I will explain this step by step, but first you need to download GITbash.

That clipboard will be paste in the GitLab web page, in your session in the SSh Key division, in the add key you will paste that.

Once the key is added and authorized it will be generated like this.

Then we use the command clone in the gitbash, we need the previous address on that command:

$ git clone git@git.fabacademy.org:fabacademy2016/fablabpuebla.git

After this, it will create a folder with all the content of the Fablab puebla folder of the repository. This folder it will be created in the same user folder in which the ssh key folder was created, in the picture below you will see the shh folder and the fablab puebla folder.

We access to the fablab puebla file, we are going to find other folders and files, we will choose the student file and I will find my folder, my student name is 239.

The image above shows that I accesed the file of the student listed as 239, you can check the list, that's me, Rolando.

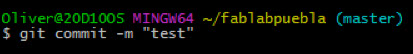

In this folder I can upload the files , in this case the page, but first I checked how we upload files with a simple image, a screen shot of this tutorial to be exact.

After that we will need to configure a name and a mail in order to make changes to the repository, they will also need to add an explanation of what you are changing this registar let the masters have a control of who is changing who because many people from around the world have access to this.

After that, we can push the file we use the command:

$ git push origin master. After that the file will be pushed, as it shows the image below.

As for my final project, the idea is to build a DLP printer.

The picture above shows some files pushed by me.

Below we have some pencil drawn sketches that I did to give my self an idea of how the whole mechanic system will work.