Designing Menu

Description: What Machine Are We Going To Make?

The whole idea came from music lovers and learning new ways of creating music. We have made

what we call 'The Music Picker', a machine that creates music by cutting little holes on the

paper and then placing the paper in a music player to let the magic start.

The initial was to have a machine where you upload your mp3 song to your computer, it processes

it and turns it into coordinates. This coordinates are sent to the machine, starts cutting and

ends playing the music.

First we had a look to older and modern music boxes that have been done to see how they

created different sounds from different musical notes. Later on, we continued to look at

automated machines connected to a computer to see how they transformed different types of

information to coordinates for the machine to cut.

As it is a very complex idea, we started creating the 'cutting machine' first. By this we mean,

to have an automated machine that cuts the notes we want wherever we want. Once we reach this point

(and if we have time), we will continue automating previous steps such us processing the music

to turn it into coordinates.

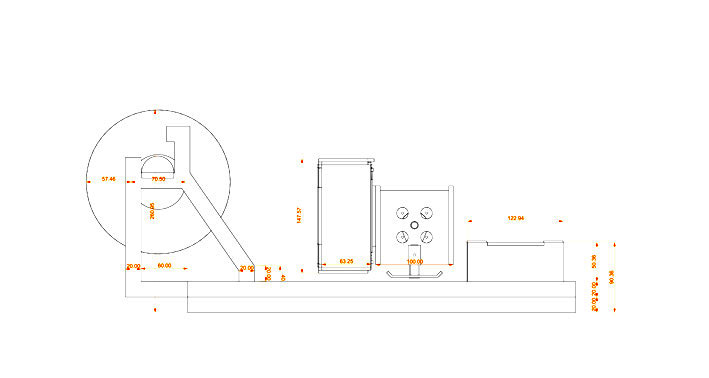

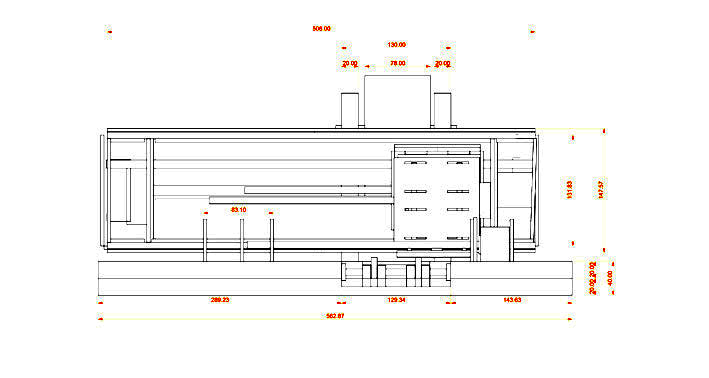

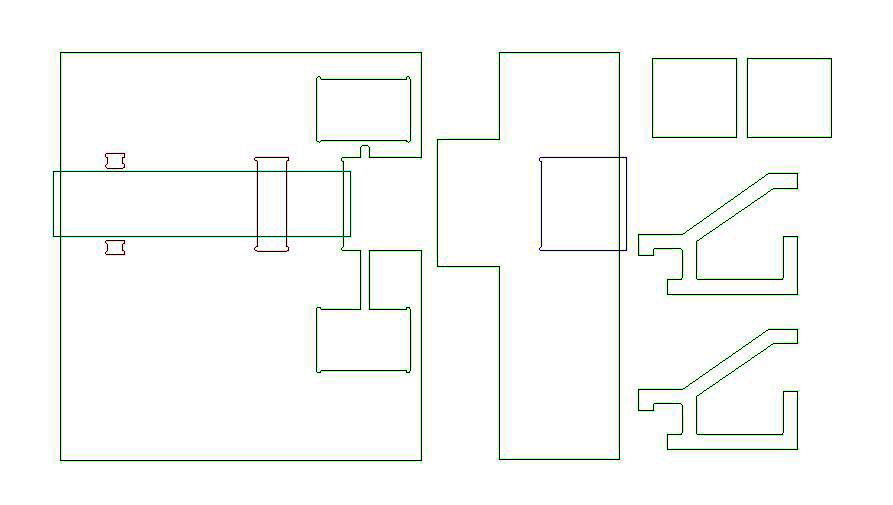

Here we have our first sketch of what we wanted.

First Sketches

Machine Documentation

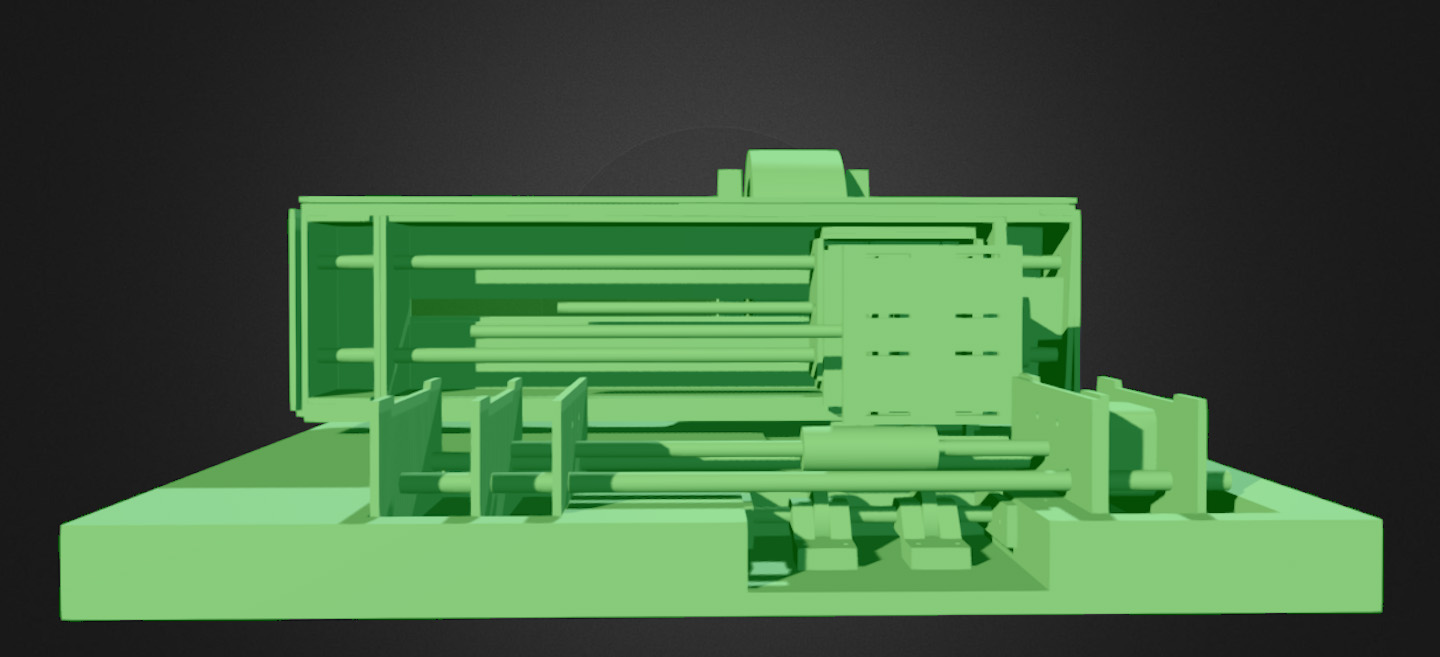

3d Virtual Model On Sketchfab

Programs We Have Used

Rhinoceros

AutoCAD

AutoDesk Fusion 360

OnShape

Adobe Photoshop

Adobe Illustrator

Adobe After Effects

OnShape

Makerbot

Materials We Have Used

-3mm Cardboard

-20mm Plywood

-PLA for 3d Printing

-PLA Filaflex for 3d Printing

-Recycling Old Printer Parts

-Glue

-

-3mm/4mm Packing Rings

-3 Nodes/3 Gestalt Motors

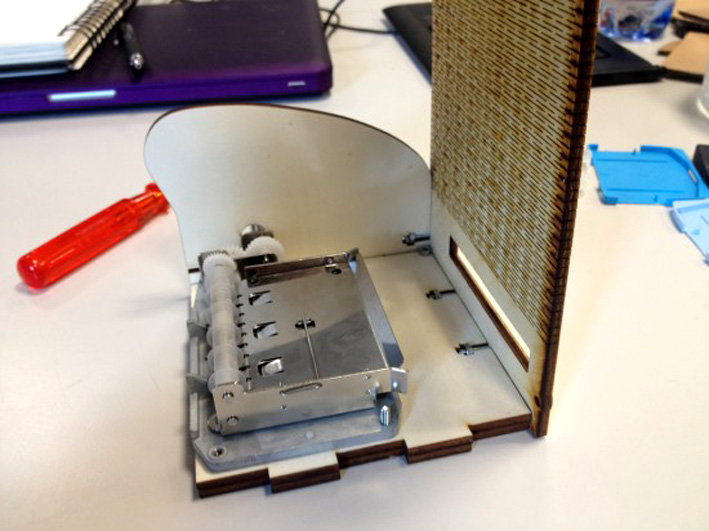

-30 Note Music Player

-3mm Medium Density Wood

-FR1 Copper Board

-Ribbons Cables

-Ribbon Headers

-Components Needed For The Fabnet Board

Music Analysis

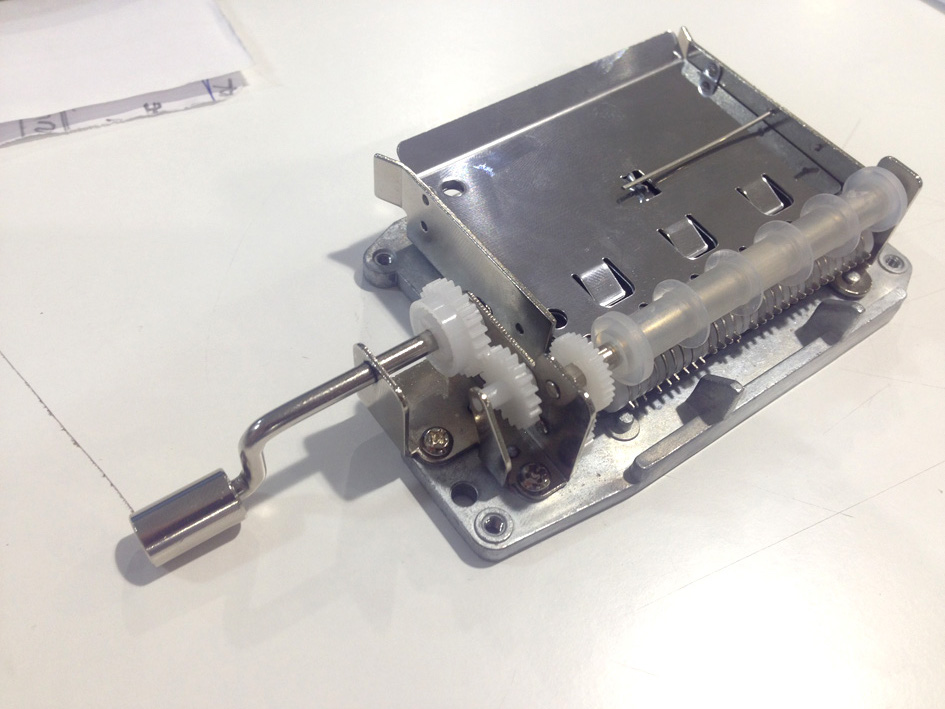

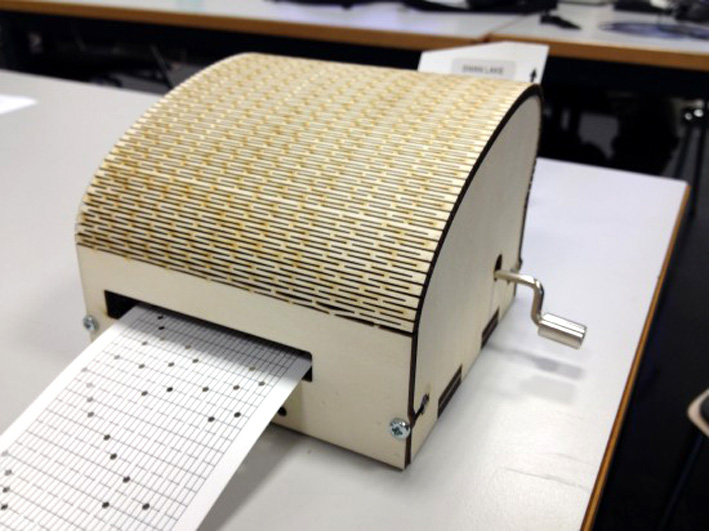

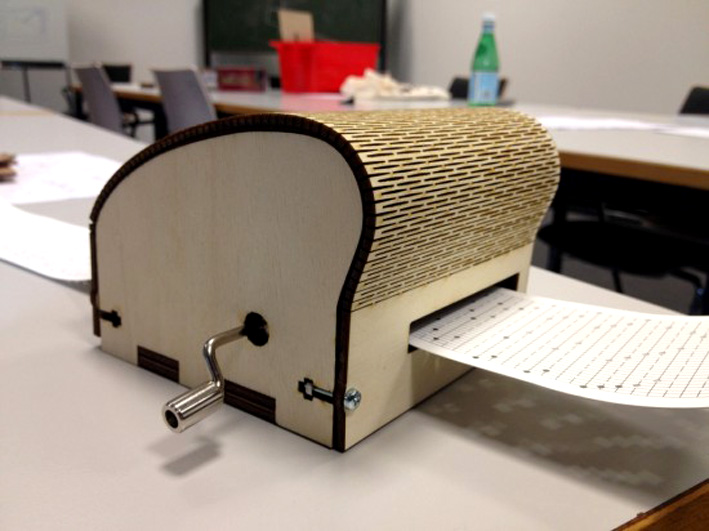

Music Player

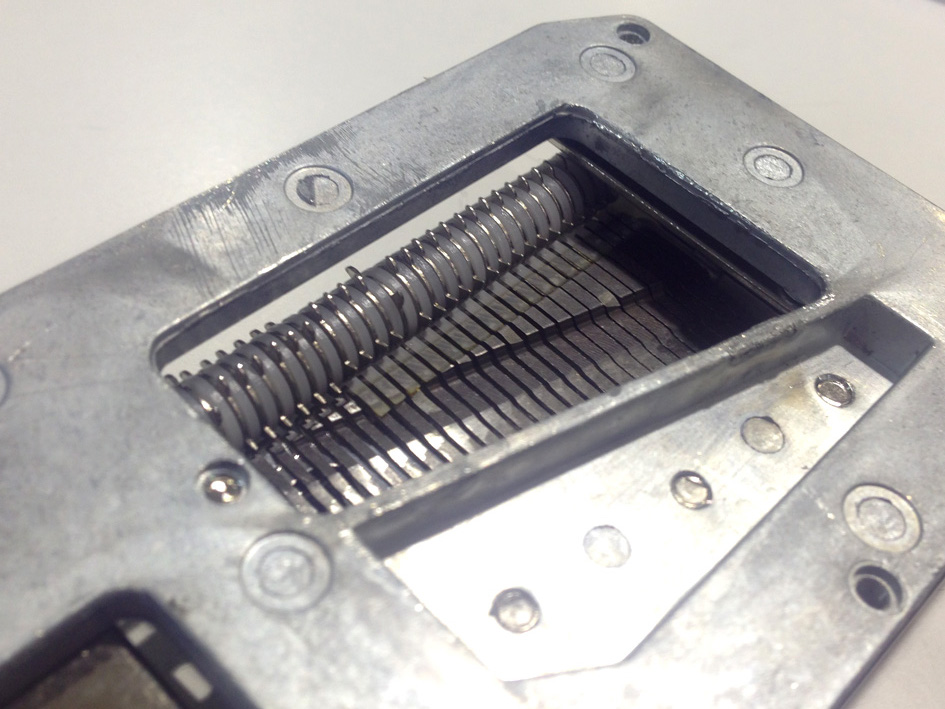

Once the paper has been cut by the machine, the idea is to test it in a music player that we bought on the internet to see if it works correctly.

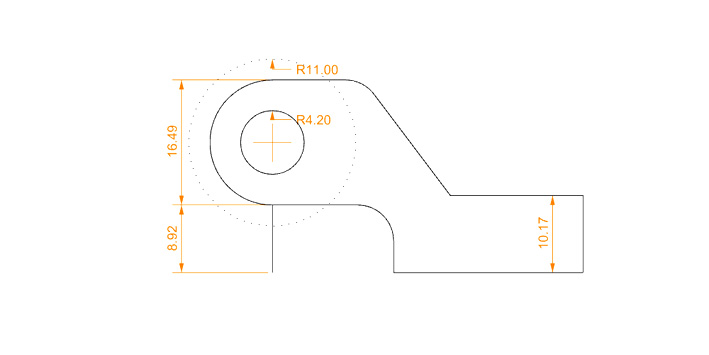

This Music Player has 30 different harmonized notes that are activated by the movement of a rotatory ring.

This rotatory ring has four ‘arms’; these are introduced into the holes made on the paper making them move

and ringing the metal bars on the opposite side.

Here there is an example of how it works:

The music is played at 80 beats per minute at a normal moving rate.

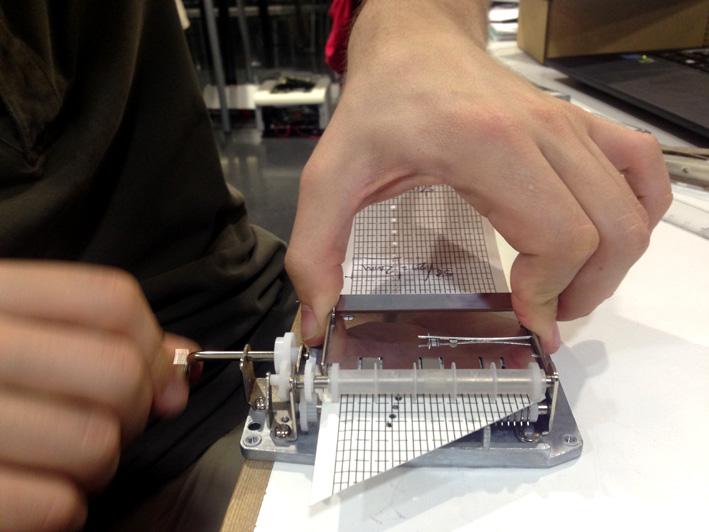

Music Paper

The music paper is 70mm width, having , having 58mm of music space as on each side there are a 6mm blank space. Each note has a 2mm maximum space to be marked and punched.

An Example Of What The Music Player Can do

An example of an improvised song punched directly on the paper

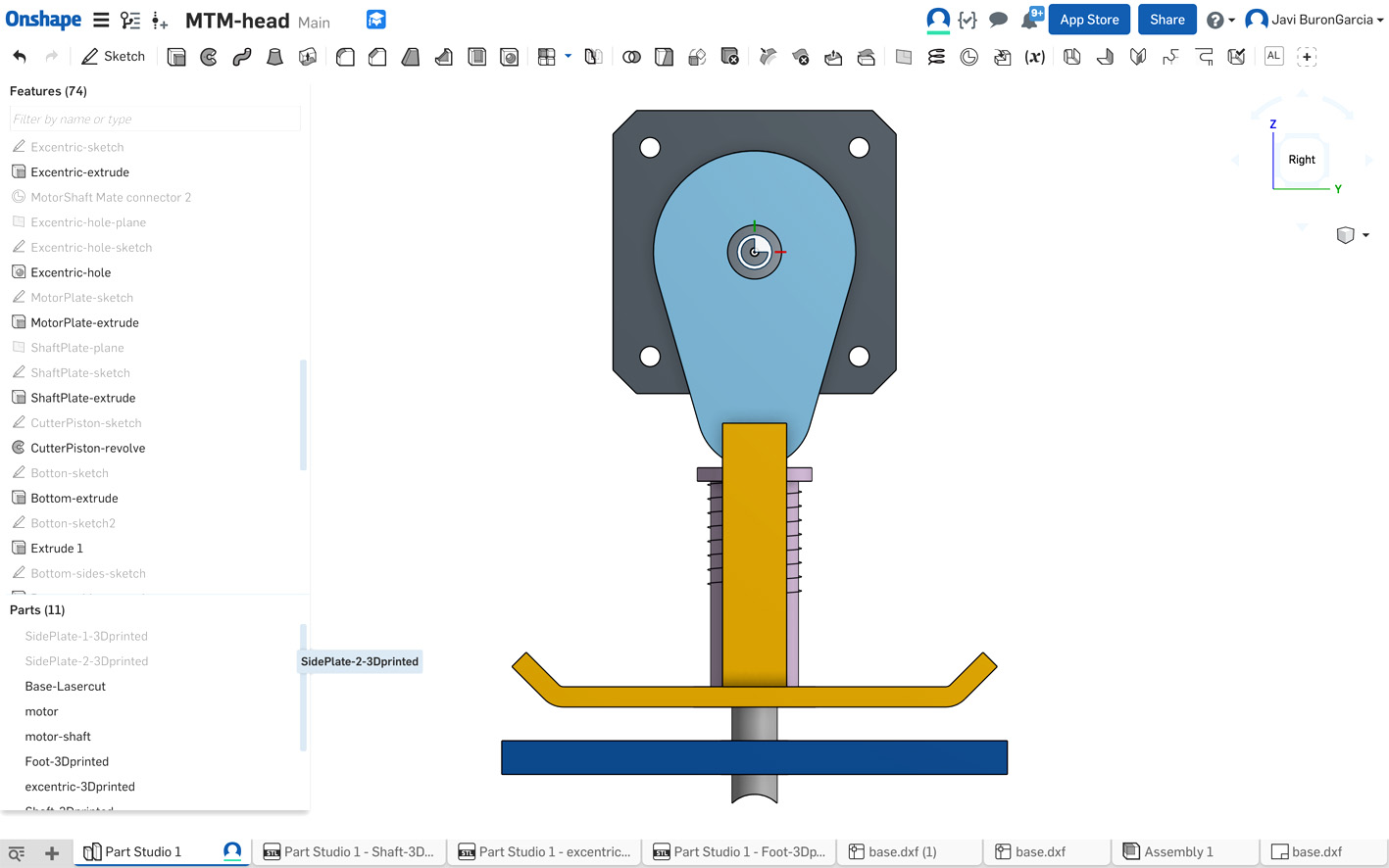

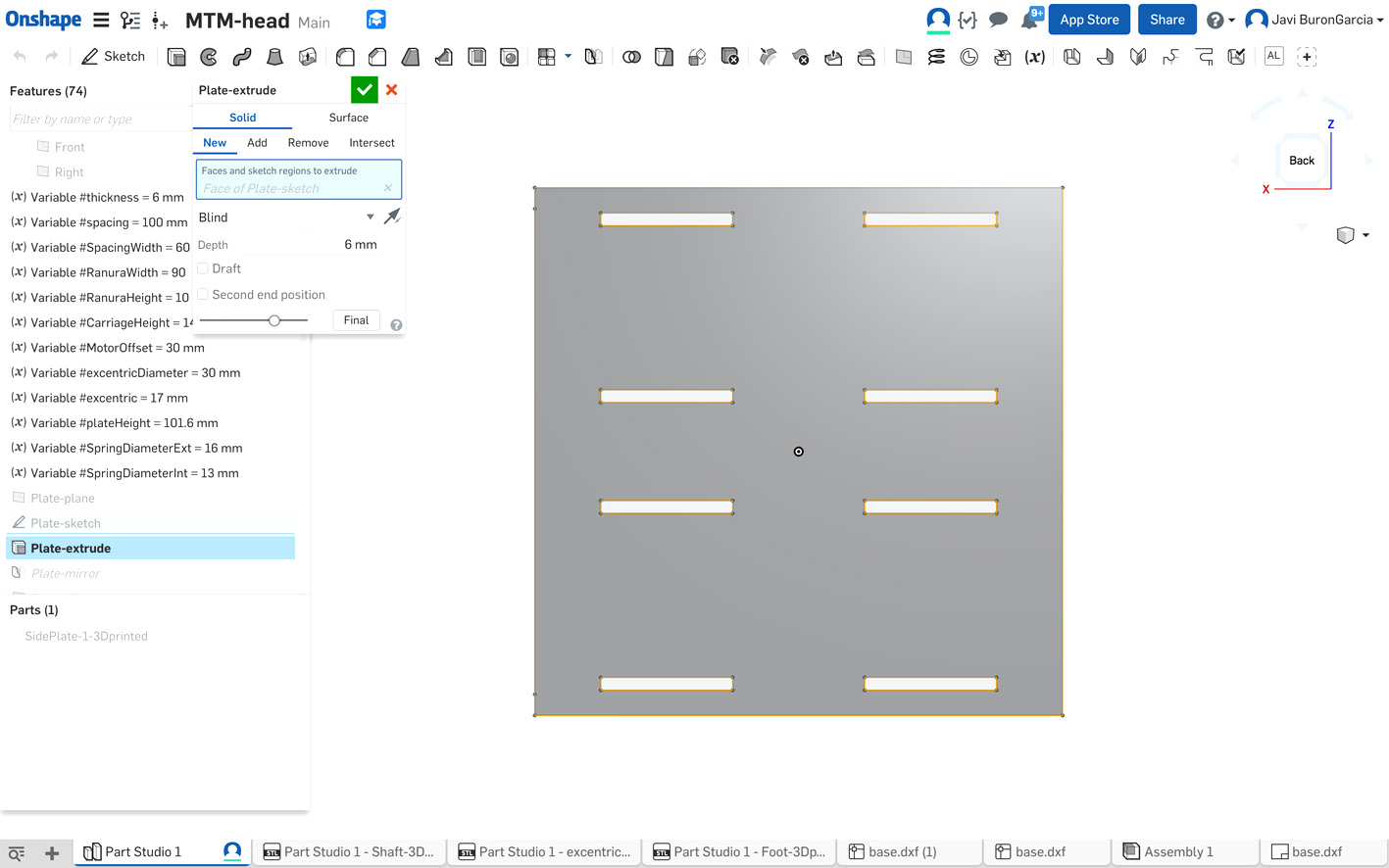

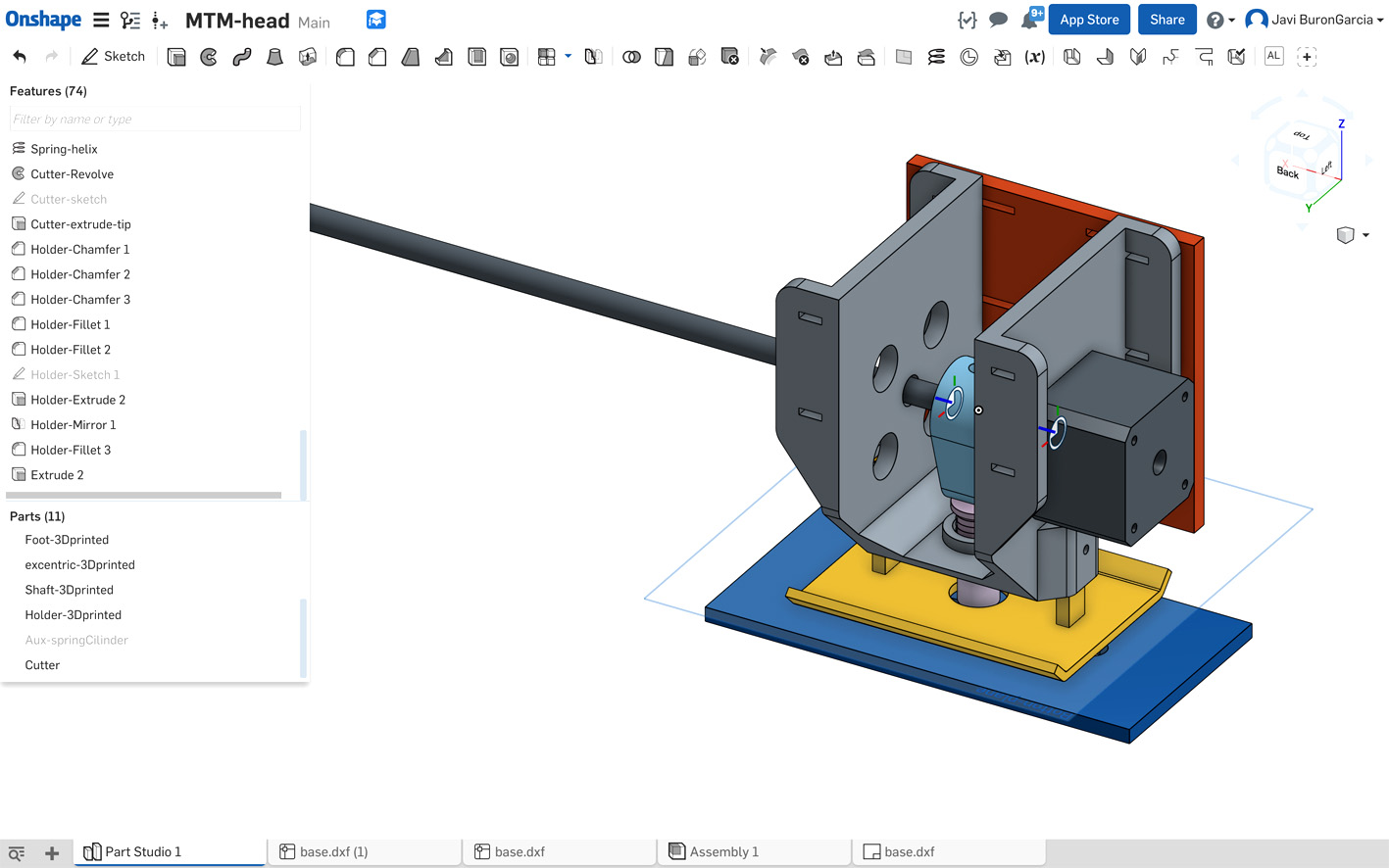

Designing the Head

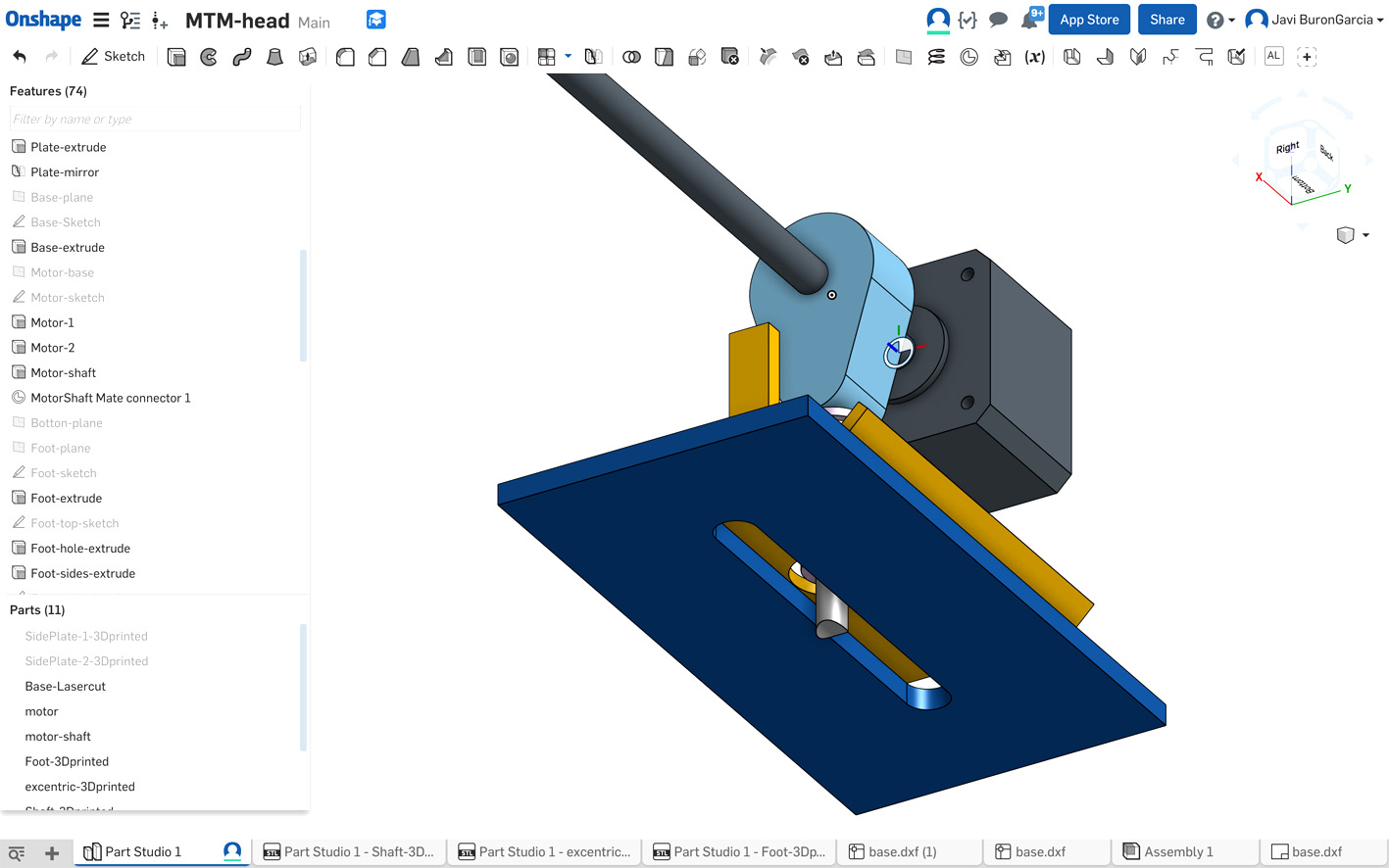

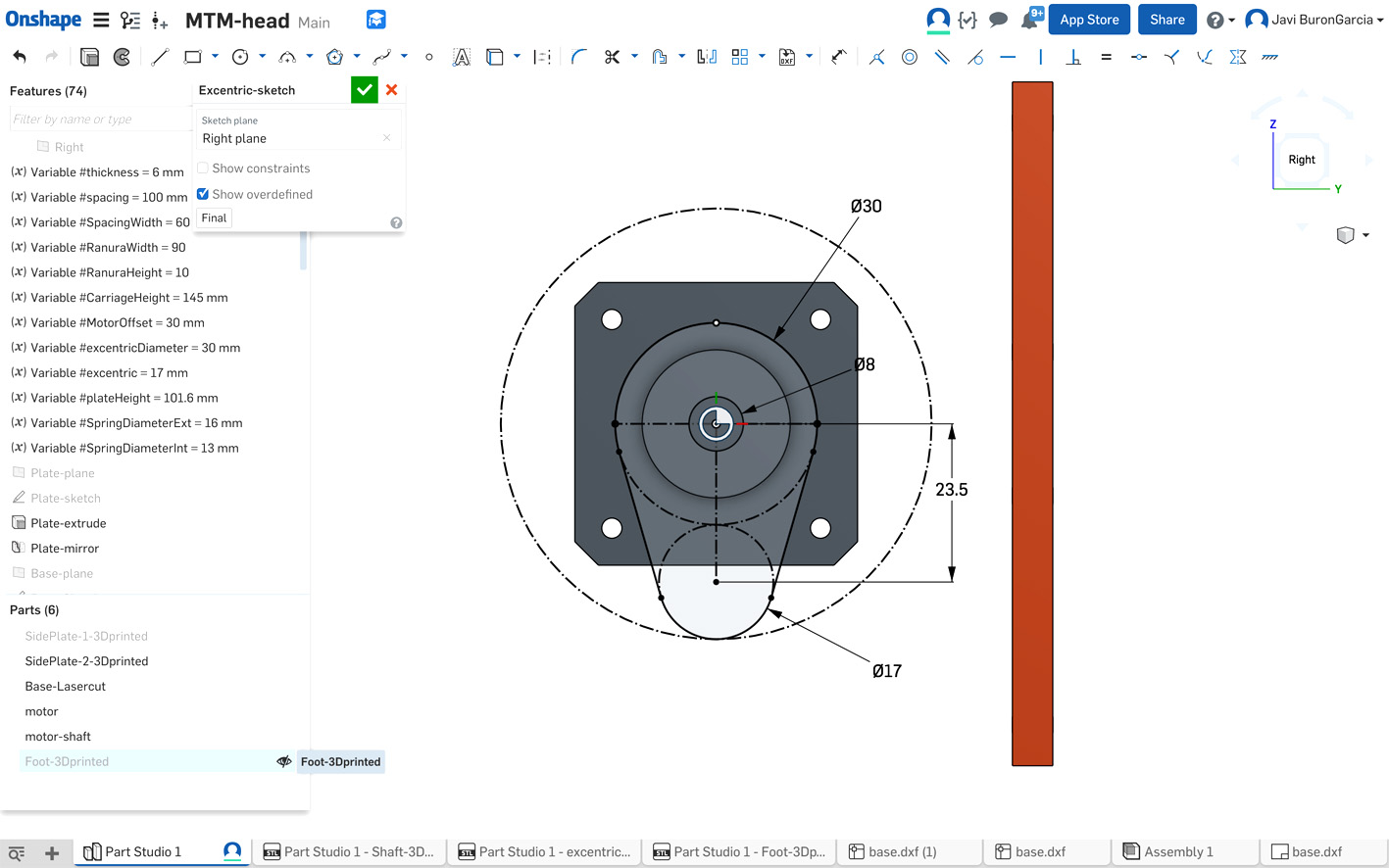

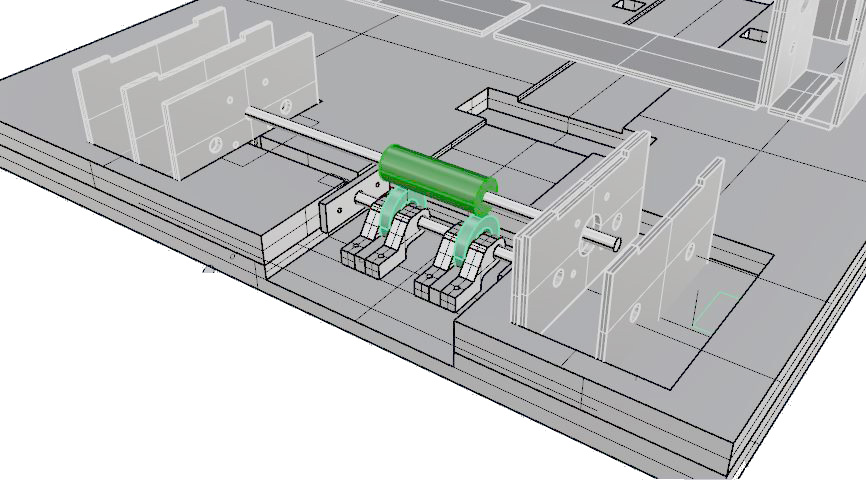

We have used Onshape for the header design as many dimensions are interrelated changing during the design process of the other components and the sourcing of additional materials and components. All header components have been designed to be 3D printed. Design is also adapted to MTM ball-screw stepper motor so no further modification is needed.

For the Head design we used three main references: the foot of a sewing machine, which allows the needle to puncture the textile while keeping the textile fixed on the vertical axis, handheld paper perforators, which uses a spring to move the shaft up and down, and the cam and follower mechanism, which uses an eccentric piece to transform a rotational movement into an sliding one.

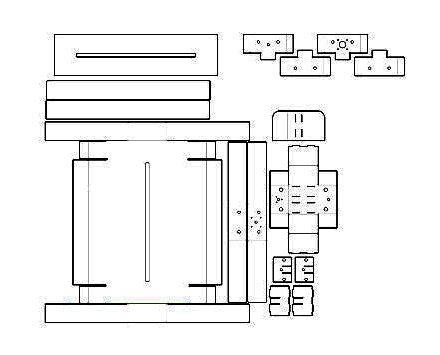

The connection with the horizontal axis is resolved using a 3D printed plate following the same pattern than cardboard design. Horizontal slots allow fine adjustment of the head respect the axis.

Excentric design is based on the cam and follower mechanism. The parametric design allows for fine tuning of the distances once horizontal axis, shaft and cutter height are defined.

Foot allows paper roll to slide easily underneath the shaft. chamfered edges prevent jamming.

Once the basic dimensions and relationships between parts have been defined, a number of fillets and changers are introduced to remove material in areas that are needed, allow a better view of the paper roll and the puncture mechanism and facilitate tool access for assembly and fine adjustment.

Designing The Stage

Our stage is a 3mm cardboard instead of the 4.04mm as the original design has. Checking the thickness of the design, we changed the original to a 3.66mm (where the 0.66mm lasercutter machine's kerf is included) and re-adapted the whole design to our machine.

Based on Nadya's building process, we proceeded to build it like that.

Designing The Base

The Base

For the base, we were looking for two different things: in one hand, we wanted a different machinery

image rather than the typical that appeared in previous years; on the other hand, we wanted to have

a rigid base to stabilise our machine.

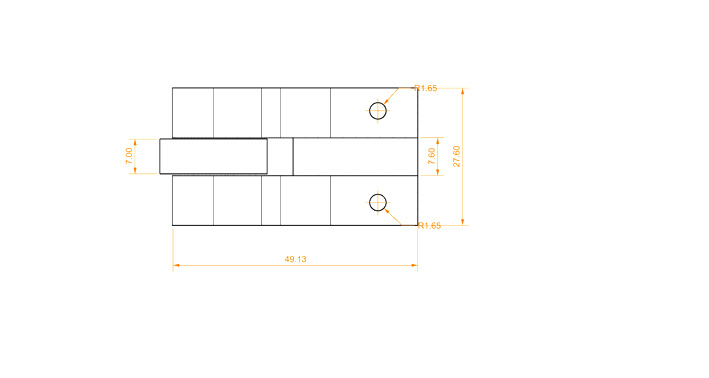

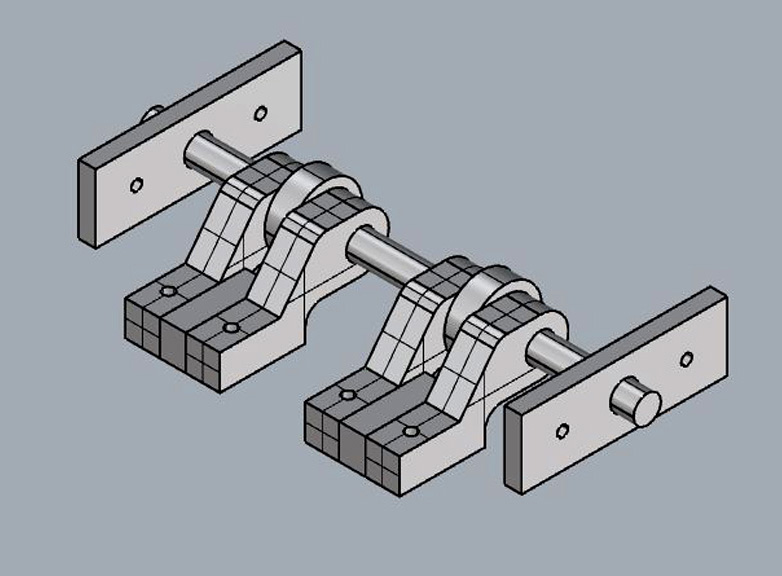

Paper Roll Vertical Supports

A 50 meter paper roll lays behind our machine ready to be cut. We designed a support that both holds and creates a continuous flow when the front motor grabs the paper to 'print it'. It is done with 20mm plywood and cut on the CNC machine. It is located at the rear side of the base.

Roll Horizontal Support

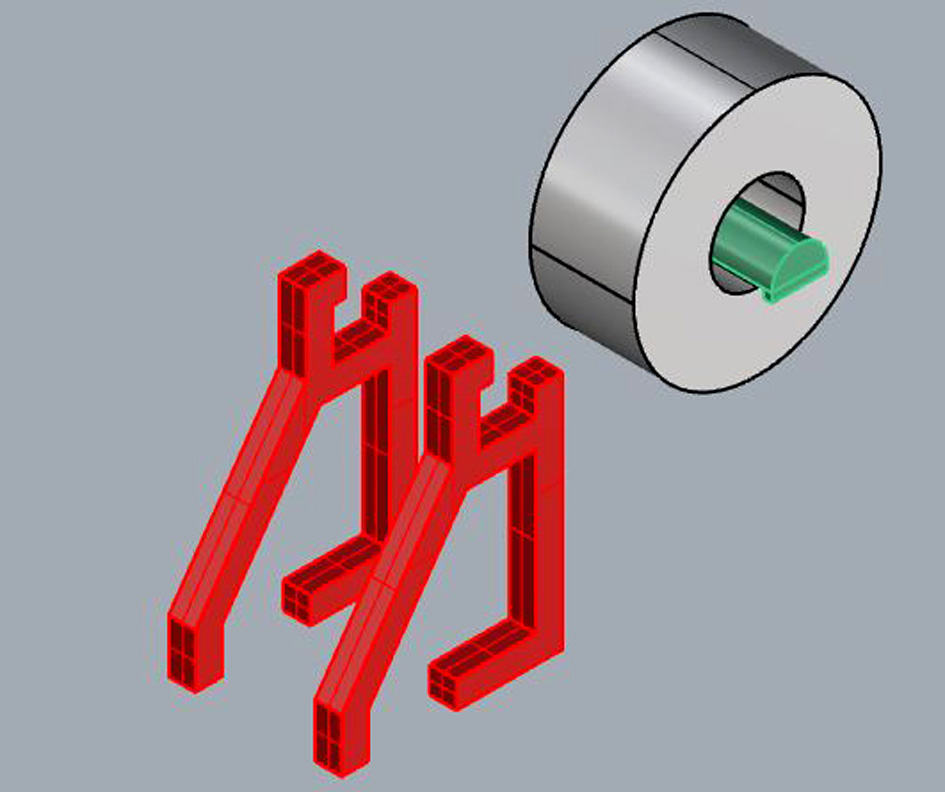

Paper Horizontal Roll Beam : As we had the disadvantage that we had to wait for the paper roll to arrive, we decided to make this part with the 3d printer as this machine lets us have more freedom when changing other parts of the machine. The goal is to hold the roll in its position and lets it move in a continuous movement.

Designing The Rolling System Mechanism

. PLA fixing-plate: The front motor has a complex moveable element that needed to be

fixed with some PLA fixing plates designed to make sure the inferior metal bar does

not move while executing its job. Done to be screwed directly to the base plywood.

Done with PLA at the Makerbot Replicator

For the roller system we need a part that holds the rod where the bearings go, and allow the rotation of the bearings but not the lateral movement. We considered the diameters of the bearings and the roll adding a screw anchoring system ,we design and print the object in 3d.

Sketchfab

Take a look to our different designs for each part of our machine.

Enjoy!

Inspiration

Older Ways To Create Music - Music Boxes

A music box or musical box is an automatic musical instrument that produces sounds by the use of a set of pins placed on a revolving cylinder or disc so as to pluck the tuned teeth (or lamellae) of a steel comb.

Symphonium and Polyphon

The tune is punched out on the disc with pitch determined by the position of the punching. In the manufacturing process, the punched metal was curled back onto the underside of the disc, creating a raised projection that resembles a letter P when viewed obliquely.

Old Music Box

As the machines above, this one is the same but instead of using metal 'disks',

it uses a cylinder.

When turning, it activates the different teeth creating the different sounds.

Modern Ways Of Creating Sounds

XOXX Composer

consists of eight rotating

discs that are used to control and create different sounds.

Magnets can be attached to the discs at one of the 16 steps

to trigger sounds via the companion application. Pitch and volume

is controlled using the included sliders and knobs as well as a slider

on the side of the system that comes complete with LED

and controls the beats per minute.

XOXX Composer from Axel Bluhme on Vimeo.

XOXX Composer

Monomatic

The Modular Music Box consists of several interconnected, plug-and-play devices that collectively reproduce the functionality of the familiar 19th century clockwork musical instrument. At the heart of the piece is a custom-made electromagnetic rotary sequencer. Melodies are stored on a series of interchangeable, acrylic, 10” disks embedded with small magnets arranged in a regular circular grid. In the same way vinyl records are located on a turntable these disks are centered on a spindle and rotate over a ‘play head’ made up of a line of magnetic field sensors – effectively replicating but superseding the set of pins on the revolving cylinder that pluck the tuned teeth of a steel comb in the traditional device.

Monomatic-MMB-PAE11-submission from Monomatic on Vimeo.

Other Interesting Ways Of Creating Sounds

Programming Music