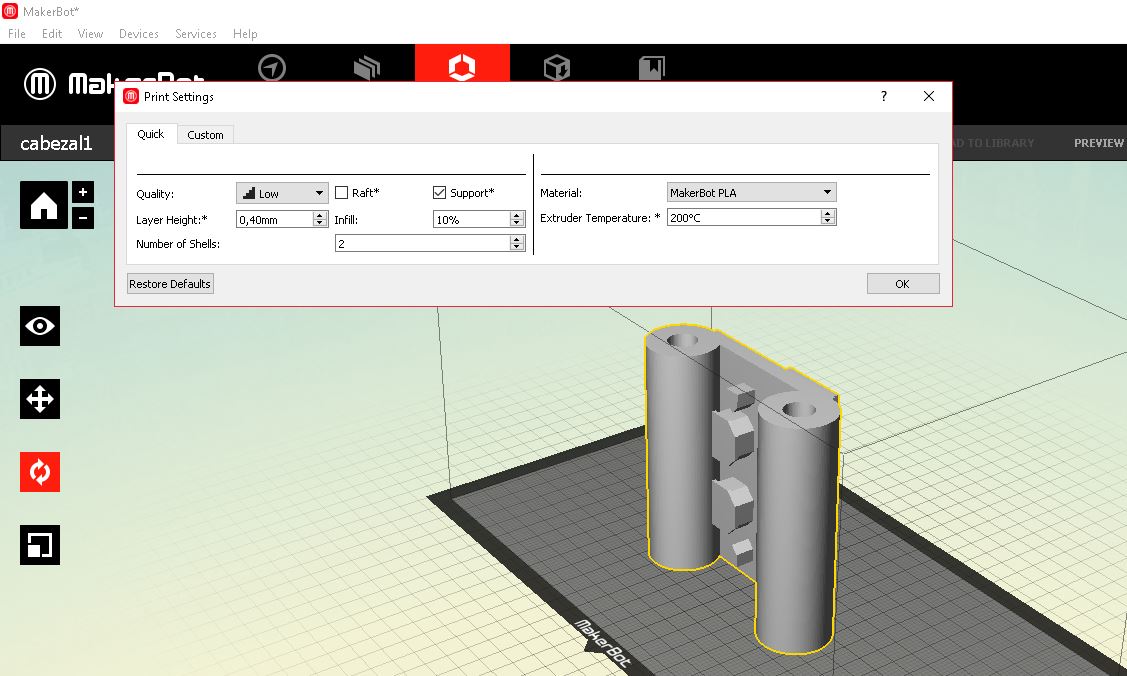

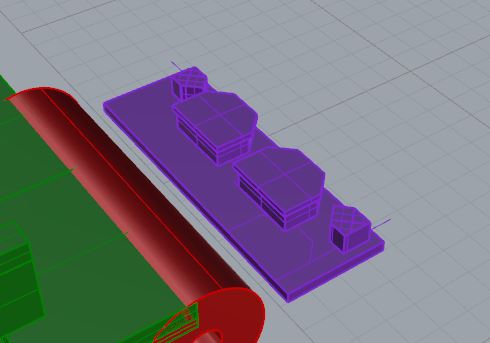

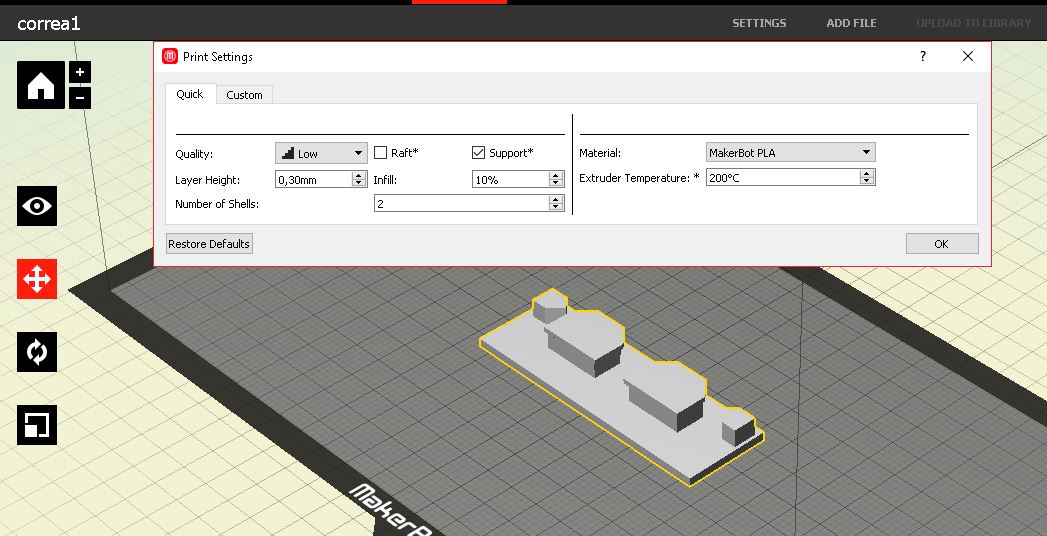

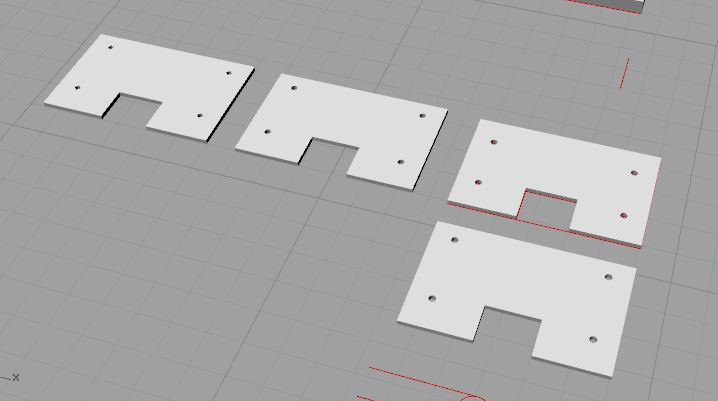

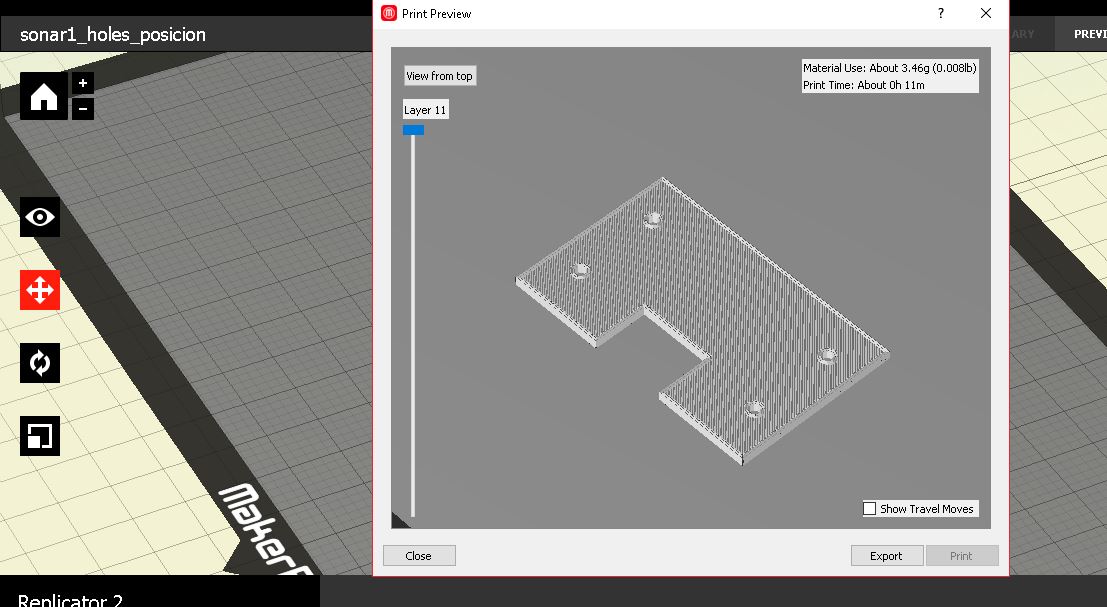

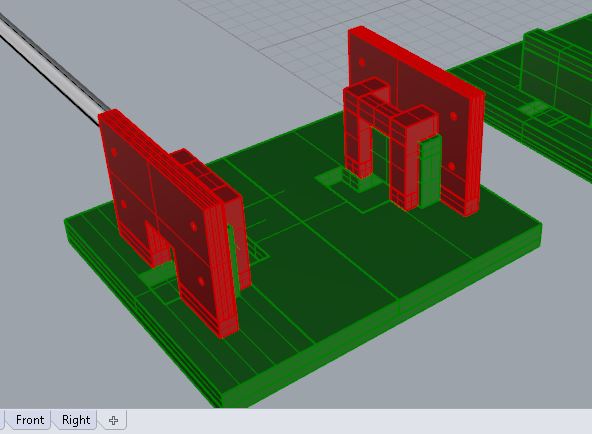

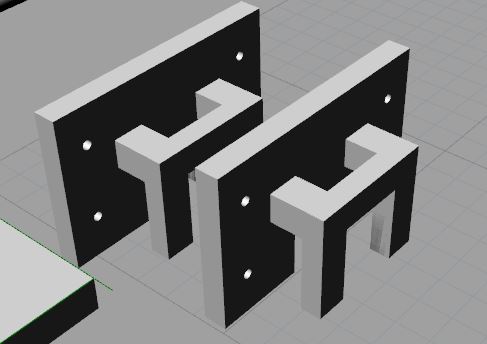

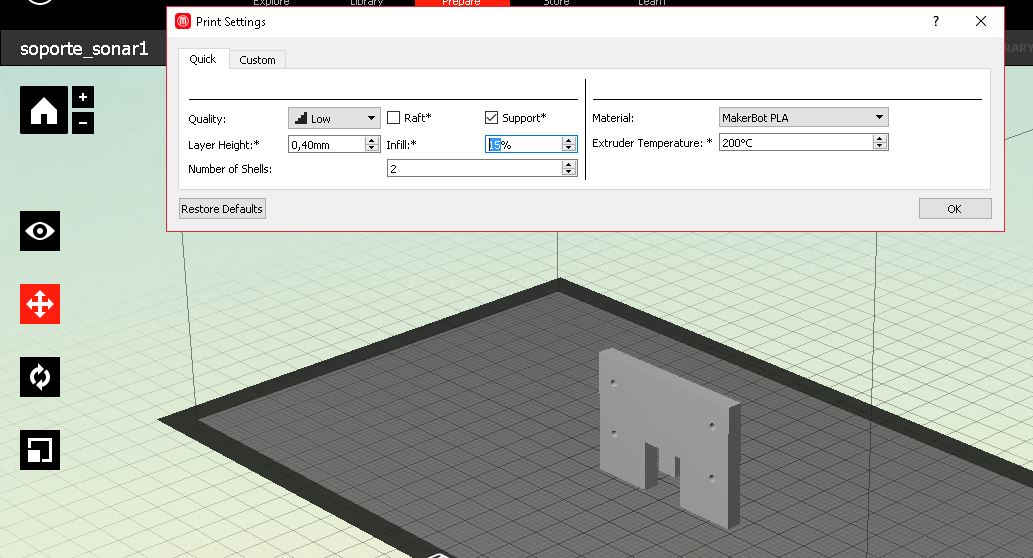

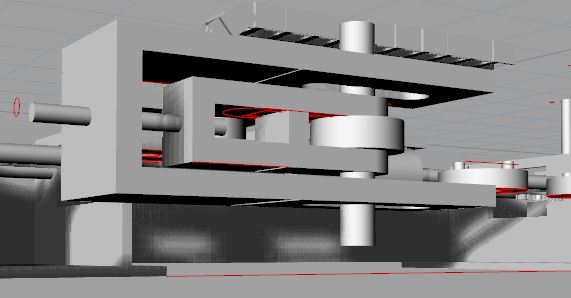

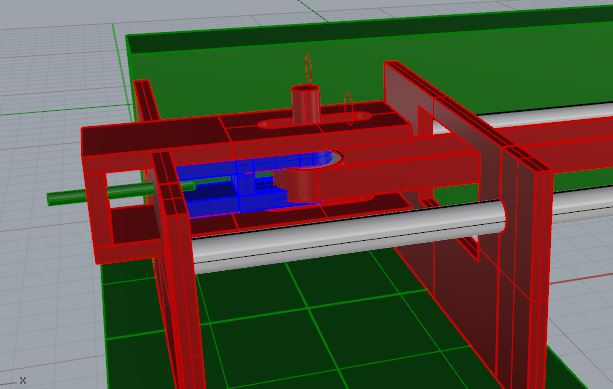

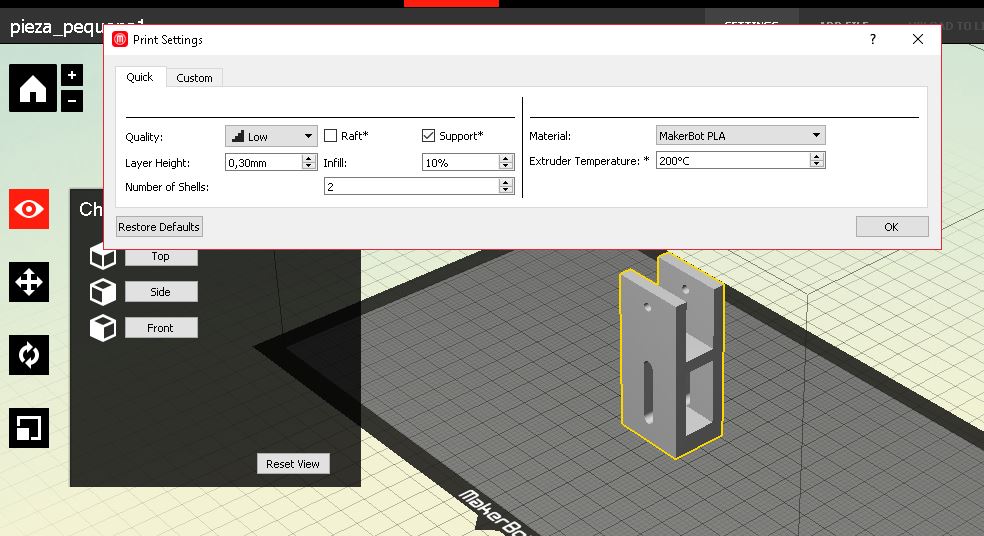

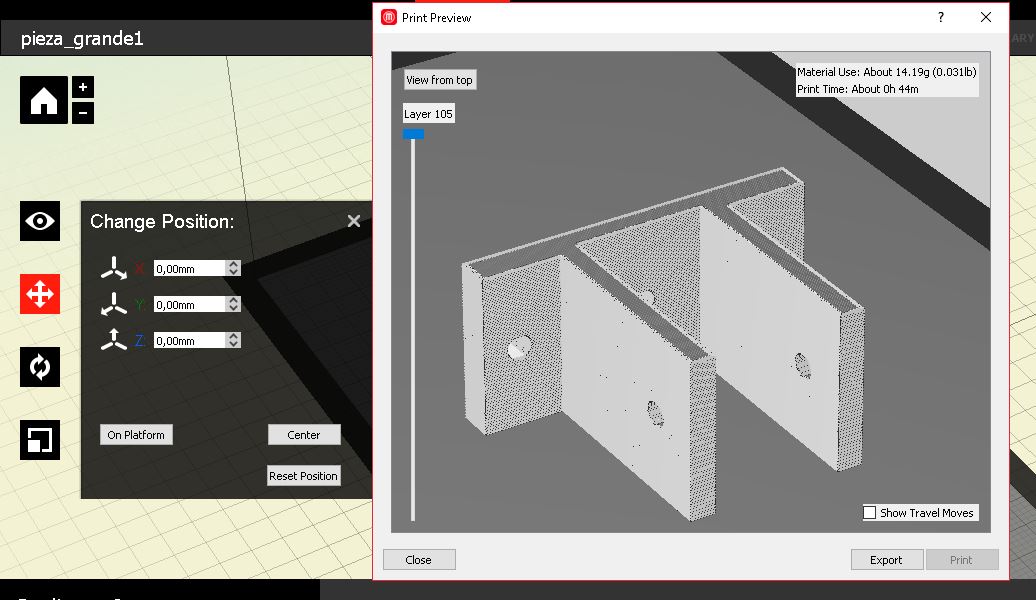

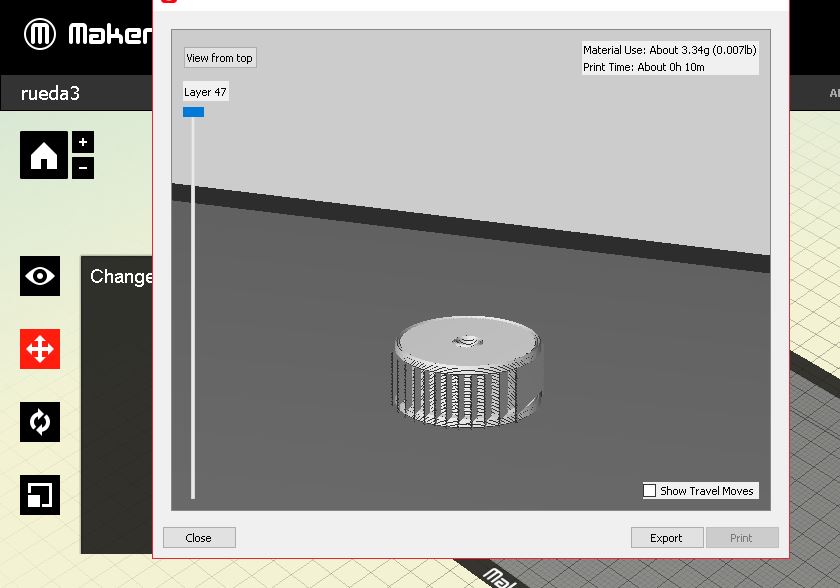

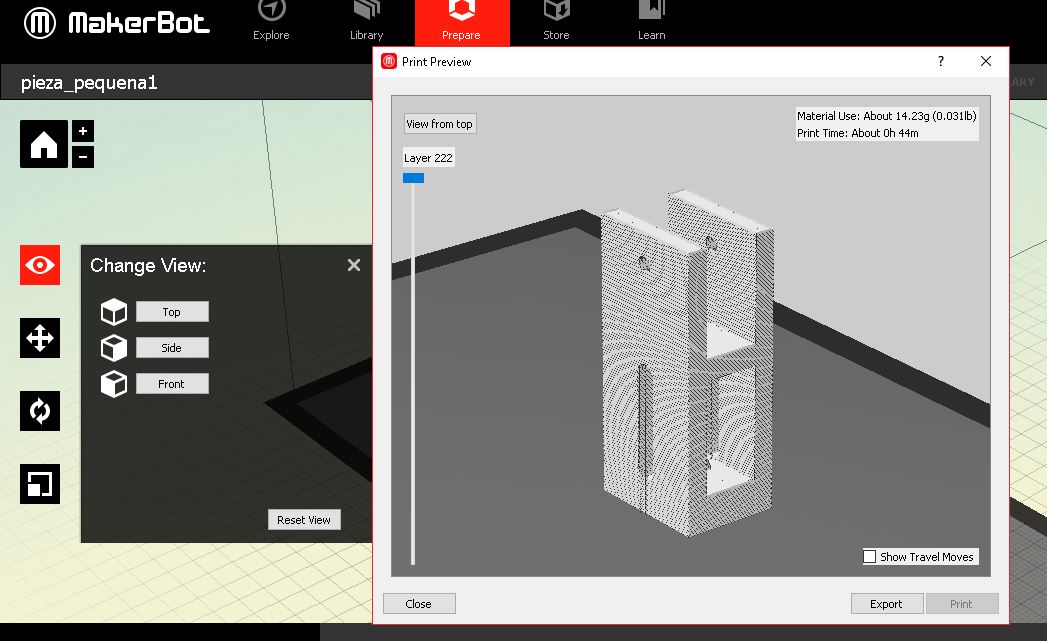

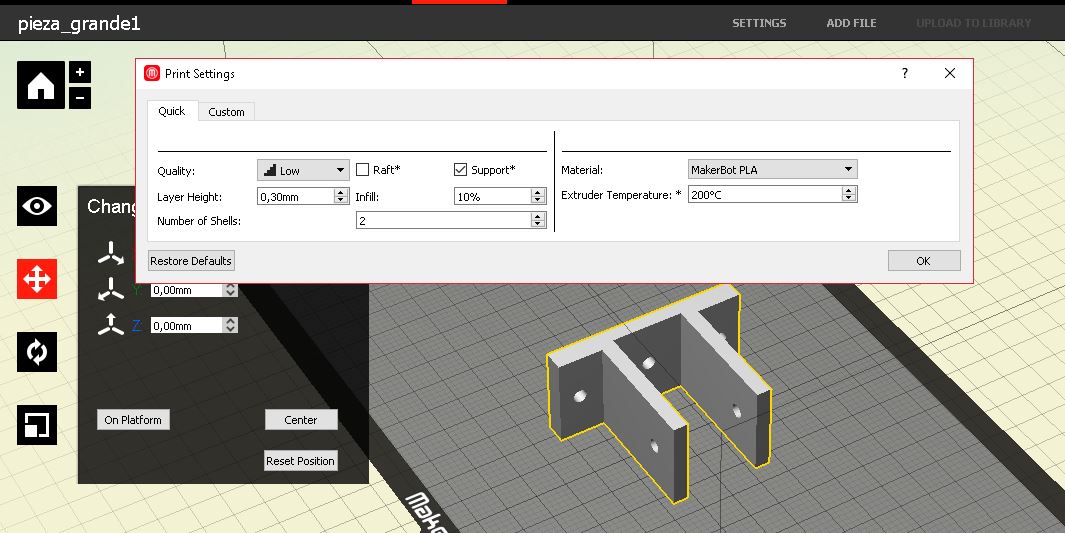

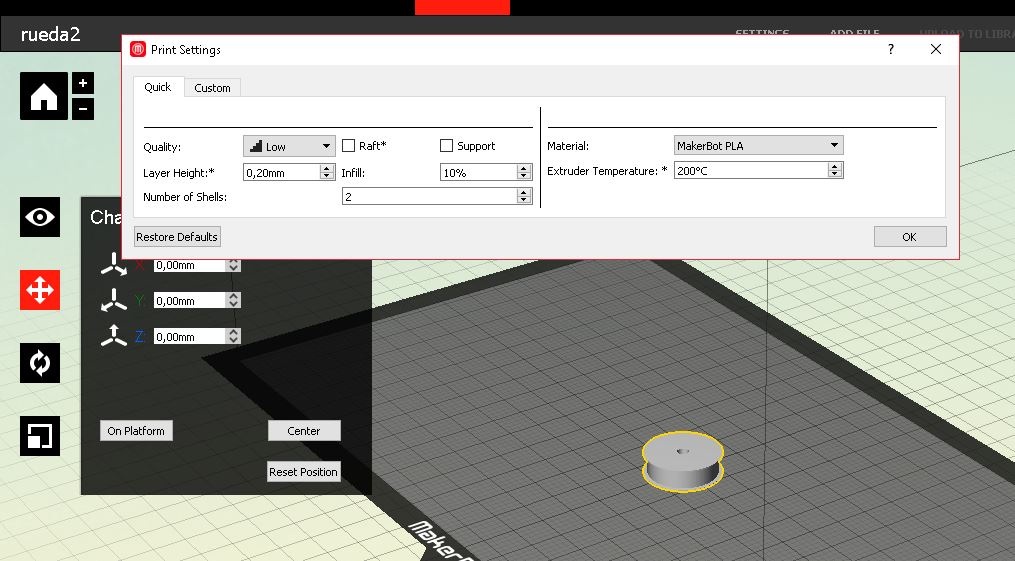

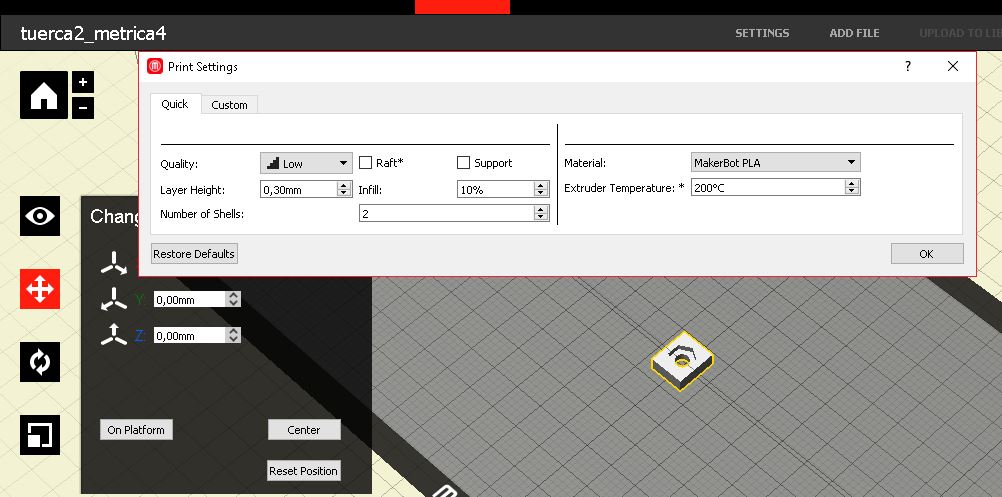

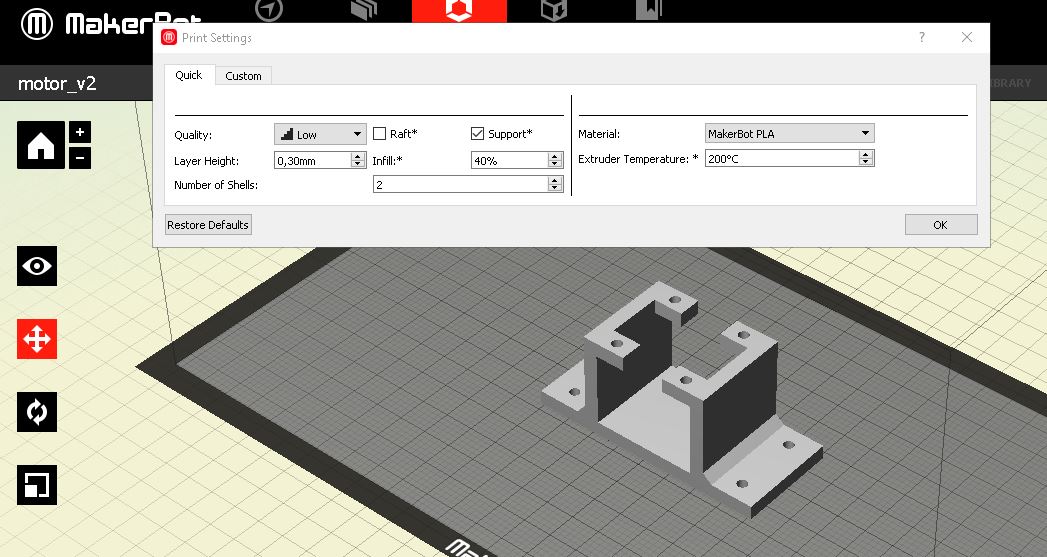

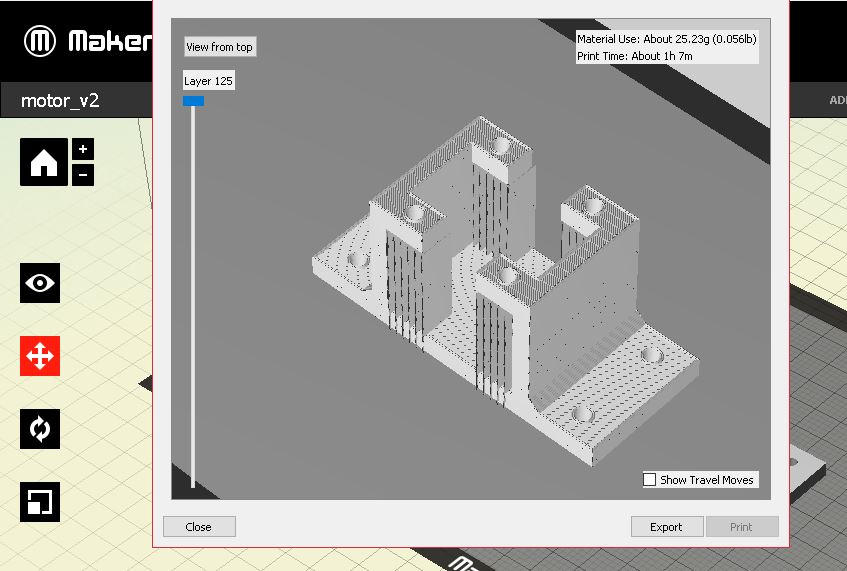

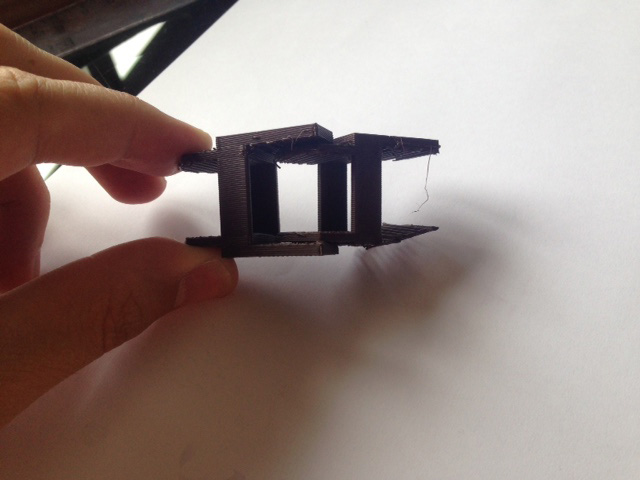

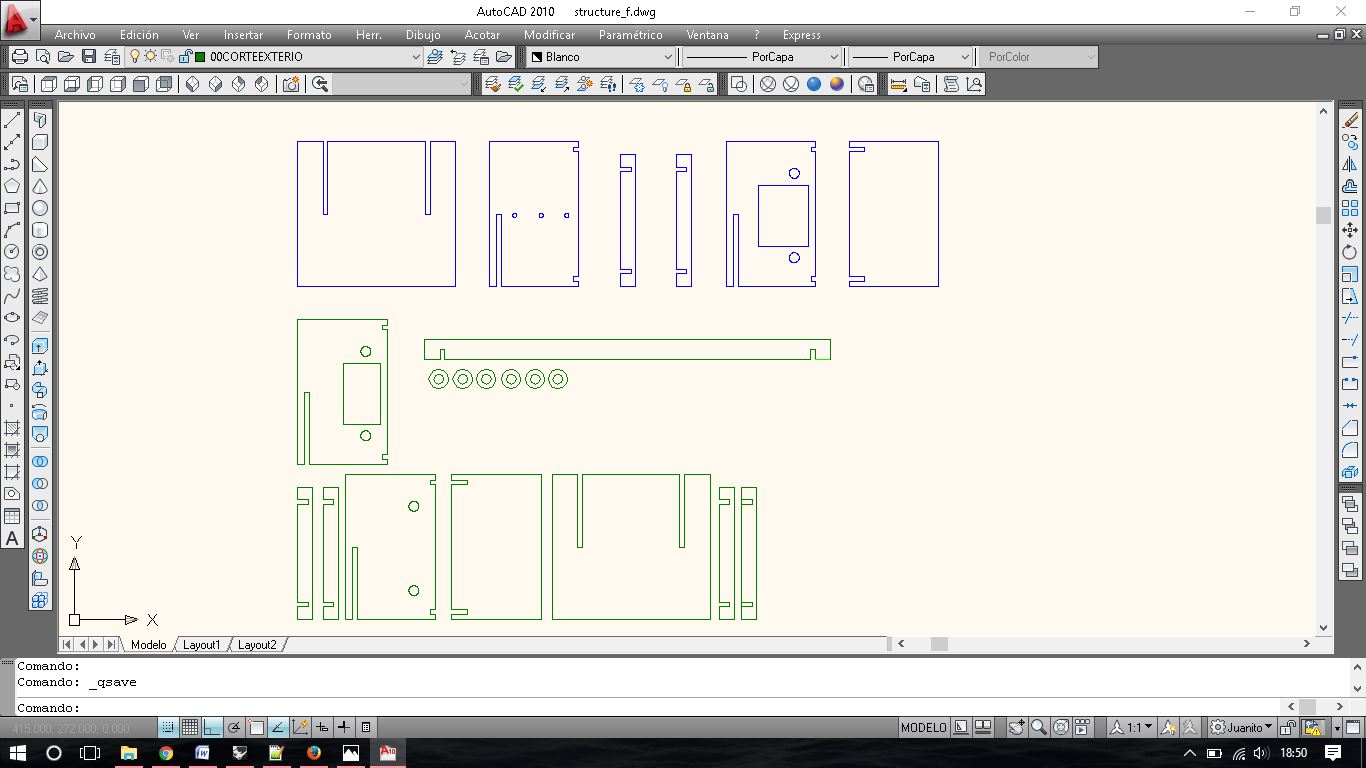

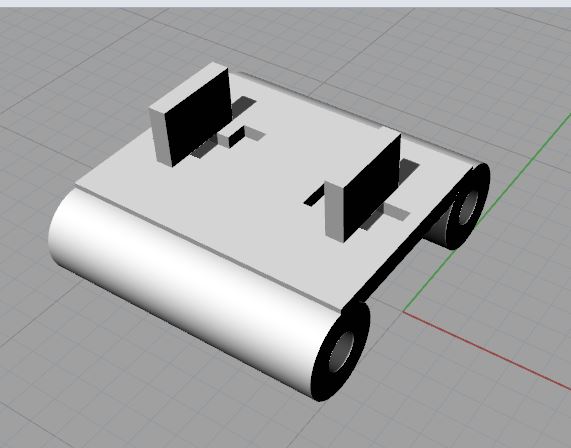

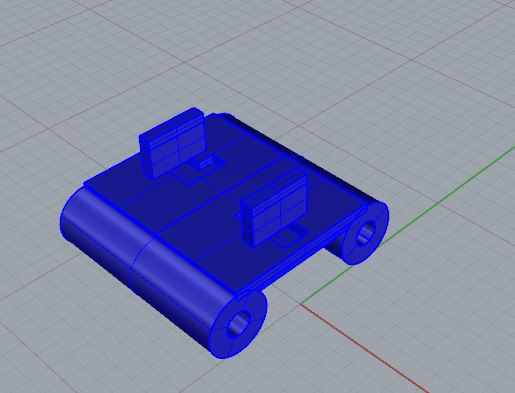

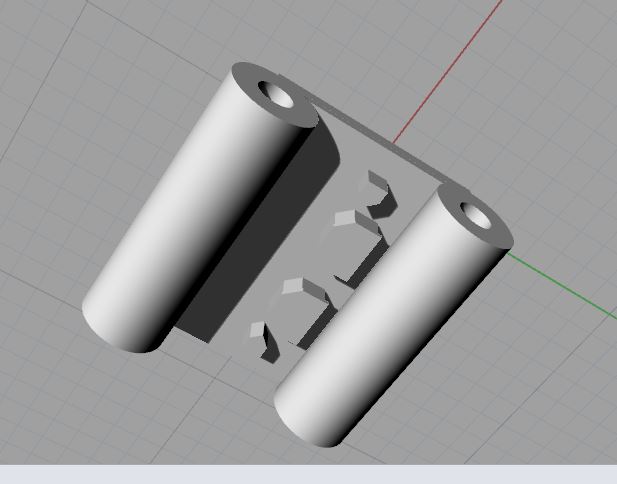

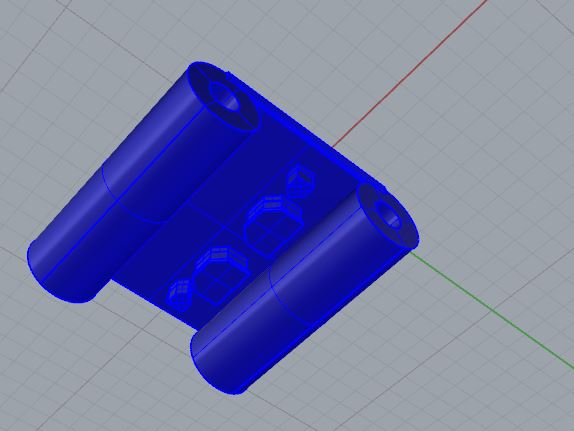

Export it as .STL file and import into makerbot for the 3d printer to make the rest of the work.

Export it as .STL file and import into makerbot for the 3d printer to make the rest of the work.