Electronics production

Task to do

1.To fabricate fab ISP board2.SMD soldering

3.Programming

After attending wednesday's lecture I get some new tricks for how to solder SMD's because before that I have soldered SMD's but that was not so good.

First of all we have to note that ISP means in system programmer.

What I did...

Process used-

Milling of board

Testing it

Programming of FabISP

Debugging of FabISP

I mill that board on Roland Modela MDX-20 machine.This machine is usefull for both milling and scanning.

I used fab module and followed same loading procedure as Vinyle only at time of selecting machine I selected Modela machine.

Note-If You are not good at soldering then put minimum 4 in place of path

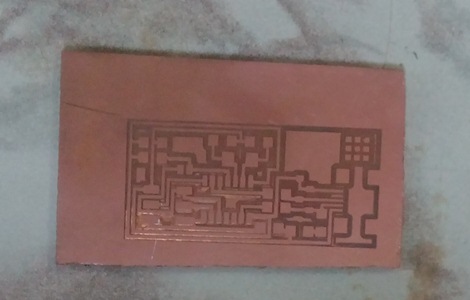

First time I got poorly milled PCB as below.due to low gravity.

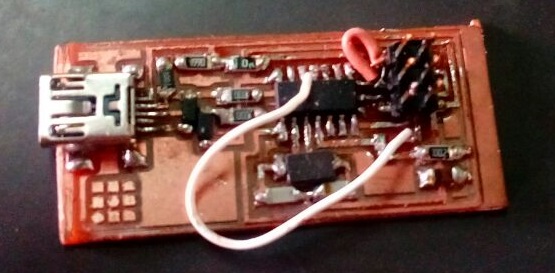

I tried 2nd and solder it. First of all I clean board with water and after drying I took it for soldering.I completed soldering in 4 hrs and it was very good thing for me as I did not had confidence for soldering of ATTiny 44.I easily soldered that IC but soldering of USB connector took time.I became very happy when I showed my soldered board to my Instructor and listen that its good.

There was some connection issues in First Fab ISP,that was not identified so I seldered another one.Alwayas Use proper connectors.Initially I had not used proper 6 pin connectors and at the time of Removing it

tracks get damaged so I esblished connectivity by using small wire

Programming

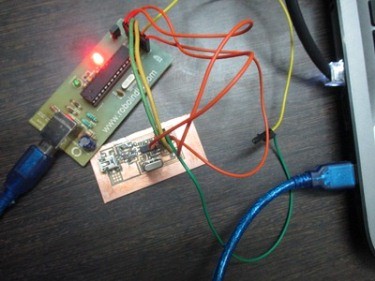

I checked connectivity,I took smoke test by connecting ISP boars to laptop with micro USB. I did not found any error into that.I am using USBASP programmer of roboindia.This is in-circuit programmer.

This board consist of ATmega8 and few passive components.It uses firmware only for USB driver.

Its features are-

- Works under multiple platforms. Linux, Mac OS X and Windows are tested.

- Jumper for 5v supply.

- Header Pin to provide easy interface for various ISP header pin.

- SCK option to support targets with low clock speed (< 1,5MHz).

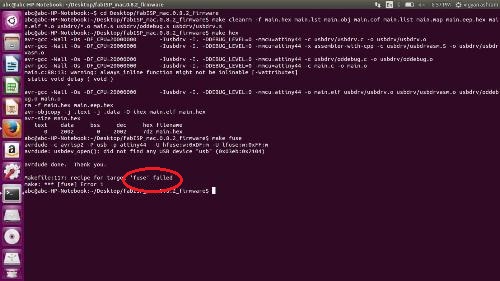

I downloaded firmware by following the tutorial on fab academy page.I was going smoothly without error but when I gave make fuse command then I got error.I try to remove that error by testing the connectivity of circuit and by changing the usb cable but it did not worked.

After long struggle I made another board and tried to program it but again same problem was raised. But I Found thread which was in my command, of fuse.

There was some bugs in my programming, note..

while typing the commands in terminal,we have to remember that it is case sensitive.I was writing UsbAsp in terminal which is wrong.

Required commands

lsusb - for listing the name of devices connected

cd ~sudo avr dude -c usbasp -p t44 -for checking connections

to fuse the programm use

sudo make fuse

sudo make programm

Now my FAB ISP is working.

first of all Install USBASP as simple usb device.For that install its driver.you will get all details by visiting above link.To transfer the Hex file to controller we require a software to access USBASP. There are lots of softwares available on internet.Software which we find easy to use with all features is Prog ISP. This softwatre you can get in above tutorial.There when you will extract the file that time WinRAR and RAR 5.31 release is recommended software.

ERRORS RESOLVED

micro USB is not connecting neetly

Getting error after using fuse command

Other methods used

I used vinyle cutter for making the circuit.For seeing settings of vinyle machine please refer this.

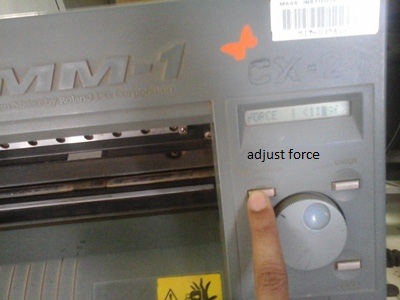

When I gave first print for ISP board that time force was 110.But that was more than requirement as it was tearing out the whole tracks.

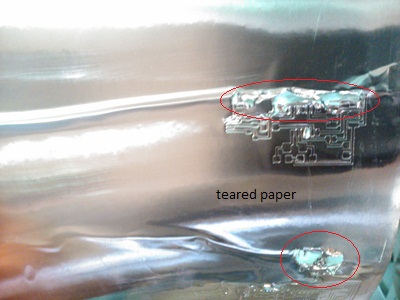

I minimized the force to 90 then also it was tearing out a paper.like below

I put force as 40 then it made circuit which is not removable. It was not cut properly it is only embossed one.

Slowly I increased the force.I come to know that even our force is less and paper has some wrinkle on its surface then paper is going to tear. So make sure that you paper is plane without any wrinkle.

I was not getting any good print by adjusting force.I changed blade of Vinyle cutter.Then I found that vinyle cutter giving good print by applying less force also.I thought that I got good design.

I cut the rectangle piece of copper paper on which my design was lying.

I started removing unwanted tracks. But I come to know that some tracks has very small gap in between and when I was removing that gap by picking the paper in squeezer that time side tracks are& braking.When I was removing one track that time whole copper paper is detaching from white sticky paper below it.This was happening as gap between tracks is very less.I not removed remaining trcks as at the time of removing unwanted tracks whole circuit is detaching from paper and tracks were cutting.I tried this on 2-3 designs.

I failed to remove unwanted copper paper as it was very thin and when I was going to remove one unwanted strip that time it is comming along with side tracks.Due to this problem I unabled to make good vinyl cut circuit.

In this assignment I learned to programm and making of fab ISP,Its trouble shooting,testing and also learned to print flexible circuits.