Greetings, here lies my work-log at

______ _ ___ _ _____ _____ __ ______ | ___| | | / _ \ | | / __ \| _ |/ | |___ / | |_ __ _| |__ / /_\ \ ___ __ _ __| | ___ _ __ ___ _ _ `' / /'| |/' |`| | / / | _/ _` | '_ \| _ |/ __/ _` |/ _` |/ _ \ '_ ` _ \| | | | / / | /| | | | / / | || (_| | |_) | | | | (_| (_| | (_| | __/ | | | | | |_| | ./ /___\ |_/ /_| |_./ / \_| \__,_|_.__/\_| |_/\___\__,_|\__,_|\___|_| |_| |_|\__, | \_____/ \___/ \___/\_/ |_|

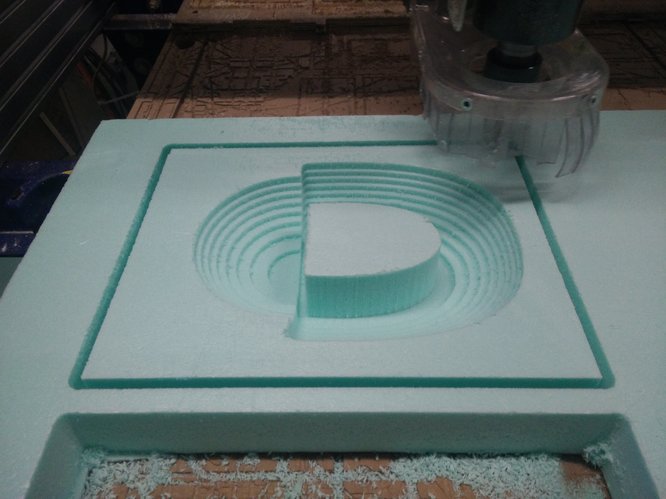

For composites, I 3d milled molds for a 'biscuit/coupon' and a 'bin' for my final project. I also visited a local marketplace/locality which specializes in fibreglass and resin composite making; they make big fibreglass negative molds to cast P.O.P figurines and statues for processions

An extensive search online and a call to the company failed to find the necessary datasheets, but as a consolation - i did lookup the hazards for the chemical ingredients listed on the epoxy/hardner bottle

I used OnShape for both designs, as it's quite a robust browser based program. I've really gotten hooked to the parametric constraint-bassed sketch solver.

The design of the biscuit template is a simple extrude, the positive mold is smaller, so as to accommodate a 4mm thick composite part

The bin is a result of a revolved profile as seen in the first picture, and then the model is split into thicknesses of the foam sheet i have.

The milling bit used was a 1/4" up-cut 2 flute bit

The milling bit used was a 1/4" straight cut 2 flute bit

I was afraid that the cling-wrapper might melt from the exothermic reaction of the epoxy/hardner, so I made a little test joint and it worked out fine.

Laying down different layers of fabric involved, spreading the epoxy/hardner mix over a layer and then laying it on the mold .

For compaction, I used clamps and 2 part-molds for both the bin and the biscuit.

To join the two sides of the bin - I've temporarily used Glue, but a permanent solution will be to lay strips of jute fabric coated with resin

Composites was one of the more oddly satisfying weeks, seems to be a very promising method of producing small batches of curvy, lightweight and tough things.