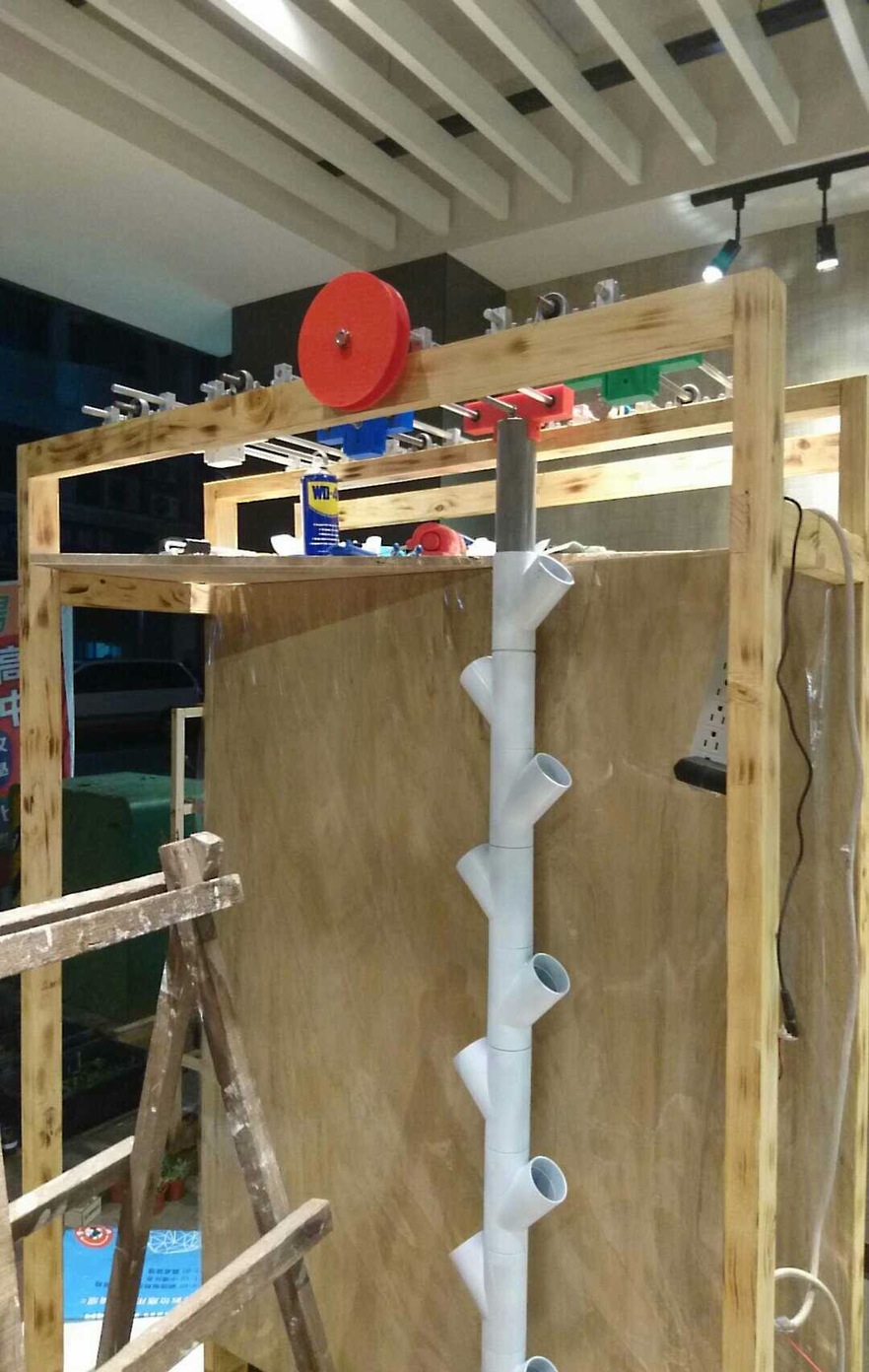

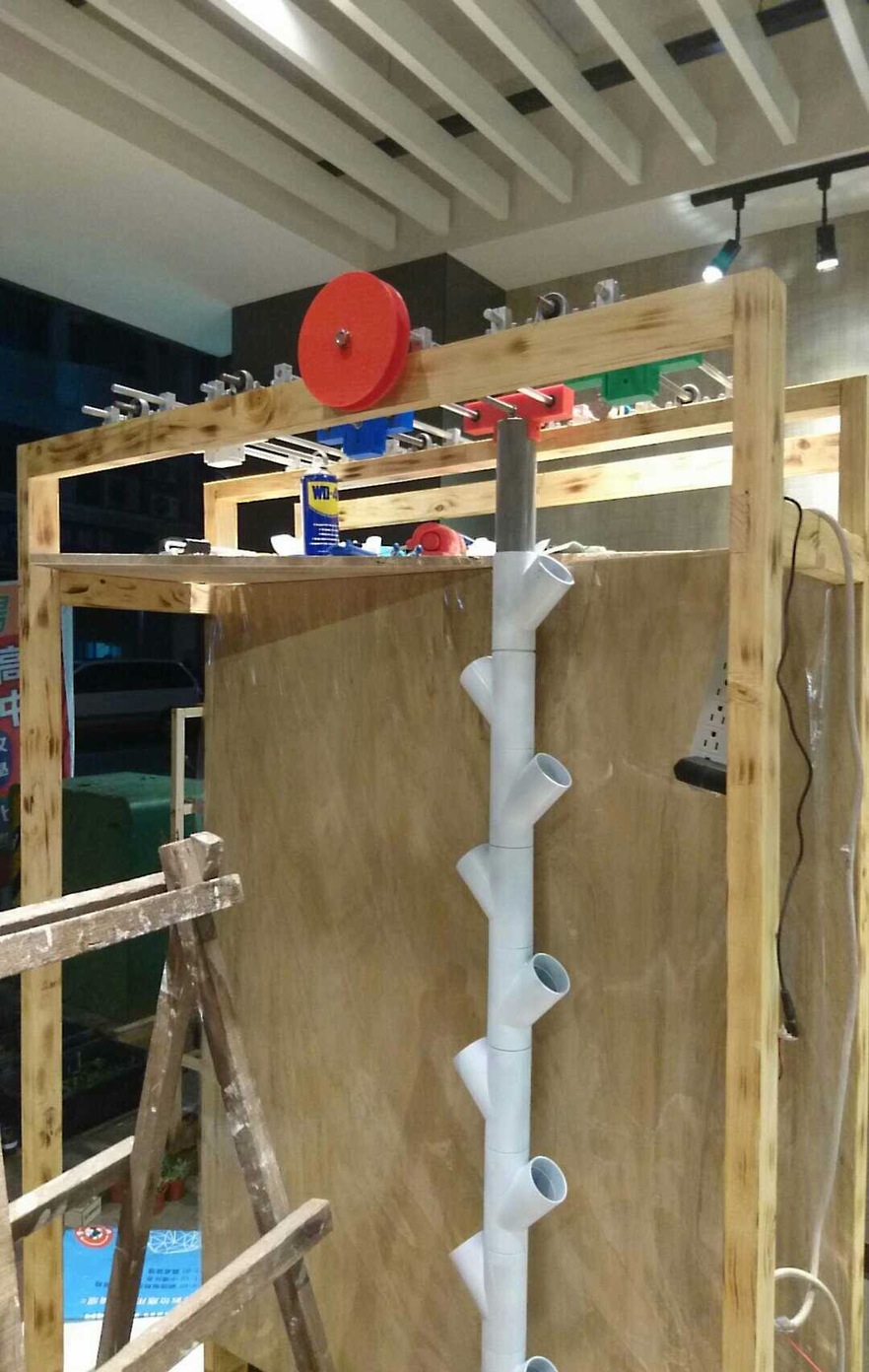

The frame

The main structure of this hydroponic system is the use of wood is completed.Fish pond is the use of wood assembled.

I also used on CNC machining latch portion (refer Week 7). After completion of the cutting assembly formed. Part using traditional tools, such as bonded backplane.

Wood used as the pool and the main framework is covered by transparent plastic cloth to avoid moldy decaying in the part of the wet.

此水耕系統的主要架構都是使用木頭完成。養魚的水池也是使用木板組裝而成。

其中使用了CNC加工卡榫部分,參照Week 7),切割完成後再拼裝而成。部分使用傳統工具,如貼合的背板。

會碰到水的部分使用透明塑膠布包覆。

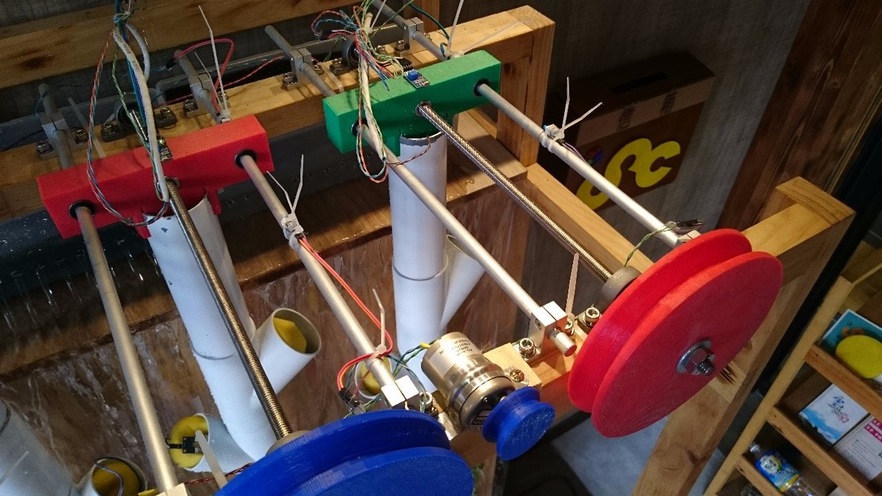

Pipe of Cultivation

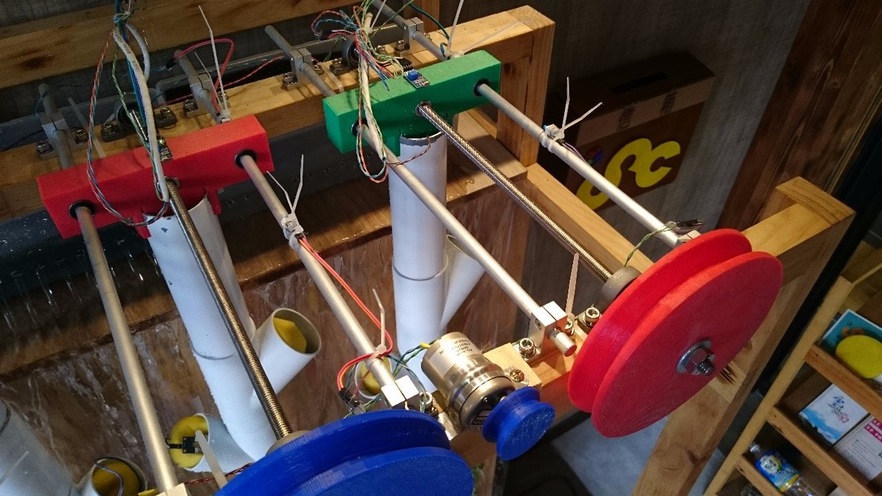

Pipes of cultivation were made by PVC pipe of Y type 2". I linked the different pipes covered by white color. Plants grown in the ten farming tubes combinated by PVC pipe, are hanging verticaily on the guideway.

養殖管是使用Y型2"PVC水管。互相接合後並上白漆。一組有10個孔可以種植植物。準備四組備用。

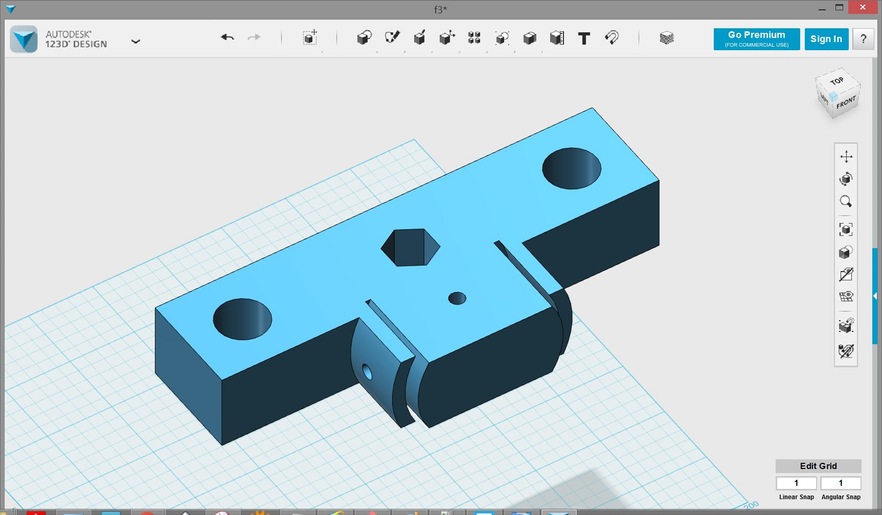

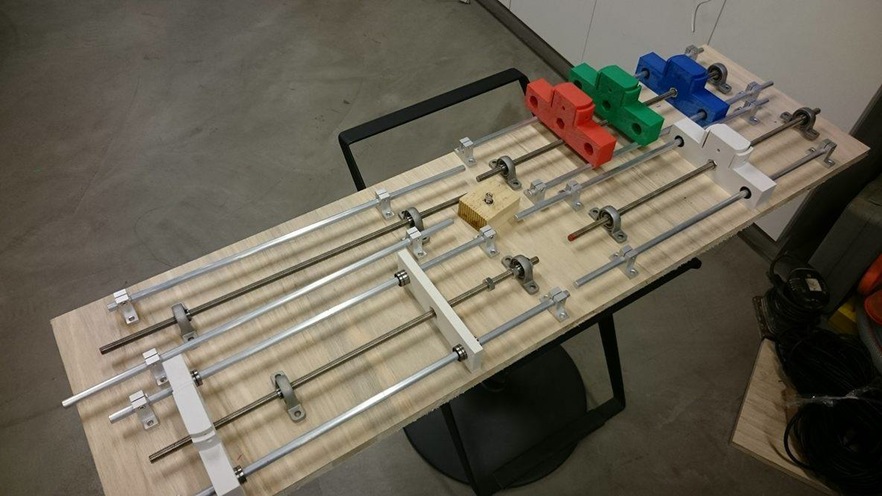

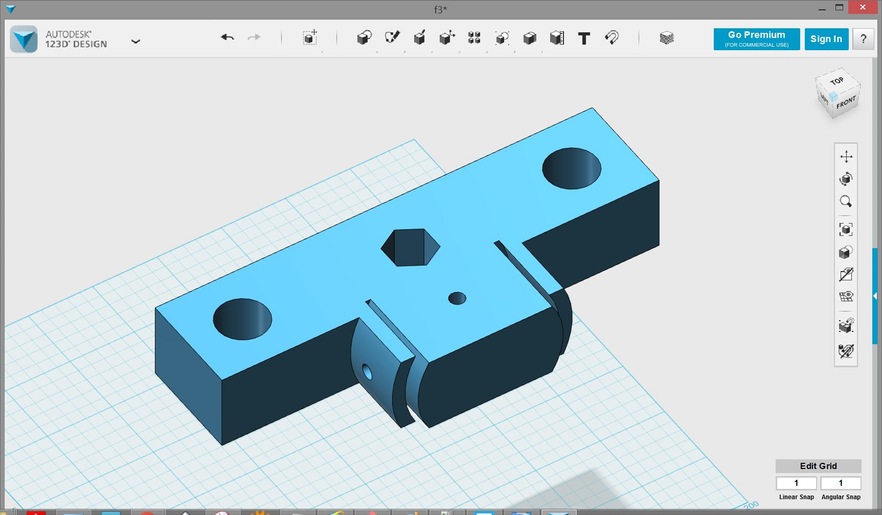

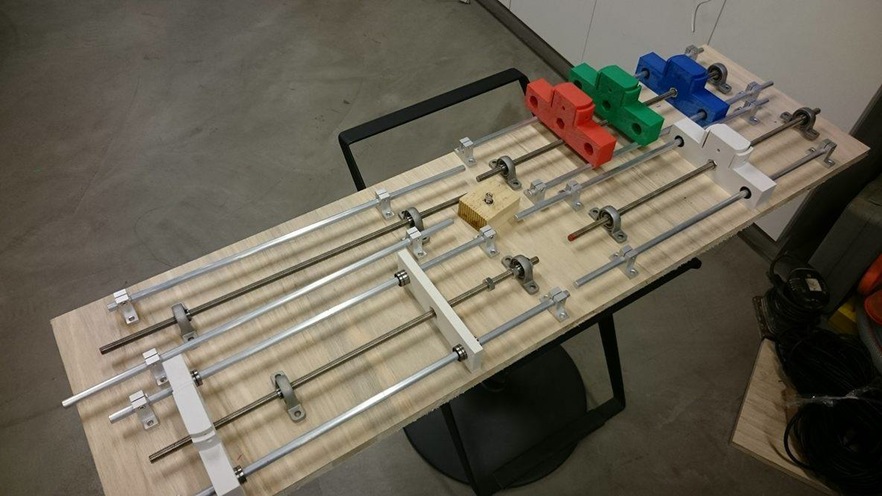

Rail systems Sliding System

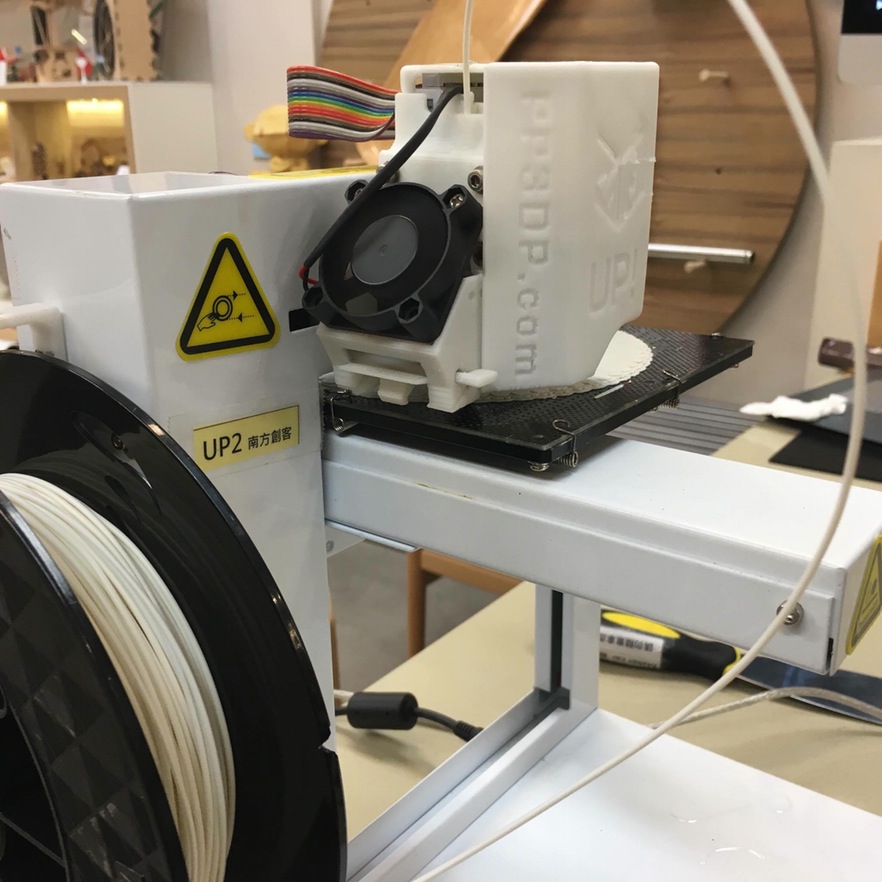

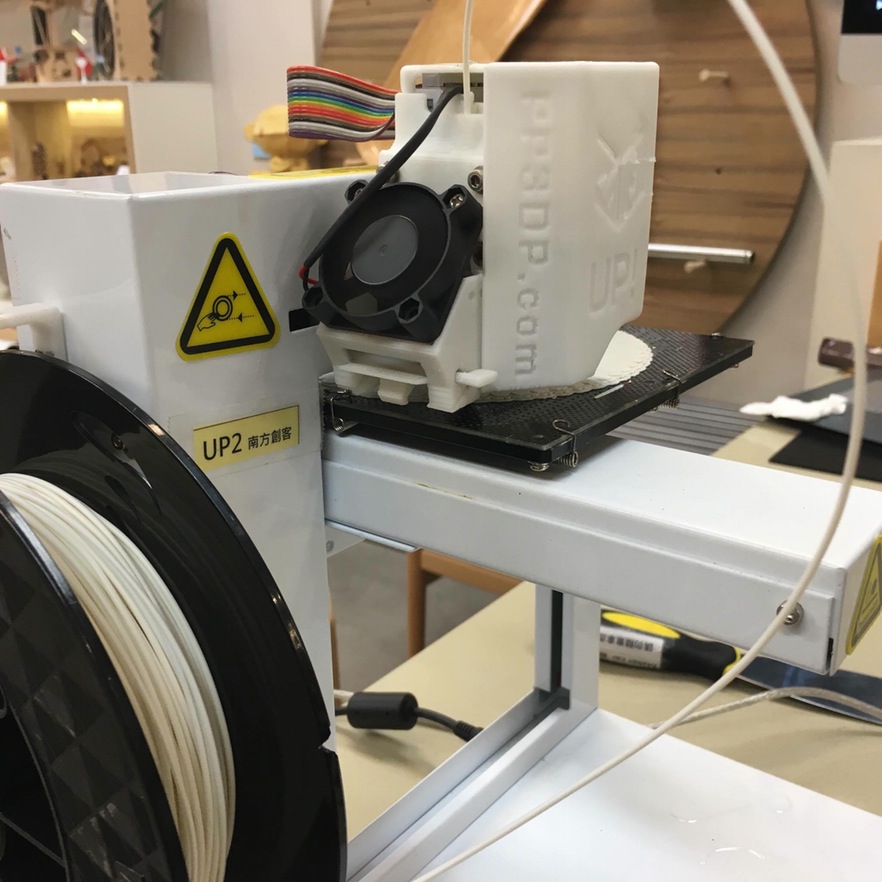

Small test work using laser cutting wood as seat rails, but the system needs to consider the big heavy load (empty tube has been farmed> 2Kg), larger size. All rock will cause burden on the system. So we need a solid metal objects. Purchase of existing housing, seat slider, screw, slider, linear bearings. Dimensions are using the M10. But the market is not ready-slider, so you must make your own. 123D Design and use the drawing to print using the UP BOX (refer week5). Both sides set aside linear bearings. The middle is the nut hole. The bottom is reserved for farming locked pipe holes. Follow-up can be used to strengthen the M4 screw fixing.

小型試作品使用雷射切割木板當成滑軌座,但考量大系統需載較重(空養殖管已>2Kg),尺寸較大。所有晃動都會造成系統負擔。所以需要穩固的金屬物件。購買現有的軸承座、滑桿座、螺桿、滑桿、直線軸承。使用的都是M10的尺寸。但滑塊市場沒有現成品,所以必須自己製作。使用123D Design繪圖並使用UP BOX進行列印(參照week5)。兩側預留線性軸承。中間則是螺母孔。下方則預留鎖上養殖管的孔洞。後續可使用M4螺絲加強固定。

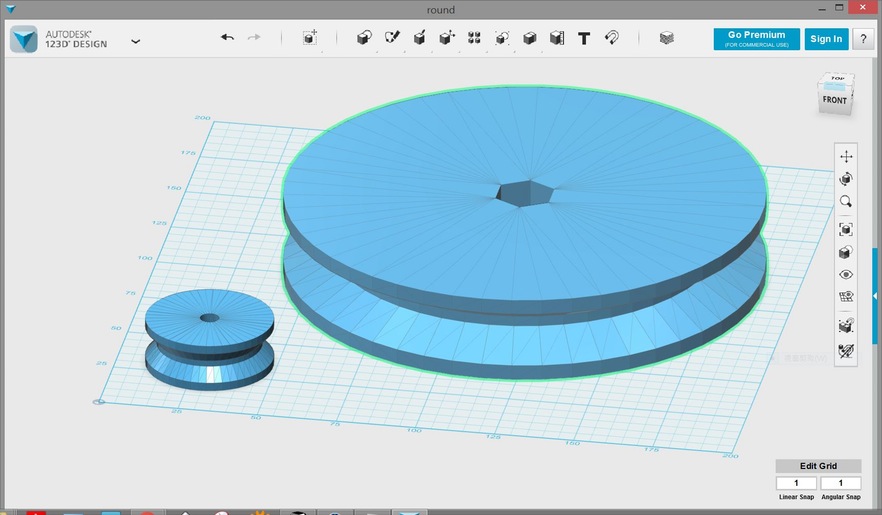

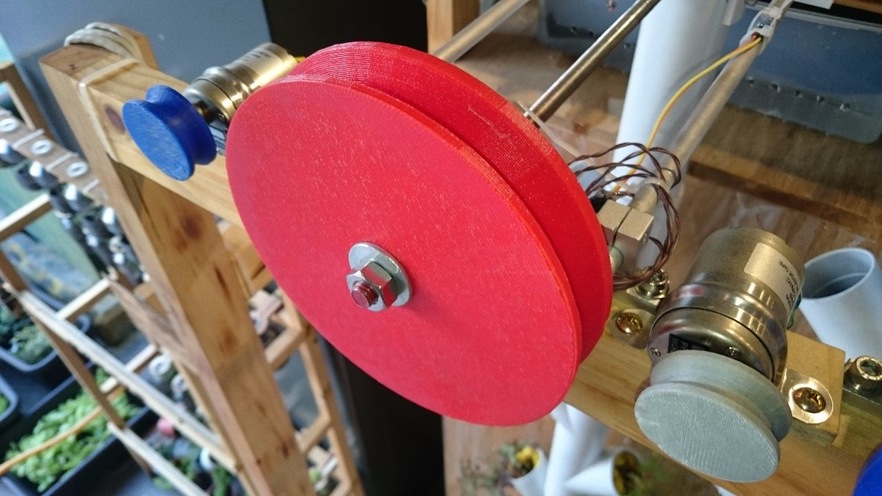

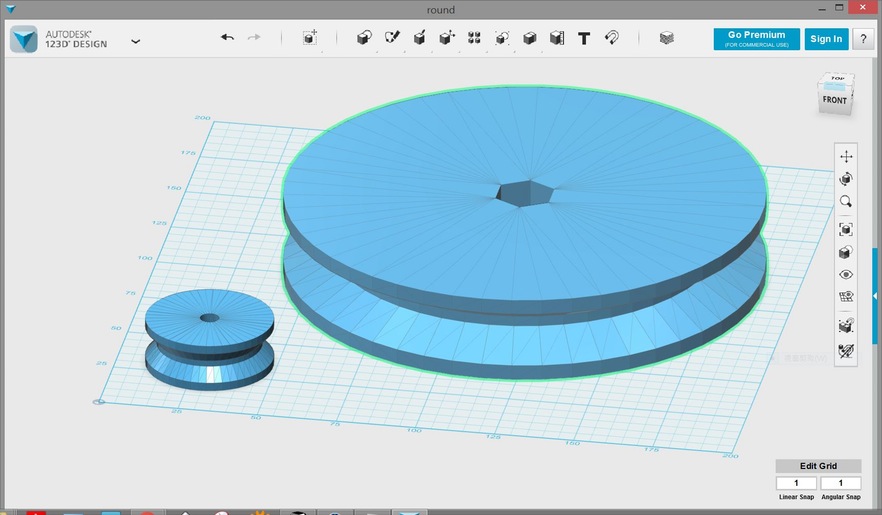

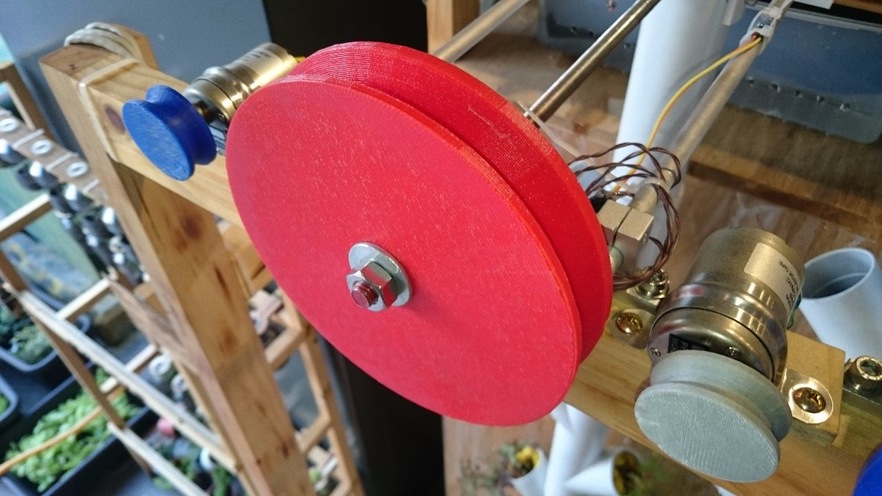

Pulley

In week12, designed two pulleys. Using 3D printing and die casting complete turn four. Reproduction of material is a poly. Large pulley directly to 3D printing is complete.

在week12,設計的兩個皮帶輪。使用3D列印及鑄造翻模完成四組。翻製材料為poly。大型皮帶輪則直接以3D列印完成。

Motor

Motor using a 12V, 600r.p.m.. This two pulleys can reduce speed, increase torque. Let planting tube is not too heavy because the weight is not running smoothly. After the rails surrounding parts are ready, it can be fixed on top of the frame, to take a good distance between each planting tube. Lock fixing screws. After fixing the motor is also mounted on the rubber band as a transmission belt.

使用的馬達是12V, 600r.p.m. 。此兩個皮帶輪能夠降低轉速,提高扭力。讓種植管不因重量太重而運轉不順暢。滑軌周邊零件都備齊後,就可以固定於框架之上,取好每個種植管的間距。鎖上固定的螺絲。馬達也固定好後,安裝上橡皮筋作為傳動皮帶。

Water Cycle

Pumped pump installed in the rear of the sink. Sent to the top of the water will sink. And flows out from the hole in the filter tank.

抽水幫浦安裝在水槽後方。會把水送往頂部水槽。再由過濾槽的孔洞流出。

主要零件、管路都安裝好後。開始佈電線。我選用的是網路線來當訊號線/電源線。有幾個優點:

1.一般網路線內有八條子線,共四對。一條網路線即可收集4個訊號。節省多條線時雜亂難整理。

2.兩條互相纏繞成麻花狀的電線具有抗雜訊功能,確保感測器功能穩定。

3.系統除抽水幫浦外,沒有使用大電力的設備,網路線線徑足夠負荷使用。

4.較一般電線便宜可節省費用。

計算好需要預留的感測器、開關、電源數量。大致拉好線後。安裝上極限開關、感測器等。使用束帶固定之。將網路線收束到後面接上控制板。

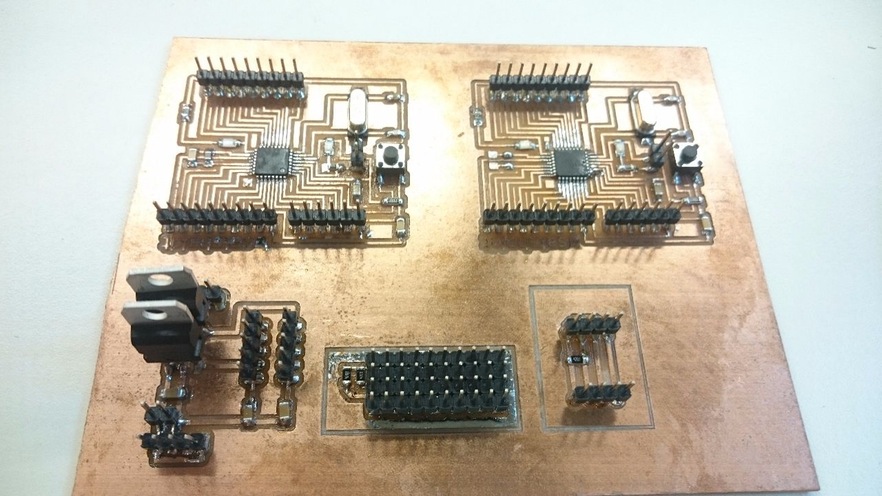

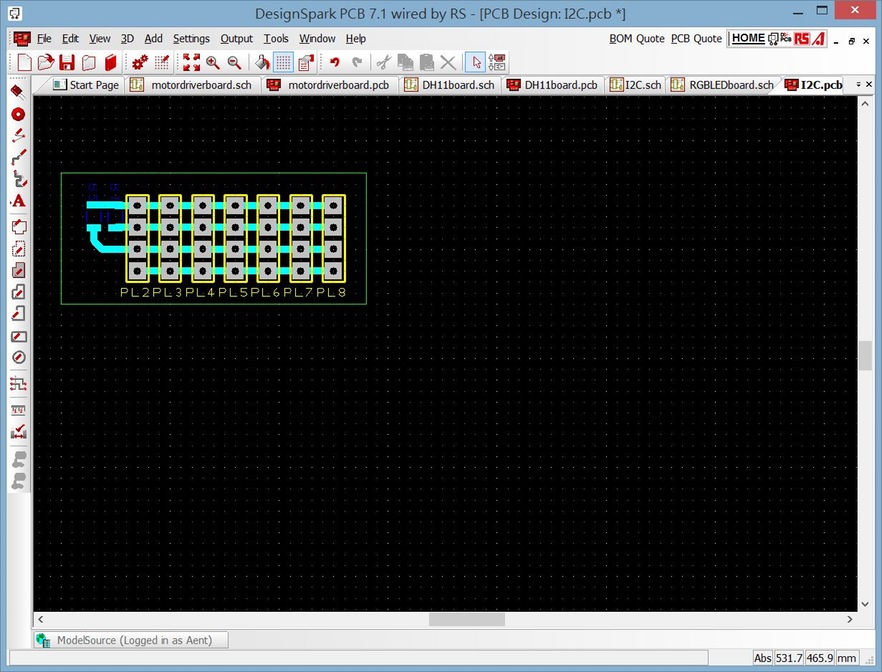

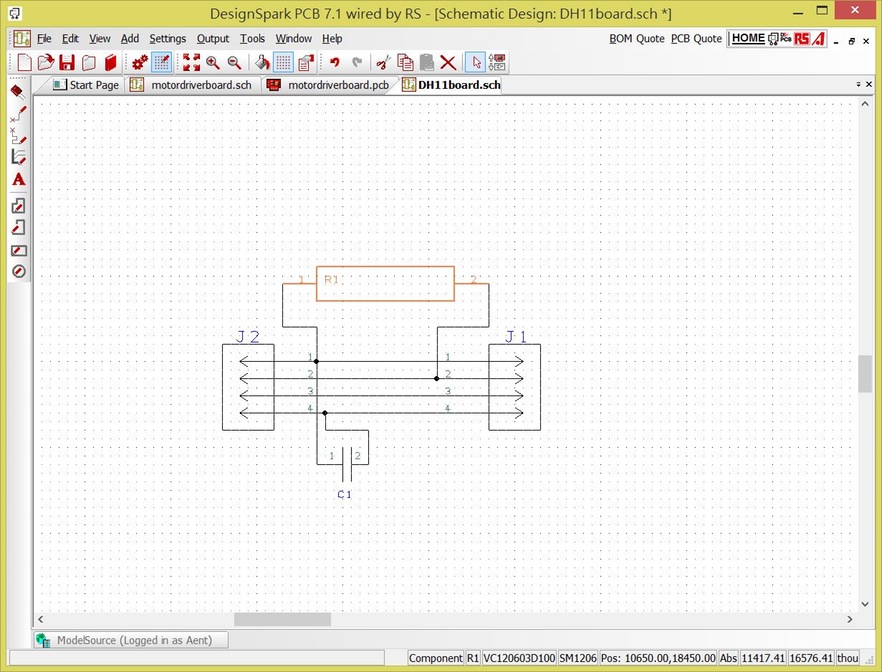

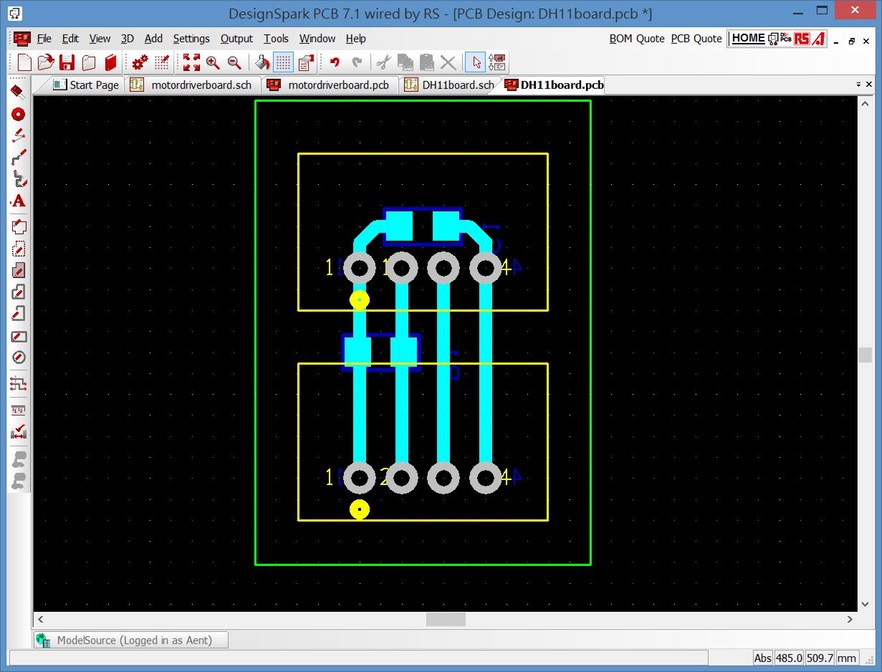

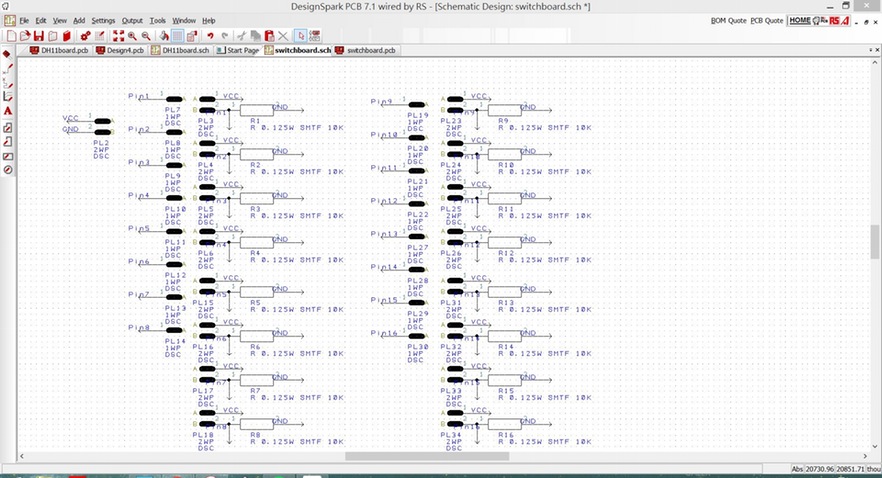

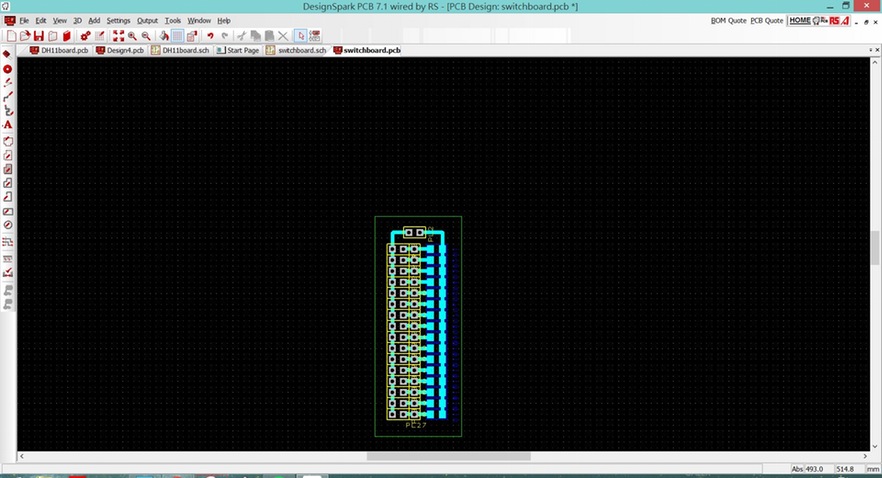

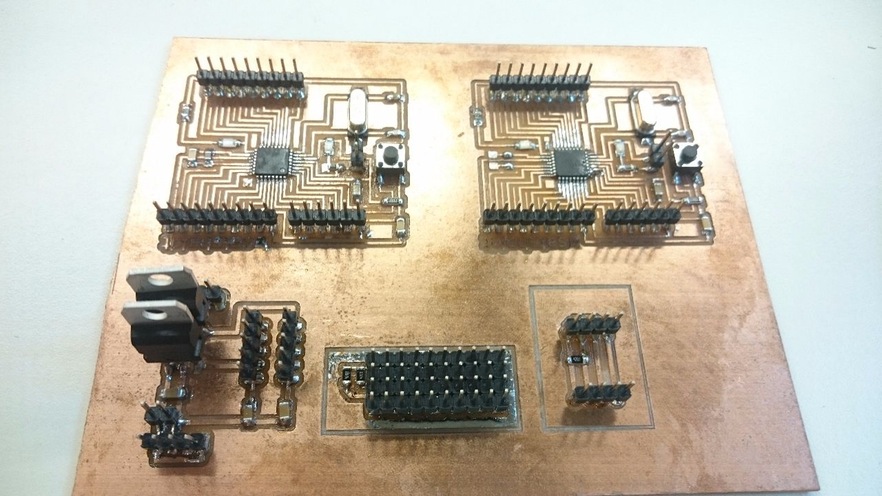

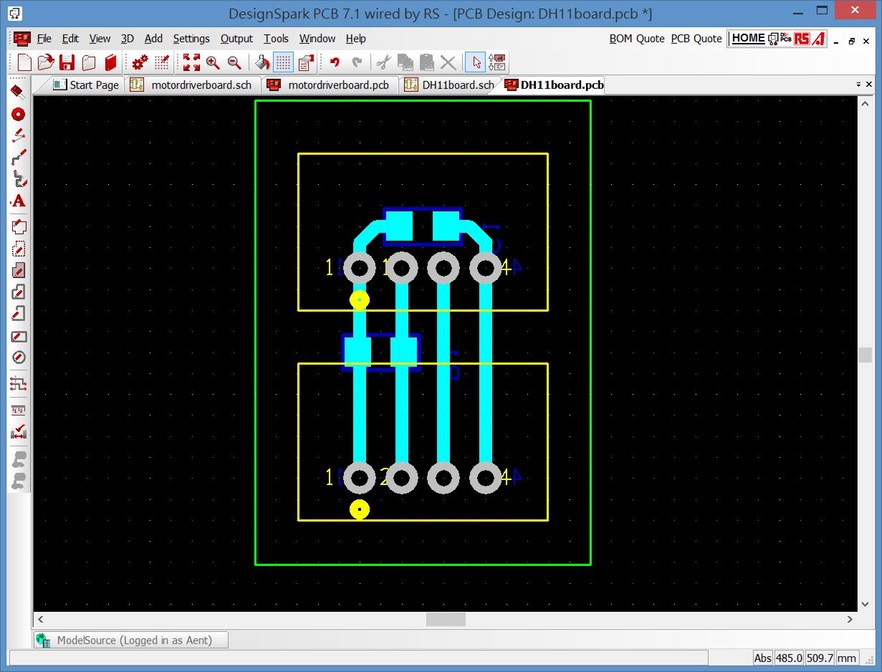

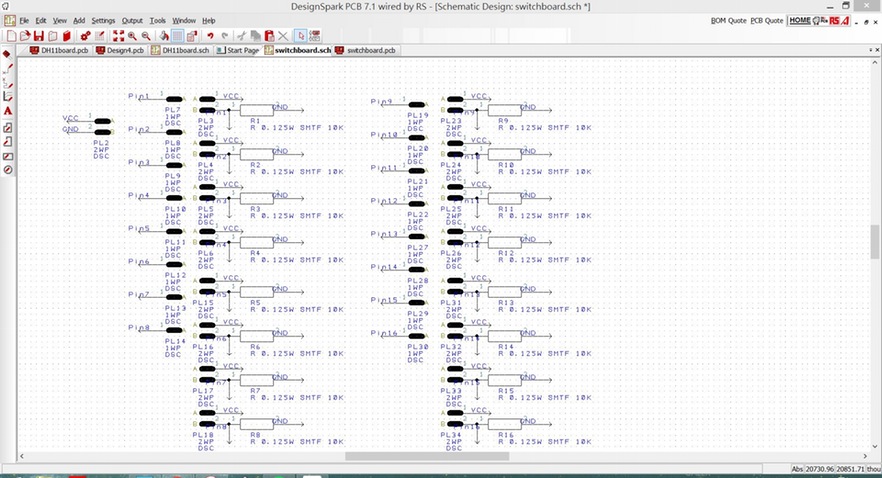

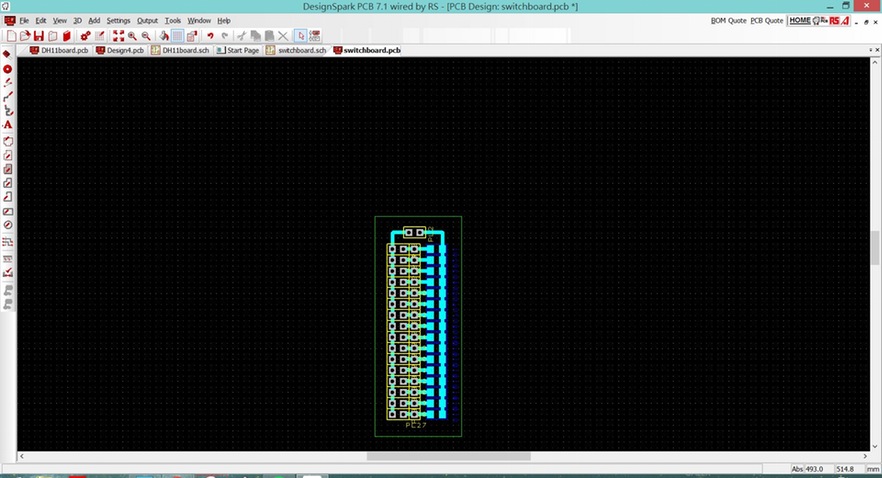

Circuit board

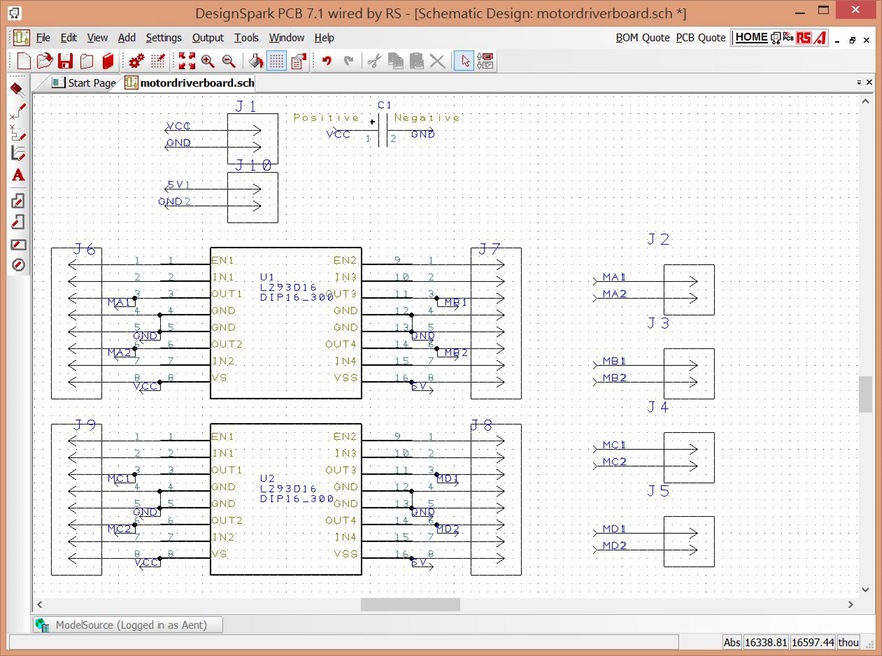

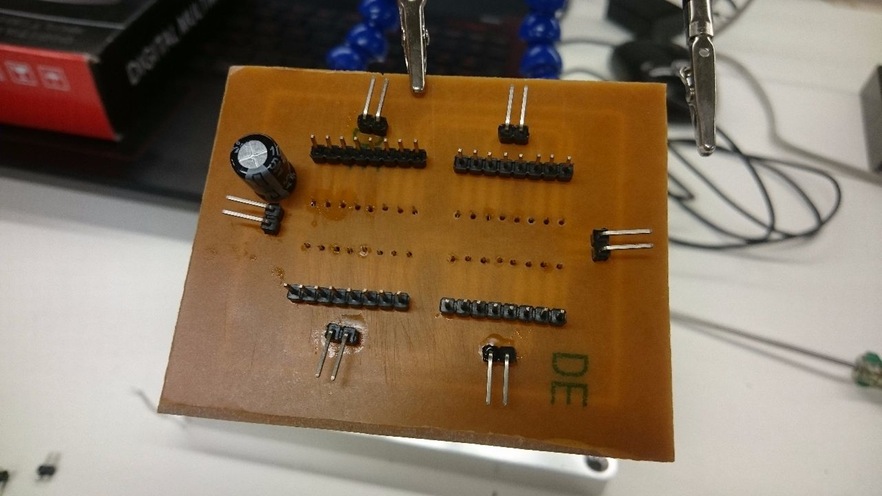

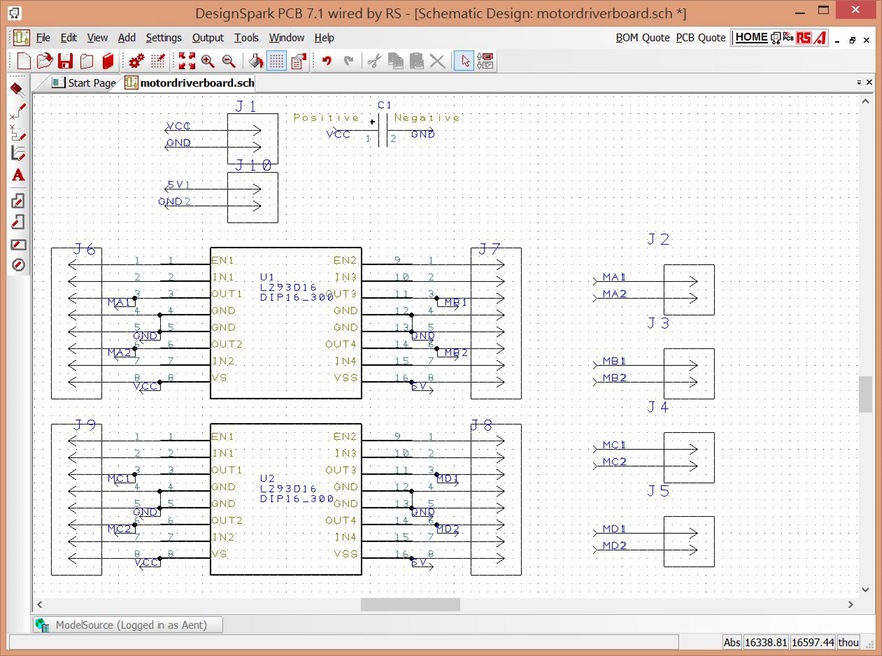

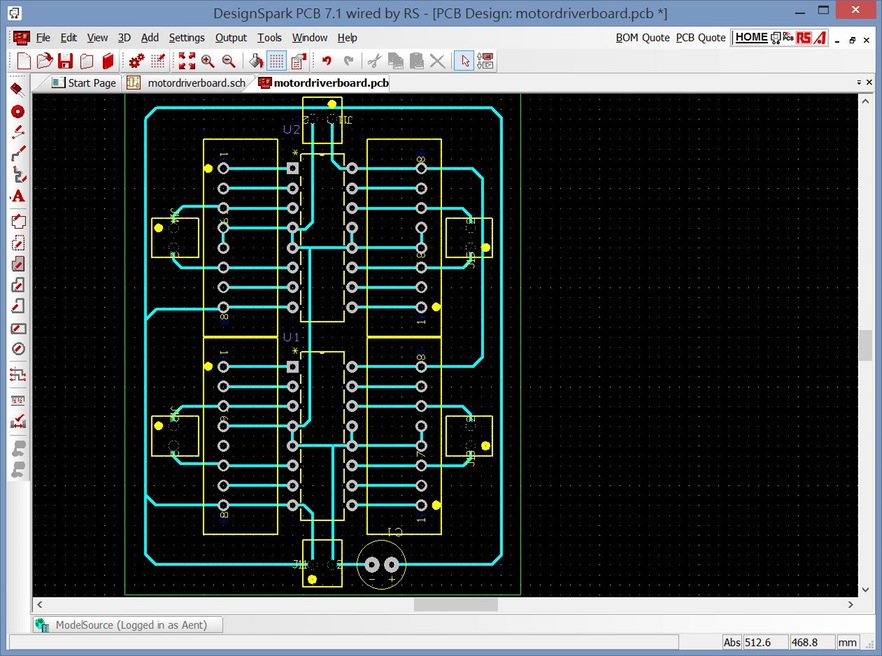

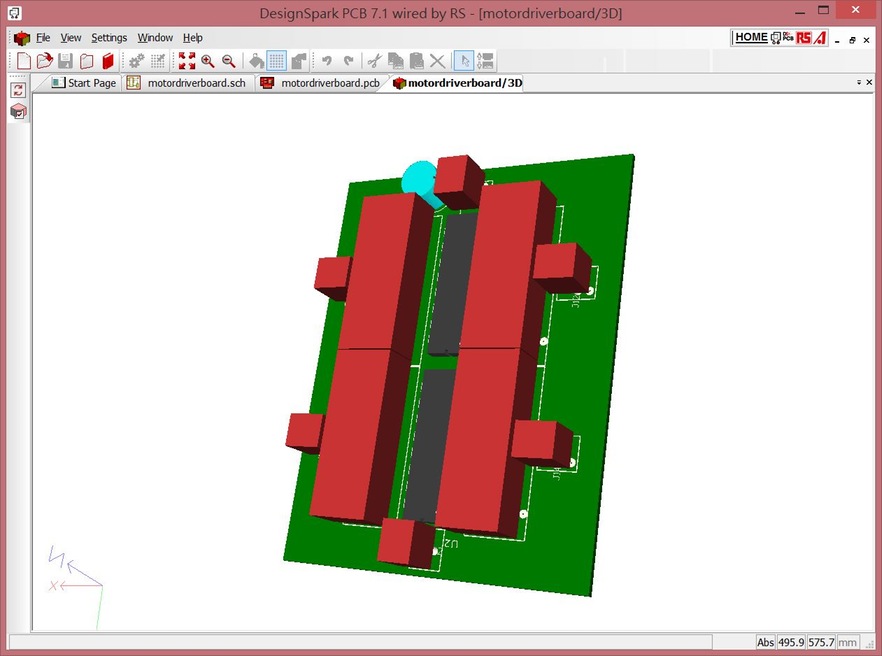

When the front row on the first step of planning all the good I / O, contains four sets of wet sensor, light sensor, temperature sensor, 8 inversion switch, reversing the motor output, Bluetooth communications, etc., used by more than pin a satshakit the I / O count. Therefore, the use of two satshakit, which then as a clearing-house through the I2C (week15) communications. Also purchased can not make their own modules, such as Bluetooth modules, temperature sensors and the like. First find several board design, and then carved on the same board. (refer week6, week8, week10, week11, week13, week15, week16)

The figure is the main control panel, features include: two satshakit, power supply board, I2C communications expansion board, DH22 temperature sensor circuit board.

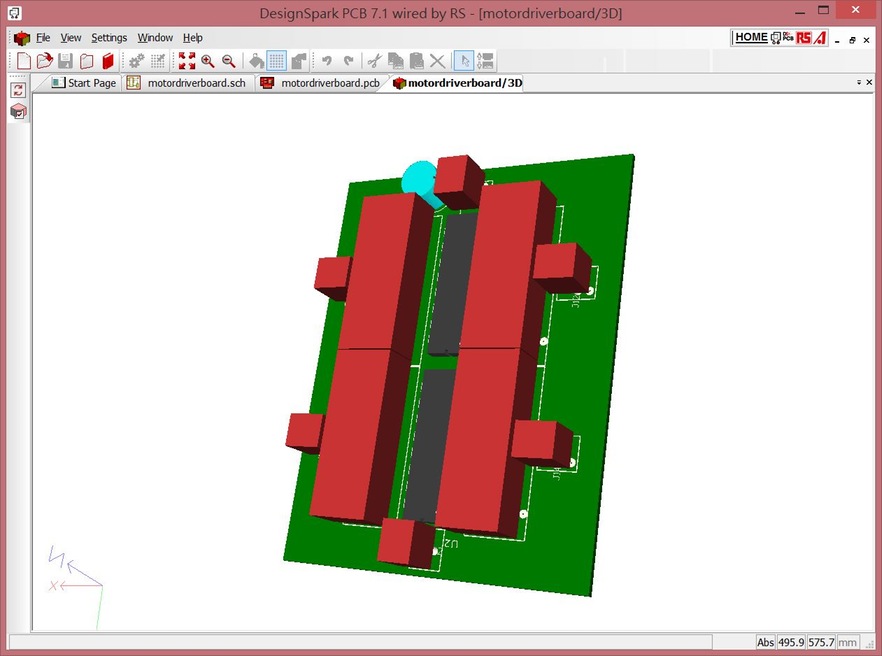

Circuit design also uses Designspark PCB. A few weeks before the reference designed board engraving, welding produced.

前步驟規劃時就先列好所有I/O,包含四組濕感應器、光度感應器、溫度感應器、8個倒位開關、馬達正反轉輸出、藍芽通訊等等,所用接腳大於一個satshakit的I/O數量。因此使用兩組satshakit,其中再透過I2C(week15)通訊做為資料交換。另外購入無法自己做出的模組,例如藍芽模組、溫度感應器等。先將數種求的電路板設計出,並雕刻再同一個板子上。用Design Spark PCB。參考前幾周將設計得電路板雕刻、焊接製作出來。(refer week6, week8, week10, week11, week13, week15, week16)

下圖是主要的控制板,功能包含:2片satshakit、電源板、I2C通訊擴充板、DH22溫度感應器電路板。

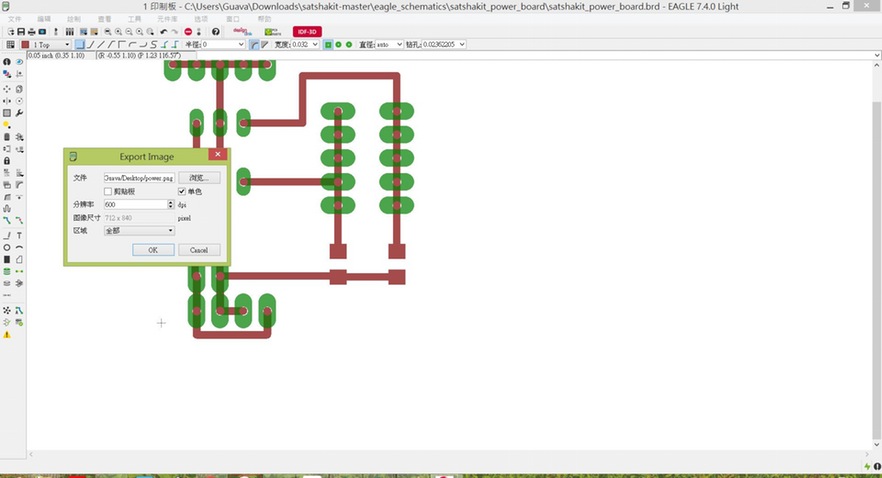

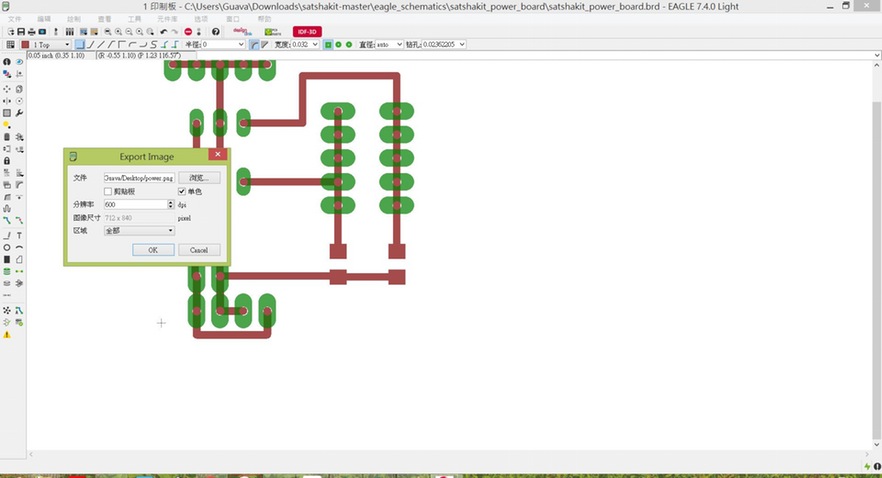

Satshakit & power board

Satshakit, and the power supply board reference Github. I would use the 12V power supply, common external MCU should also supply power to the motor drive, the power input terminals I think too little, and therefore egial editing, more than two other uses external to the motor driver board or do.

satshakit、與電源板參考Github。我會使用12V電源供應器,共應MCU外也供應電源給馬達驅動器,所電源輸入端子我認為太少,因此以egial進行編輯,多了兩組可外接至馬達驅動板或做其他用途。

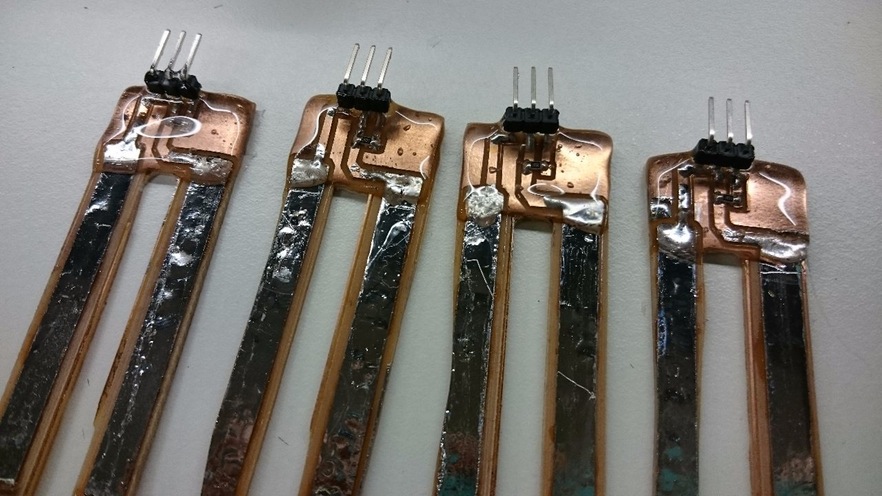

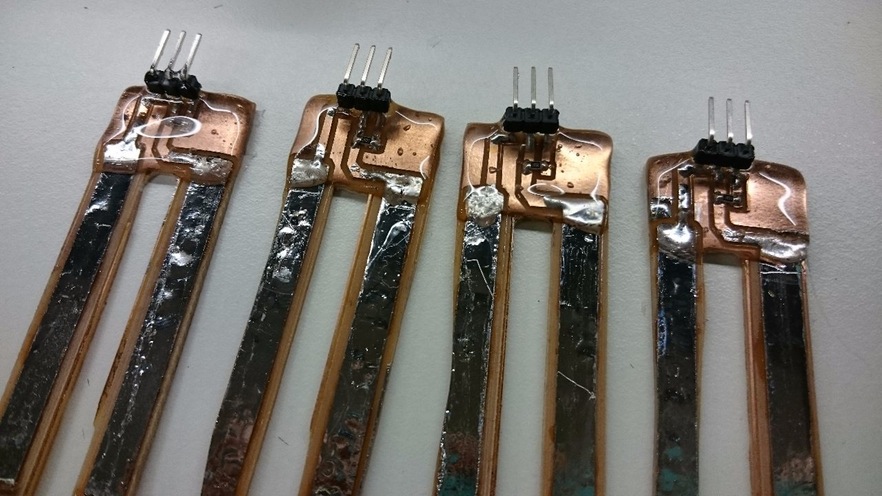

Humidity Sensor

Week 15 produced by the humidity sensors do more four groups. And the surface of tin-plated copper avoid oxidation.

Week 15所製作的濕度感應器再多做四組。且表面鍍上錫避免銅氧化。

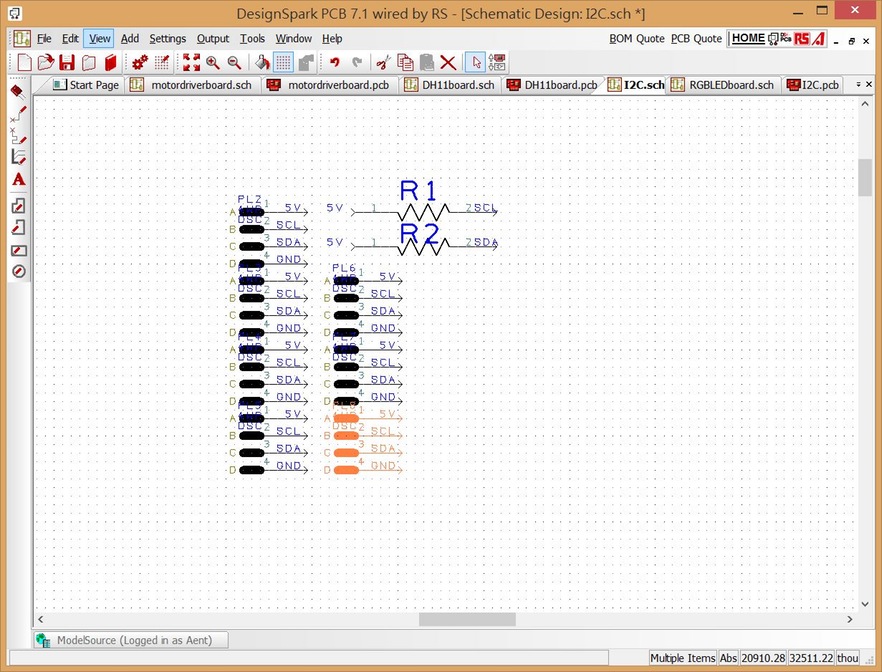

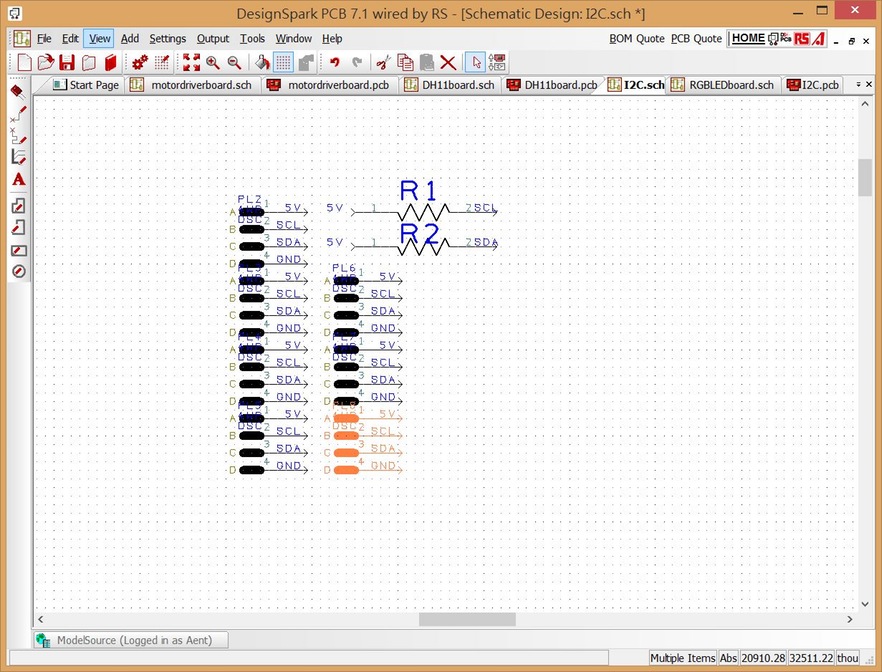

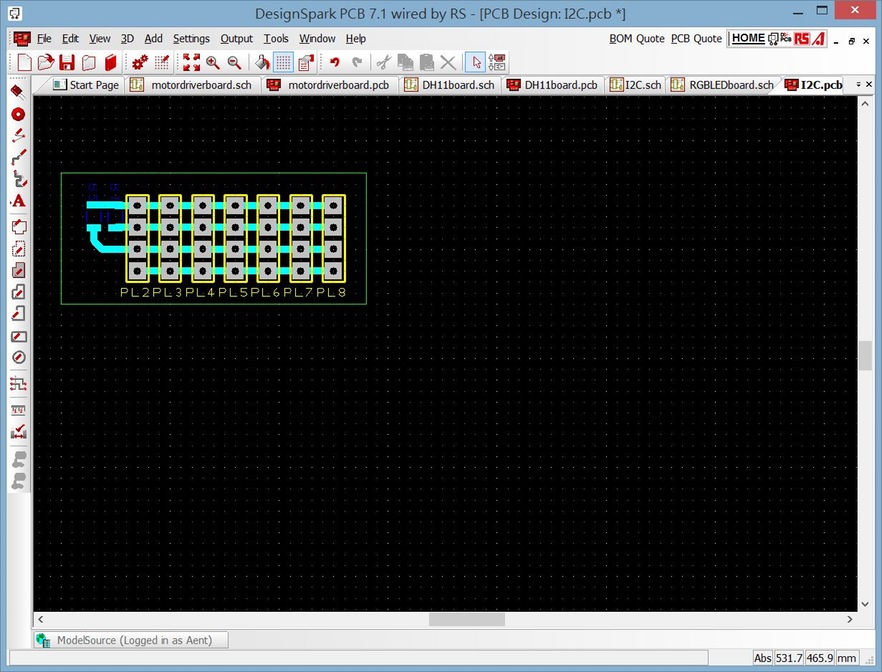

I2C communication

The SDA and SCL mush be high voltage. Using 4.7K ohm resistors connected to VCC.

串列資料(SDA)及串列時脈(SCL)必須保持高電位。加入兩個4.7K電阻。

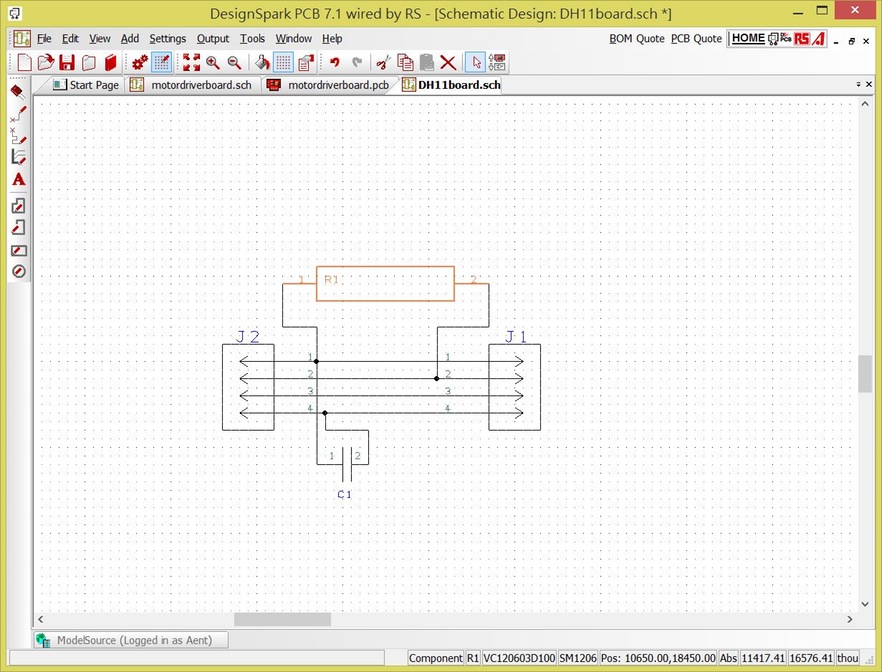

DH22 number of j-bit output temperature and humidity sensors. Signal output must be kept high potential, plus 4.7K resistor. Plus the power supply decoupling capacitor.

DH22 為數位輸出的j溫度與濕度感應器。訊號輸出須保持高電位,加上4.7K電阻。電源處加上去耦電容(decoupling capacitance)。

Voltage divider board

This block does not fit with a circuit board, and so additional production. Can be used to use the law of partial pressure sensor signal read or VCC, GND expanded use.

此塊放不下同一個電路板,依此另外製作。可用於使用分壓定律的感測器訊號讀取或VCC、GND擴充用。

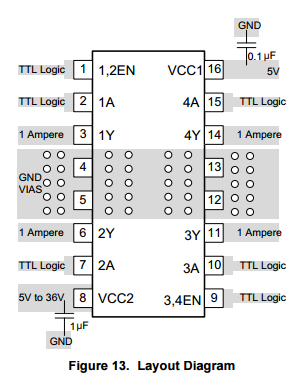

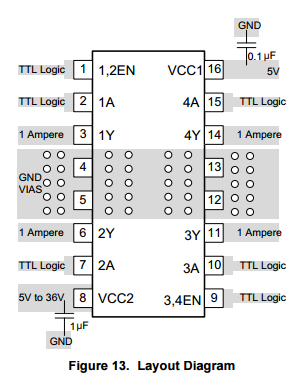

Motor drive

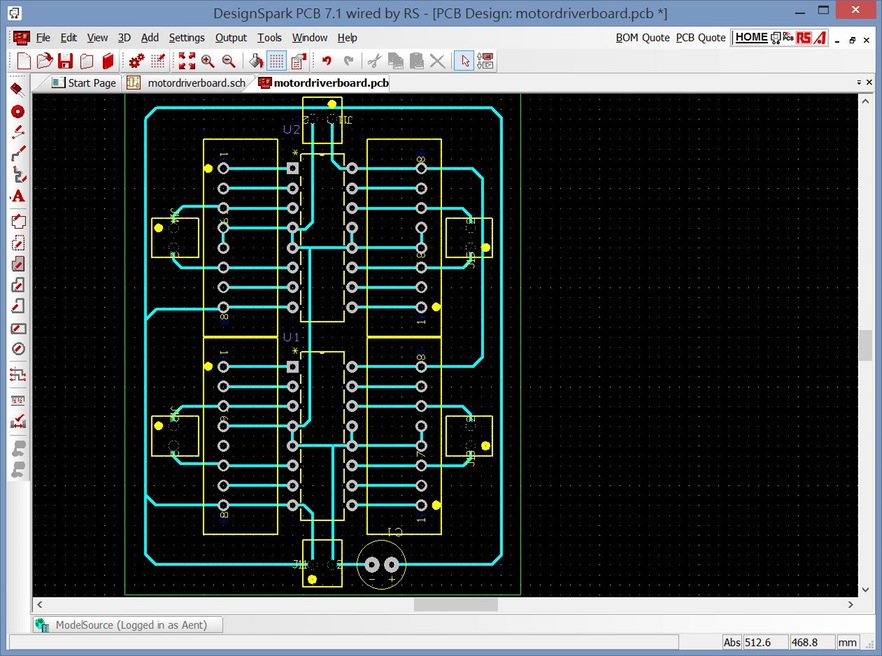

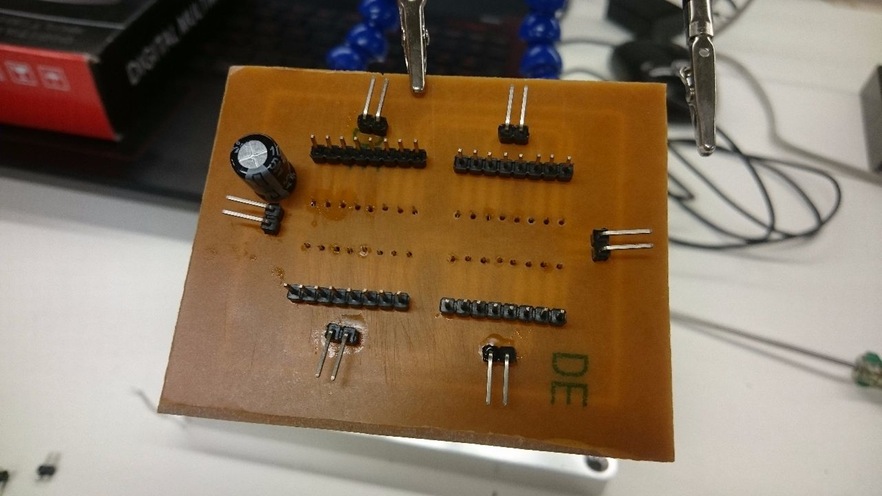

Slide DC motor, requires reversing function. The easiest way is to make use of the H-bridge circuit connected to the corresponding transistor can control the motor as forward / reverse. I am here using 'integrated IC L293D. To carry out reversing the drive motor. Received by the datasheet the pin functions and drawing board.

滑軌使用直流馬達,需要有正反轉功能。最簡易的方式使是使用H橋(H bridge) 電路連接相應的電晶體就可以控制馬達進行正/逆轉。我這邊使用的ˋ整合的IC L293D。來驅動馬達進行正反轉。由datasheet"接接腳功能及繪畫電路板。

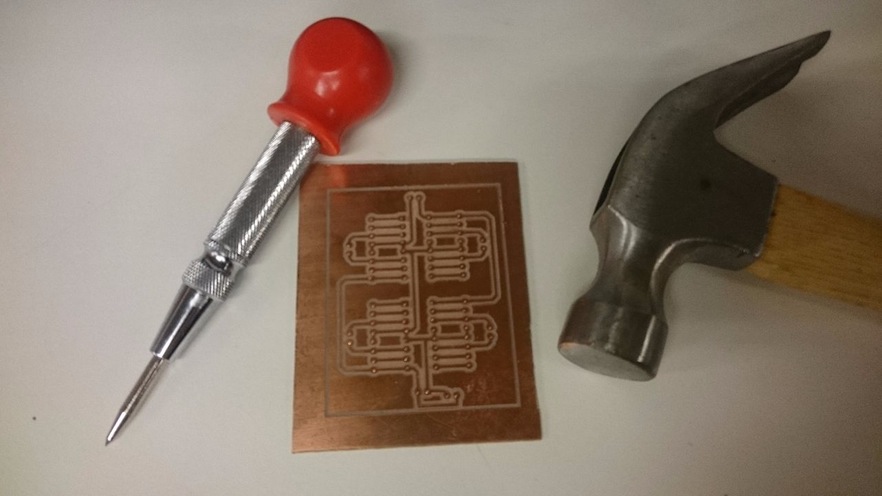

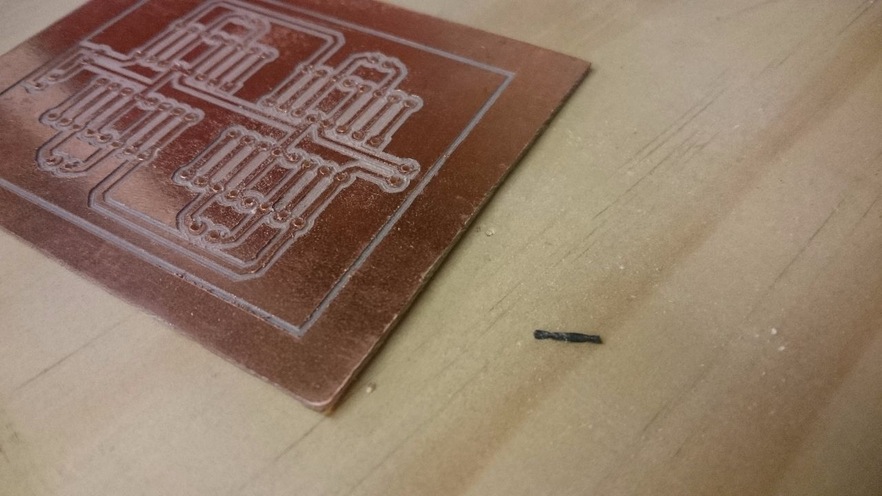

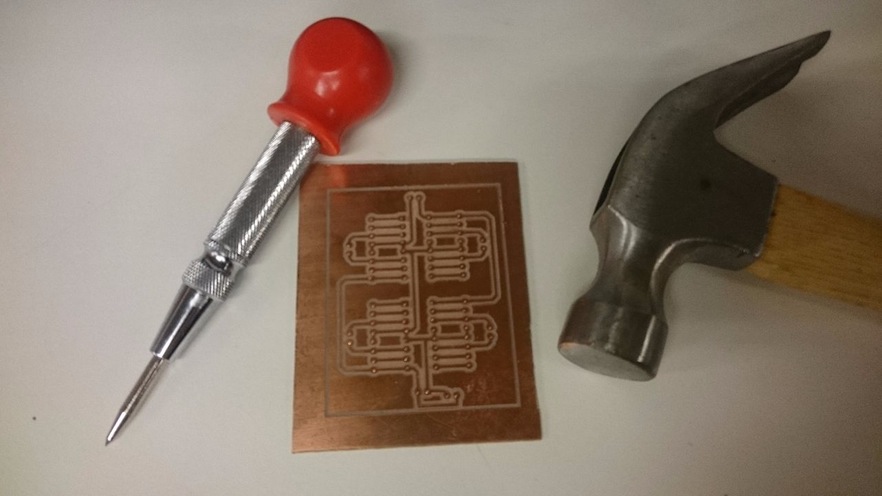

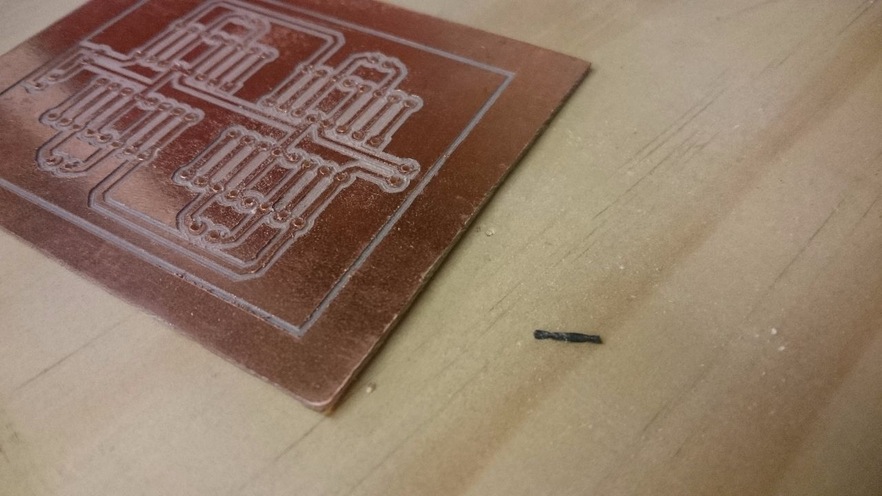

In accordance with the first few weeks after the engraving step to do, using the positioning cone to knock a small hole drilled convenient recess. Only hand-held electric hand drill, drill only 1mm. In the process of drilling holes to avoid shake and tilt, otherwise the circuit board or drill easily damaged.

依照前幾周步驟做雕刻後,使用定位錐先敲一小凹槽方便鑽洞。手邊只有手持電動鑽,鑽頭只有1mm。在鑽洞過程要注意避免晃動及傾斜,否則電路板或鑽頭易損壞。

I broke during a drill

過程中我弄斷了一隻鑽頭

Troubleshooting:

Slider because the seat and housing are separate parts, so when you install the rails on both sides have been unable to successfully parallel locked wooden frames. Once is not parallel to the front and rear sliders will not move smoothly. Repeatedly adjust until running smoothly. It take me a lot of time.

滑桿座及軸承座因為都是分開的零件,因此在安裝時滑軌兩側一直無法順利地平行鎖上木框架。一旦不是平行,滑塊將無法順暢前後移動。反覆調整直到運轉順利。

Purchase of pump is too strong, they are not required to let the water diversion in the upper end of splashing.

Purchase of pump is too strong, they are not required to let the water diversion in the upper end of splashing.

購買的幫浦太過強大,需要分流才不至於讓水在上端噴濺。

The IC of the circuit board of Motor used by IC DIP package was in the right direction. However, I also used the function of mirrored side. Let L293D IC in other side.

馬達驅動電路板使用IC是DIP封裝,已經是正確方向但我又使用了鏡射,造成與其他元件不同邊。

Tools:

Woodworking engraving machine

3D printer

Roland SRM-20

Soldering toolkit

ArkCAM

Fab Mouules

File:

DH11board.pcb

DH11board.sch

I2C.pcb

I2C.sch

motordriverboard.pcb

motordriverboard.sch

switchboard.pcb

switchboard.sch

Pulley_big.stl

Pulley_small.stl

Slider_block.stlo

Reference:

WIKI:I²C

Master Reader/Slave Sender

Wire Library

多台 Arduino 間的通訊 - 透過 I2C #1