5.3D Scanning and Pringting

This week's assignment

- Test the design rules for your printer(s) (group project)

- Design and 3D print an object (small, few cm) that could not be made subtractively

- 3D scan an object (and optionally print it) (extra credit: make your own scanner)

- Software:

- -fusion360

- -Afinia driver soft

- -123D Catch(as Scanner, iOS,Win)

- -PronterFace

- -Repetier Host

- -Sence

- Hardware:

- Afinia H480

- bonsai lab. BS01

- Sence

- Spatura

- Materials:

- Fillament 1.75mm PLA

- Fillament 1.75mm ABS

- Masking tape

- Procedures:

- 3D printer is very useful to get phisical objects.

- To get nice result, we should check everything about making 3D data, printer settings, fillament etc...

- Using 3D scanner may need some tips to get accurate data.

This week I made some 3D priting objects.

I have used below tools and materials to complete this assignment.

Procedures:

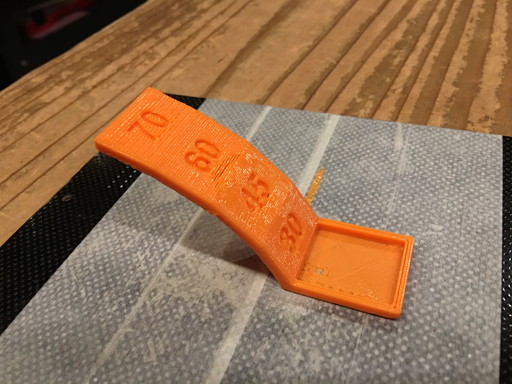

1.Test design rules

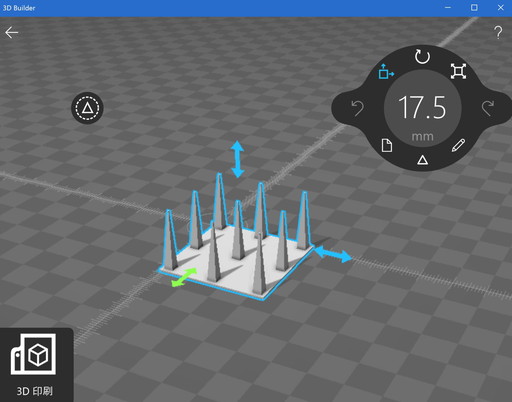

I chose some exting design from Thingiverse for testing 3D printer. Our 3D printer is Afinia H480.

Picked some design to know Afinia's accuracy

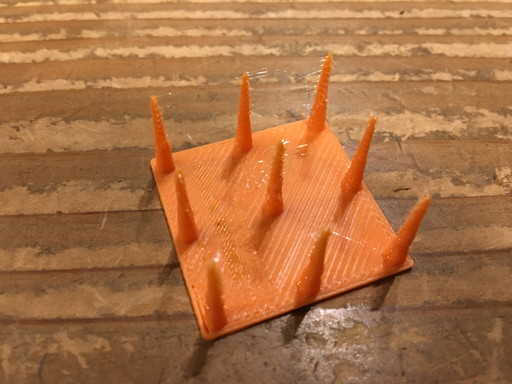

Printing test data

Result was nice except forming some threads.

Overhand design maybe tough test for 3D printer.

Result was almost perfect.

Another angle

Another design, only character was failed. It seemed too narrow.

What I've learned

Afinia is quite nice 3D printer. It can produce nice quality objects in short time. Driver software is almost automated. So need to understand all functions clearly and modify setting if necessary. To get nice quality, well configuring gap betweeen printer head nozzle and table is very important.

2.3D Modelling

I used fusin360 to make subtractively impossible design.

I want to make something silimar to ivory multi-layered sphere.

.jpg)

Put Cylinder and coil inside spehre.

.jpg)

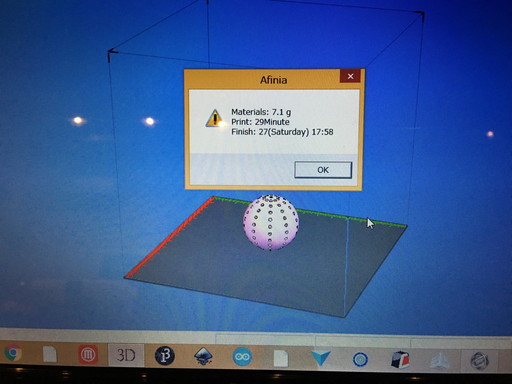

3.Output subtractively impossible design

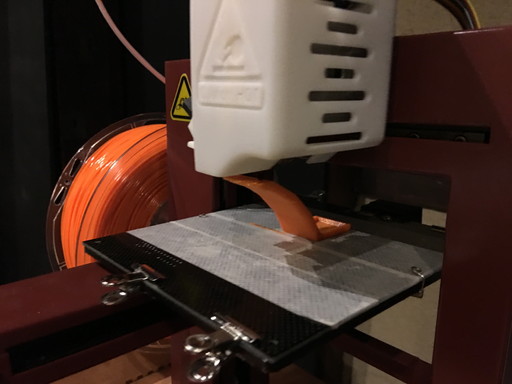

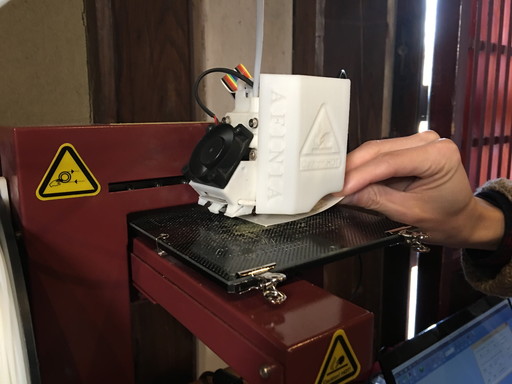

After complete 3D modelling, Used 3D printer to output.

Output data with Afinia.

Adjusting gap distance.

Seems all right.

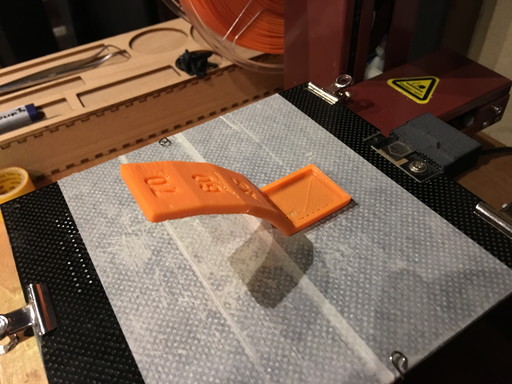

Finished. Holes were too small, difficult to see inside structure.

What I've learned

Circle mesh which I made on the sphere were too small and almost impossible to see internal construction. I should make larger holes. There were many overhanged place in internal construction, Afinia driver seems automatically added suuport but impossible to remove those complicate supports in tiny internal space. I should design the structure which don't need support or if use suport easy to remove.

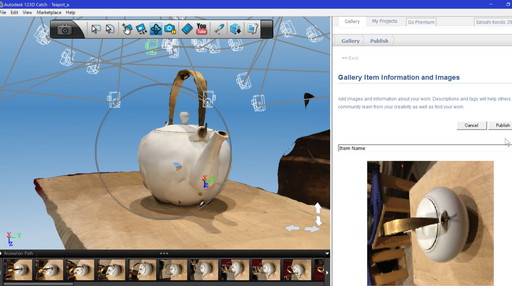

4.Scanning

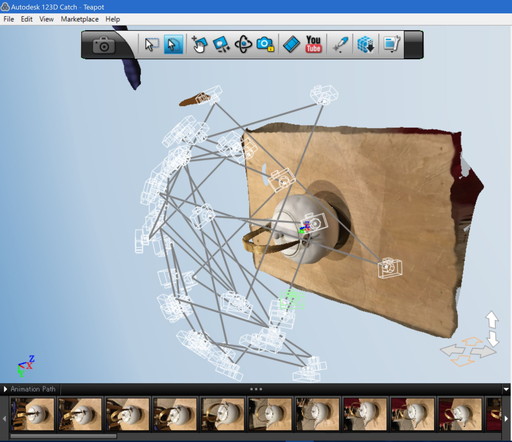

I used autocad 123D catch to scan the teapot.

I used iphone and 123D catch to scan the teapot.

I took 40 pics from diffrent angles.

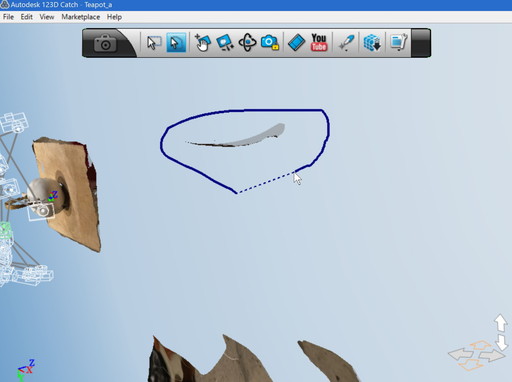

There were some trash.

There were some trash.

Clean up unnecessary objects. But scaned data seems very heavy. Software was automatically shutdowned several times.

What I've learned

To get nice quality 3D scan data, need to take pictures as much as possible and light enviroment may be the one of key factor. If use turn table maybe we could get better data easily. 3D scanned data was quite heavy and need to remove trash data and also need modification if there is any errors.

Files

Appendix

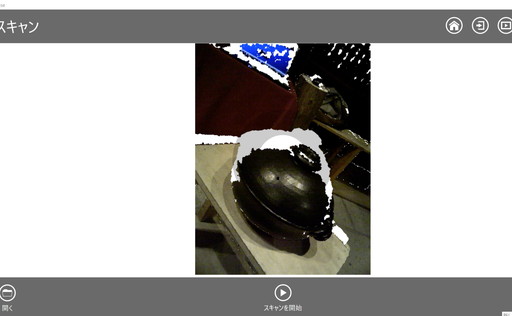

3D Scanning by Sence

I used "Sense" to scan earthen pot.

Use Sence to scan earthen pot. But lost occured so many times during scanning process.

This time "lost" happend so often and cloudn't finish scanning. Maybe light was too dark and it's better to use turn table. So that scanning data more stable.

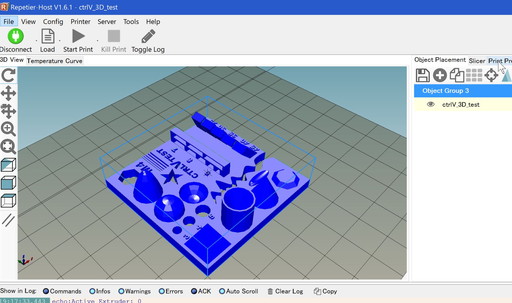

Try another printer "bonsai BS01"

We have another 3D printer in lab. Though nobody use this machine for a long time.

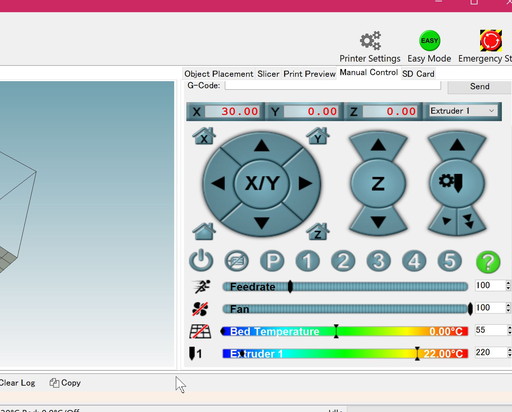

Use Repetier Host as slicer and driver.

Succeded to connect bonsai BS01 and control from PC.

There seems some mechanical problems with axis and pulley. Need to be fixed.