Week 5

Test the design rules for your printer(s) (group project)

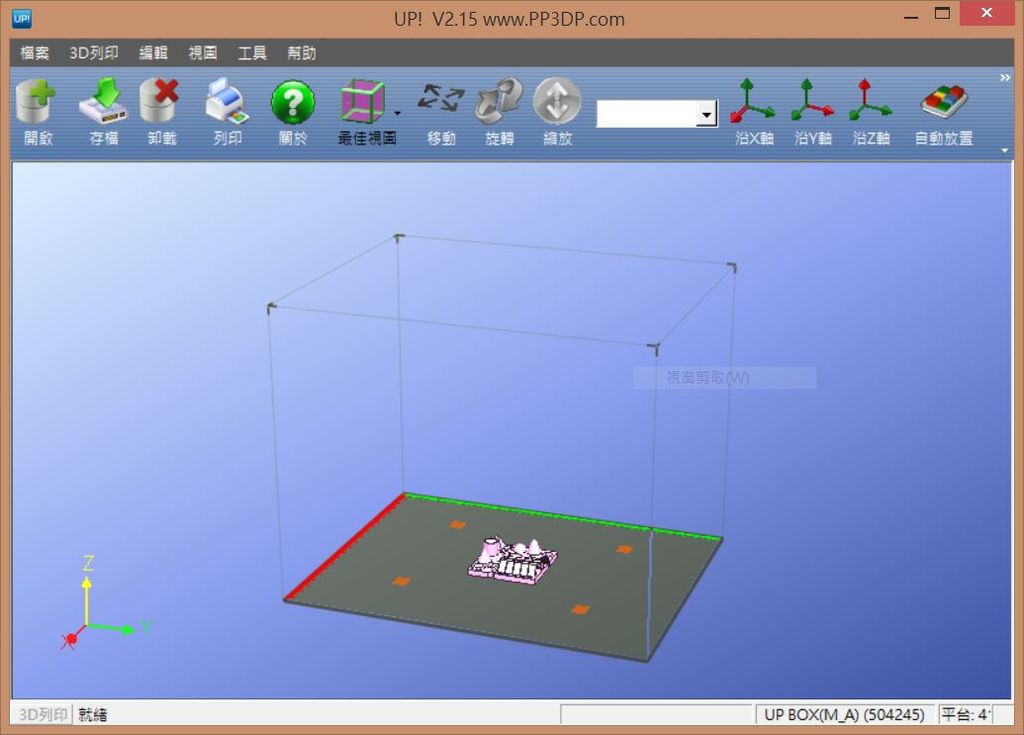

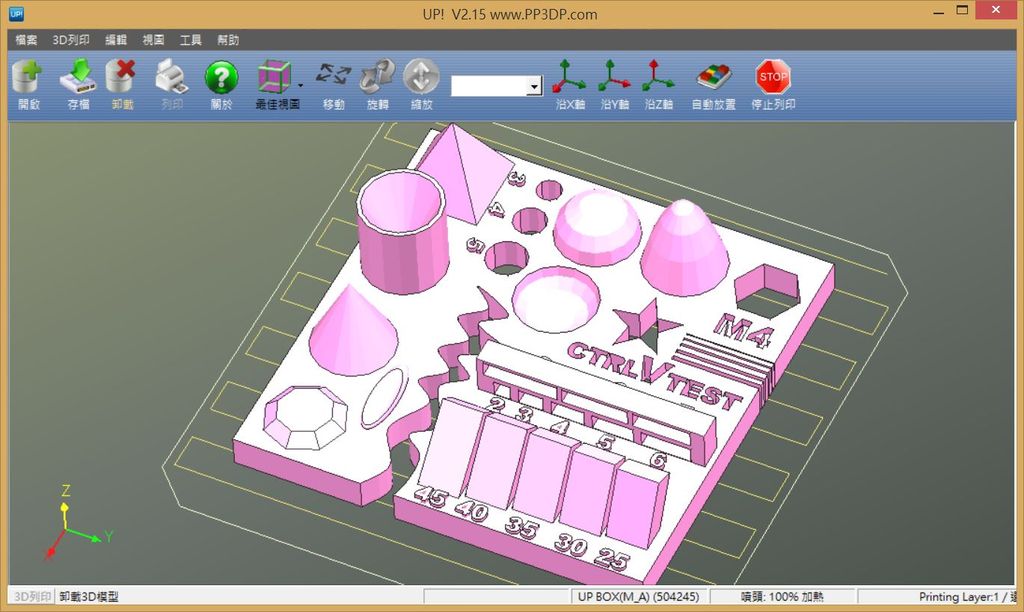

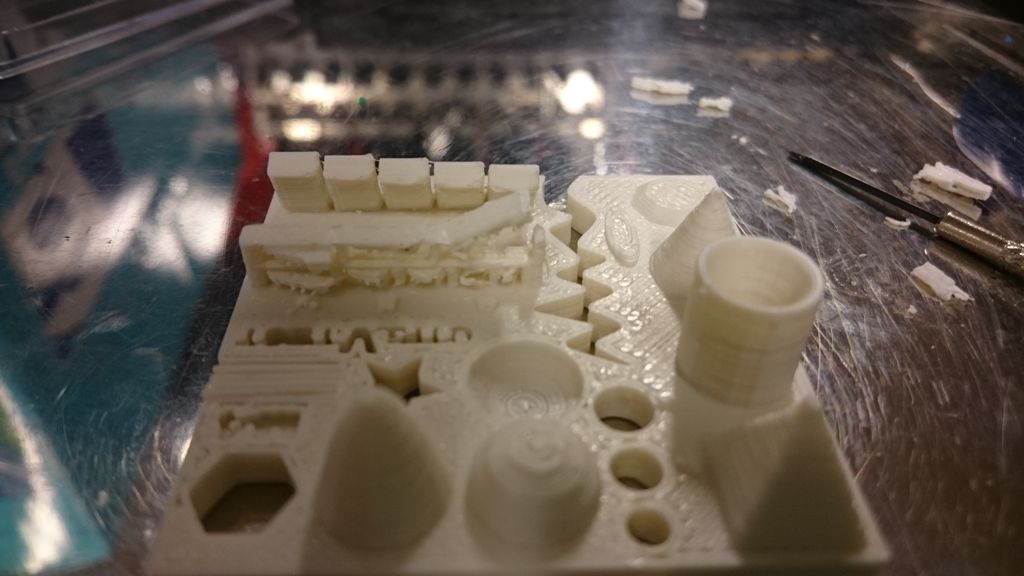

For the part of test 3D printer , I choose " Test your 3D printer! " from Thingiverse. And the fused-deposition molding machine is UP BOX . It's easy to ues, and has simple interface. Install software and set hardware.

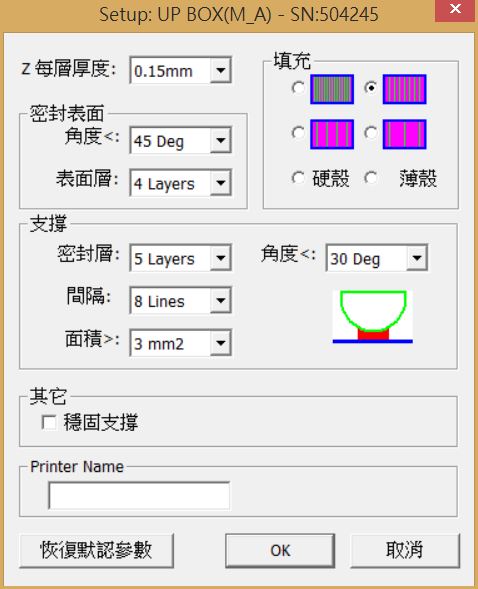

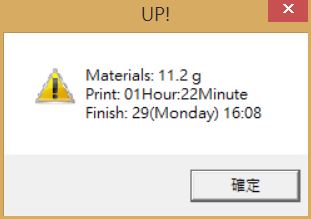

Set thickness, fill, and printing speed. Automatic calculate of print time, materials amount.

Material is ABS. Supports automatic calculation by software. Substantially print out shape,but detail is not successful presentation.(E.g word, blank lines) Screw nut could put in hole, but I break a part of model when move out the

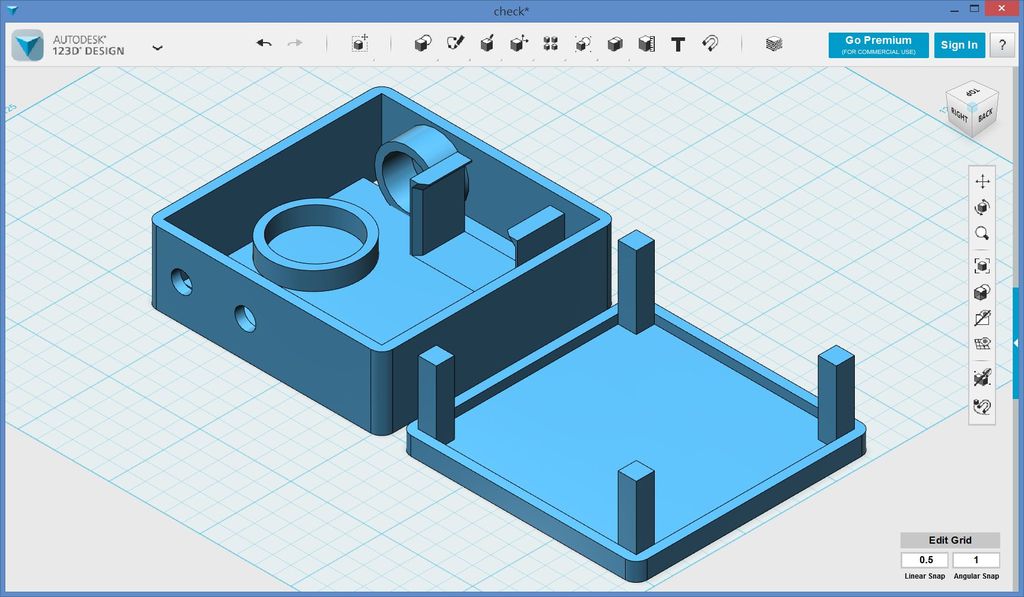

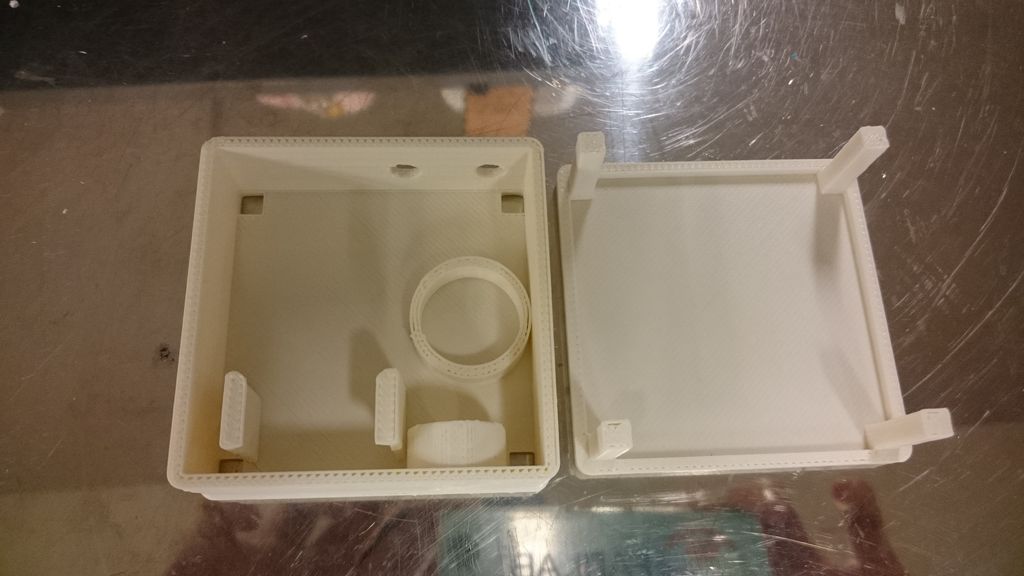

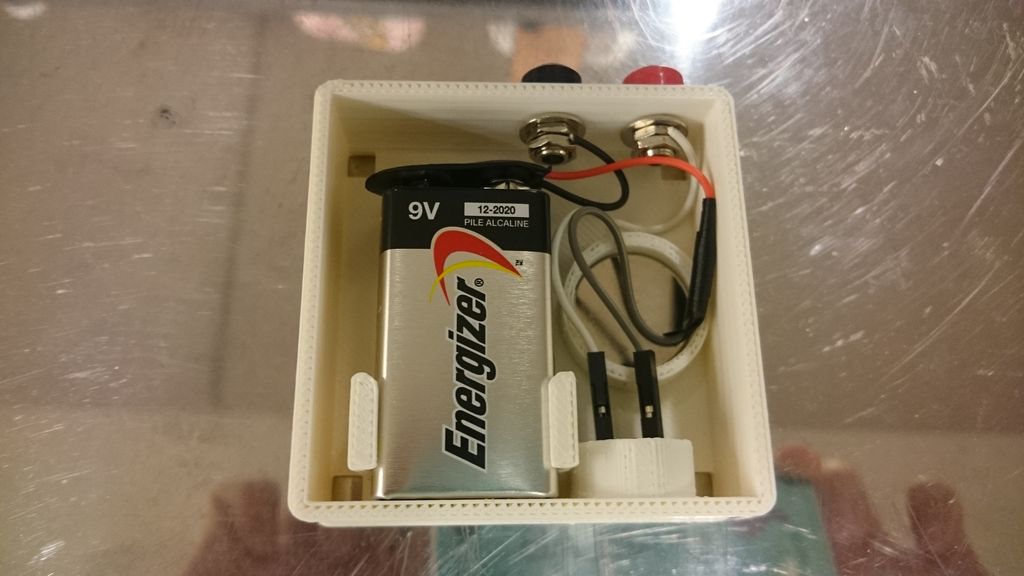

Design and 3D print an object (small, few cm) that could not be made subtractively

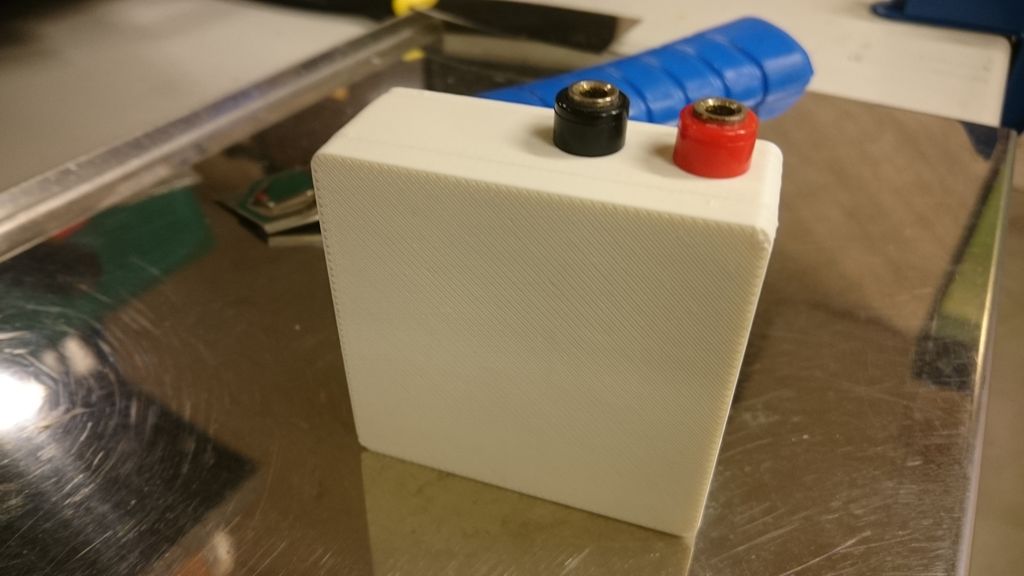

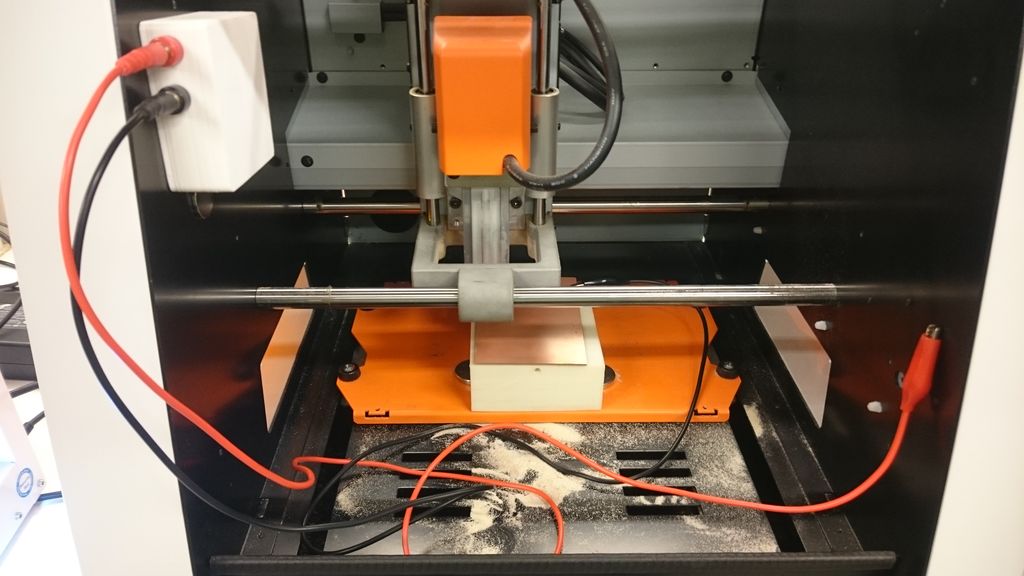

I use 123D designto draw a case which has reserved hole to put battery and buzzer. A part of structure reference form "9V Battery clip" This tool can hlep me to set CNC start point, when I cut circuit.

Opps,something worng. I cut the pin by hand.

3D scan an object (and optionally print it)

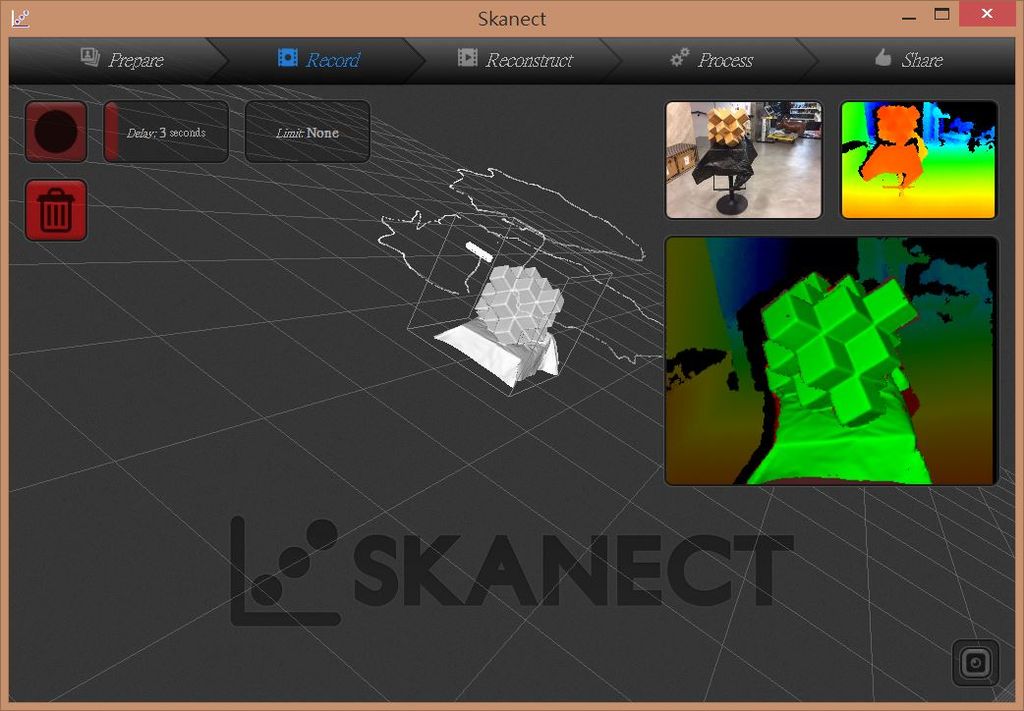

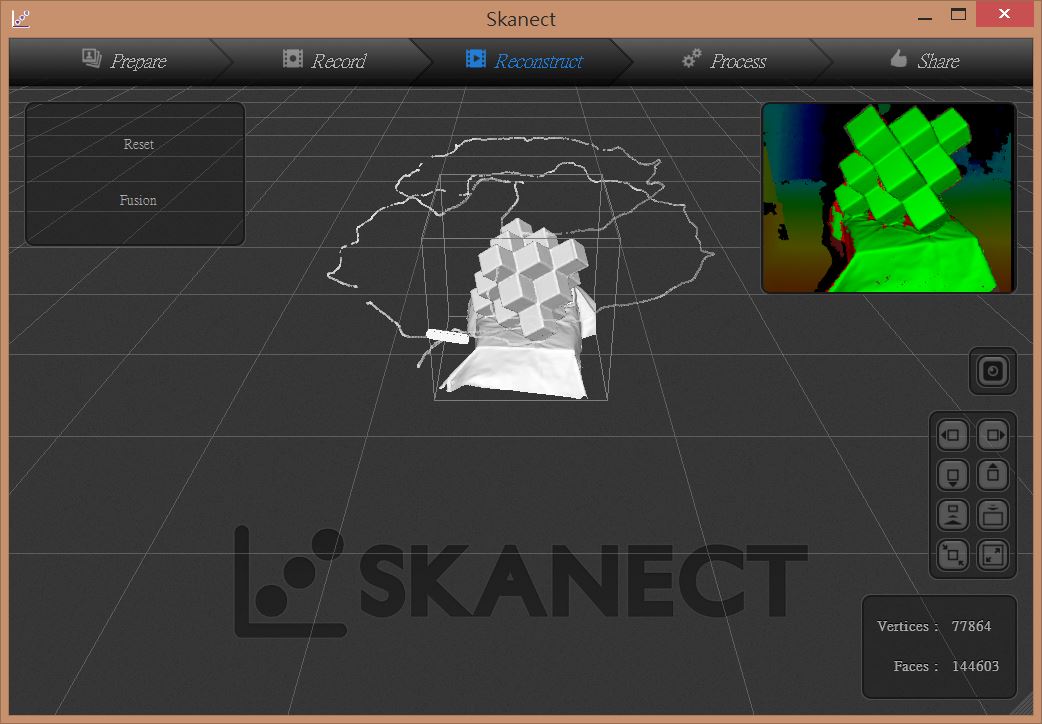

I use the IPAD and Structure Sensor suite of 3D scanning. The scanner with a small depth sensors, infrared, infrared lights and battery. With a dedicated program can quickly scan portraits, objects and space. I scanned the object is a large burr puzzle, Chair it and placed on a black garbage bag, so that the bottom background clean, easy to scan.

我使用IPAD與Structure Sensor套件之進行3D掃描。其掃描器具有小型的深度感應器、紅外線、紅外線補光燈和電池。配合專用的程式就能快速的掃描人像、物件及空間。我所掃描的物件是一個大型的魯班鎖,放置椅上並墊上黑色垃圾袋,使底部背景乾淨,有易於掃描。

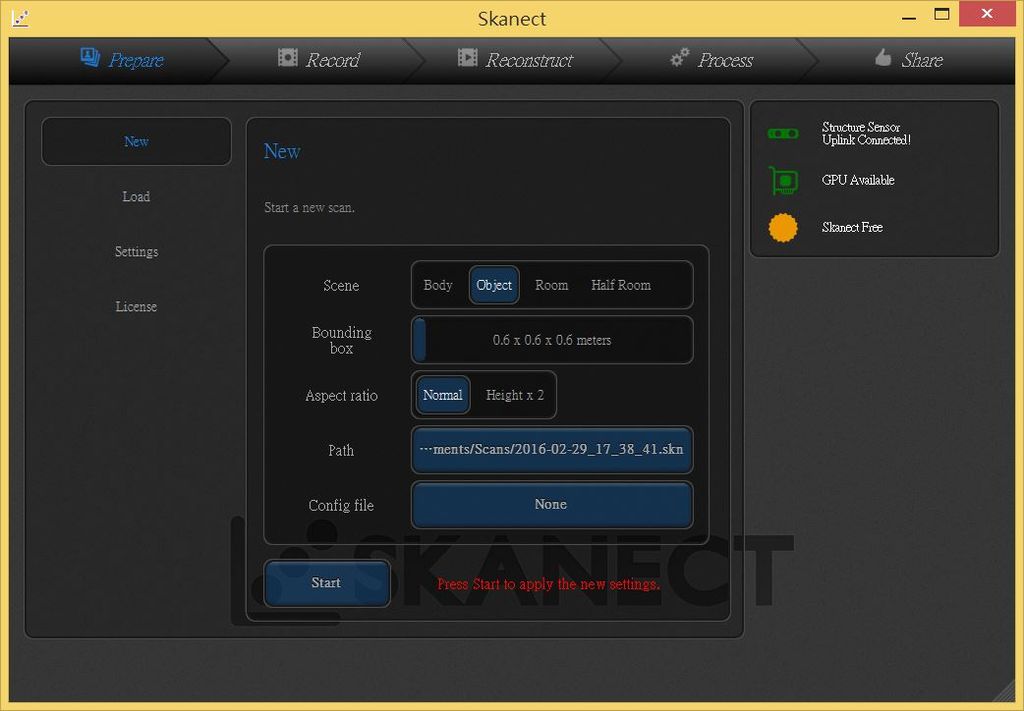

Setting Skanect software and iPad apps in computer. The apparatus and the computer at the same WIFI domain. Select the type of scan, the aspect ratio (Aspect ratio), and configuration storage path.

設定電腦上Skanect軟體、IPAD的APP,使裝置與電腦於同一WIFI網域下。選擇掃描類型、寬高比(Aspect ratio)、儲存路徑及配置。

Items rotate around the shooting and try to slow down the action of the foot, until all faces are identified. Scanning operation moved too much and fast will cause an exception or 3D drawing has a broken surface when the device does not recognize.

圍繞物品旋轉拍攝,並盡量放慢動作與腳部,直到所有面被辨識出。掃描動作太快太大設備無法辨識時會造成異常(Error),或是3D圖檔有破面。

Final, select the image format to output and adjust the details.

選擇輸出圖檔格式及細部調整進行輸出

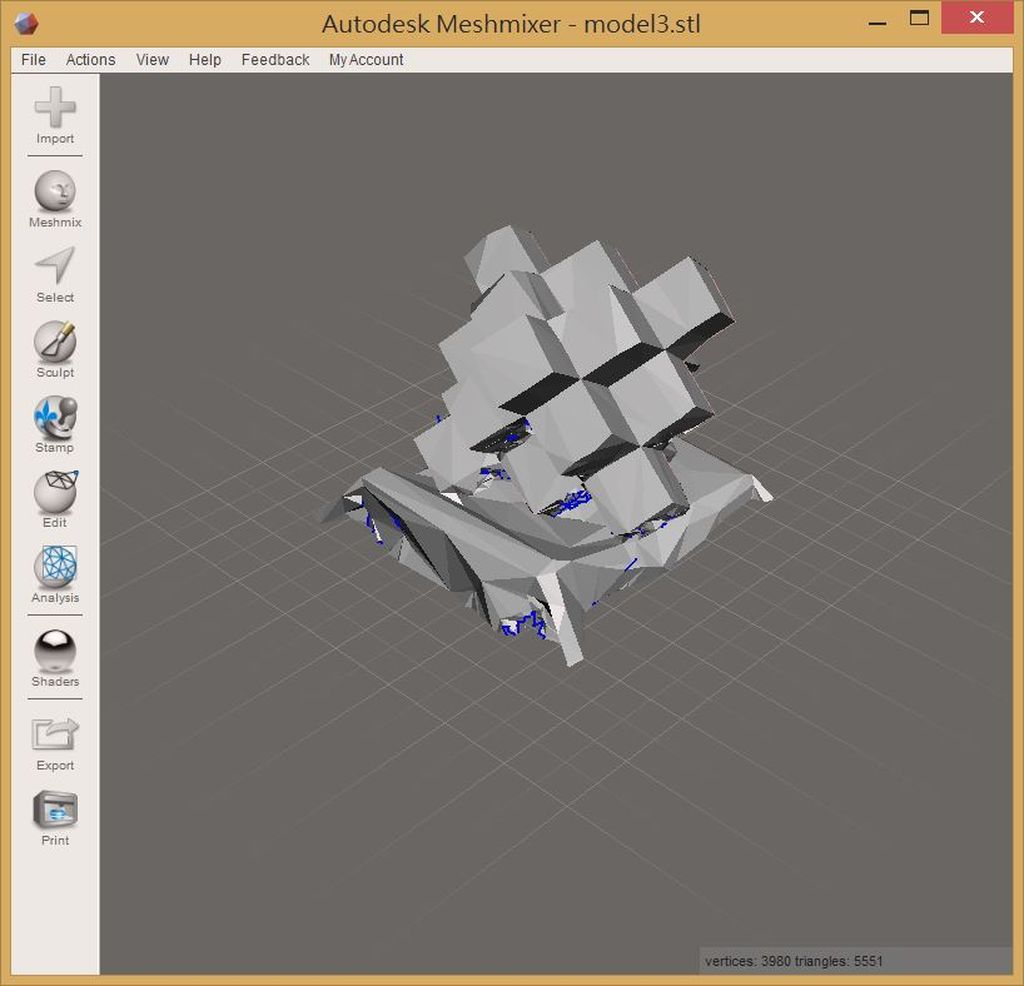

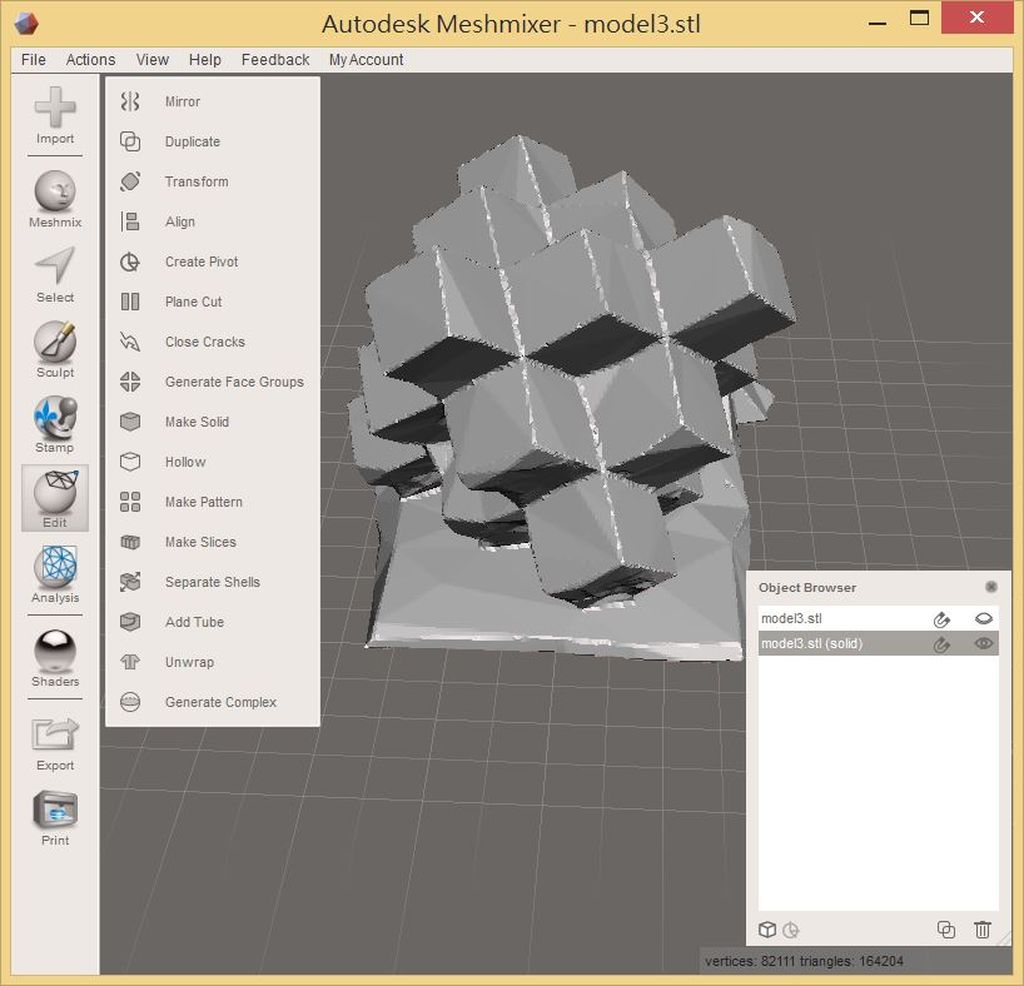

Upload the file to Meshmixer, modify, repair and crop.

將檔案放入Meshmixer進行修繕、修復、裁切。

There's little data on the original scan, using the editing functions to modify to become the solid modeling.

描圖只具有表面資料,以編輯功能進行修改成實體模型。

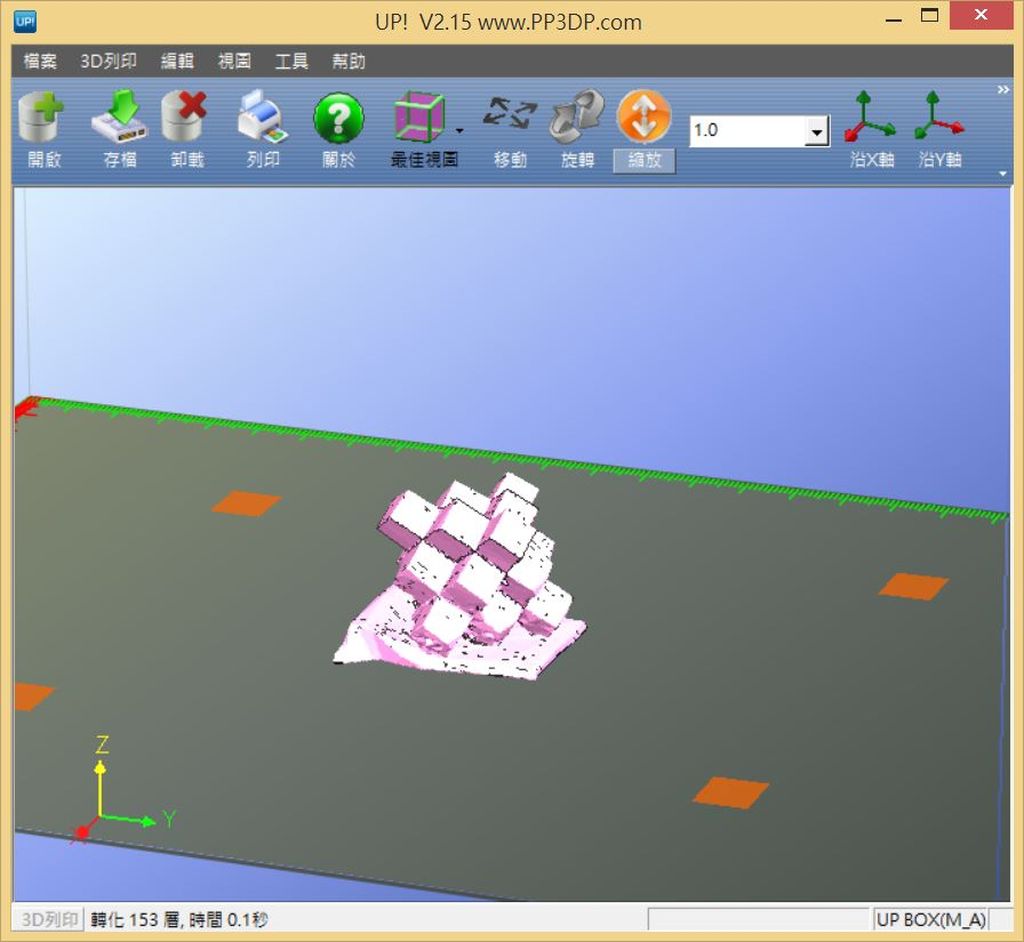

Upload the file to UP! The software starts to print.

將檔案放入UP!軟體行列印。

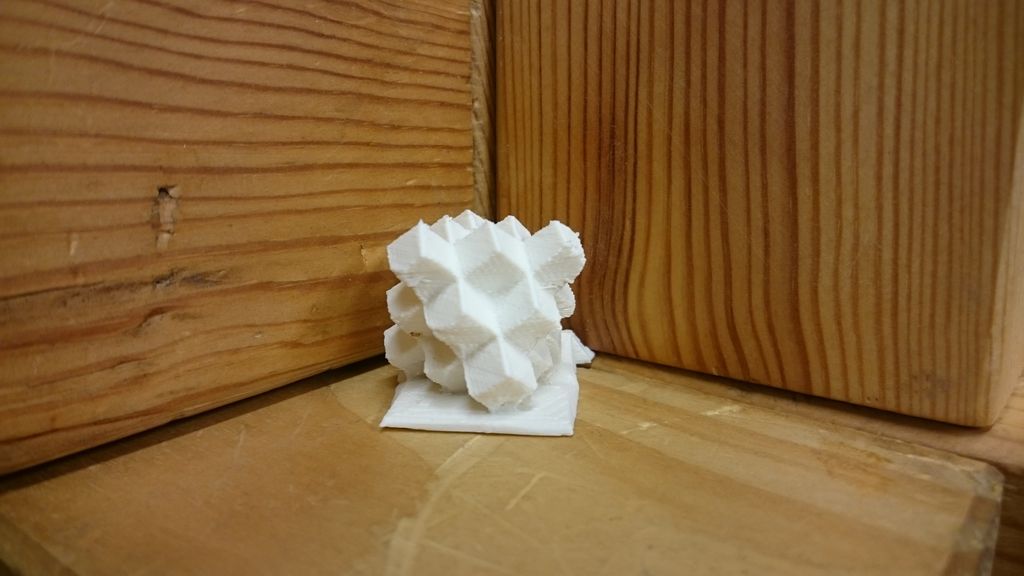

Image: 3D Printing Work

實際列印成品圖像

Troubleshooting:

3D printing machine to print the test product has a very small structure, when it is easy to disassemble the support material into ruin.

測試3D列印機之列印品具有很小的結構,很容易於拆卸支撐成材料時弄壞。

CNC feeler box design has a latch pin because other things can not be stuffed. Unable to cover obedient to cover up. After the sawed-pin box cover is available.

CNC對刀盒設計上有一隻卡榫因接腳其他物件而無法塞入。上蓋無法服貼蓋起來。鋸短接腳後盒子才可蓋上。

3D scanning has many broken unrecognizable face, but can not print. In Meshmixer edit until repair can be applied to 3D printing.

3D掃描具有很多無法辨識的破面,而無法列印。以Meshmixer 編輯修復直至可運用於3D列印。

Tools:

123D Design

UP! V2.15

Skanect

Meshmixer

UP BOX

Ipad

Structure Sensor

File:

Feeler case

Burr puzzle(Size more than 44MB, so use Sketchfab to share.)