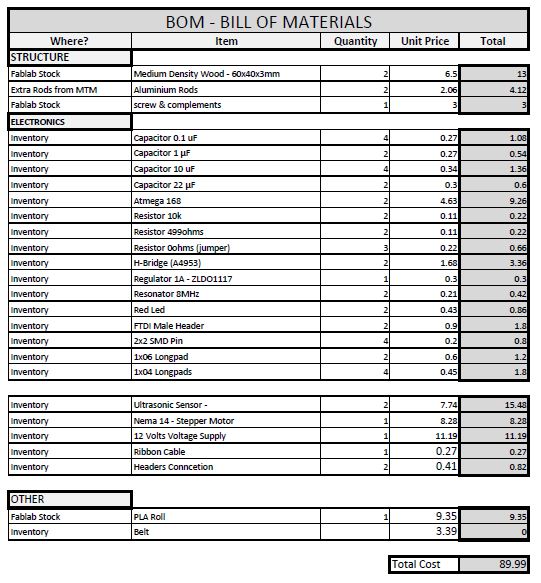

b) Who Has Done What Beforehand?

Looking for the people who have done this type of movement beforehand stands out a particular brand: 'U-arm':

This mechanism is very powerful as it can 3d print, laser engrave and help you with anything you need.

Sliding Mechanisms:

If we to photographer's field and film, a lot of them use sliders as the one just below. These first 3 images show sliders without being powered by any motor. They are moved by using your hands to keep the camera at certain height.

Its mechanism works differently depending on the distance covered and the material used.

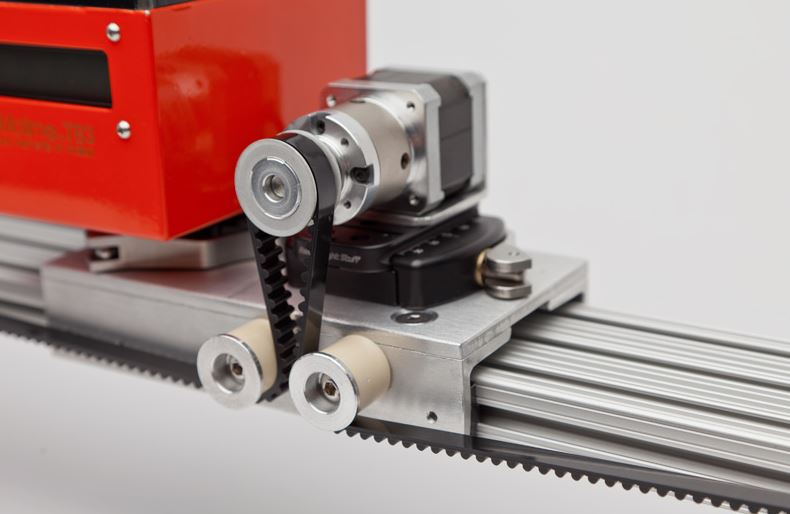

This image shows how the slider moves with the rotation of the motor's shaft. The stepper motor is placed at one end of the axis. This kind of mechanism makes the slider go slow, needing more steps to move 1cm.

A mechanism that transmit the rotation with a pulley system, transforming rotation movement to horizontal movement. The motor is at one side of the axis as in the first example. In this case, but with the advantage that using different diameter pulleys make the slider go at the speed the designer wants.

A mechanism which has the motor on the slider, moving while the slider moves. Attached to the shaft, is a belt with which the slider can move.

A mechanism very similar to exampl 3 but having the motor at one side. It also uses a belt, making it easier than example 1 to move freely.

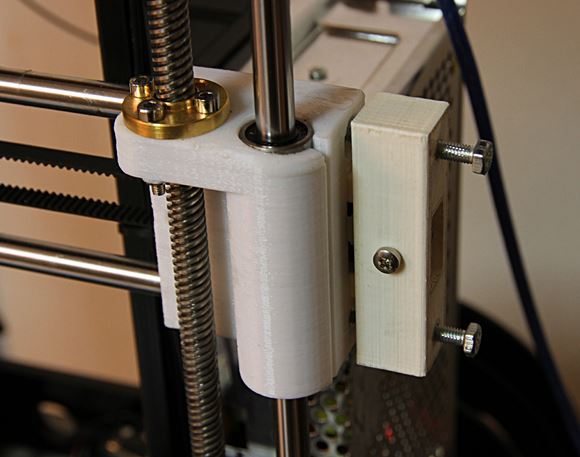

Homemade 3d Printer

Several 3d printers that are homemade, all the different parts are on the internet. Taking a look special look to the piece that creates the tension on the belt: the belt tensor.