Composites

Assignment for this week

- Design and make a 3D mold, and produce a fiber composite part in it

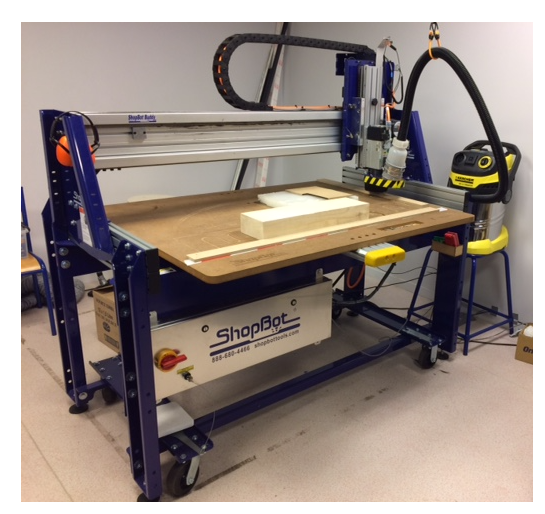

- Learn how to mill 3D on the ShopBot

- Link to this week’s homeworkpage

This page is organized as follows:

Making the mold

Since the ShopBot I could not have access to a ShopBot for this assignment I designed and made a mold with our CIF Technodrill2 CNC

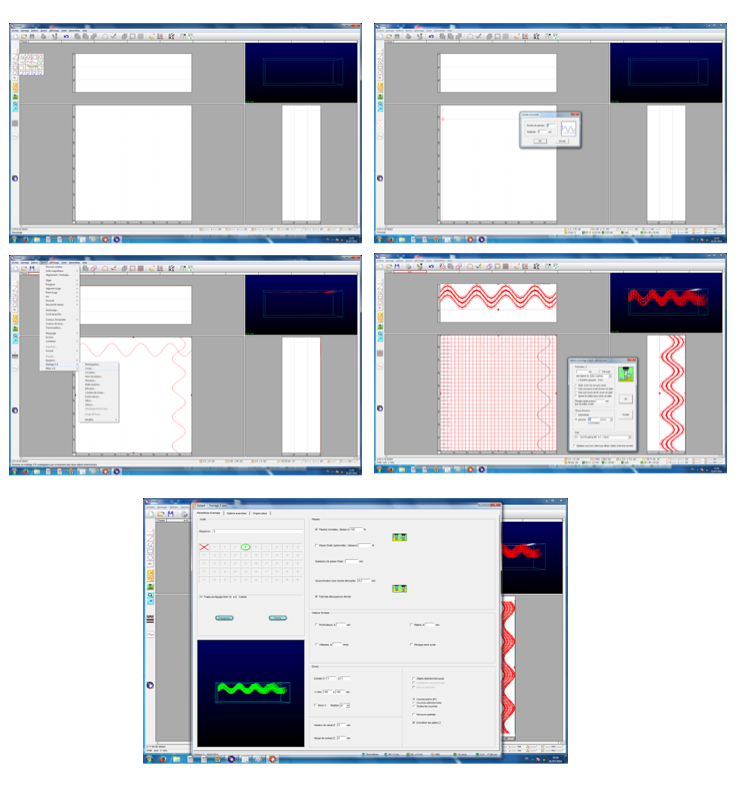

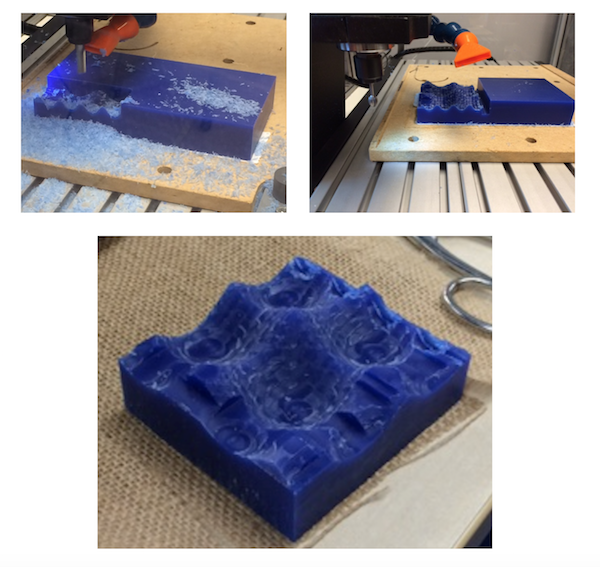

I only had a 2 mm flat end milling cutter with a 8 mm flute so it was not very convenient to make a big mold. I decided to use a bigger 6 mm flat end mill to prepare a mold as big as possible out of blue machinable wax. I designed the mold directely in the Galaad technodrill software and created 3d oscillations

and then milled it.

Of course the mold is not very smooth but the idea is there.

Making the composite

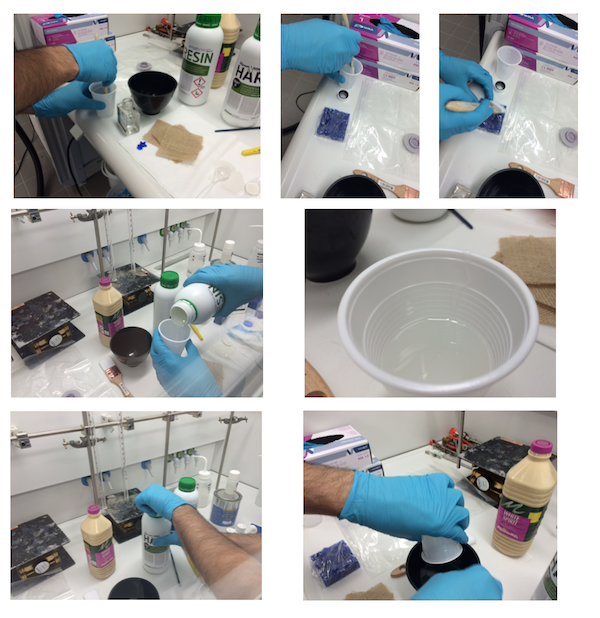

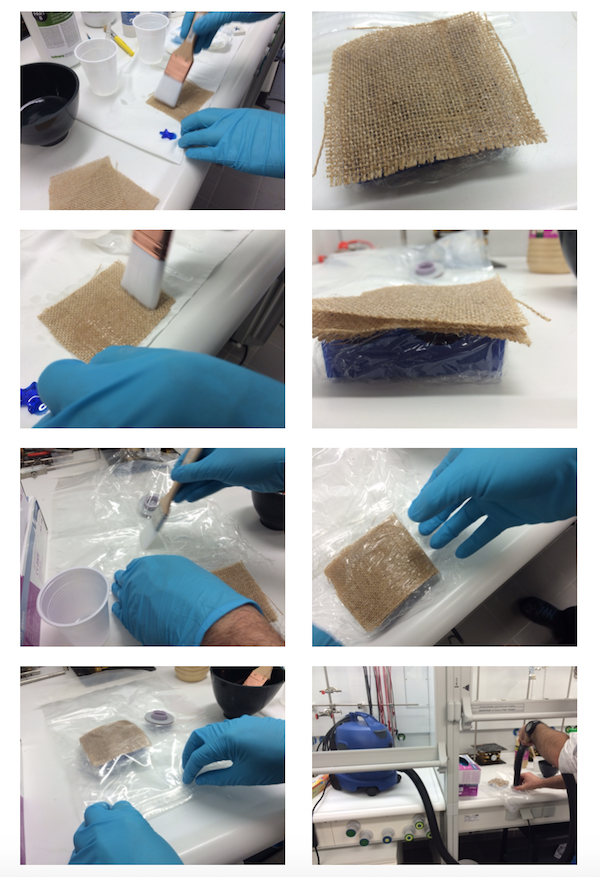

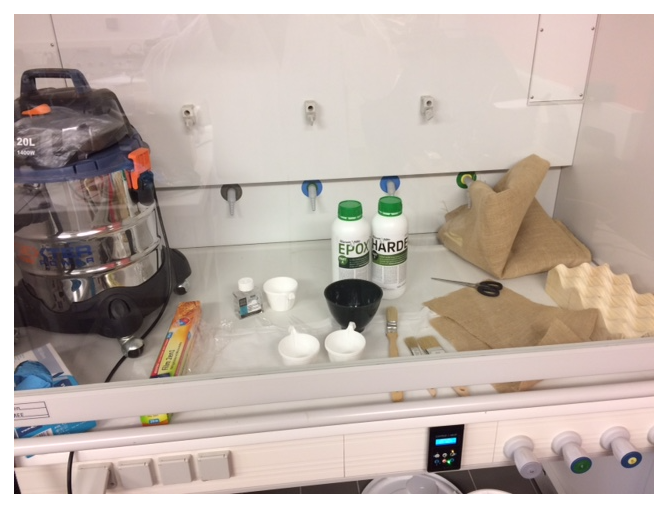

Since many fibers used for composite making can be very dangerous to manipulate (as we were told during the class) I prefered to use burlap which is safe, available and cheap. I cutted three pieces of burlap, the size of the mold.

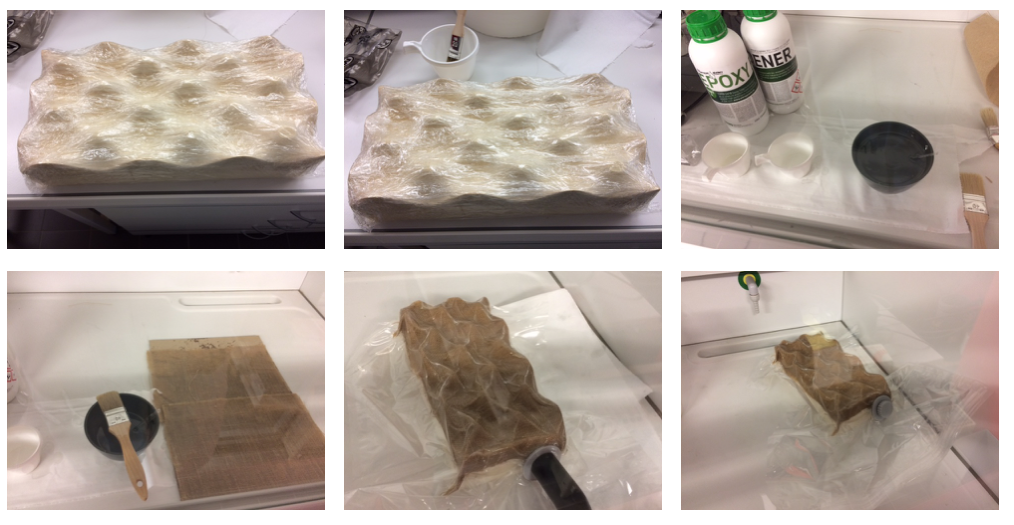

I then covered the mold with plastic wrap and started preparing the epoxy.

The resin (part A) and its hardener (part B) are contained in 2 big bottles and should be mixed with a ration of 2:1 in volume.

I first brushed the plastic wrap on the mold with demolding vaseline oil. Then I mixed the resin and its harderner.

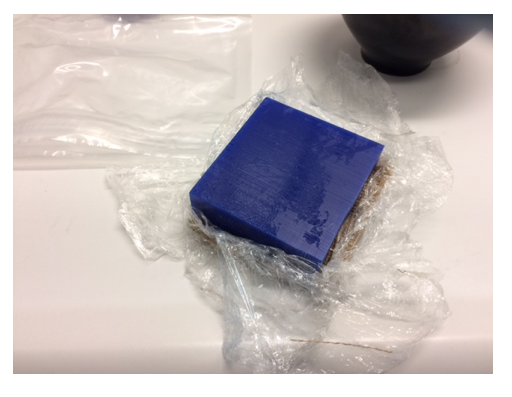

I then both sides of the burlap pieces with the mixture of resin and hardener and sandwiched them on the mold. I finally covered the sandwich with plastic wrap bushed with vaseline oil, inserted the thing in a vaccum bag and used a vacuum cleaner to pump the bag.

I pressed on the mold while pumping on the vaccum bag for the burlap pieces to match the mold pattern.

I decided to let it rest during the weekend.

And ...

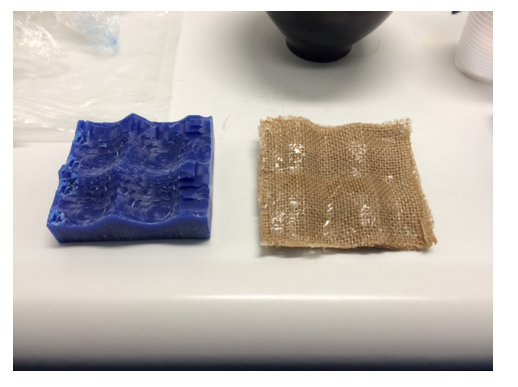

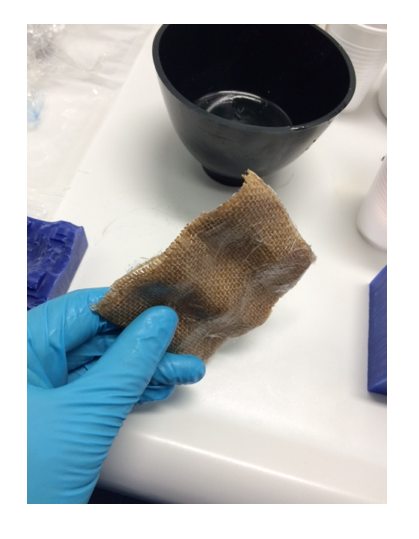

I came back to the lab and remove the thing from it vaccum bag and remove the plastic wrap.

It took a few minutes and then I obtained the final composite:

So finally it worked. I will probably repeat the process in the future with more complex and bigger molds.

Update after 1st evaluation round

After 1st evaluation round, I was told that my composite was too small and that I needed to reapeat the assignment with a bigger mold. Since our Fablab has been equipped with a Shopbot Buddy after the evaluation round, this was now possible.

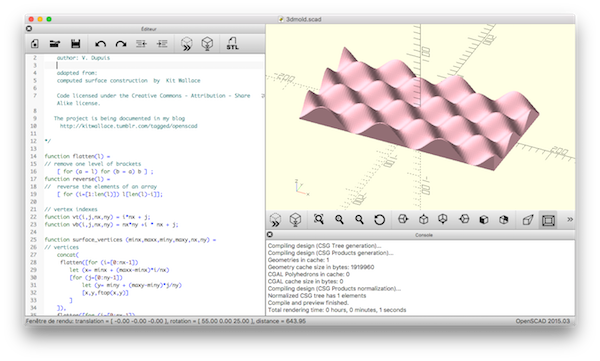

Designing the 3d mold in Openscad

I first redesign a 3d mold in openscad (because it is very easy to create a surface using a mathematical function) and exported a .stl file.

Making the mold on the Shopbot

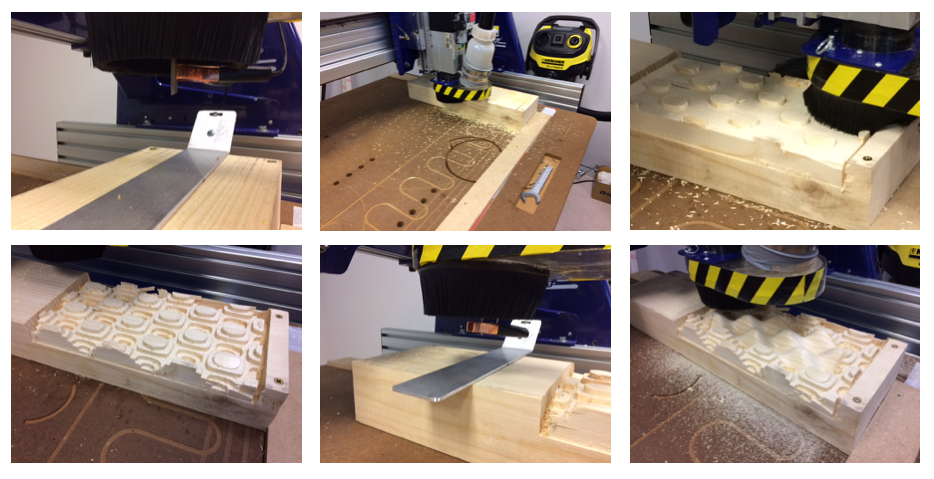

I used a big piece of wood (50 cm x 8 cm x 16 cm) as starting material for my 3d mold.

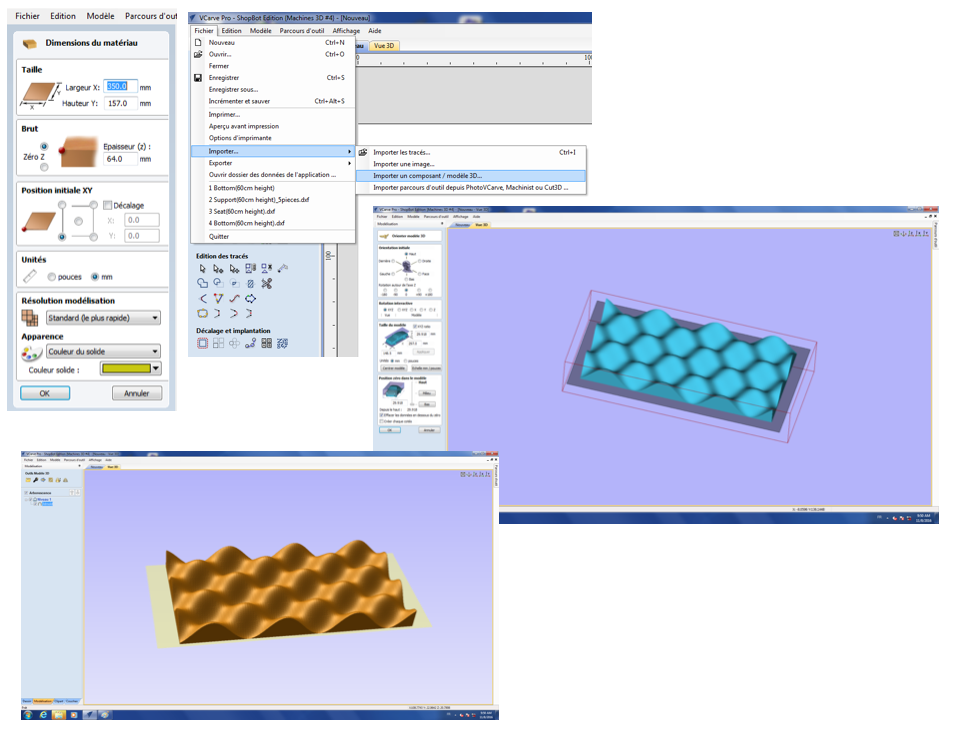

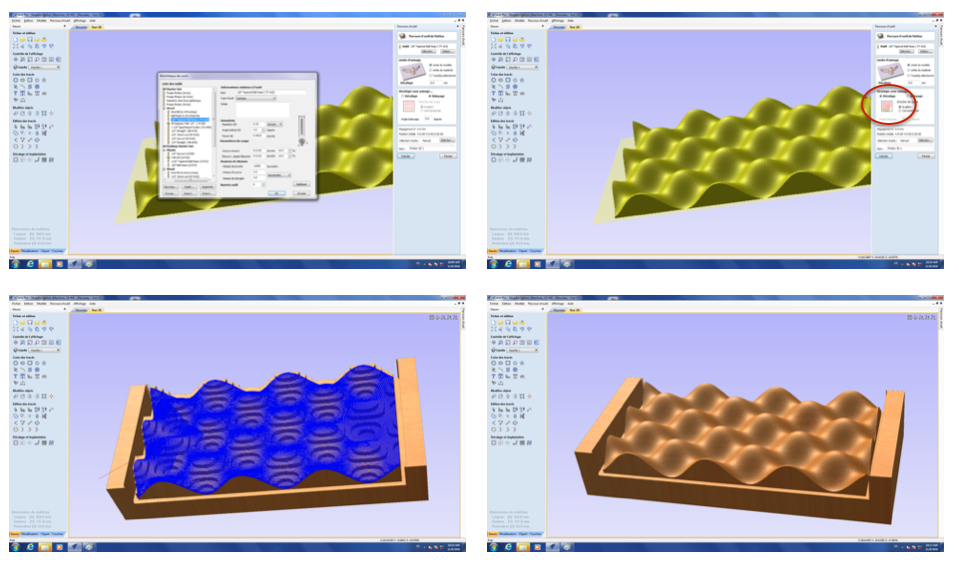

I imported the .stl file into VCarve Pro. To do that you need to create a new job, specify the dimensions of the raw material and use import in the File menu.

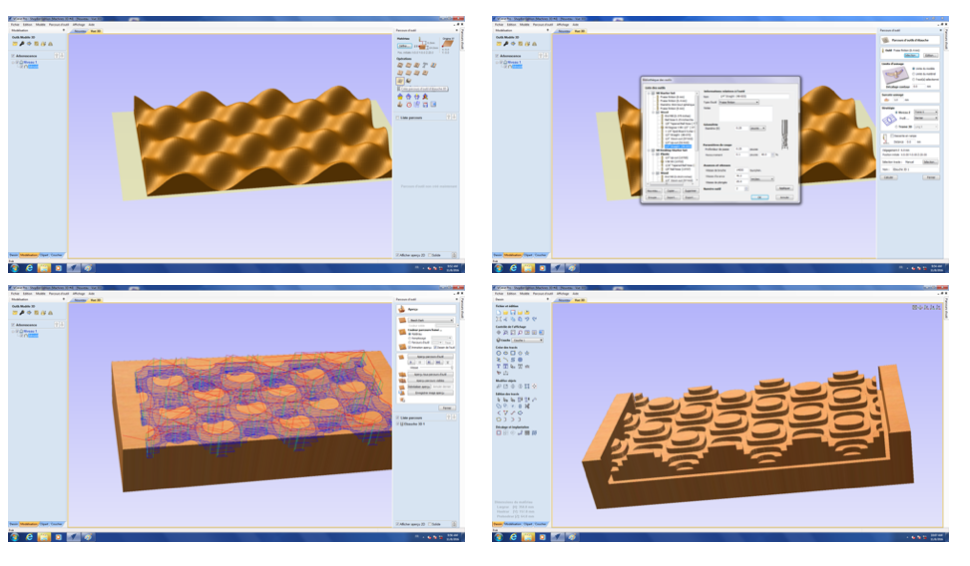

Then I created the toolpaths. First the roughcut toolpath,

then the finishing toolpath:

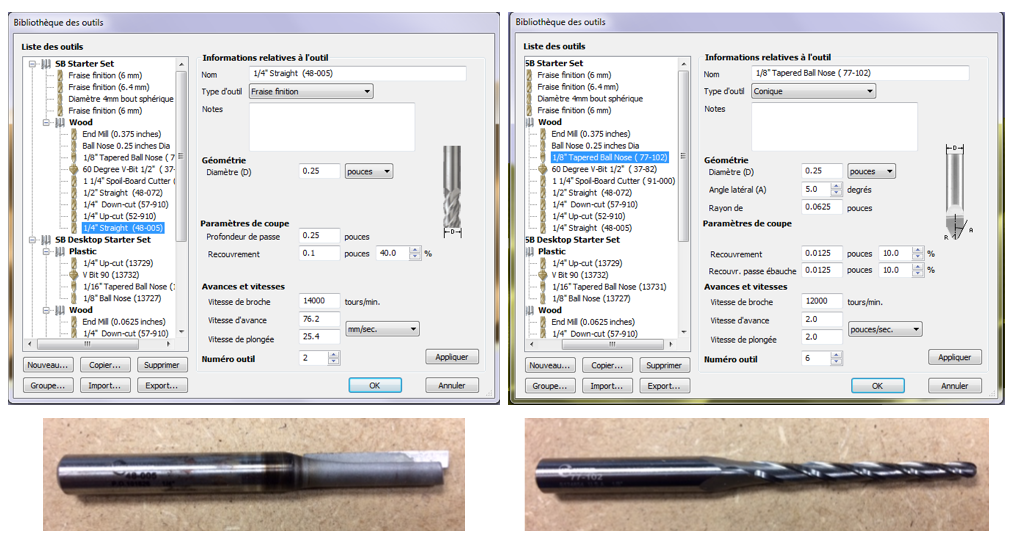

The roughcut and finishing end mills and the milling parameters (spingle rotation speed, forward and plunging speeds) are predefined in the software and recalled below:

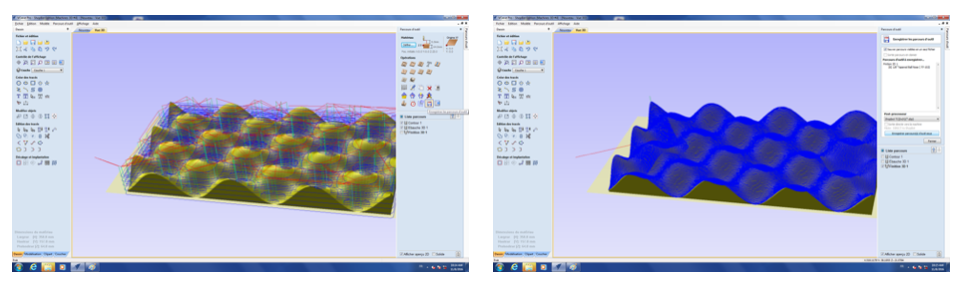

In the end I saved the toolpathes and this gave me two files: one for the roughing and another for the finishing (it's important to have two file to allow the user to change the end mill between roughing and finishing).

The toolpathes can then be loaded in the Shopbot software to start the milling (after propoer X,Y,Z zeroing).

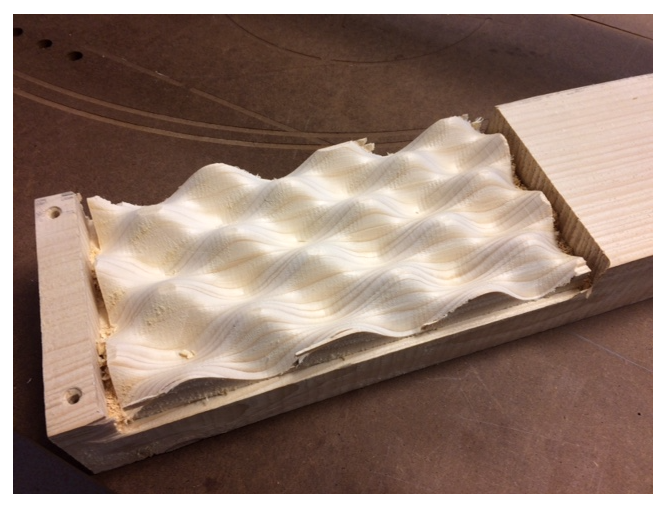

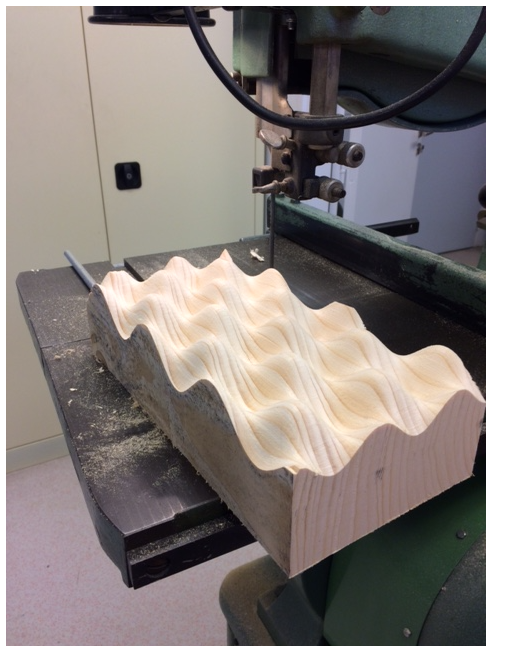

In the end, I obtained this:

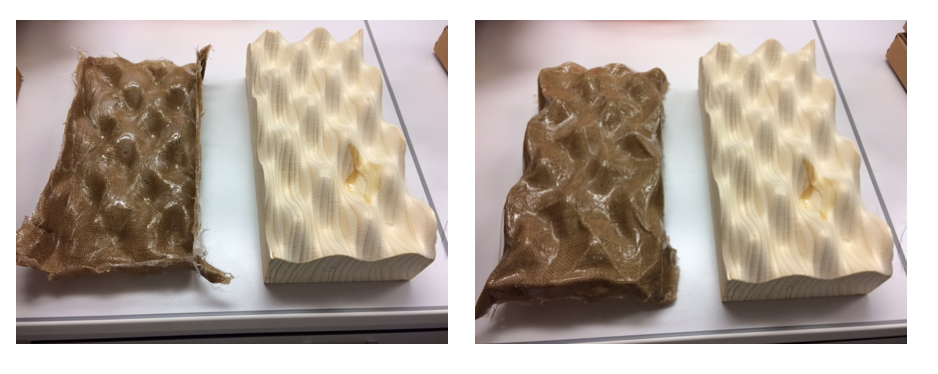

After cutting the mold from the raw material (the available end mills are too short to cut such a big piece so I used a saw) I obtained the final 3d mold which is bigger that the one made for the 1st evaluation.

Making the composite

I then reapeated the protocol to prepare a composite using this 3dmold.

I covered the mold with a plastic film, put some demolding oil on the surface, prepared the resin by mixing the epoxy and hardener (2:1 in volume), cut the burlap, covered the tow faces of burlap sheets with the resin, put the sheets on the mold, put the mold in a vaccuum bag, pumped and let at rest for 36h.

Final result

Finally, after easy demolding thanks to the demolding oil, I obtained the composite !

The design and fabrication files can be downloaded below (or in the section Files to download, top right panel):

- openscad file: 3dmold.scad

- STL file: 3dmold.stl

- roughing toolpath: 3dmold_ebauche.sbp

- finishing toopath: 3dmold_finition.sbp