Stirr it-A Basundi maker

Indian sweets are mainly made from milk.Basundi is one of the sweet dish made from milk, it's very popular in all over India The process involved boiling of milk for hours It need

continuous stirring of milk when it is boiling. The process involves lots of labor

and fuel.

Trditionlly basundi is made by keeping the pot on cooking gas or

chulha or any heating surface and have to poure milk into that pot.

Then milk is boiled and after that it requires continuous stirring.

If it is not stir then milk get stick to vessel and it burns.If milk get

burn then test and color of sweet degrades.So thats why stirring is

very important part at the time of making sweet dishes from milk

Basundi is made in the home as a sweet dish for

festivals. I love taste of Basundi but hate to make it myself ! because of its time consuming process.

That if we use parabolic reflector for cooking then its cause to save fuel and it is low cost concentrator.

But it is not possible to cook on parabolic reflector by standing infront of that continuously

as it creats heat and the rays reflected from its surface can injure our eyes.So automation is require to avoid that

Machine available in market for this process has facility to stir continuous but one person is needed

for observing the state of milk

There is no such a machine in market which uses solar reflection heat for this densing process.

IDEA !

To make a basundi maker – which will boil the milk using solar energy.

The stirrer action will take place by motorized stirrer.

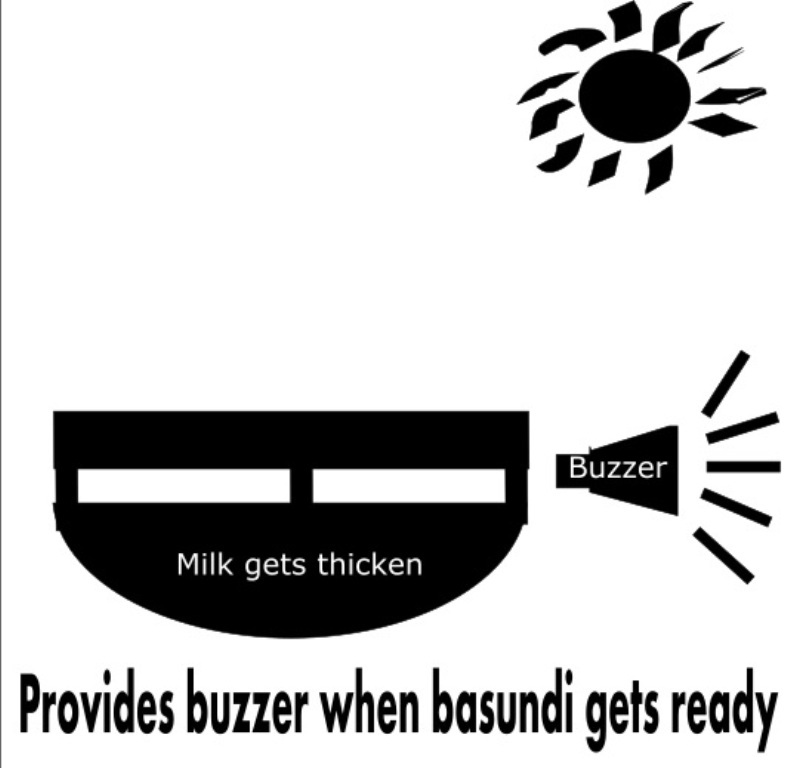

It has automatic indicators and buzzer when Basundi is READY !

Change due to Basundi maker

This machine can make basundi easily without giving your time for all process and it will reduce fuel cost.

Just start machine and forget it, machine will automatically give alarm when your Basundi will get ready

Objective –

11)

To make a stirrer which will continuously stir the milk.

22)

It will give alarm when milk become thick (viscous).

Understanding problem / Initial Experimentation :

11) Date 13-Dec-15 : I

used solar reflector in pot and kept

milk without stirrer.Evaportion rate was very slow.

22) Date 20-Dec-15 : I used flat pan for increasing

rate of evaporation.Evaporation rate was increased but milk was sticked to

the pot.

33) Date 28-Dec-15 : I added stirrer using electric

motor. Evaporation rate increased and milk turns viscose in 6 hrs ( 10am – 4

pm)

44) Following are the reading of boiling of

milk on solar.

The experiments were carried out with double jacket cooker and flat bottom steel vessel.

.Following are important observations experiment as –

Sr N

|

Duration

(Time taken)

|

Initial milk

Wt

|

Weight loss

|

Calories Captured

*

|

Remark

|

1

|

5 Hr

|

500 GM

|

300 Gm

|

200 K Cal

|

Cooker without

agitator

|

2

|

6 Hr

|

500 Gm

|

450 Gm

|

280 K Cal

|

Cooker with

agitator

|

3

|

6 Hr

|

500 GM

|

490 Gm

|

302 K Cal

|

Cooker with

agitator

|

4

|

1.45 Hr

|

1000 GM

|

800 Gm

|

507 Kcal

|

Flat bottom

steel vessel without agitator

|

Note – (Assumptions made calculating calories Captured)

· Initial temp of milk – 25 ˚ C

· For 1 Gm of milk – Increase temp by 1 ˚ C = 1

K Cal

· Milk is condensed by evaporating water

content from it , So while making khoa (thick milk) water evaporated by adding

75 K Cal to each Gm of milk to raise its temperature up to 100 ˚C.

· 540 Calories are required to transform 1 Gm

of water in to vapor form. So total calories captured in experiment = 75 K cal+

(540 * weight loss)

Experiment conclusion –· When sun heat was trapped with flat surface

vessel the highest calories were captured in minimum time. (3 times less

time with almost double calories capture)

I also tried using vaccum tube for thickening milk. But it does not work

out. Milk get stick to the tube and cleaning become very difficult.

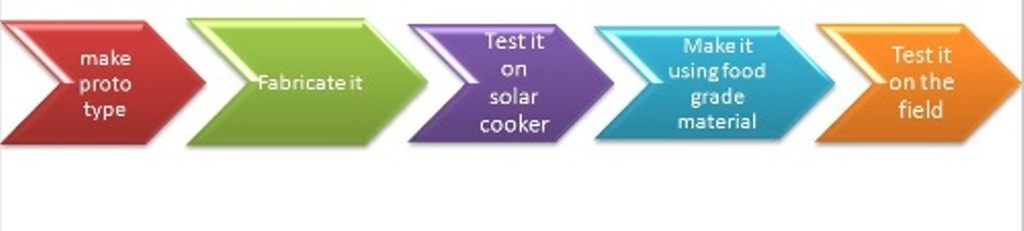

Project Plan :

Make a prototype – Fabricate – Test is on solar

cooker – Make it using food grade

material – Test it on the field

Making prototype :

Composite

have made prototype of pot using burlap,tissue paper and natural glue

For actual testing in the field, I need to use vessel using Food grade material. Which I have bought from the market.

have made prototype of pot using burlap,tissue paper and natural glue

For actual testing in the field, I need to use vessel using Food grade material. Which I have bought from the market.

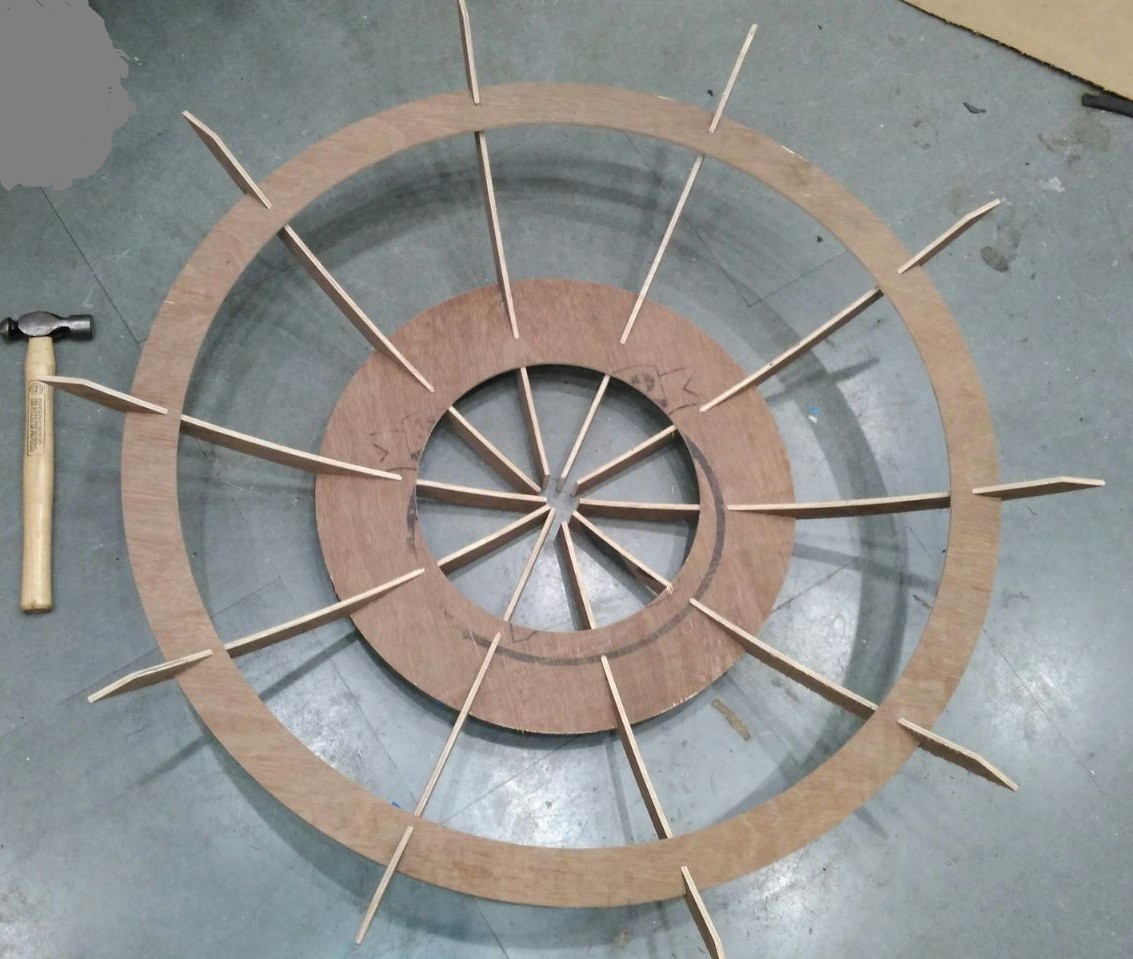

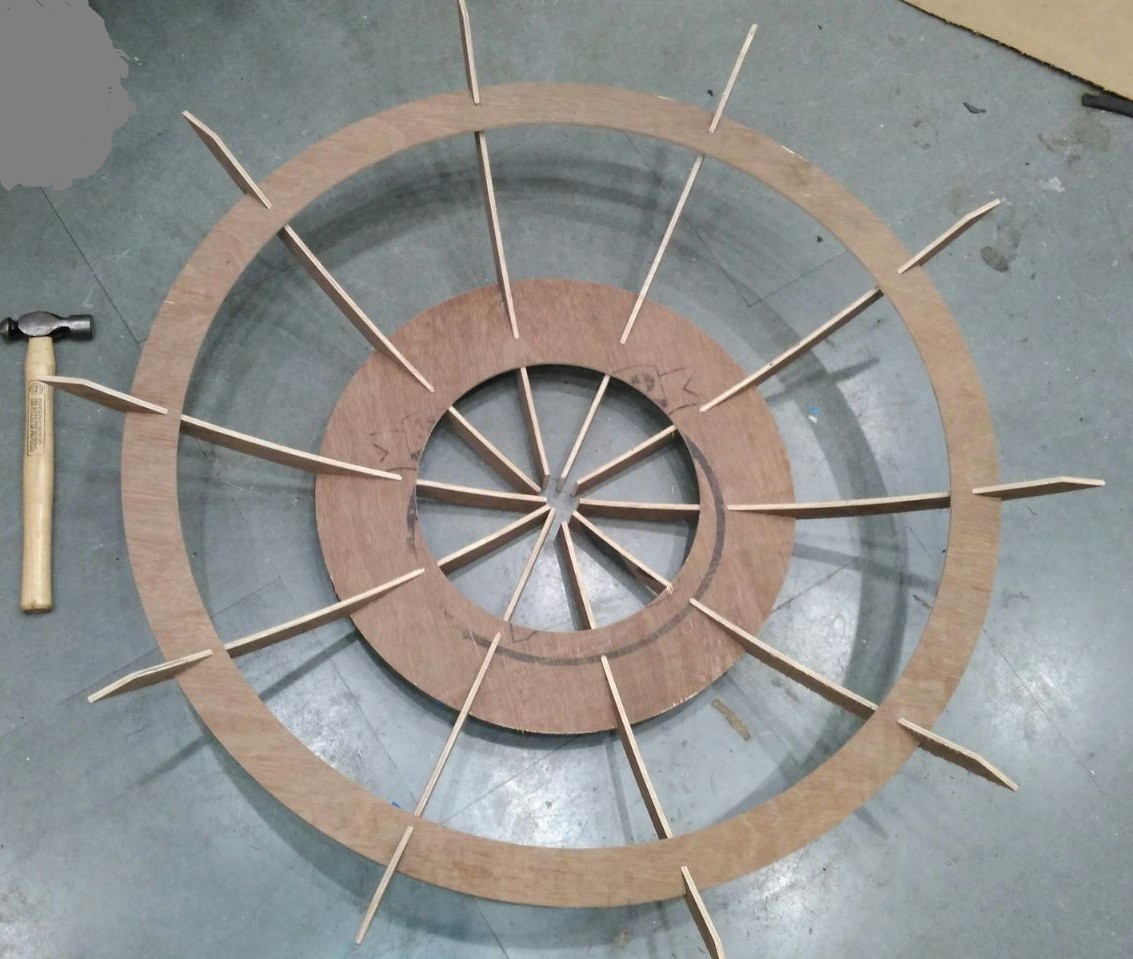

I have made prototype of solar reflector on shopbot

Input and output boards are made in respective assignments

In input I used current sensor which is sensing current drawn by motor .Motor will draw more current if load get increased so when milk become thick it will draw more current and we have to give alarm at that point.

In input I used current sensor which is sensing current drawn by motor .Motor will draw more current if load get increased so when milk become thick it will draw more current and we have to give alarm at that point.

As per design I made 2D design files and first cut it on card board paper.Then adjust its dimensions then took its impression on stainless sheet material and cut it manually .I used ss sheet because we need to use food grade material which can sustain up to 110 Degree Celsius as parabola can reach maximum up to this temperature.

Then I assembled that parts to take first trial.

I cut that design on laser cutter

Modified design

The fabricated prototype is as follows

Above in prototyping models I have given link to all original files for 3d design,input output and more...by using it you can make this stir it machine.

This machine is made to use on solar reflector but in future we can use it on regular cooking gas but,our objective of fuel saving will not complete if we go for regular cooking gas.

Here is the link for copyright and license

I have took creative common license

Future scope

Here is the link for copyright and license

I have took creative common license

Future scope

We can add knob or button in machine to take input from user to understand that how much liter of milk he have put in pot.

We have to increase machine milk containing capacity .Now it is able to thick up to 4 to 5 ltr milk

but we have to increase this capacity for bulk production.

Click here to get bill of material

Go through this link to get more details about costing and material list