Computer-controlled cutting

1. Cut something on the vinylcutter

2. Design, make, and document a parametric press-fit construction kit

Assignment for this week regards the computer-controlled cutting, creating two different exercises, one using vinyl material and vinyl cutter and, in the other exercise, using laser cutting creating a pressfit kit. In both exercises I have used Grasshopper to generate parametric patterns and parametric joints.

1. Vinyl Cutting

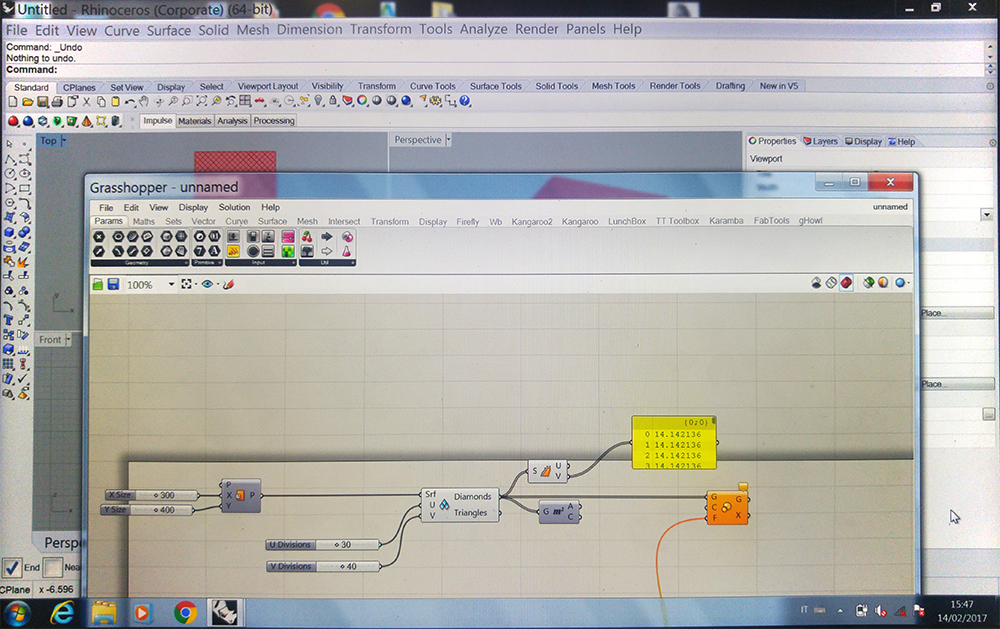

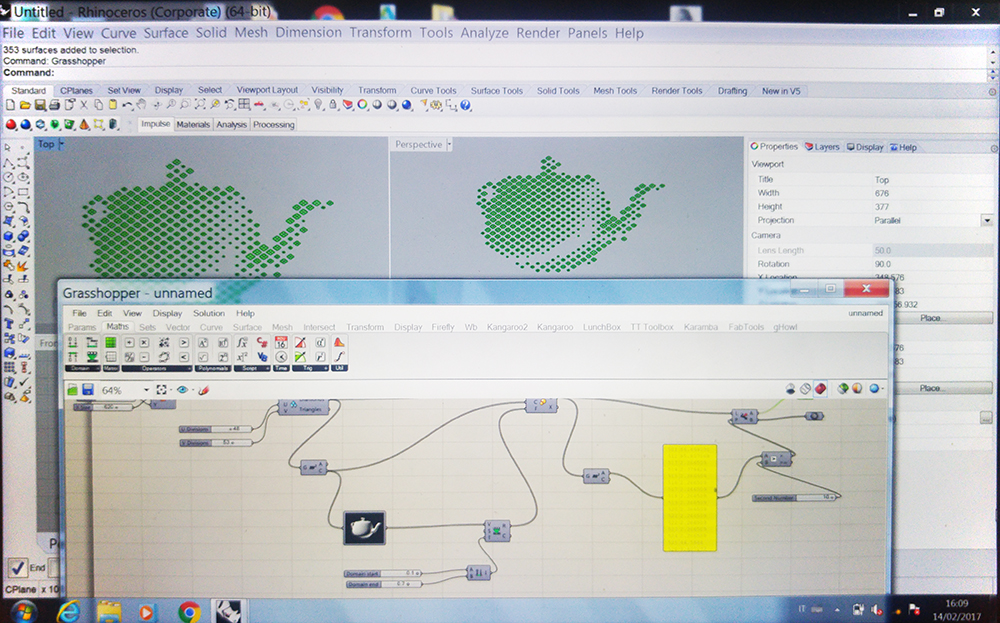

Concerning the first exercise, I have used Rhino, Grasshopper and some plugins such Lunchbox in order to create a simple algorythm. This definition allowed me to bake parametric curves, based on scaling through a bitmap.

The source I used is a very simple image, a teapot from 3ds max.

The outcome is this group of curves, scaled with a parametric factor (brightness from image). To avoid any difficulties related to small dimensions, I have decided to cull out the smallest shapes.

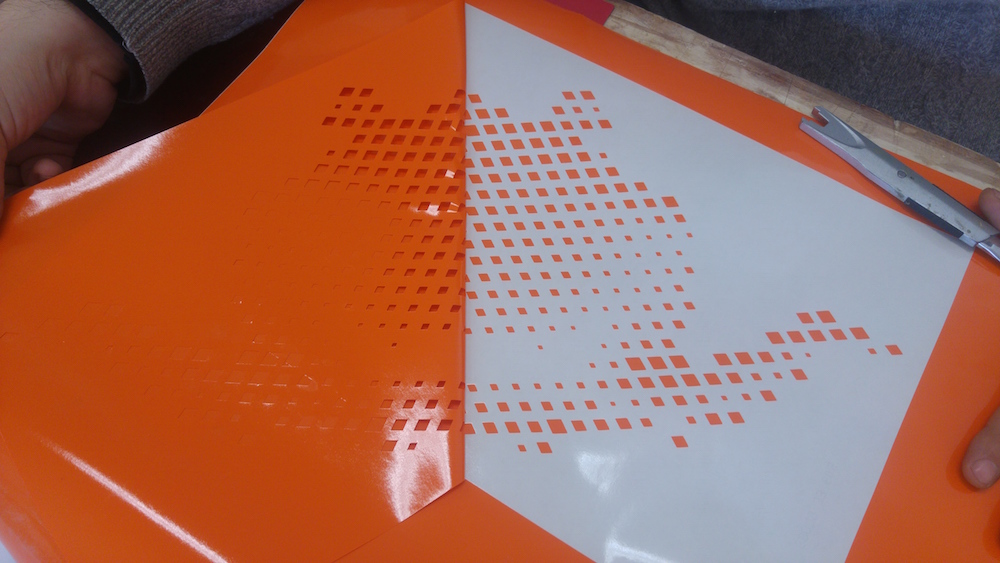

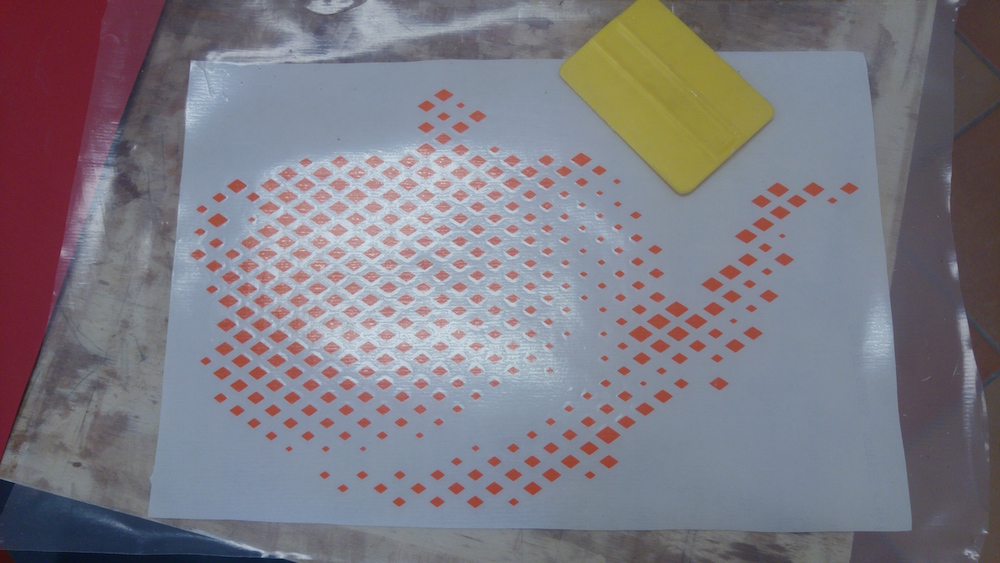

FROM VECTOR TO VINYL CUTTER

To cut the file with vinyl cutter, I used a Roland GX-24. This machine uses a pivoted cutting edge translating on 1 axis. The other axis translation is provided by a roll which move backward and forward the vinyl sheet.

DOWNLOAD FILES

Illustrator FileGrasshopper Definition

2. Laser Cutting

We started to make some tests about different joints, trying to cut different materials, such as cardboard and wood, with different settings. As a result, we've well understood that different material and thickness requires different settings. Also, a very important step is to pay attention to interference and beam of the laser (kerf), which made us to study different offset operations for shapes and joints.

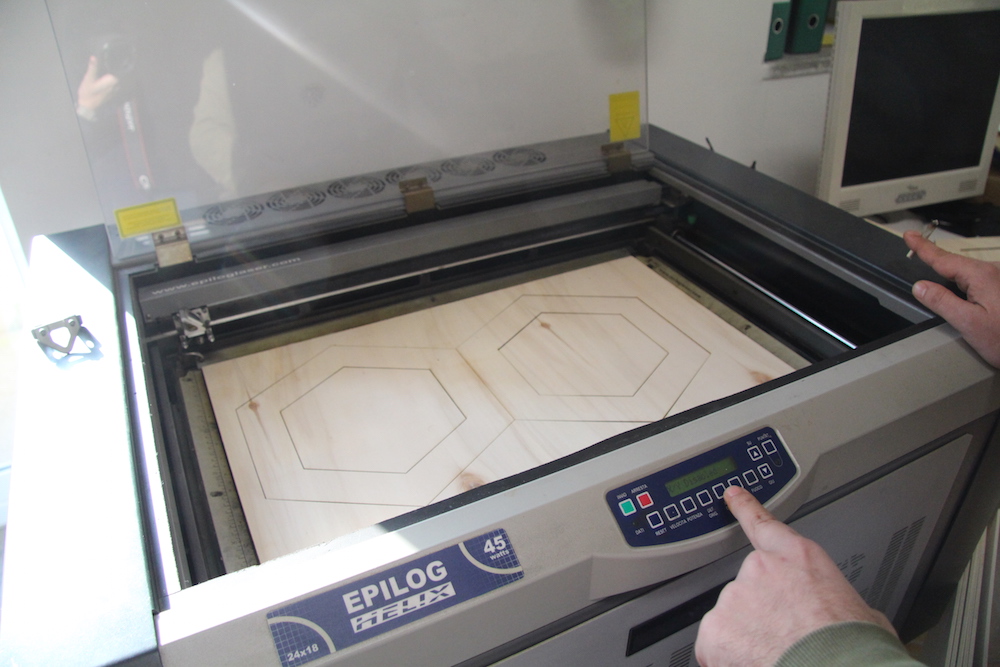

Here is the laser cutter we have used in our FabLab, an Epilog helix 24". Laser cutting technologies use a LASER (Light Amplification by Stimulated Emission of Radiation). In very simple words, electric energy is used to excite photons, creating a oriented ray, usually reflected of 90 degrees to let the beam moving in X and Y axis. Our lasercutter has a C02 laser beam, which can cut a lot of materials such as plywood, plexiglass, paper, cardboard...Vinyl cannot be cutted since this material releases hazardous substances.

MY PRESSFIT CONSTRUCTION KIT

CONCEPT

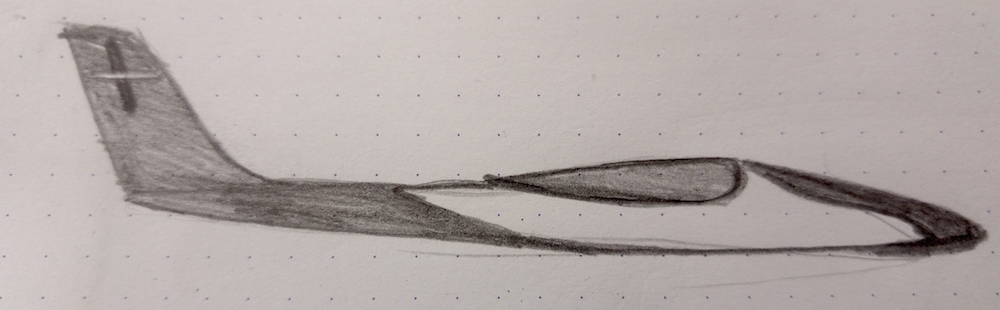

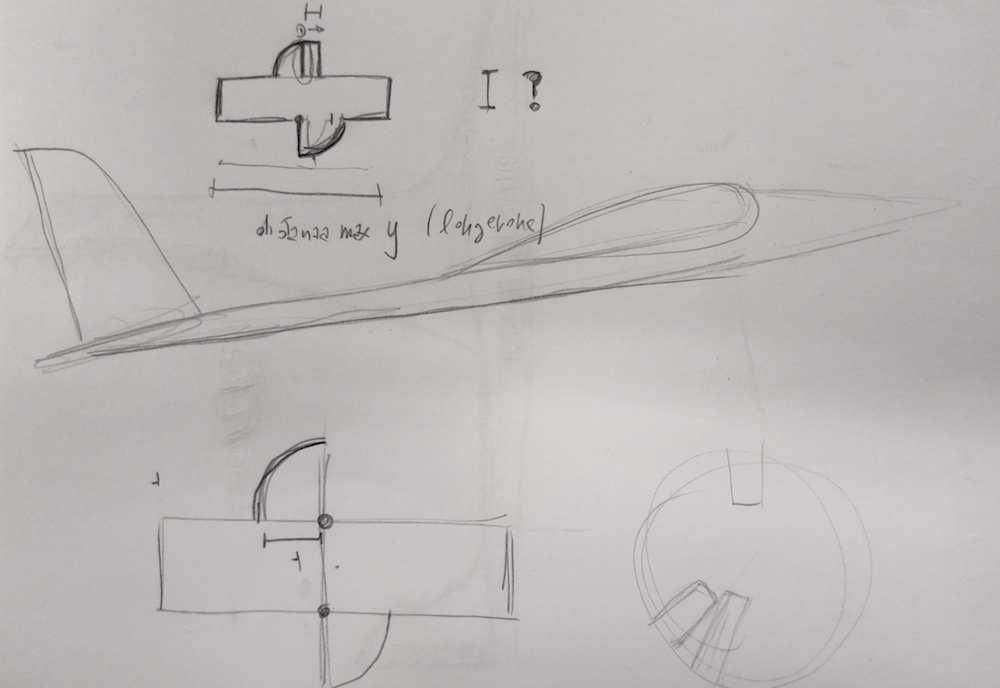

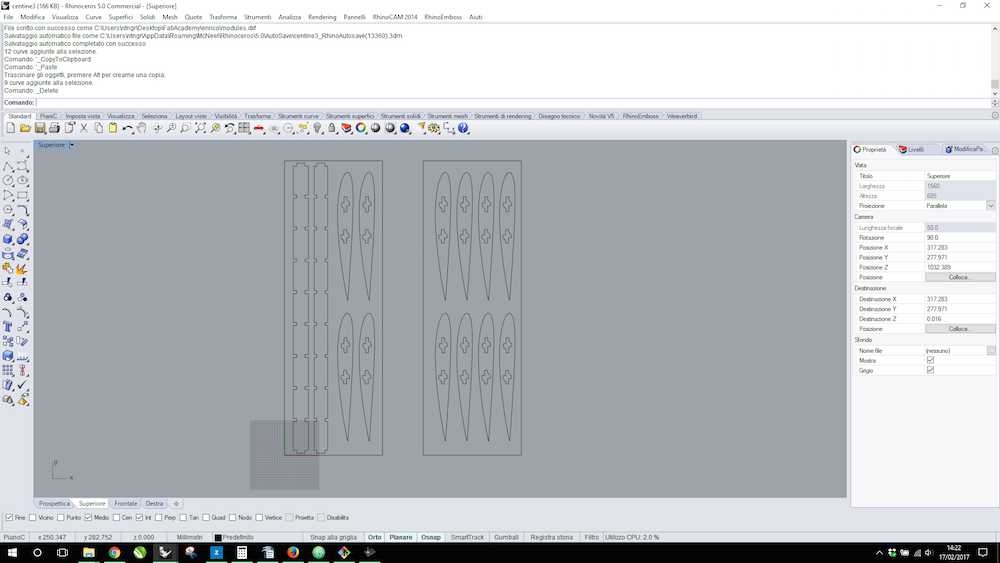

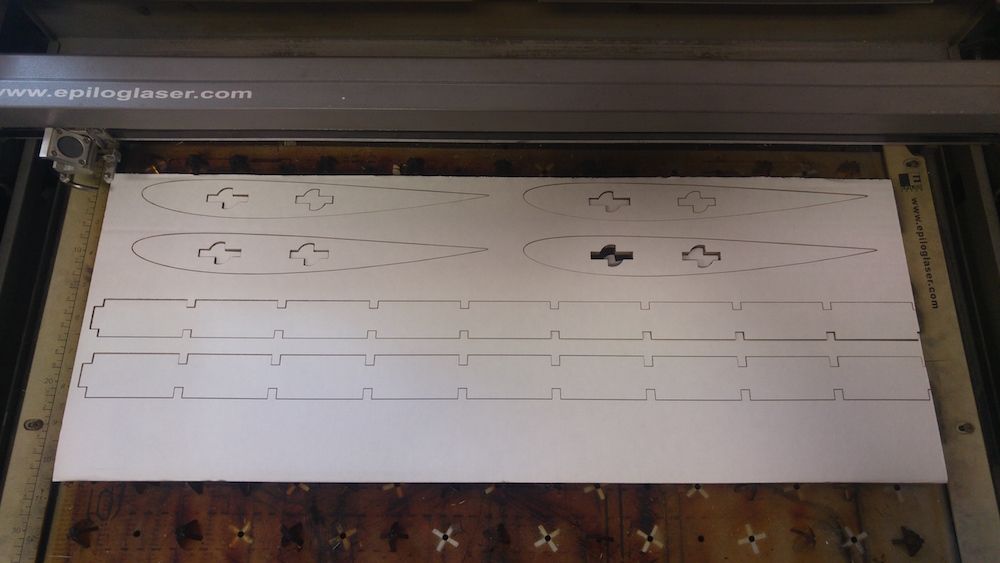

Concerning my personal exercise for laser cutting, I have decided to work with Rhinoceros and Grasshopper in order to create a parametric model of an airplane or a wing which can be cutted and fixed with parametric joints. Also, providing the best flexibility, I thought it was interesting working on plane wings section, starting from NACA points. By so doing, it is possibile to create any wing shape, from gliders to aerobatic planes model.

Parametric definition

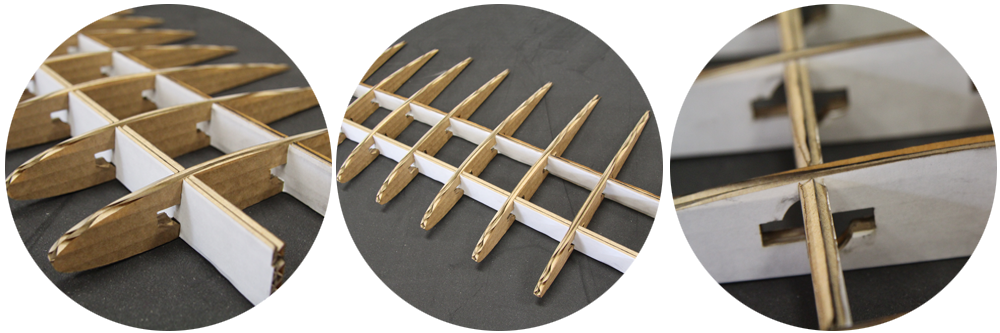

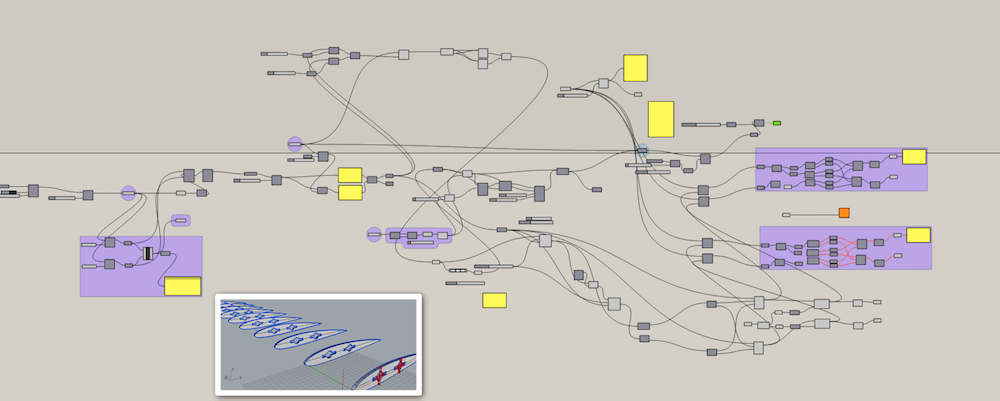

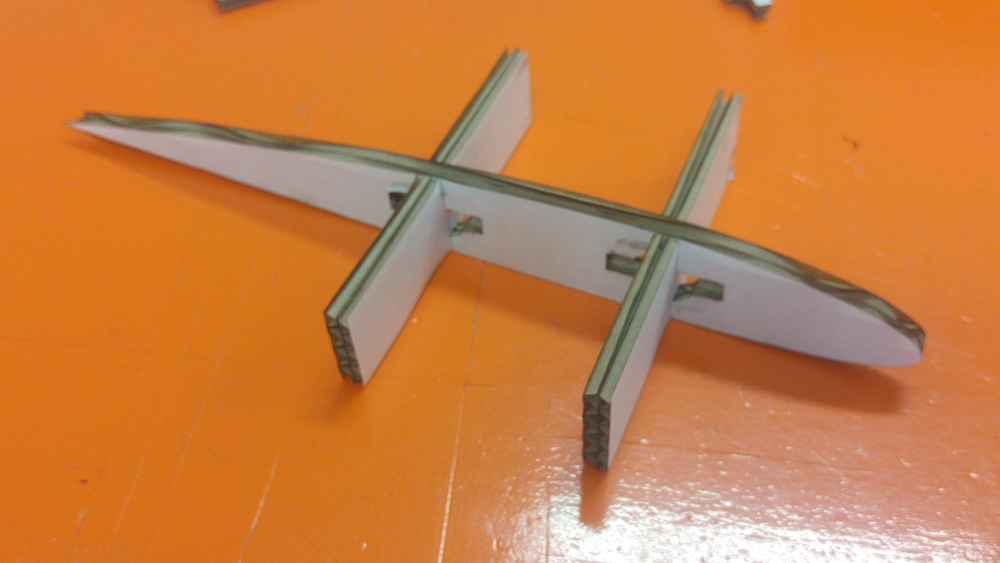

I have created and algorhytm that let me to scale automatically wing ribs, longeron and joints. I still have to work on fuselage, eventhough is the easiest part. About joints, I thought it was pretty interesting to work with some “X” joint that uses a radial interlocking motion to seal the deal, as we can see here this one.

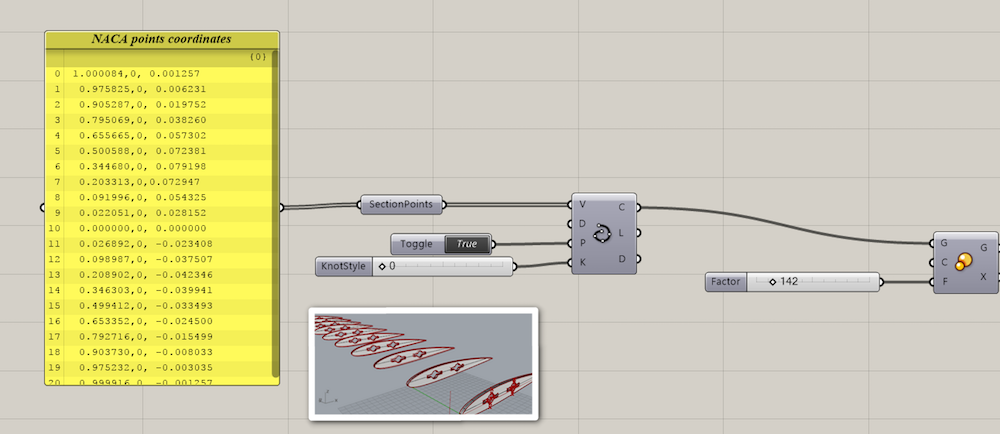

After studying all the constraints, I started to build the definition in grasshopper. The most importannt input data are the NACA coordinates, which define the wing section and its performance. I used Naca coordinates to build up the curve for wing section. I have introduced some sliders in order to operate on variables, like material thickness, kerf, interference, wing section scale, number of wing ribs, distance between each wing rib.

Tests with joints

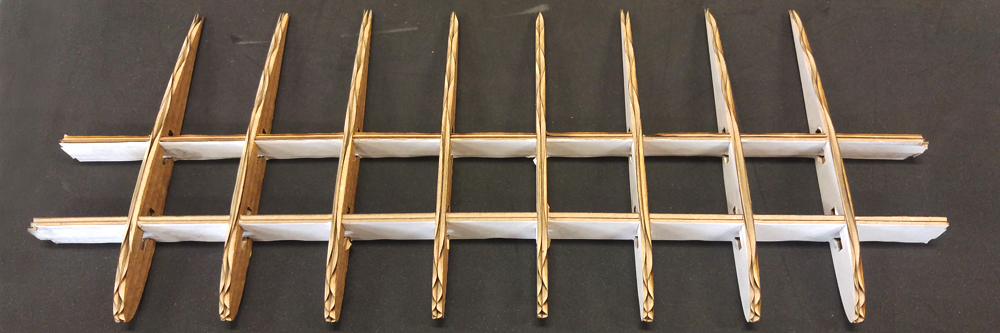

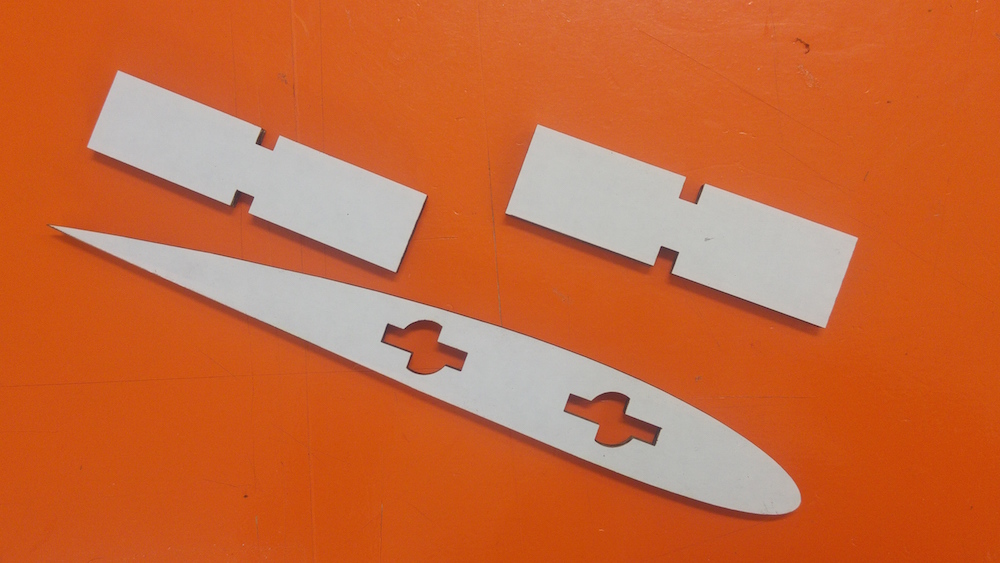

I have made some test, paying attention on material thickness, kerf and interference.

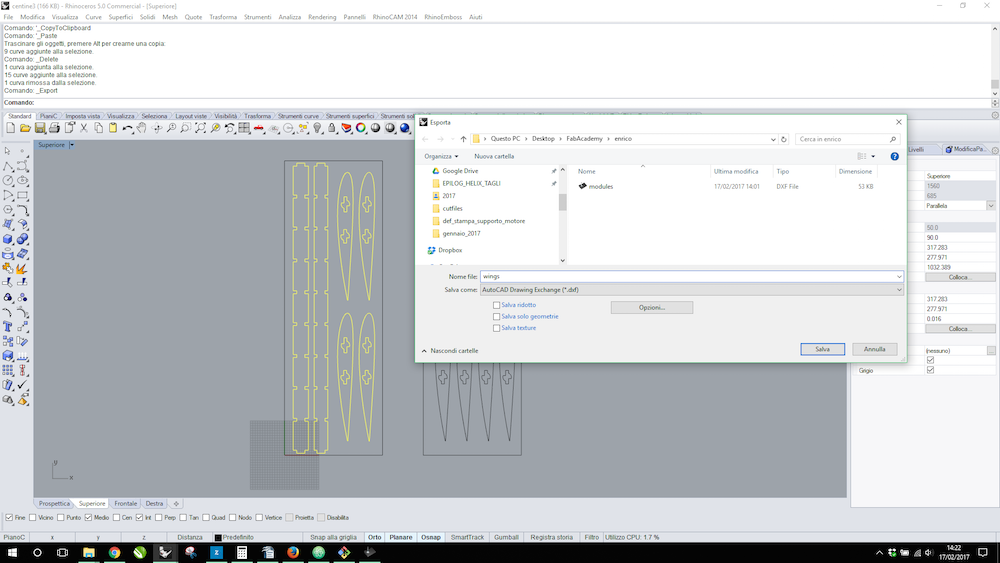

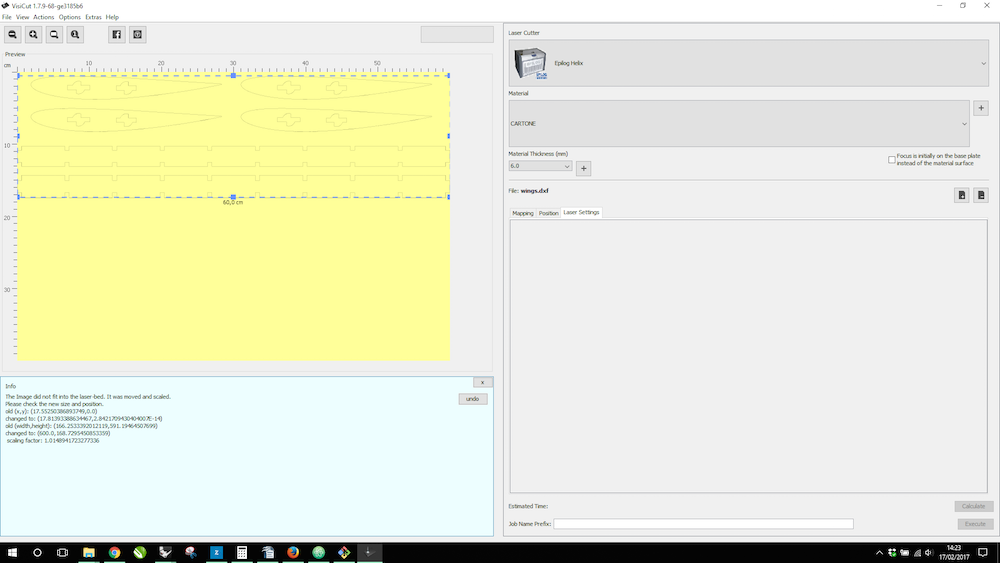

VISICUT SETTINGS

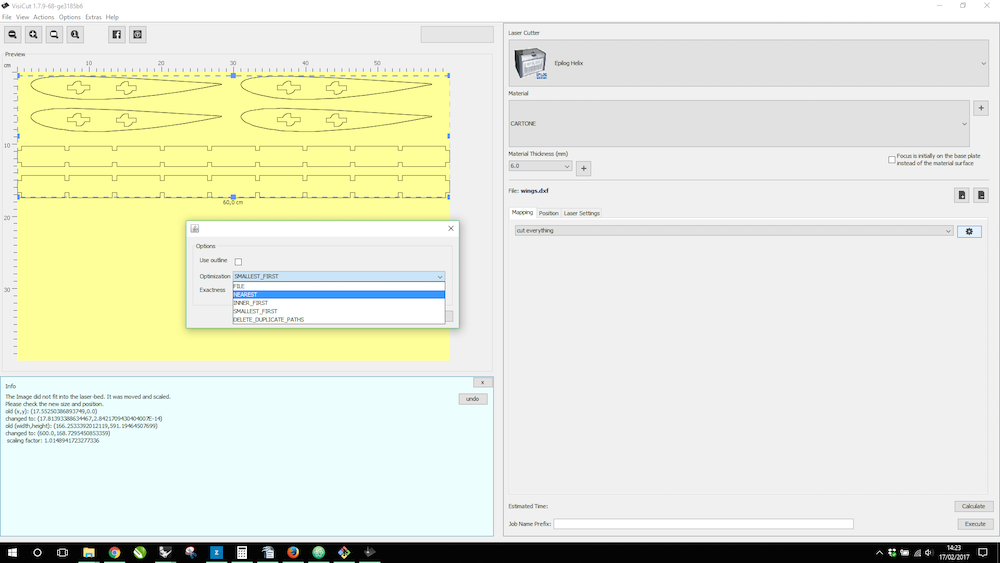

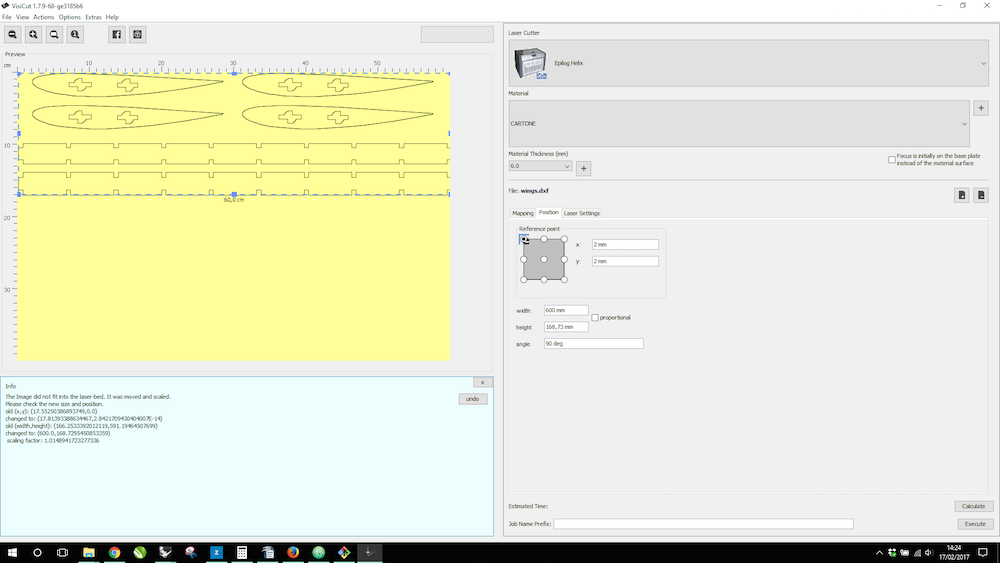

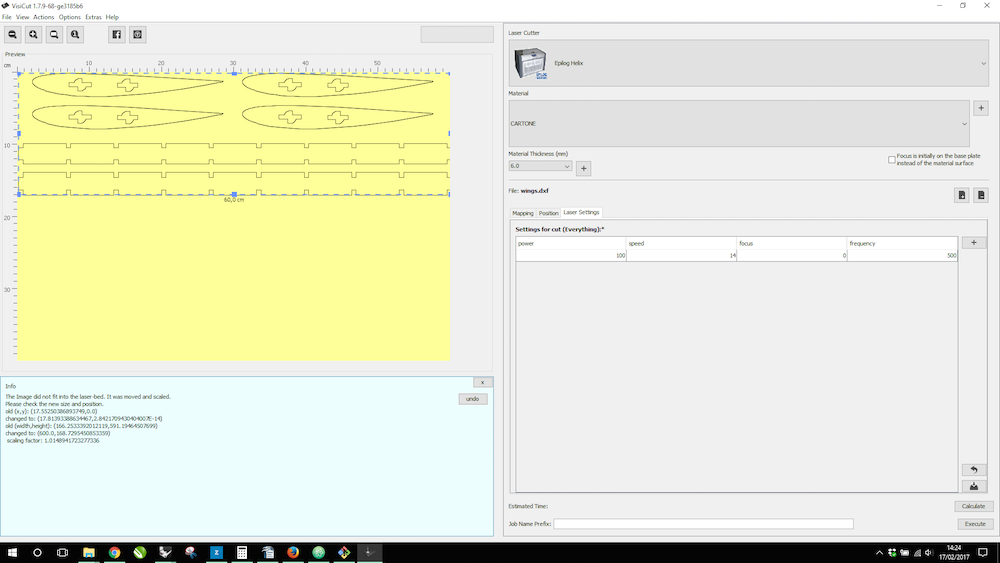

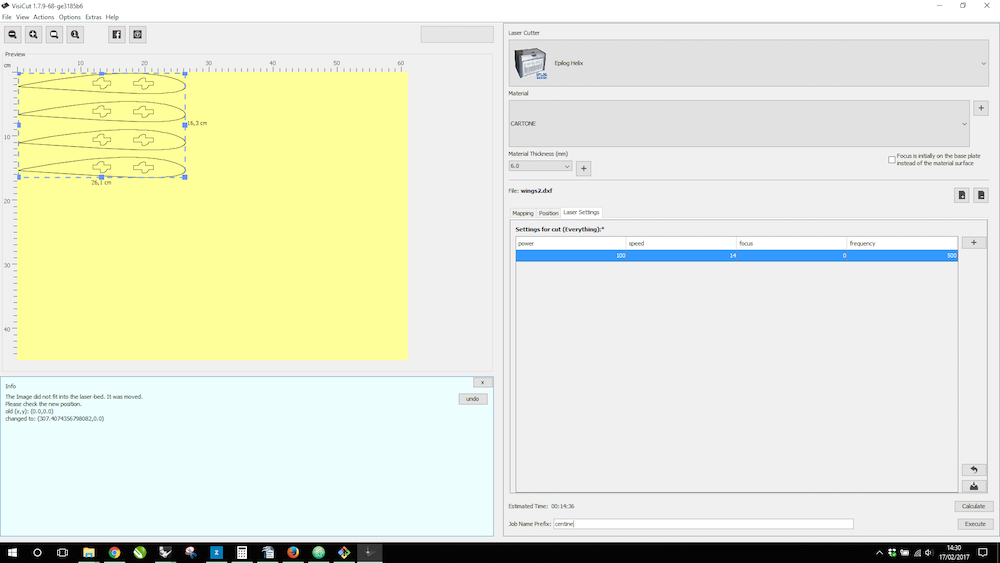

After that, I have prepared the final cuts with VISICUT. Here are some screen with the settings I used for cutting with the epilog helix.

FINAL RESULT

DOWNLOAD FILES

Rhinoceros FileGrasshopper definition