Exercise 17 Applications and Implications...

In this week assignment, neil requires the following questions to be answered in the form of documentation on individual fab academy page.

propose a final project that integrates the range of units covered:

what will it do?

who's done what beforehand?

what materials and components will be required?

where will they come from?

how much will it cost?

what parts and systems will be made?

what processes will be used?

what tasks need to be completed?

what questions need to be answered?

what is the schedule?

how will it be evaluated?

Intro

My final project will be an apparatus designed and digitally fabricated along the theme of IoT enabled device. At the week on the concept & idea , I have come out with somewhat of an end goal for my final project, and shall not deviate too much of it. The end goal is to able to control the heating of an appliance over the Internet. There is a caveat. It is not human that controls the heating over the Internet, rather, a computer (virtual machine) resides in the Internet that computes the collected temperature data and then decides the heating by sending a command to control the state of the heater. My apparatus at the first iteration will be having the input & output devices, and communication all rolled into a single apparatus.

I am also exploring on decoupling the sensing part and the controlling part of the apparatus into two separate devices, probably at the second iteration. Hence the apparatus after the second iteration will focus on a singular and simple task: for example, apparatus-A reading temperature data from the probe and relay it to a computer on the network, and apparatus-B receiving control from a computer on the network for controlling an actuator. Thus, the idea of deploying many input devices as needed to act as the sentry, connected to the cloud, and actuators reacting to the data collected will be an interesting feature to be explored.

The bulk of the computation will be done on the server, preferably a virtual machine on the cloud. One of the issue i am facing, is relaxing on the issue related with "real time" for this contraption. The questions come begging: does it matter if the control data arrive 2 seconds later than intended? what should the apparatus continue to do in the absence of control/sensor data?

What will it do

In iteration-1, the apparatus will acquire the temperature from the temperature probe DS18B20, send the temperature data to the server (a virtual machine on the network) and also an internet data visualization platform such as thingspeak.com via the wireless network that connects the microcontroller board to the Internet. The server will then process the temperature data, and compute the necessary action and send the action in a code command via the Internet to the microcontroller board that controls the Solid State Relay that is connected to the heater. Therefore, the control of heating up/down is done over the network without human intervention (besides setting the setpoint for the desired temperature).

In the next iteration, explore decoupling of functions of the microcontroller board. the apparatus-A will read temperature, and send the temperature data over the wireless network to the server. Server will then instruct apparatus-B over the wireless network to control the connected actuator e.g controlling an AC outlet.

Who done what before

Immersion circulator by the mathematical chef.

Joule the sous vide device by chefsteps.

the above are just regular sous vide cooker, but with extra features such as using an APP on a smart phone to control it. But none of this 2 vendors have a feature to control over the Internet.

There are manufacturers that have done controling of thermostat over the Internet, effectively controling heating up/down over the network. But these appliances and applications require a human agent, a smart phone app to interact with the hardware. Example of manufacturer is at this URL: http://www.pcadvisor.co.uk/test-centre/digital-home/best-smart-thermostats-2016-3583499/ The major difference

Parts and sub-systems made, processes used

In due course of fab academy, I have explored the various methodologies and experimented with the ideas implemented with ESP8266 ESP12-E. check out the following documentations on my fab academy page for the details. The enclosure will either be 3D printed, or laser cut, depending on the availability of the machines and the time constant

electronics fabrications

Electronics Design

embedded programming

input devices

output devices

Networking and communications

Interface and Application Programming

parts: required, cost, origin, and system

| quantity-- | part name---------------------------- | part price-------- | parts origin-------- | purchase source-------- |

| 2 | ESP8266 ESP12E | USD1.78 | china | aliexpress.com |

| 2 | ZLDO1117G33DICT-ND | USD0.34 | malaysia | element14.com |

| 2 | microcontroller boards | made | Singapore | FabLab@SP |

| 1 | 13A faceplate | salvaged | 1 | 13A plug | salvaged | 1 | cartridge heater | salvaged | 1 | DS18B20 | USD1.09 | china | aliexpress.com | 1 | CPC1966B | USD5.20 | USA | http://sg.rs-online.com/ | 1 | sensing circuitry | made | FabLab@SP | 1 | control circuitry | made | FabLab@SP | 1 | power source and adapter | made | FabLab@SP | 1 | sensing circuit | made | FabLab@SP |

The very optimistic estimated cost for iteration-1 prototype is USD8.41 per unit

Task to be completed

Fabrication of microcontroller boards for input and output devices

Network connectivity for the boards to the server via wireless network

Digital fabrication of housing with 3D printing or laser cutting.

Fabrication of the actuator e.g cartridge heater

Testing of the fabricated apparatuses

Documentations

Questions to be answered

how will the boards communicates with the server?

what network protocol should the apparatus used to communicate with server?

end-to-end delay? time from the sensor data acquired, transmitted, and then acquired by the server?

does nonexistence of real time feature a boon or bane?

data received by server should be idempotent?

how to ensure control data is executed exactly once?

Proposed schedule

01June16: finalise design, sourcing of parts.

8June16: Fabrication, testing, and documenting as progress

15June16: Fabrication, testing, and documenting as progress

22June16: present to fab academy

Evaluation methodology

Temperature data submitted successfully from microcontroller board to server, to be observed from Internet visualization platform www.thingspeak.com

Control data sent successfully from server to microcontroller board, to be observed from the debugging output via serial monitor on the local computer.

Heater catridge behaves accordingly to the control command send from the server residing in the network.

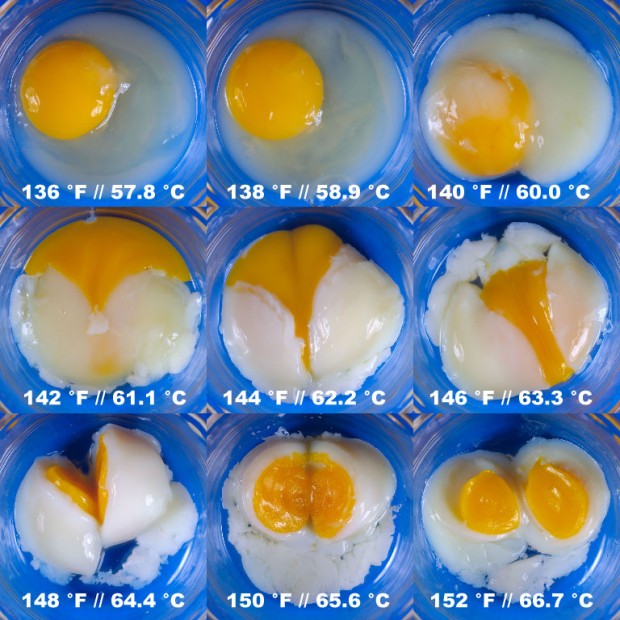

To cook an egg at 65degC for 45min with this apparatus and eat it. The proof is in the egg and eating it.

The perfect soft boiled egg

I have quite an OCD when it comes to cooking egg. The following picture from this blog http://blog.khymos.org/2009/04/09/towards-the-perfect-soft-boiled-egg/ explains egg cooking in detail.