|| what will it do?

It’s a RTC controlled lightbox that will auto light in night.

|| who's done what beforehand?

There are a lot of similar examples.

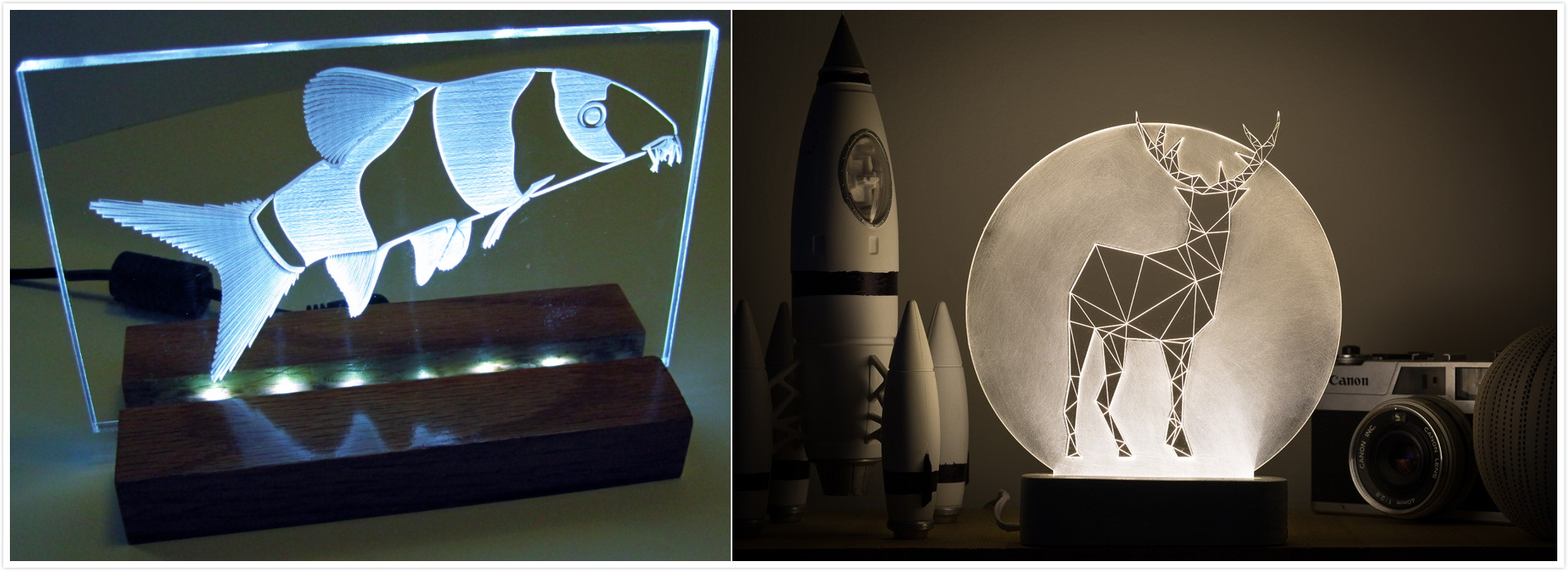

Acrylic lamps:

patterns laser engraved on the acrylic can generate amazing effect when lights go in the acrylic from sides.

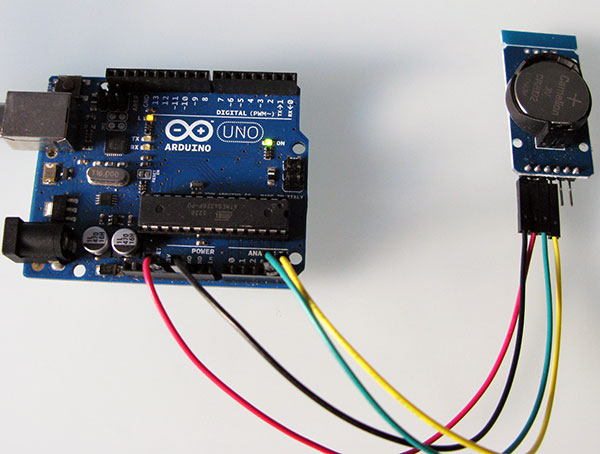

There are a lot of examples about RTC also.

|| what materials and components will be required?

1. fluorescent acrylic

2. LED strips

3. components for the control board

4. relay

5. RTC module

6. ISP

7. TTL tool

8. 3D printed project box

|| where will they come from?

Taobao! & SZOIL

SZOIL should have the components for the Atmega328 controller

And I can find LED strips / relay / and other modules from Taobao.

|| how much will it cost?

Here is the estimated price list of all the components:

1. Acrylic: 70 RMB per piece ( 80cm x 80cm),5 pieces needed, 350 RMB

2. LED strips (24W water proof) : 100RMB

3. Relay: 10 RMB

4. RTC: 10RMB

5. ISP: 10RMB

6. TTL tool: 10RMB

in total: 500 RMB

|| what parts and systems will be made?

1. Acrylic sign will be laser cut.

2. Atmega328 controller will be designed and milled at milling machine.

3. project box will be 3d printed.

|| what processes will be used?

1. CAD - 2D design

2. machine controlled cutting - CNC

3. electronic design - atmega328 controller

4. electronic production - atmega328 controller

5. Embedded programming - Arduino programming

6. 3D printing - project box

7. Networking and communication - RTC I2C communication

|| what tasks need to be completed?

1. 2D design file

2. laser cutting

3. 3D design project box

4. 3D printing

5. control board design

6. control board milling

7. soldering

8. embedded programming

9. assembling

10. documentation

|| what questions need to be answered?

1. study how to use the atmega328 as the processor of the control board

2. figure out how to use RTC module

3. figure out how to provide 5V to the control box with 220V AC power

4. figure out what kind of LED strip is suitable for outdoor environment

5. figure out how to assemble all parts onto the wall

|| what is the schedule?

1. PCB design and layout - 1 day

2. milling the board and soldering - 1 day

3. programming - 1 day

4. 2D design - several hours

5. 3D design - half a day

6. laser cutting - half a day

7. 3D printing - half a day

8. assembly - 1 day

|| how will it be evaluated?

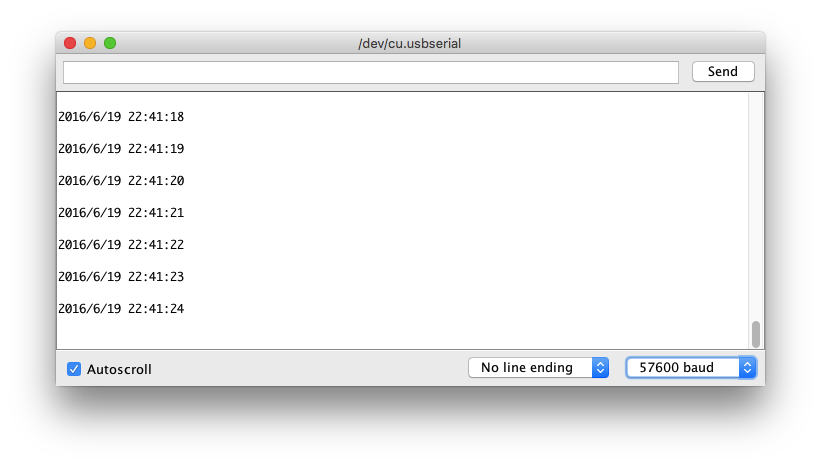

I tested it in a few ways.

1. use the time setting function in the RTC library to simulate what will happen when real time is close to the conditions I set:

My sketch is as below:

(照片)

so I changed the time to “18:59:40” and “23:59:40” to see what will happen.

2. test after assembling all things onto the wall

It’s been two days since I put all things up. It works as expected so far.

(工作照片)