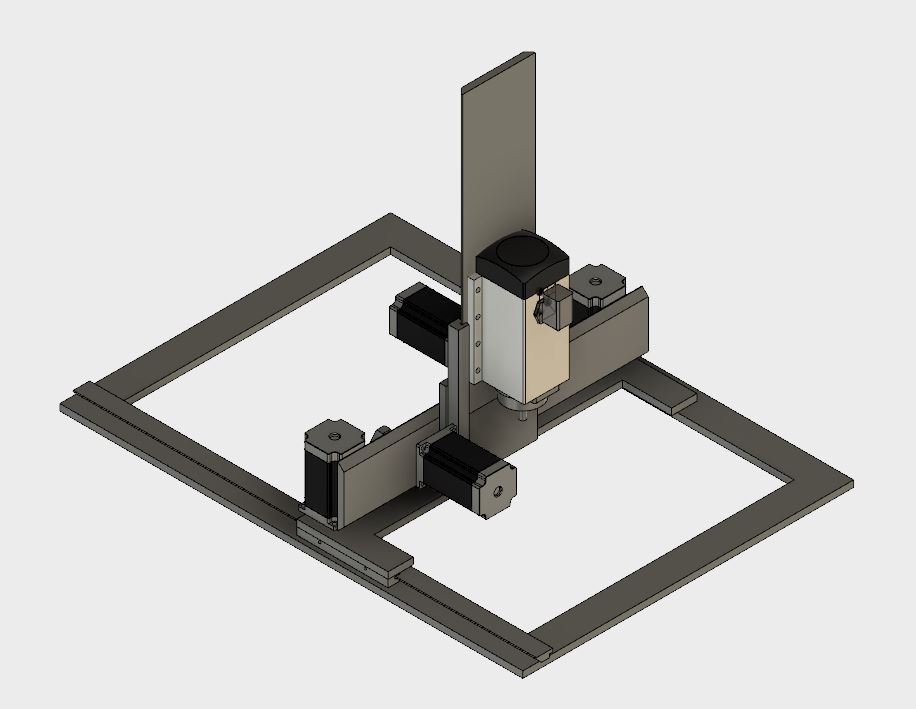

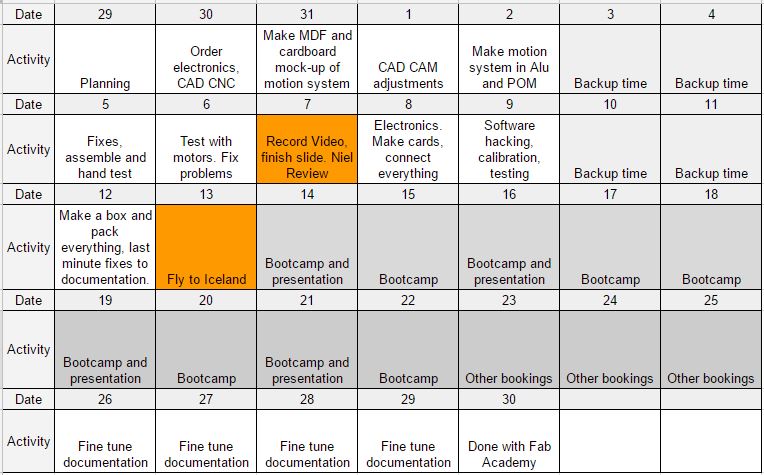

- Build (parts of?) the motion system in MDF, move it by hand

- Make the motion system in Alu and POM

- Test the motors

- Mount the motors, run them manually (7 June: Video of motors driving the motion system.)

- Test the spindle at fixed speed from the VFD

- Mount the spindle

- Mount limit switches

- Make the wiring harness and route the cables

- Make my controller run GRBL (ordered 16Mhz crystal if 20Mhz compilation seems complicated.)

- Make my connection shield. (Satshakit version: .brd .sch)

- Make three more stepper drivers. Plan B: Borrow commercial stepper drivers

- Wire up all electronics and test with computer controlled motion

- Spindle PWM to RPM control via the VFD Plan B: If this is too time consuming, finish it later.

- Make a shipping case and fit everything

- Go to Iceland, use it in bootcamps!

- Present to the Fab lab network

- Dust protection for the glide rails

- Tune the motion system

- Complete and fine tune my manual jogging interface

- Build a Z-height probing spot

- If it is heavier than 20kg, lighten it for cheaper shipping

- Add dust extraction

- Make easy to use mounts for different stocks

- Adapt the shipping case to be a dust and noise enclosure.

After the presentation or bonus tasks:

Plan B for saving time on stepper driver production

If I run into troubles with my home-made stepper driver or just lack the time to make three more then I'll borrow commercial stepper drivers and replace them with fabbed ones later.

UPDATE: I activated Plan B. I use my own stepper driver for the X-axis and three makeblock stepper drivers for the other axis.

-

Does my Stepper driver work as intended? Before making more. Do I still have time to make more before the end of the course?

Answer: It seems to work ok, but I would like to do some updates to the design before I make more of them. See my Output devices week10 page for a list of my future updates. - Can I run GRBL on my satshakit v2?

Answer: Yes, no problems at all after I changed to a 16 Mhz crystal - Does my spindle, PSU and motors work?

Answer: Yes!

- 2D elements?

- Circuit board milling

- Motion system milling

- Case milling

- Idea: Viny cut markings for axis directions, safety text etc?

- 3D elements?

- Moulds for electroics enclosure

- Chamfer on glide rails

- 3d printed cable holders and "poke-protection" for the 220V incoming power.

- Electronics?

- Controller based on updated Satshakit

- Stepper drivers based on updated Satstep6600

- Jogging and serial communication card

- Connections shield

- Input switches

- Wiring harness

- Addative techniques?

- Composite electronics enclosure

- 3d printed cable holders and "poke-protection" for the 220V incoming power.

- Subtractive techniques?

- Milling the motion system and case.

- My work can be replicated and built on by using my files?

- The manufacturing processes used are documented?

- The raw materials and purchased components are listed in a bill of materials with prices?

- Machining time and machines use is presented?

- It is clear what work was done beforehand by others?

- The CNC plaform accepts digital commands from my computer and moves when I want it to?

- I can fit it inside a box that I can send as checked in luggage? (Width+Length+Heigh = less than 1580mm.)

- Weights below 20-23 kg? (So that I can check it in without paying extra in most airlines. Less than 23kg = most airlines, less than 20 kg = all airlines.)

Have I in my final project shown that I can design and make::

Have I documented my work so that:

Is the integration of the subcomponents successful so that:

Bonus Goal: