Week3 : Computer-Controlled Cutting

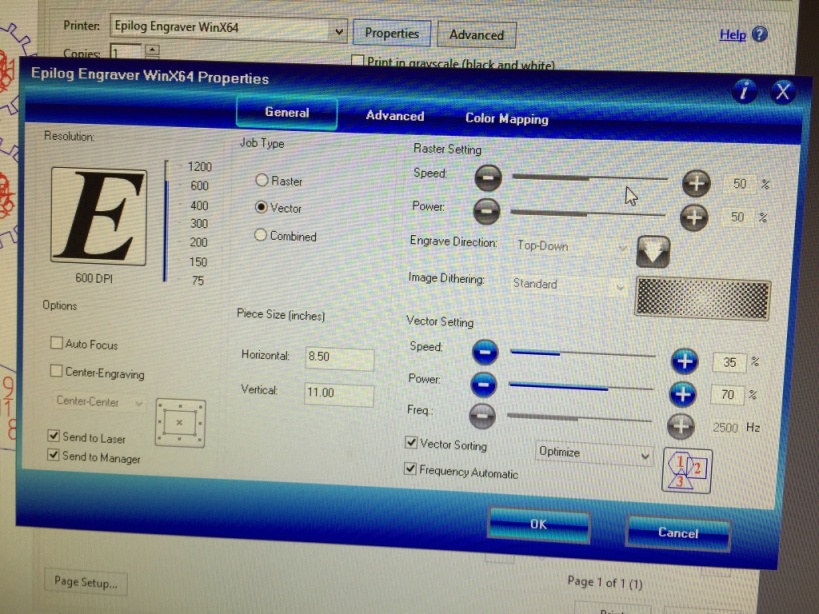

Laser Cutter Epilog Mini 24 getting the write work flow:

When using the laser cutter on several previous occasions getting the desired results is always subject to trial and error. We would initially search for a previous documented experience or guidelines. One fact we try to keep in our minds is that most of the materials that are available here (in our region) are not always similar to those mentioned by others. But the initial problem we faced was to get our the laser to cut every time we restart the desktop. Specifically for Windows 8,8.1 a link to a support page for those versions is possibly overlooked when one tries to head to the drivers download page. I am not sure exactly if I understand the details of what really happens but when if one disables the

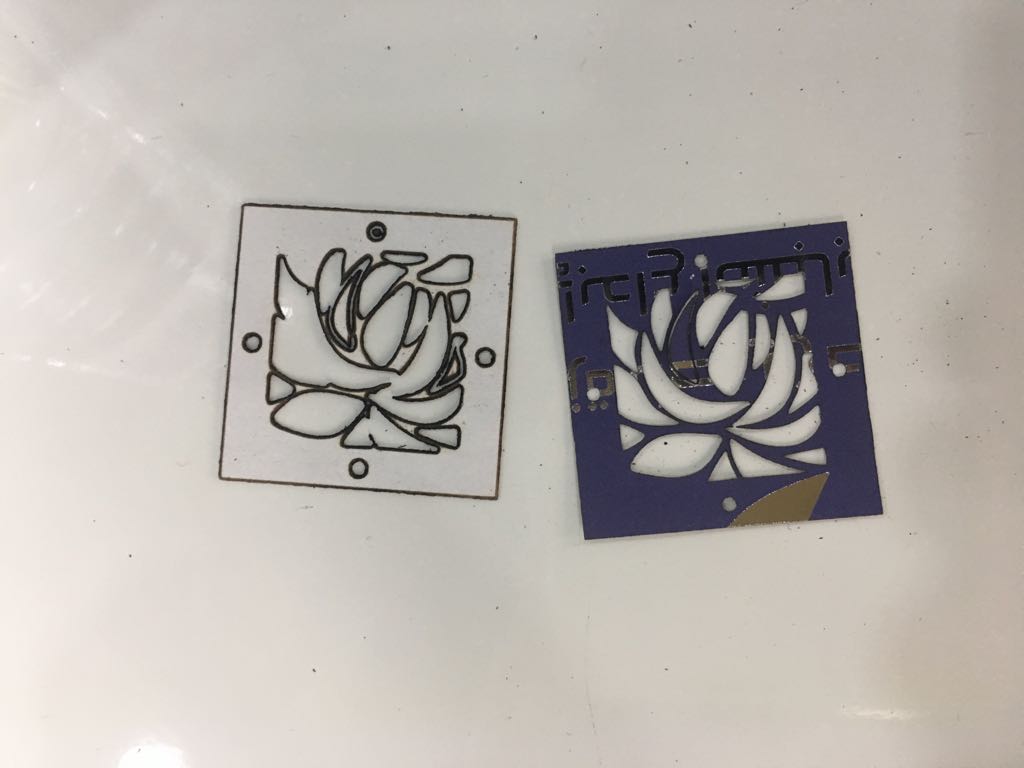

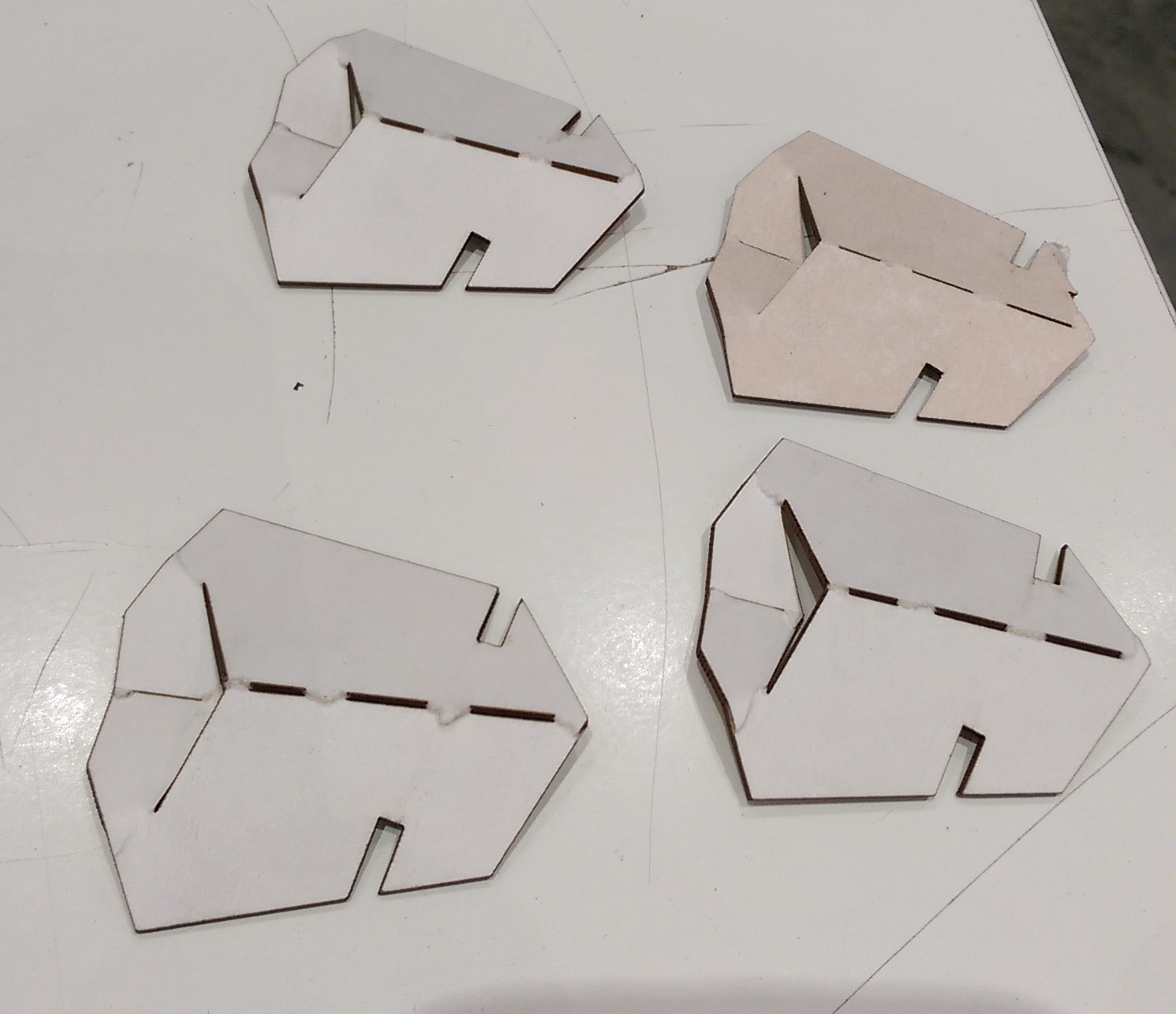

using simple patteren I tested the laser on a thin cardboard first.

Concept design and development :

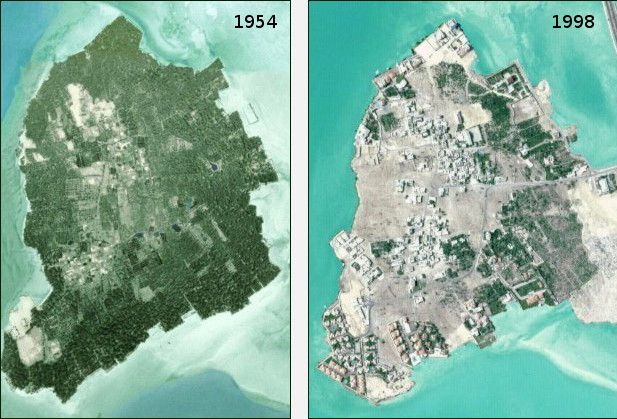

Palm trees were at one point in history one of the main economical sources in Bahrain, the numbers have decreased tremendous in the last 4 decades.

While trying to find a suitable project for this week I thought I should first find a locally available material to test it with laser cutting or engraving and by pure chance I saw the cover of the palm pollen outside the kitchen window.

It was the time of the year when farmers lay open the tree pollen and remove the covering layer. I was impressed by the texture and thickness of the material, but still it will need some work before it could be used in a laser cutter for any arbitrary project.

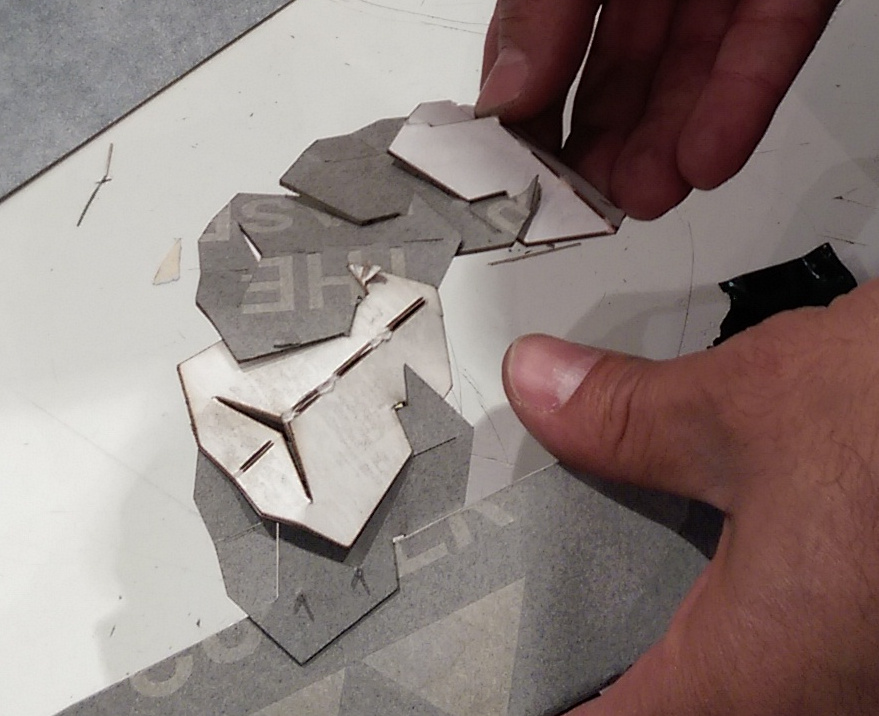

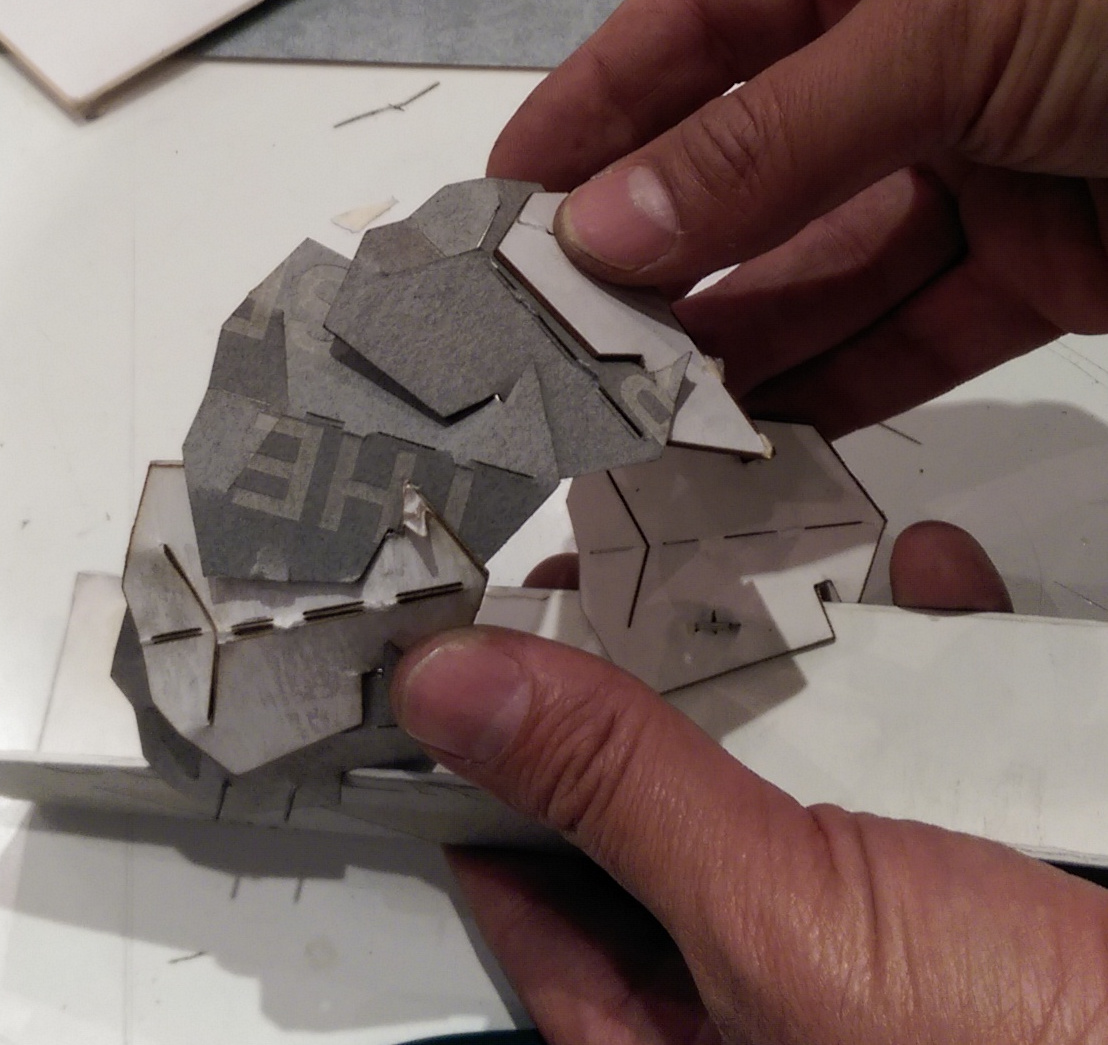

My inspiration for the press fit design also came from the palm trees, I decided to make a single element press fit system that could replicate or mimic the outer layer of a palm tree trunk.

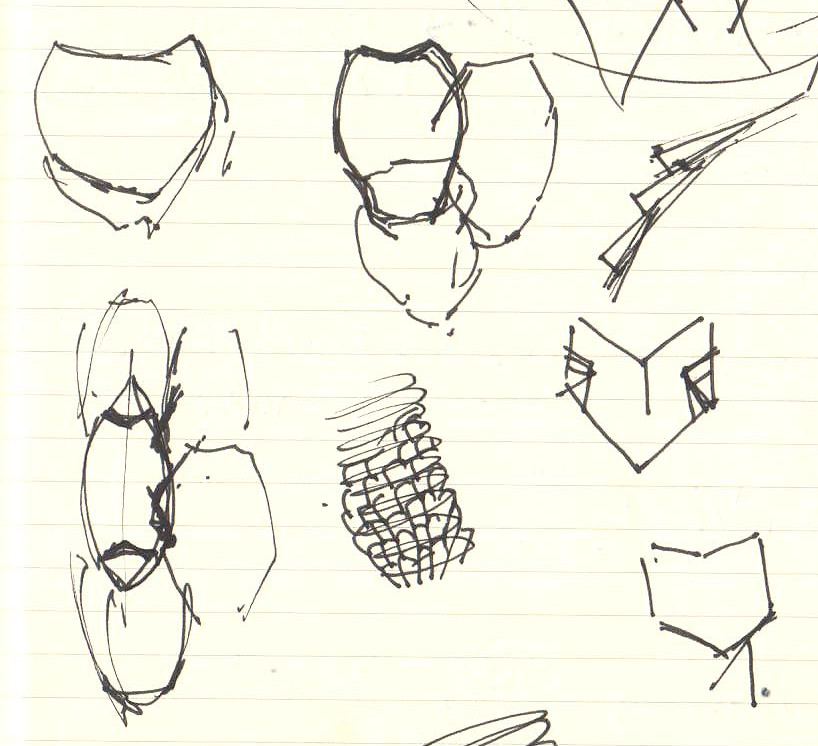

I thought of a design inspired by that. And did some scketching before starting with inkscape.

The pieces showld fit together and make a spiral shape. The design piece was symmetrical with a incomplete and complete cuts I thought the dotted or incomplete cuts will allow for bending along the lines of those cuts.

I thought the step like shape which have been used for decades to aid on palm tree harvesting an interesting load bearing design mechanism.

Parameric Design

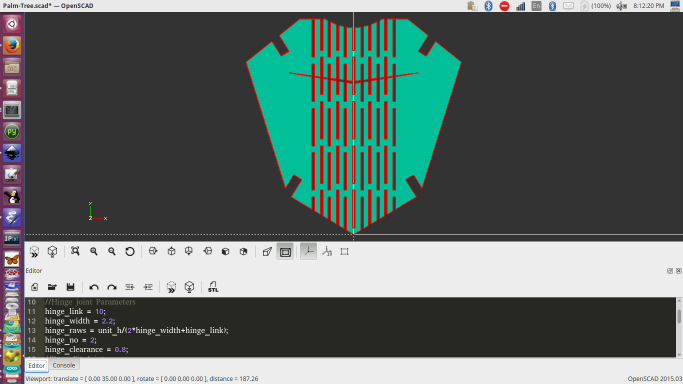

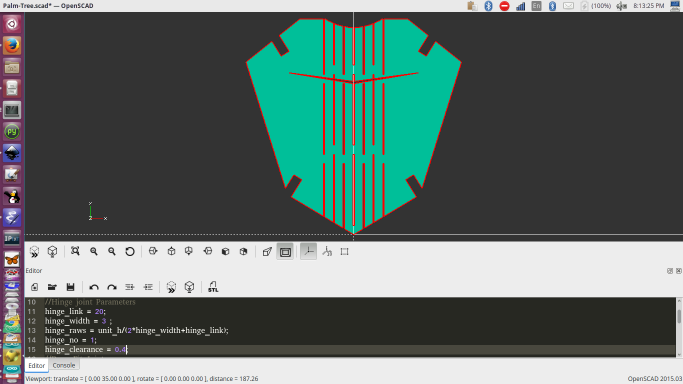

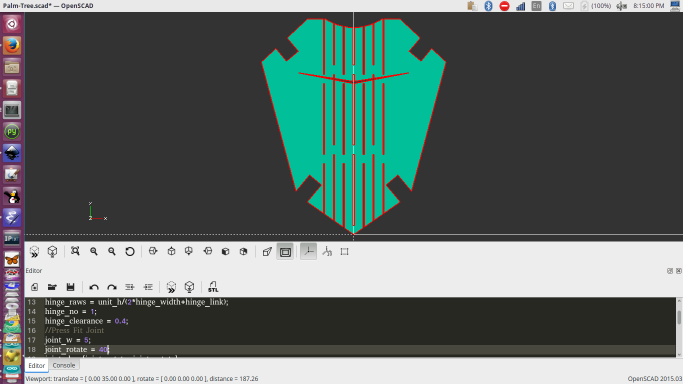

I have created a parametric file in OpenScad that would allow me to modify the

Dimensions of the piece

Dimension and orientation of the press joints

Parameters of a live hinge that would allow for bending around the center

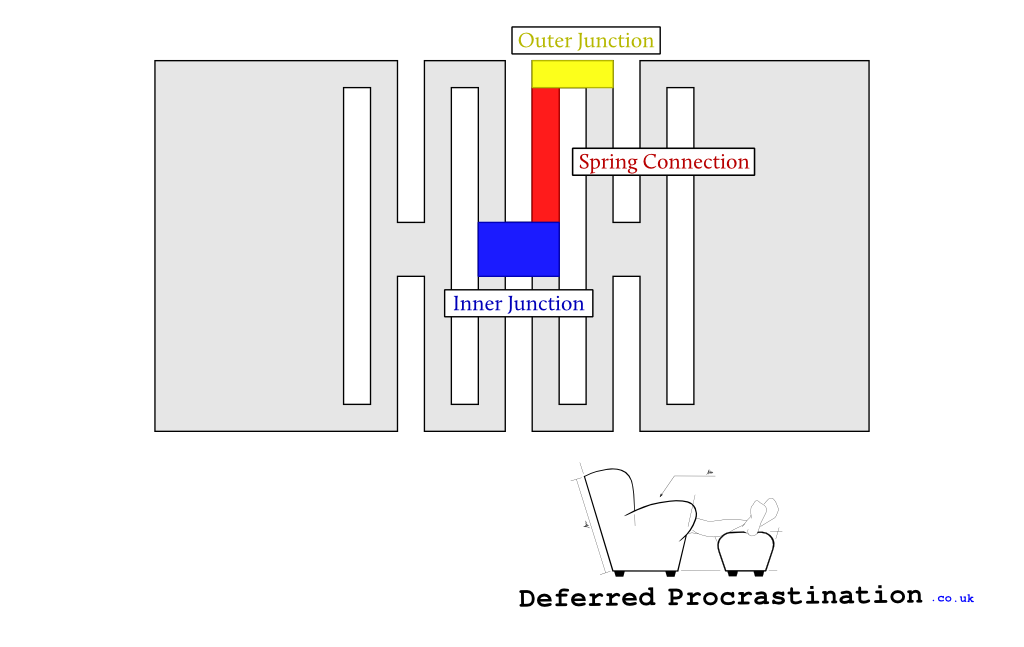

For the live hinge I found a good resource the describes the parts of a live hinge.

Based on this resource I used the information to design the different lattice hinge parts.

The following is the file

Vinyl Cutting

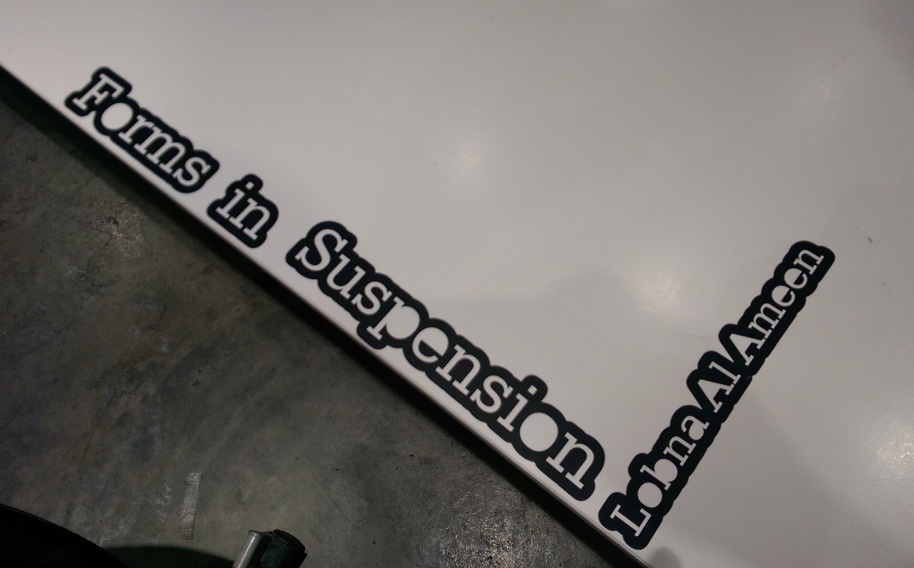

I was requested by a gallery who were hosting an artist to cut in Vinyl the title and Name of the Artisit that they would use to stick on a wall.

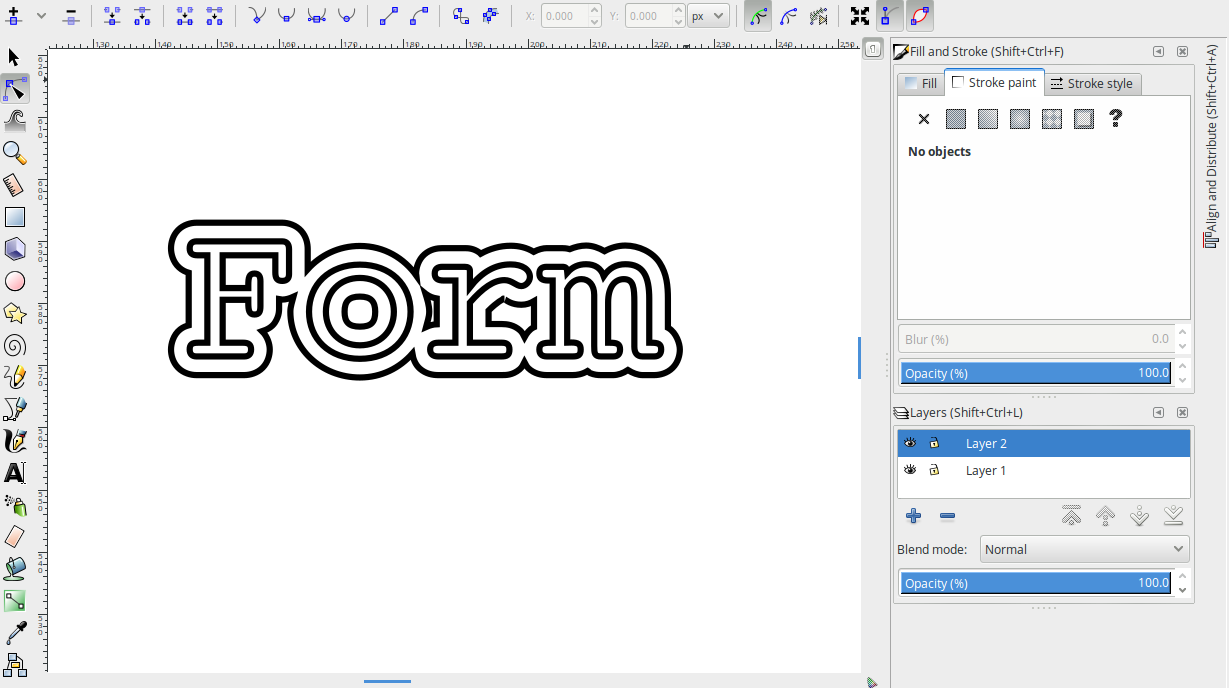

I used Inkscape and simple text then added an offset to the text. The text has to be first converted into path (Object to Path Shift+Ctrl+C)

Then all paths of letters selected and combined (Ctrl+K)

The Text is pasted on another layer

Later the combined paths are offseted using dynamic offset (Ctrl+J)

When I completed the design part I went to set up the vinyl cutter (Graphtec CE6000). Inserted the roll of vinyl, alligned the material and placed the rollers in the right position then I locked it in place by placing the leaver down in the lock position. I started the vinyl cutter and selected the right material type (Piece) and waited for the cutter to measure the sized of the material used. I imported the design and used Graphtec Cut-Studio to do the cutting, I had to select landscape as the orientation. And in the cutting setup properties I used the infromation in the machine as the dimensions of the material used.

And then sent it to the cutter. To start cutting.

I used the offset of the text as my assignment and the gallary used the cut-out text on the wall.